-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2014; 3(1A): 15-20

doi:10.5923/s.textile.201401.03

Environmental Concerns in Antimicrobial Finishing of Textiles

Faheem Uddin

Textile Engineering Department, FE, Baluchistan University of I.T. Engineering and Management Sciences, Airport Road, Balali, Quetta, Baluchistan, Pakistan

Correspondence to: Faheem Uddin, Textile Engineering Department, FE, Baluchistan University of I.T. Engineering and Management Sciences, Airport Road, Balali, Quetta, Baluchistan, Pakistan.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

A variety of antimicrobial chemical finishes recently received significant interest in the development of antimicrobial fibrous products. However, an antimicrobial inhibiting the growth or leading the death of microorganism may be harmful to other living species including human being. An increasing consumption of antimicrobial finished fibrous products, and the existing regulations for the registration and control of such products provided strong reasons to appreciate the environment concerns associated with the finished textiles. The published literature in antimicrobial finishing of fibers mainly addressed the development of finish composition, its application, and subsequent evaluation using appropriate methods. Environmental risks that may be associated with the antimicrobial; and its undesired effect during the product service life were the obvious concerns demanding investigations. State of the art development in antimicrobial finishing of textiles emphasized the need for assessing the environment-friendly character of antimicrobial finishes, and the development of antimicrobial effects using natural antimicrobials of plant and animal origin obtainable from the waste materials. Sustainable finish composition and finished fibrous product were apparently found desirable.

Keywords: Antimicrobial finishing, Chemicals, Environment, Fibrous product, Water, Microorganism

Cite this paper: Faheem Uddin, Environmental Concerns in Antimicrobial Finishing of Textiles, International Journal of Textile Science, Vol. 3 No. 1A, 2014, pp. 15-20. doi: 10.5923/s.textile.201401.03.

Article Outline

1. Introduction

- Antimicrobial finishing of textiles emerged as an important market segment comprising consumer, and technical products for healthcare and hygiene control. Nosocomial infections in hospitals, and surface contamination involving microorganism indicated the significance of antimicrobial finishing. The antimicrobial finished textiles were desired to reduce the growth and transmission of microorganism. The studies of antimicrobial finishing of textiles resulted in the significant volume of published research literature. That indicated the growth in the consumption of antimicrobial finishing chemicals and antimicrobial fibrous products. However, an antimicrobial inhibiting the growth or leading the death of microorganism may be harmful to other living species including human being. An antimicrobial present in clothing, healthcare fibrous product, and hometextile may contact an individual’s skin or it may be affecting any living species found in the surrounding environment. Therefore, an appreciation of environmental concerns is obviously important to produce antimicrobial fibrous products with an acceptable ecological performance. Recently, the importance of studying environmental concerns associated with antimicrobial finishing of fibrous material were noted [1]. However, several environmental concerns on fate of using the antimicrobials in various applications were indicated [2- 6].This study is aimed to identify the knowledge gaps in the antimicrobial finishing of fibers using important synthetic, or metal based antimicrobials. Reduced environmental risk is obviously desired in sustainable product development to prevent toxic and undesired effects on living species and environment.

2. Market for Antimicrobial Finished Textiles

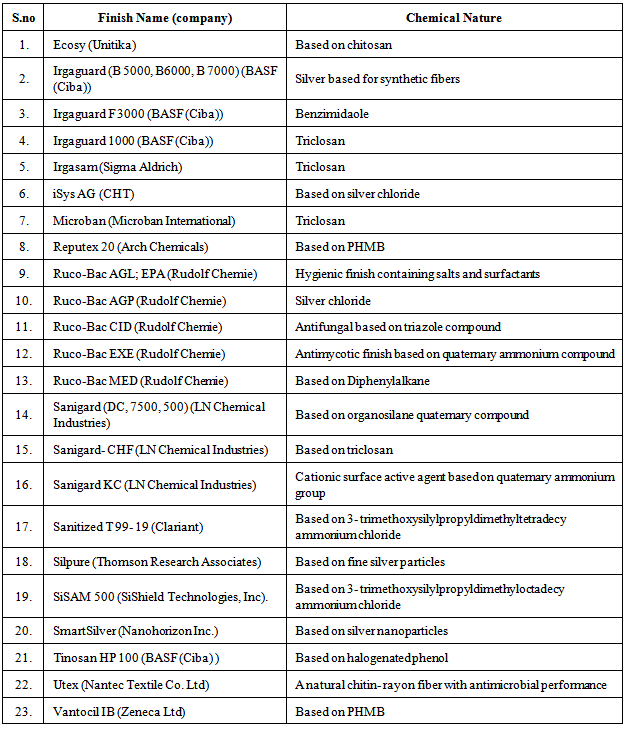

- The realization of market demand for antimicrobial finishes and additives was emerging and an increased growth expected in future [7]. The commercial gurus are identifying the business expansion strategies in antimicrobial finished fibrous products. Some examples would include the following [8]: 1. Masks, scrubs, towels, and linens for use in hospitals. In USA (United States of America) where number of hospitals is more than 6000, these products are expected to be desired in significant quantity. 2. Antimicrobial finished socks required for foot ulcer prevention. Approximately 23 million people in USA have diabetes, and the infections can be prevented in foot ulcer using antimicrobial functional socks. It was indicated that no such product was available in USA health care sector to offer continued control of bacteria and fungi causing the foot ulcer. 3. Antimicrobial and antifungal finished socks and underwear for military personnel. 4. Sportswear market comprising sport socks, gloves, sport bras, caps etc. A niche market for antimicrobial wipes was realized. The global market for consumer antimicrobial and bacterial wipes stood at approximately USA $ 5.8 billion and USA $ 1.2 billion respectively in 2007. However, the market was expected to grow and the said figures were projected to reach USA $ 8.5 and USA $ 1.7 billion respectively by 2012 [9]. Significant increase in the baby diaper market around the world is expected. The global baby diaper market will reach US$52.2 billion in 2017, according to a new report by Transparency Market Research (Albany, NY, USA) [10]. The top products projected were phenolic compounds, iodophors, nitrogen compounds and organometallics. A recent study analyzed the worth USA $ 2 billion disinfectant and antimicrobial chemical industry of USA, and forecasted the growth to 2009 and 2014 [11].The chemical nature of variety of important antimicrobials commercially known in the market may be summarized in Table 1 [12].

|

3. Regulatory Control for Antimicrobials

- Environmental concerns, including the health hazard, associated with the use of biocide and biostatic antimicrobial finishes for fibers were indicated in several regulatory measures. Important examples may be summarized as: 1. Biocidal product directive (BPD) (98/ 8/ EEC) of EU (European Union) requires the biocidal products should be used if absolutely necessary. Product specific function in using any biocidal chemical was realized in BPD. For example an active substance listed in Annex 1 of BPD for use as wood preservative, it may be authorized to place in the market, however, it may not be authorized for product type- 21 desired to function as an anti- fouling product [13]. 2. The BPR of EU, to be enforced in September 2013, requires the active substances present in biocidal products should be approved prior placing those products in EU market.3. Classification of boicidal chemicals, in EU using risks phrases R36/38: Irritating to eyes and skin, and R50/ 53 very toxic to aquatic organisms. 4. The Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), USA, provided federal regulation for distribution, sale and use of pesticides. The important functions of EPA in controlling the use of pesticide may be described as:i. Registration process involved chemical manufacturer in the assessment of pesticide. ii. Banned and unregistered products are not encouraged.iii. Promulgating the regulation.An antimicrobial or pesticide used in textile products was the subject of EPA registration provided it was not harmful to human health and environment [14]. European Oko-Tex Standard 100 label to antimicrobial textile rewarded if it was “safe for humans and environment” [15].

4. Environmental Concerns

- More than 250 commercially known microbiocides, and several chemical formulations based on these microbiocides were available in the market [16]. The diversity of antimicrobial chemicals introduced the variety in chemical and physical properties in finished products. Any antimicrobial chemical capable to modify the cell structure of microorganism apparently bears the possibility to influence the cell structure of living species present in user environment. Concentration of germicide chemical influenced the mechanism of microbial resistance. At an increased concentration multiple cellular and metabolic targets were possible, and at reduced concentrations fewer cellular targets were indicated [17]. Moreover, the release of antimicrobial through the wash- off liquor of the finished fibrous article would introduce the hazard to aquatic life.Surprisingly, the environment concerns known for the several antimicrobial substances used in textile finishing received insignificant interest to show the viability of antimicrobials for environment. Obviously, studies are desired for assessing and justifying the environment- friendly character of an antimicrobial.

5. Silver-based Antimicrobial

- The undesired effects of silver metal to environment and living species observed in various studies indicated the significance of assessing the future of silver in antimicrobial textiles. A significant number of studies addressing the environmental effects of silver- based antimicrobials were known. Toxicity, clinical efficacy, antimicrobial performance and cost- effectiveness of silver- based dressing were emphasized for rationalization. The effects of silver- based dressing, for clinical efficacy and safety, were required to experience an assessment for improvement [18].Several metals reported to exhibit antimicrobial activity, however, silver ions showed the higher level of antimicrobial performance. Generally, the silver ions bind disulfide (S- S), and sulfhydryl (- SH) groups in the microbial cell wall’s protein resulting in the disruption of metabolic processes, and ultimately in the cell death [19].When Ag particles applied with binder or cross- linking agent, an increased durability to laundering was obtained in antimicrobial activity. Significant improvement in laundering durability of antimicrobial finished cotton fabric was possible. It was through using an appropriate binder system with silver chloride or silver nm particles (AgNPs) [20- 21].One way of reducing silver emission to use any available alternative perceived more environment- friendly. For example, the use of AgNPs in socks and consumer textiles for antibacterial effects may be replaced with more environment- friendly antimicrobials [22]. Interest in assessing the exposure and risk ranking for aquatic environment in the application of nanomaterials was reported [23]. Release of silver to environment was experienced from various products around the world. Data studied for sixty four [24] countries on silver release to environment showed the USA produced highest gross emission to environment. However, on continent basis Asia was the largest producer of silver direct to water and land [25]. It was estimated that silver released to environment was more than 13 Gg.Antimicrobial efficacy of nanosilver finish was known for variety of bacteria including Staphylococcus aureus (S. aureus), Escherichia coli (E.coli), Staphylococcus aureus methicillin resistance strain (MRSA), and Pseudomonas [26]. However, washing of nanosilver finished textiles release nanosilver into the discharge water, creating a potential health hazard to aquatic organism. An example was the finding that indicated nanosilver lethal to small fish. Nanosilver particle was binding/crossing an egg membrane and entering into the fish embryos [27]. Stereo-type application of nanoparticles can be replaced with microparticles when the desired performance effects are achievable. For example, cellulose fiber substrate immersed in solution of Ag NO3 exhibited the desired performance effects [28].An important factor that may be considered in chemical finishing is why to use nanoparticles when the desired effect was obtainable using an increased particle size. Difference was realized in comparison of silver particles and AgNPs in the ability to bind/ cross the cell membrane.

6. Evaluation on Commercially Available Antimicrobial

- Sporting antimicrobial products manufactured outside the US were evaluated, and eight out of ten failed to pass an antimicrobial efficacy test in terms of wash- durability. The products were indicated failed at either zero washes, or well before 25 washes [29]. The EPA has the authority to inspect textile product shipment, prior entering to USA, alleged to be finished using unregistered antimicrobial. There may be commercially available antimicrobial not exhibiting the desired or promised performance. Six silver based textile products were evaluated [30]. It was found that the two finished fabrics limit the viability of human cells to a lesser extent. There was only one product showing the antimicrobial effect without affecting the viability of human cells. An interesting study was made by The Swedish Chemicals Agency. The said agency analyzed 30 textile articles in terms of three antimicrobial (biocide) agents including silver, triclosan and triclocarbon [31]. Silver was found to be present in sixteen out of thirty products prior to washing; and two products were containing a combination of triclosan and triclocarbon.Importantly, with any of the three investigated finishes, the concentration of biocide used was reduced following washing in the samples treated. The original silver concentration was in the range of 0.4 mg/kg textile and 1.360 mg/ kg textile. After ten washes 10- 98 percent of the silver washed out from the textiles. Half of the silver washed out after three washes in several textiles. The washing standard used was ISO 6330: 2001.

7. Use of other Metal Particles

- Several other metal based substances including metal salts, and metal particles, in addition to silver, have shown antimicrobial activity in cellulosic fibers. Zinc and copper salts, following the silver particles, were apparently important in the published studies. However, the study of these salts was limited to the antimicrobial performance evaluation against the chosen microorganisms. Environmental effects were not considered, however, in some cases the use of binder or cross-linking agent for improved binding of salt with the fibers were determined. Fewer cellulosic fibers, other than cotton, were the subject of study in the recently published literature on antimicrobial finishing. Cellulose lyocel fibers (Zimmer A G) were investigated to enhance the performance features. Specific charging of these fibers with metal ions introduced antibacterial properties [32]. Such modification was not affecting the desired properties of lyocel fibers required for textile products. Nanometer sized- zinc oxide particles were obtainable using wet chemical method where zinc nitrate and sodium hydroxide used as precursors and soluble starch as stabilizing agent [33]. The use of a binder or a cross- linking in finishing with nm particles of Zn O may improve the durability of finishing effect to laundering [34]. Cellulose fabrics pretreated with succinic acid anhydride to assist the adsorption of metallic salts, CuSO4 or ZnSO4 [35]. In this study the pretreatment of cellulose fabric with succinic acid anhydride was more effective in improving the adsorption for Cu ions than Zn ions. Polycarboxylic acid produced ester cross- linking with cellulosic fiber. It was indicated to introduce improved binding of heavy metal salts to cellulosic fibers. The metal salt studied included zinc acetate, zinc chloride, zinc sulfate, cupric acetate, cupric chloride, cupric sulfate, and nickel sulfate [36].

8. Triclosan-based Antimicrobial

- Triclosan (5-chloro-2-(2, 4-dichlorophenoxy) phenol (TCS) was a known chemical finish for producing antimicrobial effects in textiles. It is known to be used for bacteriocidal and bacteriostatic effects. At bacteriocidal dosage, triclosan exhibit multiple nonspecific functions resulting in the disruption of cell wall and cell death, and at bacteriostatic concentration its function can be specific [37]. Triclosan (CAS 3380- 34- 5), and triclocarbon (CAS 101-20-2) finished samples were evaluated. These were releasing the triclosan and triclocarbon content in wash- off water.TCS was detected in aquatic ecosystem since it was partially removable through waste water treatment. It’s by- products including methyltriclosan and other chlorinated phenols may be of increased resistant to degradation and showing higher toxicity level relative to TCS [38].However, concern was shown for TCS tendency to cause endocrine disruption, and aquatic species including algae, invertebrates and some types of fish were found more sensitive to TCS relative to mammals. Apparently, the use of TCS in fibrous products that experience repeated laundering in service life should be reduced. Serious concerns were raised for TCS use in consumer products in 2009 and 2010 demanding the removal of TCS. Consequently, several consumer item producers removed TCS content. Those included Colgat-Palmolive- producer of Softsoap; GlaxoSmithKline- producer of Aquafresh, and Sensodyne tooth paste. US Environmental Protection Agency received comments of over 10, 000 individuals in support of banning the use of TCS as an antimicrobial [27].

9. Environment-Friendly Antimicrobial

- Perhaps the type of an antimicrobial effect like slow- releasing biocidal mechanism introduced by halamine chemistry bear reduced hazard to environment. Halamine finished textile exhibited durable and generable antimicrobial performance. Range of microorganisms was indicated to be inactivated by halamine chemistry without introducing drug resistance [39]. An important category that may offer promising effects to environment will include antimicrobial like chitosan and activated charcoal [40]. Natural antimicrobial or those derived from the modification of natural material could be interesting source of producing environment-friendly finish effects. Chitosan was such an important finish studied in the textile finishing. Several studies addressed the evaluation of antimicrobial performance of chitosan finished textiles, however, those were lacking in the assessment of any environmental effects. Antimicrobial effect obtained using fruit or vegetable waste may be interesting in producing environment- friendly performance. Fruit peels including pomegranate, orange, and lemon are presently the subject of study for the possible alternative development [41]. Hydrogen peroxide is a natural antimicrobial produced by human cells to inhibit invasive bacteria. It was found in honey acting as preservative. Antimicrobial activity of hydrogen peroxide was known for bacteria, mold, mildew, fungi, algae and viruses. Smaller concentration of H2O2 may produce some of the desired effects including the resistance to staining, odor and substrate deterioration. A type of commercially available finishing effect based on hydrogen peroxide called Stay Fresh® was described to receive EPA registration. This finish was said to achieve antimicrobial effect in various textile products including apparel, interior furnishings, automotive, upholstery and carpeting [42].

10. Conclusions

- Environmental concern, particularly during the service life of finished fiber substrate, is an important part in the production and marketing of antimicrobial textile products. However, till to date, the published research studies in the development of antimicrobial textiles concentrated the synthesis, production of finish, and its evaluation against particular microorganisms.The effects of finish content released in waste water bath, and the release of finish content to surrounding skin of user, and its contact / inhalation / consumption by other living species require studies.The washed out content of an antimicrobial contaminate the sludge. The contaminated substances in the sludge may be consumed by the cultivated plants and eventually becoming component in feed and food. Contamination is also possible in water and soil organisms.Antimicrobial effect obtained using natural material of plant and animal origin may be interesting. Fruit or vegetable waste may be investigated in producing environment- friendly performance.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML