-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Materials and Chemistry

p-ISSN: 2166-5346 e-ISSN: 2166-5354

2013; 3(A): 29-38

doi:10.5923/s.ijmc.201303.05

Nanostructured Float-Glasses after Ion-exchange in Melts Containing Silver or Copper Ions

Mariela T. Dimitrova1, Yordanka Y. Ivanova1, Yanko B. Dimitriev1, Isabel M. Miranda Salvado2, M. Helena F. V. Fernandes2

1Department of Silicate Technology, University of Chemical Technology and Metallurgy, Sofia, 1756, Bulgaria

2Ceramics and Glass Engineering Department, CICECO, University of Aveiro, Aveiro, 3810193, Portugal

Correspondence to: Mariela T. Dimitrova, Department of Silicate Technology, University of Chemical Technology and Metallurgy, Sofia, 1756, Bulgaria.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Ion-exchange technique is widely used for obtaining coloured glasses. In this research we treated float glass samples in vapour and melts of copper and silver containing mixtures. We have studied the influence of experimental conditions (composition of the melt, temperature and processing time, additional treatment) on the size of colloidal nanoparticles, the optical characteristics and the achieving a variety of colour shades of the ion-exchange glasses. We have clarified the role and influence of the presence of tin ions in the surface layer of the glass matrix on the transmission of the glasses, the mechanism for the formation of the colour layer, the depth penetration and the size of colloidal nanoparticles. The optical properties of the nanostructured glasses were investigated by UV-VIS spectrophotometer. The structural and microstructural properties in the glass matrix, showing the formation of nanocrystalline particles have been studied using Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFT) and Scaning electron microscopy (SEM). The particle size and the roughness of the background of the structure have been determined by AFM.

Keywords: Ion-exchange, Float Glass, Nanoparticles, Copper, Silver

Cite this paper: Mariela T. Dimitrova, Yordanka Y. Ivanova, Yanko B. Dimitriev, Isabel M. Miranda Salvado, M. Helena F. V. Fernandes, Nanostructured Float-Glasses after Ion-exchange in Melts Containing Silver or Copper Ions, International Journal of Materials and Chemistry, Vol. 3 No. A, 2013, pp. 29-38. doi: 10.5923/s.ijmc.201303.05.

Article Outline

1. Introduction

- The vitreous state has unique properties related todisordered structure of the glasses and the structural changes accompanying the glass transition. These specifications can be used to obtain new glassy materials by controlling the composition and structure of the glass matrix. Different techniques for modifying the vitreous surface weredescribed in details by Norris and Povey as the most widely is the application of ion-exchange method[1, 2]. Ion-exchange processes between melt and glass surface were performed highly intensively during the 70s of the last century inconnection with the modifying of some properties of the glasses: increasing of mechanical strength, chemical resistance[3-8] photochromic properties[9], opticalabsorption andcolouring[10-13]. One of the important properties of modifying ions is their high mobility in the glass, due to their unique electronic configurations. The mobility of an ion alsodepends on its place in the lattice, thus the investigation of the preferential place for modifying ions is important to develop new functional glasses not only changing the refractive index, but also making it with photoluminescence properties[14-16]. It has been found that surface treated glasses are promising candidates for many new applications: optoelectronic components, nonlinear opticalmaterials[17-22] and planar waveguides[23-29]. Therefore it is a topical search to study new ways to modify the glass surface controlling diffusion processes[30-39]. The generation of nanosized metal particles in amorphous matrix, the changes of the optical properties and the intensity of the colouring of the new materials were analyzed based on Surface Plasmon Resonance (SPR) [40-47]. Formation of copper and silver nanoparticles, shape, size and their distribution in the glass matrix and the structural changes in the glass after ion - exchange are established using classical and modern analysis techniques such as optical microscopy, UV-VIS spectrometry, TEM, HRTEM, XRD, EXAFS, XPS. In our previous research connected with the application of ion-exchange process for staining of industry glasses we developed a method for obtaining coloured glass type “copper ruby” after treatment in melts containing Cu ions and subsequent UV and X-ray irradiation at appropriate thermal treatment[48]. We also investigated the colouring of glasses treated in silver-containing molten salt. The study of the spectral characteristics of ion exchange coloured glasses shows an absorption peak at 430-450 nm (colouring with silver ions) and 550–650 nm (with copper ions). It is proved that its appearance is a result of the formation of colloidal Ag or Cu particles[49]. Investigations by other authors[50-58] prove the relation between the change in the spectra kinds and the intensity of the absorption peak of the content of Ag or Cu which diffuse into the surface layer of the glass and the size of colloidal particles. It was found that the deep profile of the generated particles is strongly influenced by the concentration of modifying ions in the surface layer of the glass, the gas environment in which ion exchange is carried out and the composition of the glass. Growing interest in the study of ion-exchange processes and their applications in various fields, as well as our previous experience on the colouring of the industry glass motivates us to continue our research in this direction. As an object in this research we have to study the peculiarities of ion-exchange processes for treatment of float-glass in melts containing silver or copper ions, to clarify the role and influence of the tin ions contained in the composition of the glass matrix on these processes, the formation of nanoparticles in the surface layer of the ion-exchange glasses and the influence of the ion-exchange conditions on the size and aggregation of colloidal particles, the intensity of colouring and optical characteristics of the glass.

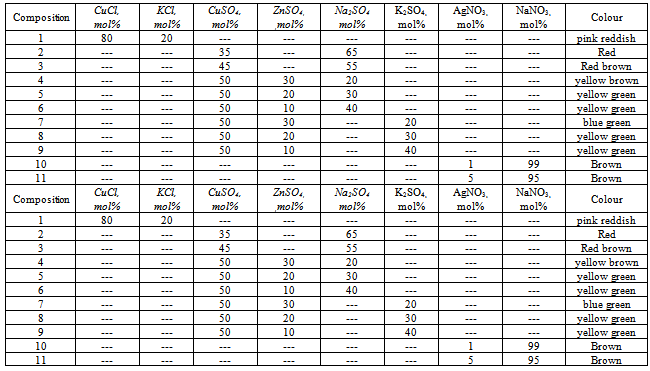

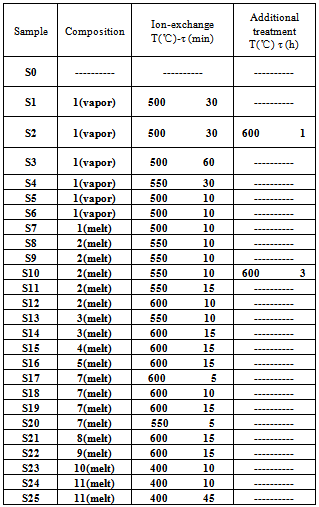

2. Experimental

- The experiments were conducted on samples of float-glass with composition 72SiO2.13Na2O.8CaO.4MgO.2Al2O3(wt %) and size 25x20х3mm. They were treated in vapour and melts of several salt mixtures presented in Table 1The melting of mixtures was carried out in a vertical electrical furnace. The glass samples were immersed in molten bath in porcelain crucible and processed toion-exchange under the following conditions: for silver containing molten salt the temperature and time are respectively 400°C, 5-45 min; for copper sulphate melts – 550-610°C, 5-30 min and for copper chloride vapour and melts 500-550°C, 10-60 min. After the ion-exchange, the samples are immersed in diluted solution of HCl and washed in H2O. The ion-exchanged samples are subject to additional thermal treatment at 600°C, 1-3h.UV-VIS spectra were recorded on UV-VISSIBLE(Cary100-Varian) spectrophotometer in the 300-800nm range. Structural and microstructural changes of the glass matrix, proving the formation of nanocrystalline particles were studied by Diffuse Reflectance Infrared Fourier Transform Spectroscopy (DRIFT-FTIR Spectrometer MATSON 7000) and Scanning electron microscopy (SEM-JEOL 5510). Particle size and roughness of the structure are registered by AFM (Nano Scope Tapping Mode TM). The ion-exchange conditions are given in Table 2

3. Results and Discussion

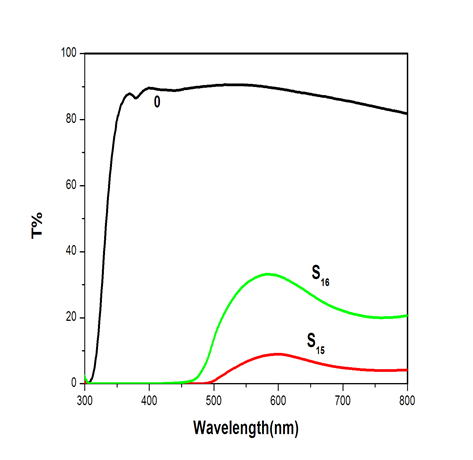

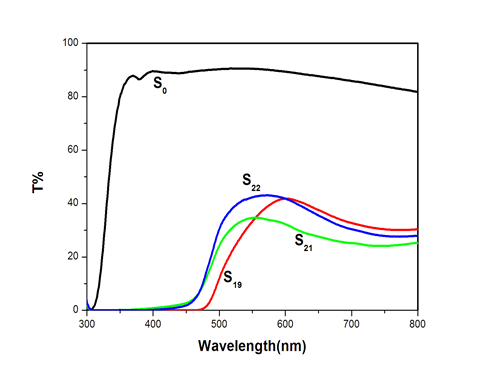

- The results of the ion-exchange indicate that glasses treated in binary sulphate melts are coloured in red, red-brown and red with the presence of greenish spots which rise with the increase of the concentration of Cu ions in the melt. The glass surface is smooth. Insignificant corrosion occurs in samples treated at higher temperatures and longer processing time. Samples treated in ternary copper sulphate melts are coloured in yellow-green and blue-green. The surface is corroded and the corrosion rises with the increase of time of the ion-exchange process.

|

|

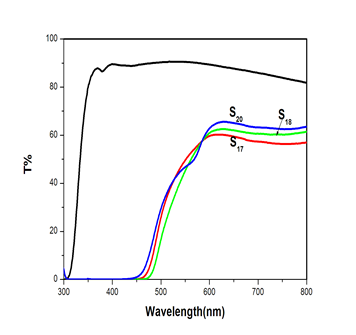

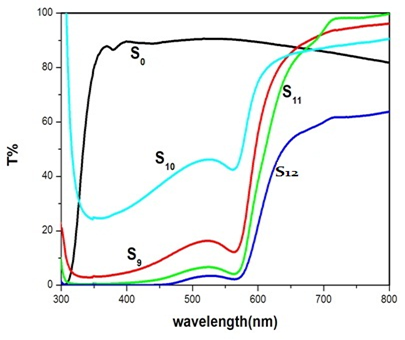

| Figure 1. Transmission spectra of float glasses treated in the melt of a sulphate mixture containing 35mol%CuSO4, 65mol% Na2SO4 at dependence of temperature, processing time and additional treatment |

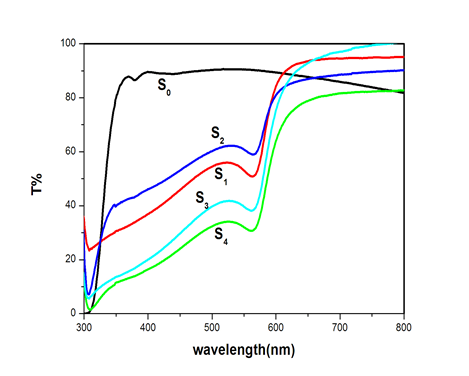

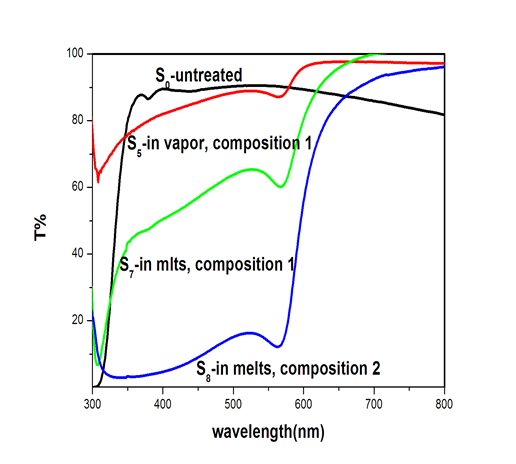

| Figure 6. Transmission spectra of float glasses treated in vapour or melts of copper containing salt at permanently ion-exchange time (10 min) |

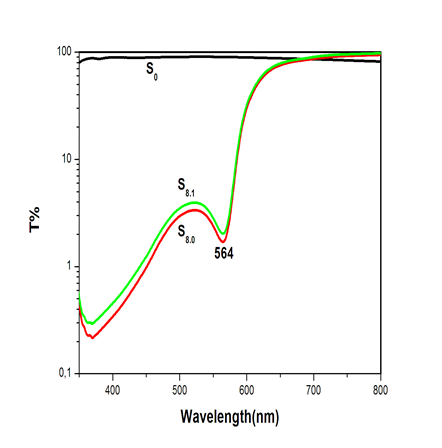

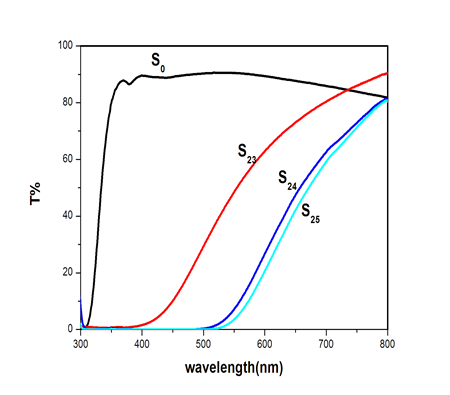

| Figure 8. Transmission spectra of float glasses treated in melts of silver containing salt depending of concentration of AgNO3 at permanent temperature and different ion-exchange time |

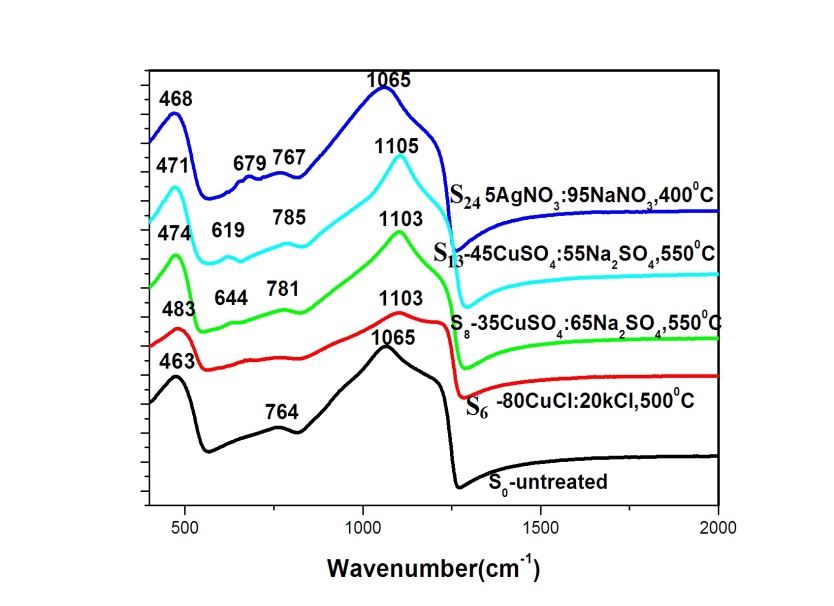

| Figure 9. DRIFT spectra of float glasses treated in melts with different composition of molten salt at permanently processing time (10 min) |

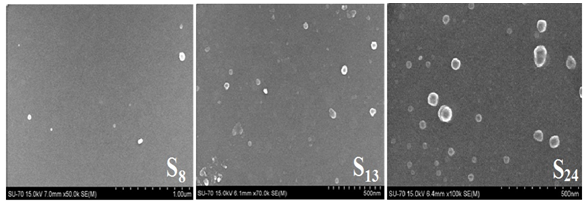

| Figure 10. SEM micrographs of ion-exchange treated glasses for 10 min in melts with different composition: S8- 35mol%CuSO4, 65mol%Na2SO4; S13- 45mol%CuSO4, 55mol%Na2SO4; S24-5mol%AgNO3, 95mol%NaNO3 |

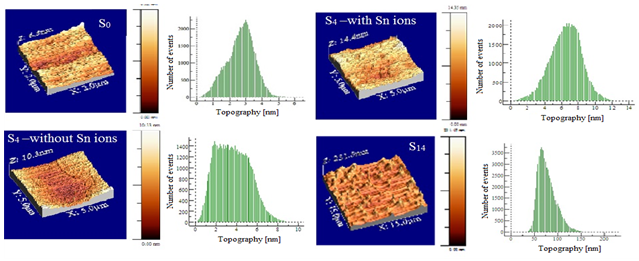

| Figure 11. AFM images of an untreated glass sample (S0) and the samples treated in vapor for 30min (S4) or melt for 15min (S14) after ion-exchange occurring in copper-containing salt at 550℃ |

4. Conclusions

- Depending on the conditions of the ion exchange process (composition of the melt, temperature and processing time, the kind of colouring ions) coloured glass with different shade (yellow-green and blue-green, red ruby, red brown and brown) can be obtained.It was found that with increasing the ion exchange time and temperature, the transmission of treated glasses in the visible range significantly decreases and the cut-off wavelength of the transmission shifts from 300 to 520nm.Red ruby glasses is possible to be obtained only after ion exchange treatment of float glass in vapour or melts of binary copper chloride and copper sulphate molten salt. On the UV-VIS spectra of these glasses an absorption peak in 560-570 nm range is registered, proving the formation of copper colloidal nanoparticles. The appearance of this peak, as well as new characteristic bands on the DRIFT spectra of the studied samples in the range of 400-800 cm-1 are a strong evidence of the beginning of crystallization processes occurring on the surface of the ion-exchange coloured glasses.To prevent corrosion of the surface of the glass treated in ternary melts ion exchange treatment is required to be performed at a lower temperature (5500C), less processing time (5-10min), the amount of ZnSO4 in the composition of the salt bath should not exceed 10mol% and Na2SO4 to be replaced with K2SO4.

ACKNOWLEDGEMENTS

- This paper has been produced with the financial assistance of the European Social Fund project numberBG051PO001-3.3.06-0014. The author is responsible for the content of this material, and under no circumstances can be considered as an official position of the European Union and the Ministry of Education and Science of Bulgaria”.The authors are grateful for the financial support by Research and Development Sector of University of Chemical Technology and Metallurgy (Contract № 10978).

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML