-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Mechanical Engineering and Automation

p-ISSN: 2163-2405 e-ISSN: 2163-2413

2017; 7(4): 119-123

doi:10.5923/j.jmea.20170704.07

Fabrication of a Washing and Shredding Machine for Processing of Commingled Waste Plastics

Noel Deepak Shiri, Gedrick Pinto, Amith Almeida, Joshwin Sequeira, Dean Fernandes, Joshua Fernandes, Gilson Fernandes, Glen Pinto

Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India

Correspondence to: Noel Deepak Shiri, Department of Mechanical Engineering, St. Joseph Engineering College, Mangaluru, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The fabrication and working details of a machine capable of washing and shredding Commingled waste plastics is presented in this paper. The developed machine performs washing and cleaning, along with shredding of waste plastics using an arrangement of rotary and fixed blades to provide fine shredded form of waste plastics as output. The cleaned and shredded waste plastics form the input raw material for subsequent extrusion-injection moulding machine used to manufacture plastic lumber. The developed machine performs the cleaning and shredding operation within a single chamber; thereby reducing the need for two separate units. This Commingled Waste Plastic Washing and Shredding Machine developed is used in combination with Extrusion-Injection Moulding Machine in a waste processing facility for the manufacture of Plastic lumber.

Keywords: Commingled (Mixed) Waste Plastics, Recycling, Plastic Shredder, Waste Plastics Cleaning

Cite this paper: Noel Deepak Shiri, Gedrick Pinto, Amith Almeida, Joshwin Sequeira, Dean Fernandes, Joshua Fernandes, Gilson Fernandes, Glen Pinto, Fabrication of a Washing and Shredding Machine for Processing of Commingled Waste Plastics, Journal of Mechanical Engineering and Automation, Vol. 7 No. 4, 2017, pp. 119-123. doi: 10.5923/j.jmea.20170704.07.

Article Outline

1. Introduction

- Plastics are synthetic materials derived from organic compounds that are produced from oil and natural gas as raw materials. In today's modern world, the rapid rate of urbanization and development, and increase in the global population resulting in the rising demand for food and other essentials, has led to the rise in the usage of film packaging plastics like PE, PP, PS, multilayered plastics and laminates etc. This low value plastic wastes i.e Commingled Waste Plastics have proven to be a serious environmental issue, as plastic waste is increasing day by day due to the lack of knowledge, awareness and the need for proper collection and disposal systems. The problems in plastic waste management and disposing them in landfills and burning them severely effects the environment and leads to pollution of Air, Water and Soil. Mechanical recycling of low value waste plastics i.e. shredding or agglomeration of the plastics is primarily necessary in converting the waste plastics into a more useful form of recycled plastics using further recycling methods like extrusion, injection or other recycling methods. Solid waste management is a crucial problem; not only for developing countries but for the developed countries as well. Enormous amount of waste is generated throughout the world and the most crucially posed question is how to manage these wastes effectively and efficiently to save the environment for the continuous existence of mankind [1]. The process of plastic recycling starts with the shredding of waste plastic material using shredders, grinders and agglomerators. The basic principle of shredders, grinders and agglomerators is reducing large volume of plastic to a smaller volume. The reason for using a shredder is because the waste materials used are soft plastics which are fluffier and less dense than hard plastics. Limbasiya et al. [2] studied the various plastics available in the Indian markets and listed the various stages in which the plastic was recycled. He also suggested various size reduction techniques and pointed out various methods currently available for plastic recycling. The publication also discussed various advantages and disadvantages of plastic recycling and methods of reducing the environmental damage caused by plastics. He also found out that there is a great potential for development of different technologies applicable to plastic waste disposal management with energy and material recovery. He suggests that for recycling to achieve its intended purpose, government authorities must play an important role in the promotion and viability of plastics reprocessing activities not only by their approaches to local waste management but also by the economic policies they adopt [2]. Khandelwal et al. [3] designed a prototype of a waste plastic agglomerator and provided information regarding the mathematical models associated with the prototype. Through his research he found out the limitations of pre-existing agglomerator machines and tried to fix these limitations through his prototype. He also formulated mathematical formulae for various constraints of the machine like minimum required speed of the blades, minimum length of the blades, minimum diameter of the drum, etc. Odior et al. [4] developed a polythene recycling machine and provided the design of the developed machine. He provided the various design considerations for various components of his machine like the drum, blades, shaft, frame, etc. He also explained how he could reach those necessary design considerations. After the construction of the machine he could conclude that the machine was capable of processing 30 kg of polythene wastes per hour. Plastics are shredded between the rotor knives and a fixed counter knife in the presence of water. The agricultural film plastics are usually contaminated by soil, sand, and other foreign material coming from the fields. The sand wears the blades of the shredder while any stones or metal can break these blades. Dry cutting of plastics cannot be performed (unless an expensive shredder with internal water cooling is used) since the overheated blades melt the plastic and contaminants (paper labels, adhesives, dirt, etc.) together, into a molten mass [5]. This is particularly true for low melting polymers like the PE. Wet shredding also can increase blade life since water is washing and flushing the contaminants (dirt, sand, etc.) from the product before granulating. Blades in a wet grinder generally can go about three times longer between resharpenings than blades in a dry grinder [5]. To tackle the problem of waste plastics, a plastic extruder was developed to convert the plastic wastes into plastic bricks. The development of an extrusion machine which converted the shredded plastic waste into a more economical material i.e., plastic bricks, was considered [6]. After the plastic bricks were produced by the extrusion machine, the bricks were subjected to compression testing to determine the amount of load the plastic bricks could tolerate. The results revealed that waste plastic material mixed with rubber powder and Calcium Carbonate, and the subsequent bricks which were produced, had the highest compressive strength and could sustain high compressive loads [6]. Study was done by mixing different types of mixed waste plastics in different percentages along with materials like Fly Ash, Rubber Powder and Calcium Carbonate. The developed waste plastic-rubber composite material was three times stronger than the normal fired clay brick and could be used as a cheaper alternative to clay bricks and various other building materials in construction like bricks, interlocks, floor tiles and roof tiles etc. [7]. This study attempts to use the above listed findings in developing a machine that combines the process of washing and shredding of waste plastics to granulated chips for further processing.

2. Objective and Working Principle

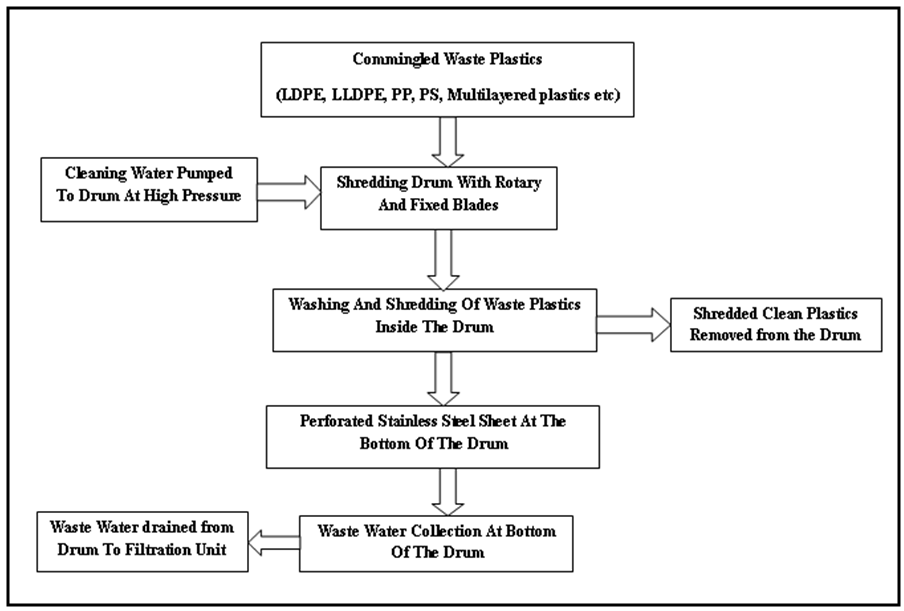

- This work was carried out with the objective of designing and developing a washing and shredding machine for the conversion of waste plastics into granulated chips which is to serve as input to an extruder-injection moulding machine to manufacture plastic lumber. The focus in developing the washing and shredding machine was to create a machine with minimal parts, possess durability, affordability, easy to operate, and safe operating conditions. The process begins with the loading of plastic waste like LDPE, LLDPE, PP, PS, multilayered plastics, and laminates into the drum. The plastic waste is loaded in terms of batches. The batch sizes entering the drum will be approximately between 30-45 kg in weight and it is loaded manually. The loaded plastic will then be subjected to wet shredding in presence of pressurized cleaning water sprayed from the top of the drum using the water pump. The shearing effect or cutting action takes place due to the interaction of the moving blades with the fixed blades. Thus, the soft plastic breaks away into small chips or flakes and is pushed to the sides of the drum wall due to centrifugal force. The blades rotate at a speed of about 900 RPM and as a result causes the shredded plastics to keep rotating in a vortex within the drum causing further reduction in size. Also, during the process of shredding, water is sprayed at high pressure from the top of the drum which cleans the waste plastics while wet shredding takes place. Water also increases the blade life as it cools the blades during the cutting action of the waste plastics. Once this shredding and cleaning process is completed, the plastic outlet is opened by means of rotating a hand wheel and the shredded plastic moves out of the drum due to centrifugal force and is collected in sacks / bags/ containers. The water that is obtained from the cleaning process is drained into the water chamber present at the base of the drum via the perforated base sheet below the rotary blades. This water is then drained into a water filter via pipes attached to the base of the drum. Figure 1 shows the block diagram of the process.

| Figure 1. Block diagram of the process inside the washing and shredding machine |

3. Machine Construction

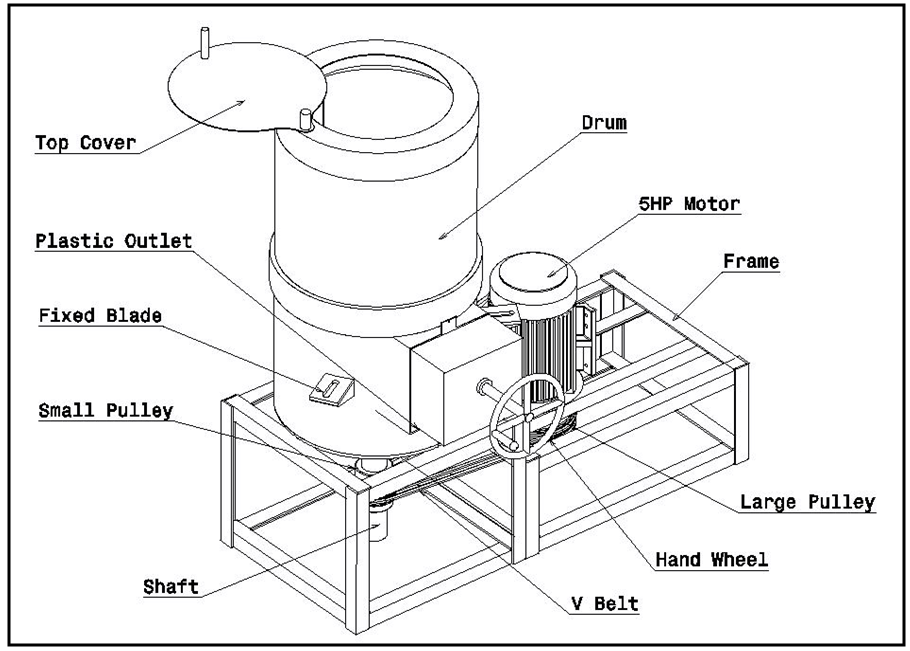

- The methods used in the construction of the designed machine include machining operations like turning, facing boring operation on lathe machine, keyway cutting on slotting machine, drilling operations on drilling machine, milling operations on Vertical Milling machine, Rolling of M.S Sheet in Sheet rolling machine, flame cutting of M.S sheet and S.S sheet using oxyacetylene gas cutting machine, grinding for good finishing, electric welding using arc welding machine. The cutting blades were heat treated to get the required strength. The line diagram of the washing and shredding machine is shown in the Figure 2.

| Figure 2. Diagram of Commingled Waste Plastic Washing and Shredding Machine |

3.1. Materials Selection

- The different materials selected for the fabrication of the machine are discussed in this section. Factors considered for selection are cost of the materials; and mechanical properties of the materials and durability of the machine.The following materials are used in the construction of this machine: Mild Steel is used for Drum, fixed top cover for drum, fixed blade supporting ribs and machine frame. EN-9 is used for shaft, Stainless steel is used for moving blade base rotor, clamping nut, circular perforated base, perforated base side and centre covering and bottom supports, movable top loading cover, water pipe connector to supply water inside the drum etc. Alloy steel is used for bearing housing, lock washer, hand wheel and screw for plastic opening door. Three Fixed blades and two Rotary blades inserts are made from HCHC steel. Large and Small pulleys are made from Cast Iron. Rubber Oil seal is used to prevent water from entering the bearing housing and another rubber oil seal is used to prevent the lubricating oil from leaking outside the bearing housing.

3.2. Equipment

- The parts used in the machine are as follows: 3 phase, 5 H.P Induction electric motor, Machine drive shaft, two tapered roller bearings, Bearing housing, Lock washers, Large and Smaller Pulleys, V-belt drive, Rotary blade base, two rotary Blade Inserts, three Fixed blades, Single phase 0.5 H.P water pump for circulation of cleaning water into drum and electric control panel with electric motor starter and contactor, control switches for machine and water pump. The diagram of Commingled Waste Plastic Washing and Shredding Machine is shown in Figure 2.

4. Working

- The operational principle of this machine is as follows:(a) Switch on the shredder machine and switch on the water pump to supply the cleaning water into the machine drum for shredding of different waste plastics. (b) After opening the movable top loading cover, mixed waste plastic is loaded into the drum with the batch size between 30 - 45 kg.(c) The moving blade rotor rotates at 900 RPM and the fixed cutting blades does the Wet Shredding and cleaning of mixed waste plastics in the presence of water at high pressure supplied using the water pump.(d) The time required to completely shred and clean the waste plastics is generally around 10 - 15 minutes. Longer processing time is necessary for stronger and multilayered plastics and the time for processing increases based on the degree of contamination of the supplied batch of waste plastics for cleaning and shredding.(e) The waste water obtained after cleaning the waste plastics is discharged from the drum through the perforated sheet to the bottom of the drum and is drained into the filtration unit and then this waste water is dumped to the open pit in the ground. (f) The plastic obtained after cleaning and shredding will be in the form of flakes and small shred pieces and is obtained from the plastic outlet of the drum.The photograph of the final assembled Commingled Waste Plastic Washing and Shredding Machine is shown in Figure 3.

| Figure 3. Photograph of the final assembled Commingled Waste Plastic Washing and Shredding Machine |

5. Conclusions

- Dirty commingled plastics obtained from the dumping yards can be shredded and cleaned by using this machine. The output obtained will be in the shredded form of plastic flakes. The waste water coming out of this machine after cleaning the dirty waste plastics has low COD value and this waste water is filtered in a water filter unit next to the shredder machine and the filtered water can be dumped into an open pit in ground without any impact to environment. The shredded plastics which is obtained as output will be slightly moist and hence the plastics obtained from the machine may be subjected to open air-drying process. The shredded plastics, once dried can be collected in sacks/bags/containers and sent for further processing. The Washing and Shredding Machine will be used in combination with an Extrusion-Injection Moulding Machine, for use in waste processing facility named "EcoHub" under the “The EcoGram Project” of T.A.I.C.T in Bengaluru. This machine can be effectively used in small scale waste plastic recycling centres and waste processing facilities.

Funding Organization

- We are extremely grateful to Ms Myriam Shankar Krafft, Trustee, The Anonymous Indian Charitable Trust (T.A.I.C.T), Bengaluru and Co-founder of Solid Waste Management Round Table (S.W.M.R.T), Bengaluru and Mr Wolfram Thurm, Product Designer, Bauhaus University in Weimar, Dresden, Germany for recognizing our previous research work and for voluntarily providing with the necessary financial support for developing this machine for the benefit of society in dealing with problems of waste plastics.

ACKNOWLEDGEMENTS

- The authors are very much thankful to Dr Joseph Gonsalvis, Principal - St Joseph Engineering College, Mangaluru, for his valuable interactions, suggestions and comments for the successful completion of this work. We thank Mr P. Varun Kajava, Mr Ranjan H. V, Mr Nikhil Lloyd Pais, Mr Vikhyat M. Naik, alumni of St Joseph Engineering College, Mangaluru for developing an award-winning Waste Plastic Extruder which was the foundation for developing this machine. Our sincere thanks to Mr Ravindra, Janani Plastic Industry, Baikampady Industrial Area, Mangaluru for permitting us to do study on different shredders. We would like to express our gratitude to Chrisage Engineering Company, Baikampady Industrial Area, Mangaluru for helping with the fabrication of many key machine components and successful completion of the machine. We thank Mr Roby Vaz, Fleetcare Company, Mangaluru for helping us with rotor balancing. We thank Mr Sudheer Kini, Assistant Professor, Mechanical Engineering Department, St. Joseph Engineering College, Vamanjoor, Mangaluru for his useful interactions. We are indebted to the Management of St Joseph Engineering College - Vamanjoor, Mangaluru for providing the work space and the constant support and encouragement during the research work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML