R. R. Udawant , K. C. Mohite , M. G. Takwale

School of Energy Studies, University of Pune, Pune, India

Correspondence to: R. R. Udawant , School of Energy Studies, University of Pune, Pune, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

The demand for process heat particularly low pressure steam is increasing in recent past. Solar energy can be utilized for generating medium temperature (100°C -150°C) low pressure (T<200°C) steam. By using solar concentrators, low pressure steam can be generated by using low cost technology [1]. Fresnel lens solar concentrators are very useful to generate low pressure steam for industrial and cooking applications. The study of performance of Fresnel lens solar concentrator and steam generation using Fresnel lens solar concentrator is presented in this paper. The overall efficiency of Fresnel lens solar concentrator is around 51% and can generate process steam required in the industry. The thermal performance and cost benefits of Fresnel lens solar concentrator are also described. The studies presented in this paper concerns with Fresnel Lens Solar Concentrator System which are most useful for generating process heat for industrial applications. Thermal performance of Fresnel lens solar concentrator (FLSC) system can be studied by evaluating useful heat gain from the system when exposed to solar radiation [1]. FLSC system consists of Fresnel lens, receiver tracking system and heat removing device. An attempt has been made to evaluate the performance of FLSC system with two methods viz.continuous fluid flow test method and Steam generation test method. The study reveals that Fresnel lens Solar Concentrator system has a very good potential in generation of low pressure steam.

Keywords:

Solar Concentrator, Fresnel Lens, Solar Energy, Steamgeneration

Cite this paper: R. R. Udawant , K. C. Mohite , M. G. Takwale , Study of Performance of Fresnel Lens Solar Concentrator, International Journal of Energy Engineering, Vol. 6 No. 1A, 2016, pp. 14-22. doi: 10.5923/s.ijee.201601.03.

1. Introduction

The Energy demand over the world is increasing exponentially, while fossil fuel reserves have started depleting. In order to sustain the development, continuous supply of energy is required. There is need to find energy resources which can be regenerated, such as solar energy, geothermal, biomass or will not deplete with time. Renewable energy source is one which can be regenerated or does not deplete with time. Solar energy is the most important source of energy which can fulfill future energy needs. There are many technologies developed to use solar energy for domestic use. The Fresnel lens solar concentrator developed at school of energy studies, university of pune is designed for direct steam generation using solar energy. The solar concentrator system has been designed for generation of low pressure steam for various applications such as industrial process heat and steam cooking. The point focus and line focus Solar Concentrators are already been developed by industries in India and abroad [6, 7]. The glass and aluminium material are normally been used as reflectors in the solar concentrators. An unique attempt has been made to develop line focus refracting type solar concentrators for thermal applications. A procedure is developed for thermal performance evaluation of Fresnel lens solar concentrator for continuous fluid flow and direct steam generation [4]. The Fresnel lens solar concentrator developed at school of energy studies, university of pune is designed with following objectives. Objectives: 1. To estimate thermal performance of Fresnel lens solar concentrator.2. To study the effect of mass flow rate, intensity of solar radiation and inlet temperature on efficiency of FLSC system.3. To estimate quantity and quality of steam.4. To estimate the efficiency of Fresnel lens solar concentrator at different operating pressures (steam temperatures).

2. Experimental

2.1. Continuous Fluid Flow Method

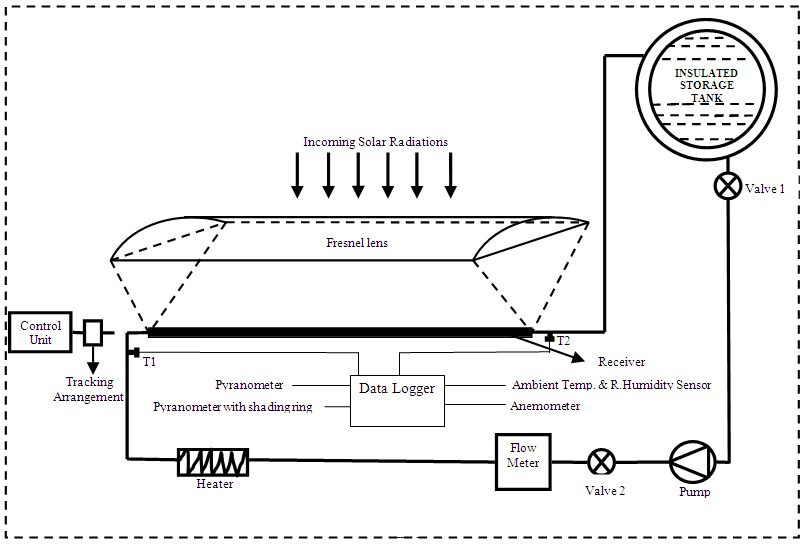

A setup for “continues fluid flow” test was developed in the laboratory, the schematic view of the test set-up is shown in the Fig.1 it essentially consists of,1. Refracting type Fresnel lens and a receiver placed at the focal line of the lens.2. Single axis tracking system.3. Fluid circulation system consisting of storage tank, fluid circulation pump. Flow meter for heating inlet fluid to desired temperature and well insulated connecting pipe lens.4. Two temperature sensors, one at inlet and other at the outlet of the receiver. | Figure 1. FLSC System Experimental setup (Continuous Fluid Flow) |

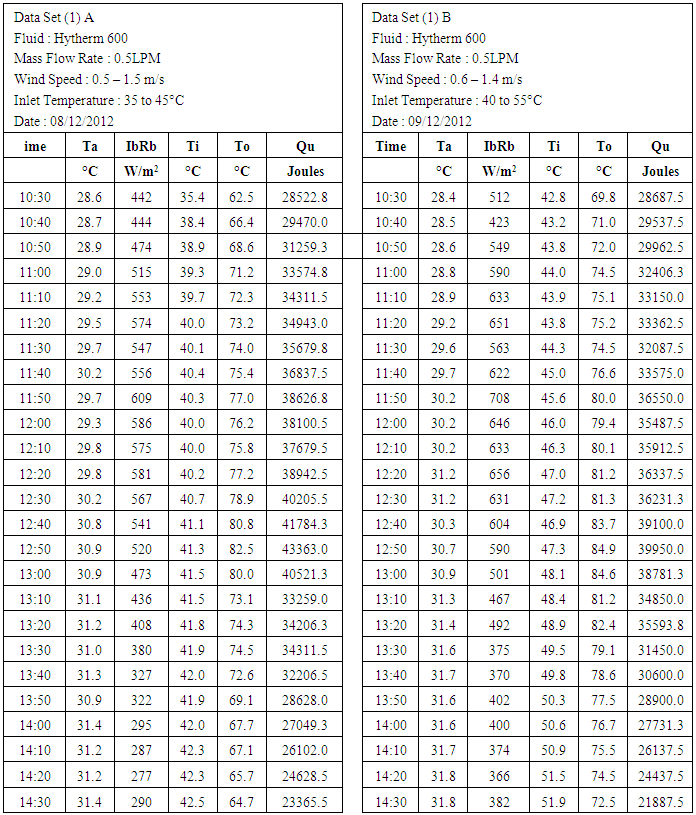

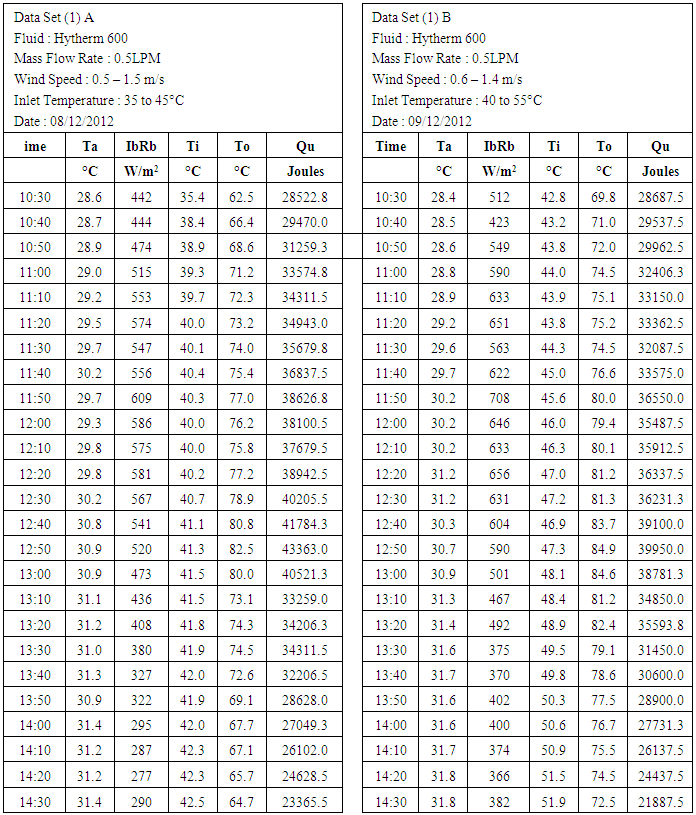

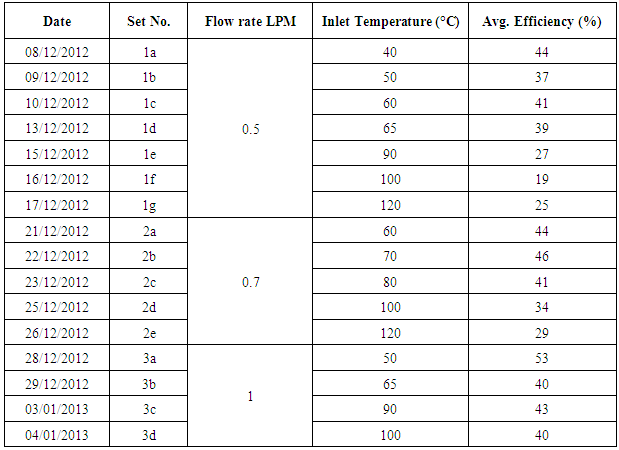

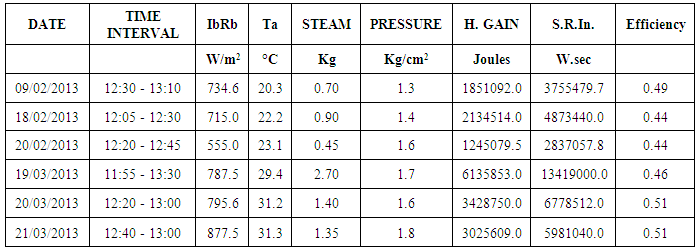

In addition to FLSC system, following equipment’s are used for collecting thermal performance data;1. Pyranometer (1) for measuring Global solar radiation on horizontal plane.2. Pyranometer (2) with shading ring to measure diffuse solar radiation.3. Temperature and humidity sensor for measuring ambient temperature and relative humidity.4. Anemometer for measuring wind velocity.Temperature sensors shown in Fig.1 and above equipments are connected to data logger having 16 channels and memory module to collect and store the data.The protocol to evaluate thermal performance of FLSC system is essentially based on ISO standards. The experiments are carried out during clear sunny days and when intensity of solar radiation (beam) is more than 400 W/m2. Following parameters are measured at the interval of 05 minutes. Data logger records average value of each parameter over a period of 05 minutes.1. Inlet temperature of fluid (°C)2. Outlet temperature of fluid (°C)3. Temperature of storage tank (°C)4. Global solar radiation using pyranometer (1) (W/m2)5. Diffused solar radiation using Pyranometer (2) (W/m2)6. Ambient Temperature (°C)7. Wind velocity (m/s)8. Relative Humidity (% RH)The data is collected by varying thermic fluid flow rate (LPM) from 0.5 LPM to 1 LPM and inlet temperature of fluid from Ambient to 120°C. Inlet temperature of the fluid is controlled by the heater fixed near the inlet of the receiver tube. The data is collected when sky is clear and during the time form 10:30 am to 02:00 pm, so that intensity of solar radiation does not change much. Table 1 shows data collected as an example.Table. 1. Data Collection (Continuous fluid flow)

|

| |

|

The useful heat collected by the thermic fluid during time interval ∆t is given by  Where,

Where,  is the useful heat gain during time interval

is the useful heat gain during time interval

is the specific heat of the fluid (J/Kg °C)

is the specific heat of the fluid (J/Kg °C) is the inlet temperature of the fluid (°C)

is the inlet temperature of the fluid (°C) is the outlet temperature of the fluid (°C)

is the outlet temperature of the fluid (°C)

2.1.2. Instantanious Efficiency of Flsc System

The instantaneous efficiency of the FLSC system is evaluated using following equation [3] Where,

Where,  is the heat gain from the collector during time interval of 10 minutes

is the heat gain from the collector during time interval of 10 minutes  is the aperture area of the Fresnel lens and

is the aperture area of the Fresnel lens and  is the intensity of solar beam radiation received during time interval of 10 minutesThe incident solar radiation consists of diffuse radiation and beam radiation [3]. However solar concentrator’s uses only beam radiation to focus on the receiver [3]. We have measured Global radiation and diffused radiation falling on the horizontal surface. Therefore intensity of solar beam radiation falling on the horizontal surface is given by,

is the intensity of solar beam radiation received during time interval of 10 minutesThe incident solar radiation consists of diffuse radiation and beam radiation [3]. However solar concentrator’s uses only beam radiation to focus on the receiver [3]. We have measured Global radiation and diffused radiation falling on the horizontal surface. Therefore intensity of solar beam radiation falling on the horizontal surface is given by, Where,

Where, is the intensity of beam radiation falling on horizontal surface,

is the intensity of beam radiation falling on horizontal surface, is the intensity of global radiation on horizontal plane,

is the intensity of global radiation on horizontal plane, is the intensity of diffused radiation on horizontal plane.The intensity of beam radiation falling on the aperture of the Fresnel lens is given by

is the intensity of diffused radiation on horizontal plane.The intensity of beam radiation falling on the aperture of the Fresnel lens is given by  Where,

Where, is the intensity of beam radiation falling on the aperture of FLSC

is the intensity of beam radiation falling on the aperture of FLSC is the tilt factor

is the tilt factor

2.2. Steam Generation Test Method

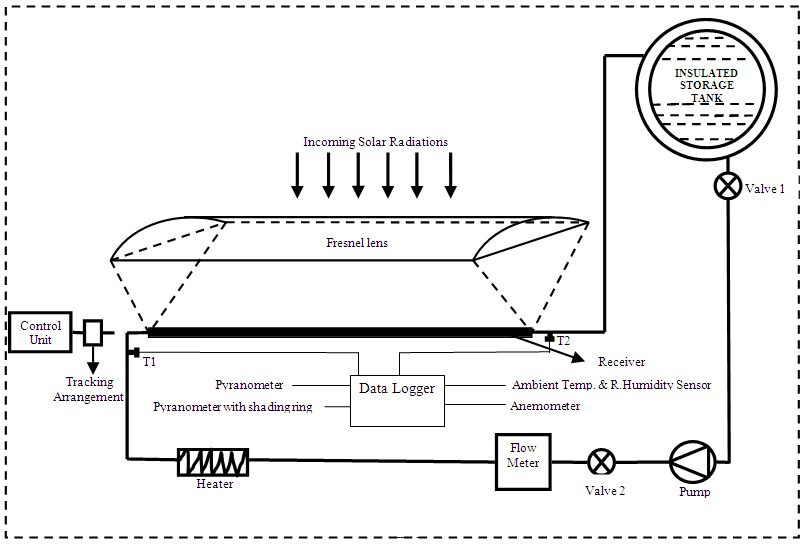

Solar concentrators are mostly used for generating steam or heating thermic fluid [11]. Low pressure steam is required in many process industries such as food processing, dairy, chemical and pharmaceutical industries. Hence we decided to test the performance of the FLSC system for steam generation. | Figure 2. FLSC System Experimental Set-up (Steam Generation) |

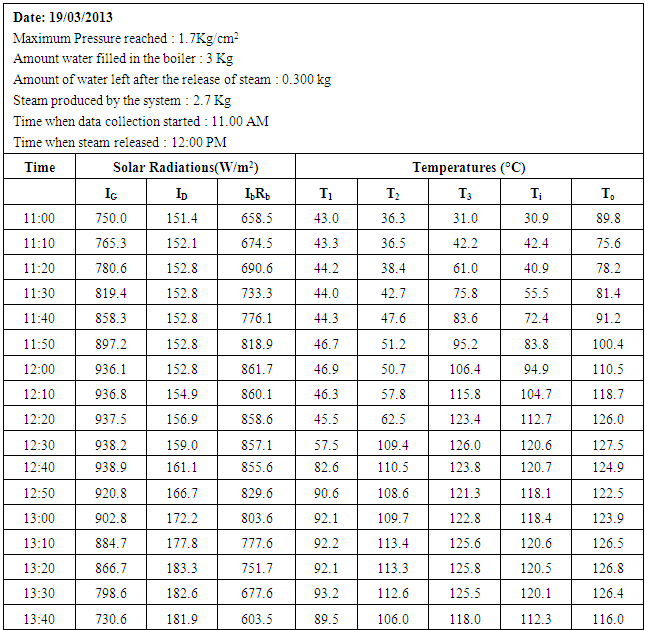

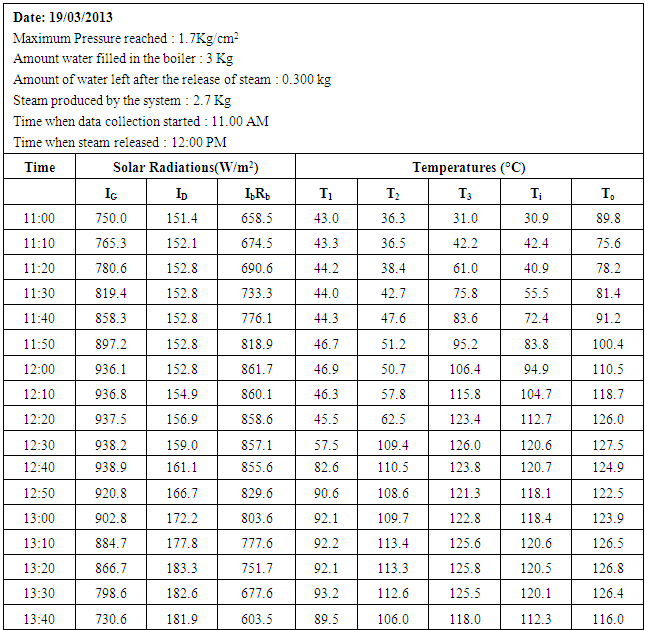

The system used for generating the steam is basically closed loop system based on thermosyphon principle. The thermic fluid system was suitably modified to generate the steam. The schematic view of the system is shown in the Fig.2. The system consists of;1. Fresnel lens solar concentrator system with lens, receiver and tracking system2. Small boiler place above the FLSC to generate steam3. Thermosyphon system to circulate water through receiver.4. Two temperature sensor Ti and To fixed at inlet and outlet of the receiver5. Three temperature sensors fixed to boiler (T1, T2, T3) to measure temperature of water in the boiler (T3), Temperature of Steam (T2) and temperature of outgoing steam (T1).6. Two pressure gauges to measure the pressure of steam inside the boiler and when steam is released.When solar radiation is concentrated on the receiver, the temperature of the water in the receiver increases and heated water is pushed to the boiler. The equal amount of water from the boiler then pushed to the receiver, form inlet side thus thermosyphon generated a convective flow which circulates water through the receiver. The continuous flow thus generated transfers heat received by receiver to the boiler and temperature of water in the boiler increases. Finally the steam is generated in the boiler. The procedure to measure the performance of the FLSC system is given below.Initially cold water is filled in the boiler such that about one third volume of boiler is empty. On a clear sunny day, at about 10:30am, the Fresnel lens is adjusted so as to focus solar radiation on the receiver tube. Then the tracking system is started to track the sun. As soon as solar radiation is focused on the receiver tube, water in the receiver starts heating. The temperature gradient between receiver and boiler pushes hot water into the boiler and cold water from bottom of the boiler tank is pushed into the receiver. Thus convective flow is set into system by thermosyphon, which keeps water circulating through the receiver. During the circulation of water, heat is transferred to water which raises the temperature of water in receiver and subsequently in the boiler. Once the temperature of water reaches boiling point, steam begins to generate which is accommodated in the empty space of boiler. When pressure of the steam is above 1.5 – 2.0Kg/cm2, the valve V1 is slowly released and steam is exhausted through the outlet pipe of the boiler. The valve is adjusted in such a way that while steam is released, the pressure in the boiler remains constant. This steady state is continued for about 1 hour during which following parameters are recorded by the data logger.1. Inlet Temperature of water (Ti)2. Outlet Temperature of water (To)3. Water Temperature in a tank (T3)4. Steam Temperature in a Tank (T2)5. Temperature of steam when released from boiler (T1)6. Global and diffused radiation on horizontal surface (IG , ID)7. Ambient Temperature (°C) and relative humidity (%RH)8. Wind Velocity (m/s)Table 2 shows the data collected for a particular day as an example.Table 2. Data collection for steam

|

| |

|

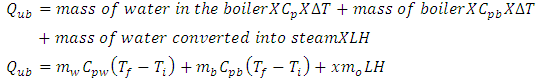

2.2.1. Heat Gain and Efficiency of FLSC System for Steam Generation

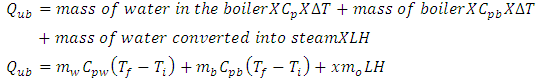

Thermal performance of FLSC system for steam generation is carried out as follows,When Fresnel lens focuses solar radiation on the receiver tube, heat is generated by absorbing solar radiation. Fluid in the receiver gets heated and it is pushed to boiler, thus thermosyphon is activated. The temperature of water in the boiler increases due to heat transfer from receiver to boiler. When boiling point is reached steam is generated in the boiler. Therefore useful heat received by the boiler is,  Where,

Where,  is mass of water filled in the tank (kg)

is mass of water filled in the tank (kg) is specific heat of water (KJ/Kg°K)

is specific heat of water (KJ/Kg°K) is Final Temperature of Water (°C)

is Final Temperature of Water (°C) is initial Temperature of water (°C)

is initial Temperature of water (°C) is mass of boiler (kg)

is mass of boiler (kg) is specific heat of boiler material (KJ/Kg)

is specific heat of boiler material (KJ/Kg) is dryness factor of steam ~ 1.0

is dryness factor of steam ~ 1.0 is mass of steam generated (kg)LH is latent heat of vaporization of water (KJ/kg)When we release steam at constant temperature and pressure ∆t = 0Therefore efficiency of the system given by,

is mass of steam generated (kg)LH is latent heat of vaporization of water (KJ/kg)When we release steam at constant temperature and pressure ∆t = 0Therefore efficiency of the system given by,  Where,

Where,  is intensity of beam solar radiation

is intensity of beam solar radiation is Aperture area of the FLSC and

is Aperture area of the FLSC and  is time interval i.e. time during which steam at constant pressure is released

is time interval i.e. time during which steam at constant pressure is released

3. Results and Discussion

The performance of the Fresnel Lens Solar Concentrator (FLSC) system depends on several parameters. Some of the factors affecting the performance of FLSC system are,1. Optical efficiency of FLSC system2. Heat removal factor of the system3. Mass flow rate of fluid used for extracting heat from the receiver4. Overall heat loss factor 5. Inlet temperature of the fluid and6. Intensity of solar radiationThe effect of above parameters on the performance of FLSC system is studied using the data collected as described in Table 1 and Table 2.

3.1. Effect of Mass Flow Rate of Fluid on Efficiency

After collecting the performance data for FLSC system using continuous fluid flow test method the data has been analyzed to evaluate performance of the system. Using hytherm 600 as thermic fluid for removing heat, Optical efficiencies at different mass flow rates are as below,For 1st set of experiment, where flow rate is 0.5LPMη = 0.51 – 1.37 ∆T/IbRb,Where ∆T = (Tm-Ta) & Tm = (Ti+To)/2Hence, Optical efficiency = FR(τα)e = 0.51Heat Loss coefficient = FRUL = 1.37For 2nd set of experiment, where flow rate is 0.7LPMη = 0.56 – 1.44 ∆T/IbRb,Where ∆T = (Tm-Ta) & Tm = (Ti+To)/2Hence, Optical efficiency = FR(τα)e = 0.56Heat Loss coefficient = FRUL = 1.44For 3rd set of experiment, where flow rate is 1 LPMη = 0.60 – 1.63 ∆T/IbRb,Where ∆T = (Tm-Ta) & Tm = (Ti+To)/2Hence, Optical efficiency = FR(τα)e = 0.60Heat Loss coefficient = FRUL = 1.63An increase in the mass flow rate of the fluid increases the value of the heat transfer coefficient [3]. Due to this, the collector efficiency factor FR(τα) and heat loss factor increases. Hence it was observed that when mass flow rate increases both optical efficiency and heat loss factor (FRUL) increases.

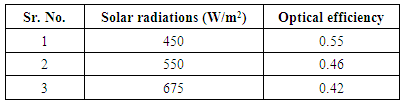

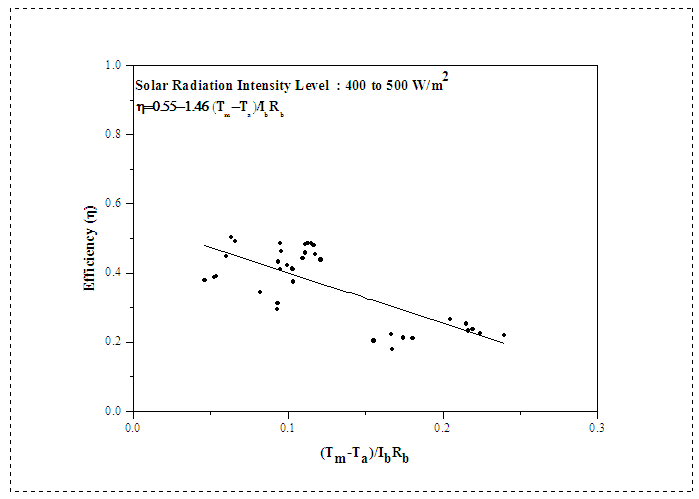

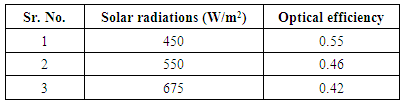

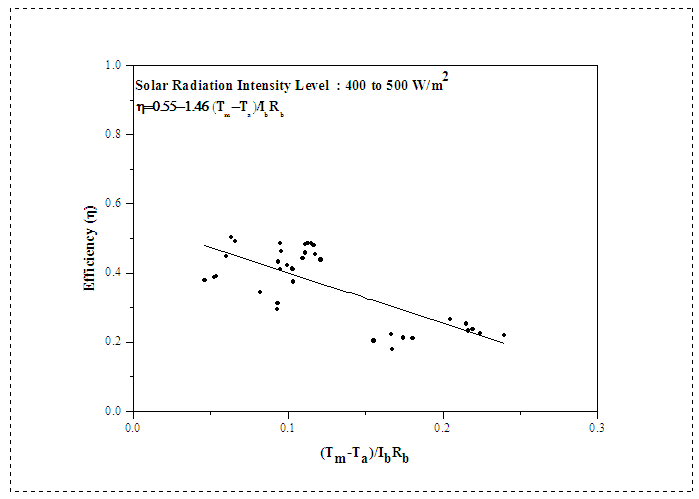

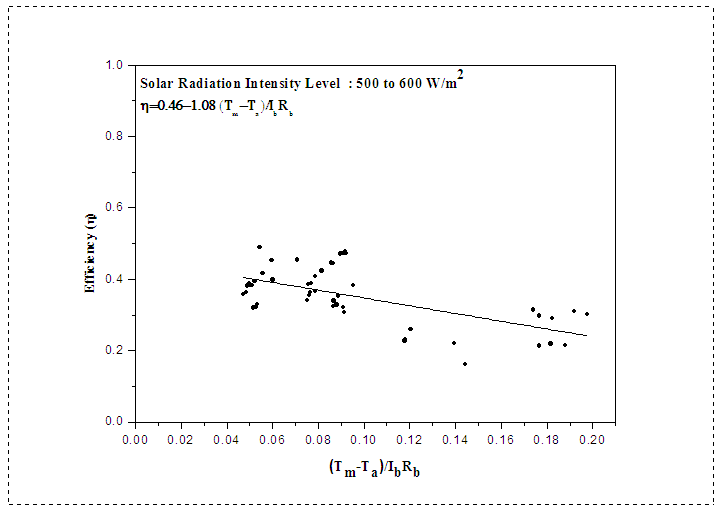

3.2. Effect of Intensity of Solar Radiation on Efficiency

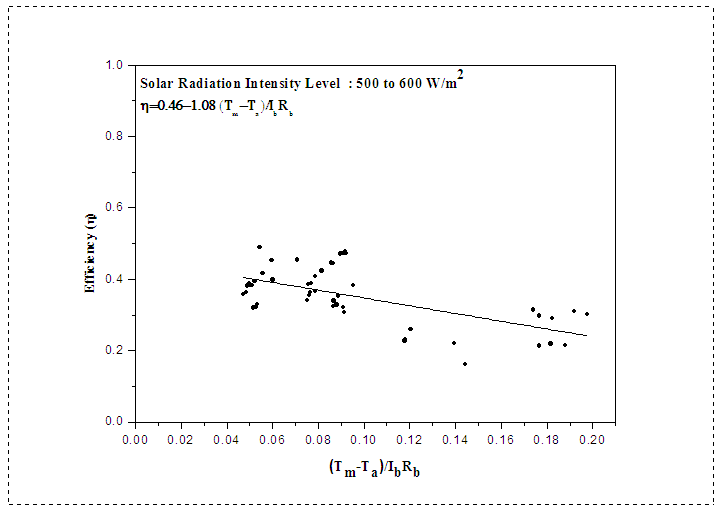

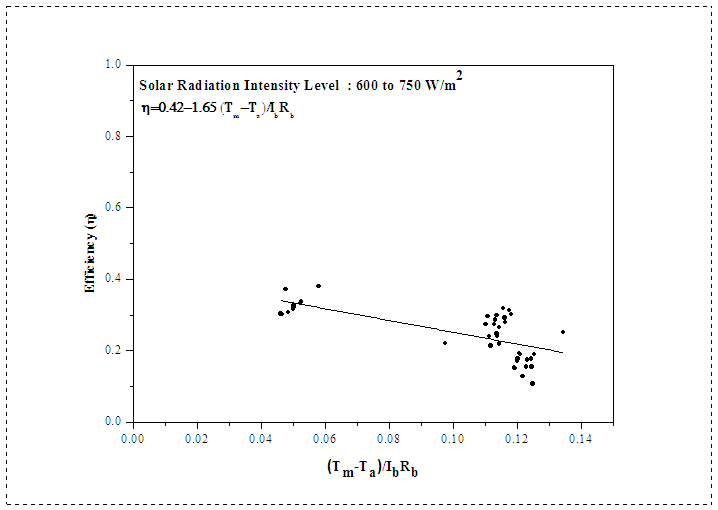

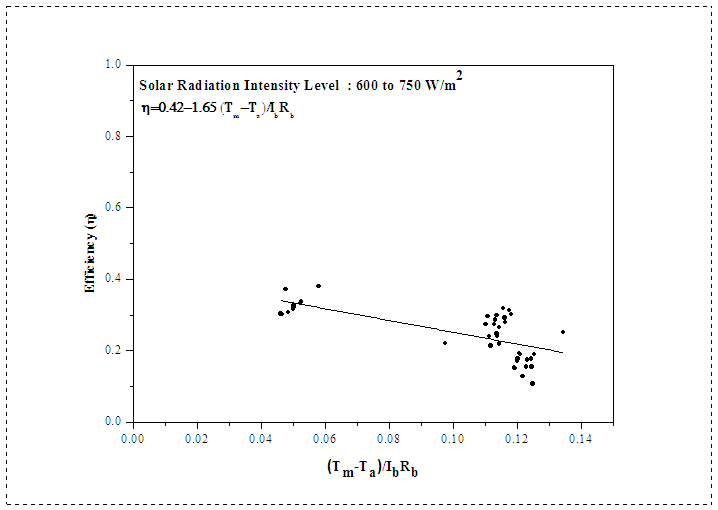

The effect of Intensity of Solar Radiation on efficiency of FLSC system is shown in the Fig.3, Fig.4 and Fig.5. The variation of efficiency with (Tm-Ta)/IbRb has been plotted for three different levels of solar radiation (450 W/m2, 550 W/m2 and 675 W/m2). It was observed that the efficiency of FLSC system is strongly influenced by the intensity of solar radiations. The optical efficiencies at three different Intensity levels are as below,

| Figure 3. Variation of Efficiency with (Tm-Ta)/IbRb for IbRb = 400-500  |

| Figure 4. Variation of Efficiency with (Tm-Ta)/IbRb for IbRb = 500-600  |

| Figure 5. Variation of Efficiency with (Tm-Ta)/IbRb for IbRb = 600-750  |

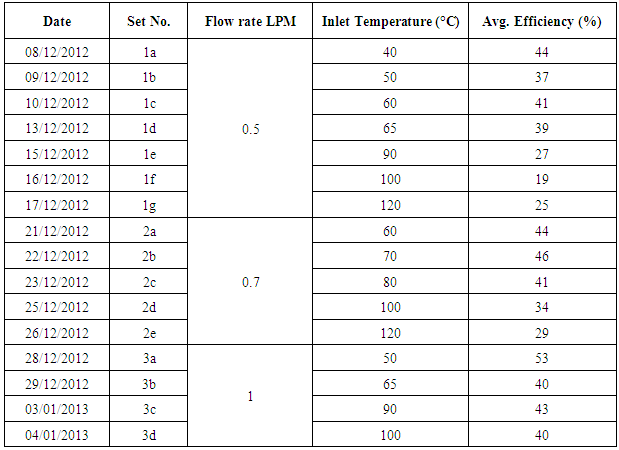

3.3. Effect of Inlet Temperature on Efficiency

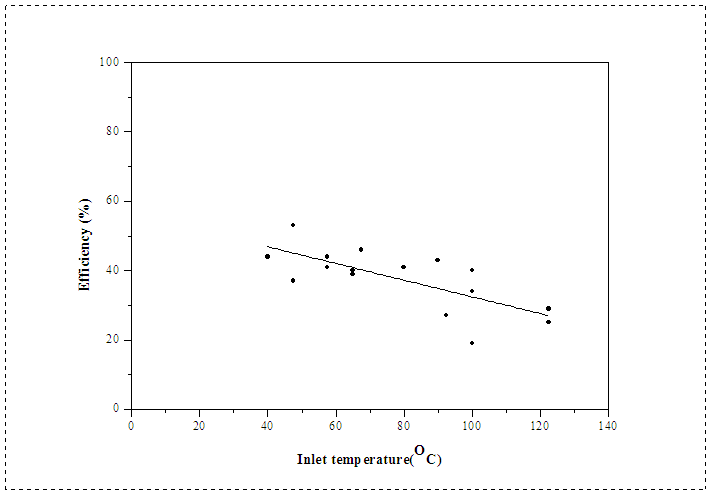

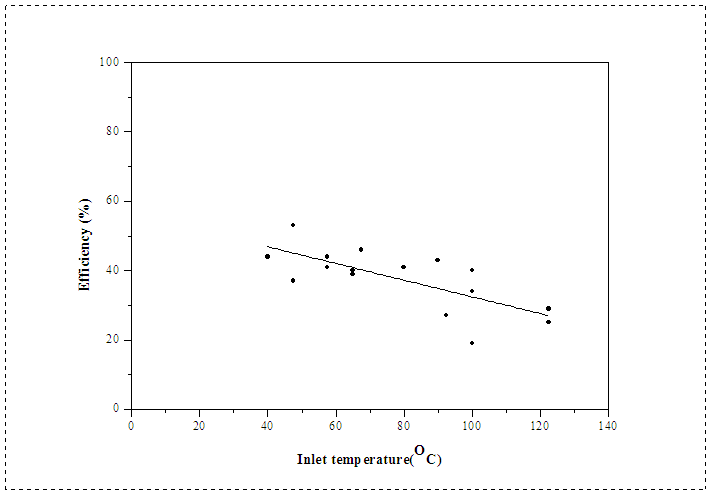

The inlet temperature of the fluid affects the efficiency of the FLSC system. As inlet fluid temperature increases the receiver temperature also increases due to the heat gain from the solar radiation. When temperature increases the convective and radiative heat losses from the absorber tube also increase [3]. Due to the increase in the heat losses the overall heat gain decreases and hence efficiency also decreases. The data was collected at different inlet temperature with different mass flow rates which is summarized in the below Table 3. It was observed that as inlet temperature increases the optical efficiency increases. The results are shown in Fig.6. | Figure 6. Effect of Inlet Temperature on efficiency |

Table 3. Effect of inlet temperature on efficiency

|

| |

|

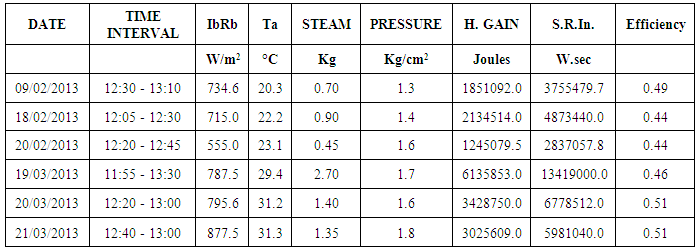

3.4. Steam Generation Using FLSC System

The demand for process heat particularly low pressure steam is increasing exponentially. Solar energy can be utilized for generating medium temperature (100°C -150°C) low pressure (T<200°C) steam. By using solar concentrators, low pressure steam can be generated by using low cost technology. Fresnel lens solar concentrators are very useful to generate low pressure steam for industrial and cooking applications. The study of performance of Fresnel lens solar concentrator and steam generation using Fresnel lens solar concentrator is presented here. The overall efficiency of FLSC System is found to be 51% and can generate process steam required for the industry. Table 4 gives the summary of the steam of output of steam when steam is released at constant pressure. The maximum pressure measured to be of 1.8 Kg/cm2. It was also observed that the steam generation depends on the intensity of solar radiation. The higher the intensity, steam generation will be more. It also revealed that at higher temperature more steam will be generated.Table 4. Steam generation Efficiency of FLSC system

|

| |

|

4. Conclusions

Refracting type solar concentrator has been designed and developed which can be used for generating heat in the temperature range of 100°C to 200°C. This Fresnel Lens Solar Concentrator system is useful to generate low pressure steam for various applications like industrial process heat and steam cooking. One of the advantages of this refracting concentrator system over reflecting type solar concentrator system is the durability of the system.It has been found that the Fresnel Lens has life of more than five years which is important aspect for cost effective application, where as for reflecting type solar concentrator, the mirrors need to be changed for every two years.

ACKNOWLEDGEMENTS

The authors thankful to Prof. S.V. Ghaisas, Director, School of Energy Studies, University of Pune for providing laboratory facilities for this work. The authors thankful to Prof. S.R. Jadkar, Department of Physics, University of Pune, Dr. A.M. Pathak, Thermax Ltd. Pune, Mr. S.D. Gunjal, Mr. Prasad Chaudhary and Mr. Onkar Shinde for their continuous help and support during this research work.

References

| [1] | Development and study of Fresnel lens based solar concentrator, A.M.Pathak, PhD Thesis, University of Pune, Pune (2009). |

| [2] | An experimental investigation of a natural circulation heat pipe system applied to a parabolic trough solar collector steam generation system, Liang Zhang, Wujun Wang, Zitao Yu, Liwu Fan, Yacai Hu, Yu Ni, Jianren Fan, Kefa Cen, Solar Energy, Volume 86, Issue 3, March 2012, Pages 911-919. |

| [3] | “Solar Engineering of Thermal Processes”, Third Edition (Year 2006) by John A. Duffie and William A. Beckman. |

| [4] | Procedure for thermal performance evaluation of steam generating point-focus solar concentrators, Vishal R. Sardeshpande, Ajay G. Chandak , Indu R. Pillai Solar Energy 85 (2011) 1390–1398. |

| [5] | “Solar Heat for Industrial Processes, Medium Temperature Collectors”, Report of International Energy Agency IEA), Task 33/IV, Publisher: AEE INTEC, Feldgasse 19, A-8200 Gleisdorf, Austria, May, 2005. |

| [6] | “Development and Optimization of a Parabolic Trough Collector System for Generation of Industrial Process Heat”, www.fabrikderzukunft.at. |

| [7] | “Solar Concentrator for Industrial Process Heat,’ Update”, A newsletter of Industrial Research and Consultancy Centre, IIT Bombay, Issue-1, 2006. |

| [8] | Gadhia Deepak, “Successful use of Solar Concentrators for various applications from cooking to process needs for rural development: Indian Experience”, www.gadhiasolar.net. |

| [9] | Design of a Non imaging Fresnel lens for solar concentrators, Ralf Leutz, Akio Suzuki, Atsishi Akisawa and Takao Kashiwagi Solar Energy Vol. 65, No.6, pp.379–387, (1999). |

| [10] | “PTC 1000 - Modular parabolic trough collector”, estec 2005, the 2nd European Solar Thermal Energy Conference, 21-22 June 2005 Freiburg. |

Where,

Where,  is the useful heat gain during time interval

is the useful heat gain during time interval

is the specific heat of the fluid (J/Kg °C)

is the specific heat of the fluid (J/Kg °C) is the inlet temperature of the fluid (°C)

is the inlet temperature of the fluid (°C) is the outlet temperature of the fluid (°C)

is the outlet temperature of the fluid (°C) Where,

Where,  is the heat gain from the collector during time interval of 10 minutes

is the heat gain from the collector during time interval of 10 minutes  is the aperture area of the Fresnel lens and

is the aperture area of the Fresnel lens and  is the intensity of solar beam radiation received during time interval of 10 minutesThe incident solar radiation consists of diffuse radiation and beam radiation [3]. However solar concentrator’s uses only beam radiation to focus on the receiver [3]. We have measured Global radiation and diffused radiation falling on the horizontal surface. Therefore intensity of solar beam radiation falling on the horizontal surface is given by,

is the intensity of solar beam radiation received during time interval of 10 minutesThe incident solar radiation consists of diffuse radiation and beam radiation [3]. However solar concentrator’s uses only beam radiation to focus on the receiver [3]. We have measured Global radiation and diffused radiation falling on the horizontal surface. Therefore intensity of solar beam radiation falling on the horizontal surface is given by, Where,

Where, is the intensity of beam radiation falling on horizontal surface,

is the intensity of beam radiation falling on horizontal surface, is the intensity of global radiation on horizontal plane,

is the intensity of global radiation on horizontal plane, is the intensity of diffused radiation on horizontal plane.The intensity of beam radiation falling on the aperture of the Fresnel lens is given by

is the intensity of diffused radiation on horizontal plane.The intensity of beam radiation falling on the aperture of the Fresnel lens is given by  Where,

Where, is the intensity of beam radiation falling on the aperture of FLSC

is the intensity of beam radiation falling on the aperture of FLSC is the tilt factor

is the tilt factor

Where,

Where,  is mass of water filled in the tank (kg)

is mass of water filled in the tank (kg) is specific heat of water (KJ/Kg°K)

is specific heat of water (KJ/Kg°K) is Final Temperature of Water (°C)

is Final Temperature of Water (°C) is initial Temperature of water (°C)

is initial Temperature of water (°C) is mass of boiler (kg)

is mass of boiler (kg) is specific heat of boiler material (KJ/Kg)

is specific heat of boiler material (KJ/Kg) is dryness factor of steam ~ 1.0

is dryness factor of steam ~ 1.0 is mass of steam generated (kg)LH is latent heat of vaporization of water (KJ/kg)When we release steam at constant temperature and pressure ∆t = 0Therefore efficiency of the system given by,

is mass of steam generated (kg)LH is latent heat of vaporization of water (KJ/kg)When we release steam at constant temperature and pressure ∆t = 0Therefore efficiency of the system given by,  Where,

Where,  is intensity of beam solar radiation

is intensity of beam solar radiation is Aperture area of the FLSC and

is Aperture area of the FLSC and  is time interval i.e. time during which steam at constant pressure is released

is time interval i.e. time during which steam at constant pressure is released

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML