-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Construction Engineering and Management

p-ISSN: 2326-1080 e-ISSN: 2326-1102

2013; 2(4A): 13-16

doi:10.5923/s.ijcem.201309.03

The Impact of Cloud Computing Technology to Precast Supply Chain Management

Muhammad Abedi1, Mohamad Syazli Fathi2, Norshakila Muhamad Rawai1

1Faculty of Civil Engineering, Universiti Teknologi Malaysia, 81310 UTM, Johor, Malaysia

2UTM Razak School of Engineering & Advanced Technology, Universiti Teknologi Malaysia, Jalan Semarak, Kuala Lumpur, 54100, Malaysia

Correspondence to: Mohamad Syazli Fathi, UTM Razak School of Engineering & Advanced Technology, Universiti Teknologi Malaysia, Jalan Semarak, Kuala Lumpur, 54100, Malaysia.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Poor integrations and lack of collaboration are the major obstacles within the precast construction projects. In order to improve collaboration among precast supply chain stakeholders on the various phases of precast construction (planning, design, manufacturing, transportation, installation and construction), a system are needed for an effective communication and accessing to up to date information. This paper is aimed to explore the potential of the cloud computing technology as the construction collaboration tools for precast supply chain management. The research findings are established according to the study of comprehensive literature on information technology, supply chain management and precast construction industry. Findings shows that the poor planning and scheduling, high cost of precast concrete components, the poor design, lack of architectural creativities, the poor production timing, large size and heavy precast components, wrong deliveries, poor on site coordination and collaboration, poor specialised contactors and lack of good communication among parties are the main barriers within the precast supply chain. These barriers within the precast supply chain phases may result to adverse consequences on the performance of precast project delivery. Hence, the cloud computing technology was found to have huge potential to provide efficient collaboration systems within the precast construction.

Keywords: Supply Chain Management, Information Technology, Cloud Computing, Precast, Collaboration Tool

Cite this paper: Muhammad Abedi, Mohamad Syazli Fathi, Norshakila Muhamad Rawai, The Impact of Cloud Computing Technology to Precast Supply Chain Management, International Journal of Construction Engineering and Management , Vol. 2 No. A, 2013, pp. 13-16. doi: 10.5923/s.ijcem.201309.03.

Article Outline

1.Introduction

- The off-site precast construction industry which has been existed for 150 years is a system arrangement of numerous activities, products and materials sequences and the services flow[1] between the various parties including the clients, architects/engineers, developers, manufacturers, general contractors, subcontractors, suppliers and consultants in order to improve productivity, less time and reduce the construction costs[1];[2]. Precast construction is a system in which the concrete will be casted in moulds and then concrete will be cured in a controlled environment, it will be transported to the construction site and finally it will be assembled within the construction structure[3]. Cloud computing technology was suggested to overcome the characteristics of dynamic, difficulties, hazards and information-intensive within the precast construction projects. This research is aimed to discover the utilization of the collaboration tools such as cloud computing technology which will potentially improve the precast construction supply chain management success.The following section will discuss the concepts of precast supply chain management, the stakeholders and the precast SCM phases. Then this paper will investigate the cloud computing technologies and types. Finally this paper will propose an approach to enhance the precast supply chain management via cloud computing implementation.

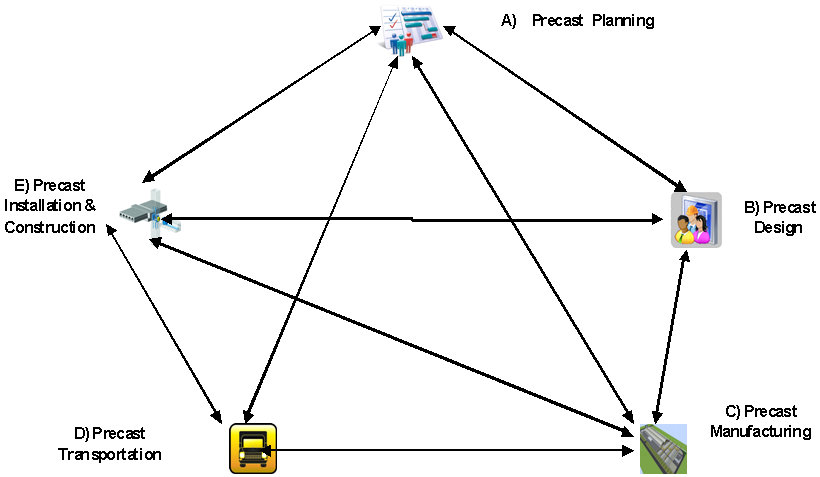

2. Precast Supply Chain Management

- The concept of Supply Chain Management (SCM) was originated in the manufacturing industry with the objective to increase both efficiency and effectiveness, to achieve organizational goals, and lead to greater synergy[4]. Since it was introduced, SCM assumed the characteristics of an evolutionary concept, increasingly enriched by innovative tools and techniques.The Construction Supply Chain (CSC) is a network of many relationships and organizations such as client/owner, consultant, designer, supplier, general contractor, sub - contractor, warehouses, retailers and customers dealing with information, materials, services, products and funds in order to directly or indirectly supply the customer’s needs[5];[6]. Nevertheless, Construction Supply Chain Management (CSCM) is defined as “a system where suppliers, contractors, clients and their agents work together in coordination to install and utilise information in order to produce and deliver materials, plant, temporary works, equipment and labour and/or other resources for construction projects”[7]. As defined by Aloini[8], CSCM is the systematic approach to the coordination and integration of processes and the members involved in the Construction Supply Chain (CSC) that creates long-term, win/win, and collaborative connections and relations among the supply chain and between the stakeholders. Zheng and Mao[9], asserted that the CSC is the process launched with the establishment of efficient project necessities from the project decision - making level (planning phase) to the project implementation level (design phase and construction phase).The construction industry has made extensive efforts in the implementation of SCM, especially within the last two decades with the aim of improving performance[10], facilitating business objectives and enhancing competitive advantages[11], improving coordination[12], achieving successful construction[13], increasing trust and cooperation [9] enhancing the connections between supply chain parties [14], improving quality and customer satisfaction[15] and reducing waste[10]. Moreover, Akintoye[16], noted that the major benefits of construction supply chain management, particularly to the contractors, were the client’s benefits, customer service improvement, paperwork reduction, enhanced profitability, minimised organisational costs and increased market competitiveness. Mingqiang and Zuxu[17], identified the main key factors of the construction supply chain which included: trust, supply reliabilities, support of the top management and mutual interests, while, as they discovered, the major issues of the construction supply chain consisted of: poor commitment from top management, lack of communication and inadequate support systems. It should be noted that for effective implementation of SCM and to avoid the possible barriers, the supply chain parties, such as the general contractors and subcontractors, should properly formulate an efficient managerial structure, suitable organisational methods, technological applications and strategically planned and appropriate relations[18]. Figure 1 illustrates the construction supply chain framework consisting of phases, the parties involved and the diverse flow of information, materials, funds, services and demands. The information intensive of the precast construction supply chain requires a system to integrate and collaborate effectively between parties. One of the technologies available is cloud computing that will be discuss in the following section.

3. Cloud Computing

- Cloud computing are collections of distributed computers like data centres and servers delivering on-demand services and resources over Internet[19]. According to Gark[20], cloud computing is a convenience and ubiquitous evolutionary for applying powerful computing resources such as the networks, servers, storage, applications and services. While, Rawai[21]) stated that cloud computing is an evolving paradigm of computing which substitutes the computing of a personal commodity to a public utility.

| Figure 1. The diagram of the precast supply chain phases |

- Cloud computing deployment models (delivery models) includes: public, private, community and hybrid. Whereas, Gark[20] explained the public cloud such as an open system for the public which is built as a pay-as-you-go approach to any users while, a private cloud that is a closed system and will be accessed just for the special business users to internal data-centres that are not open to the public[22]. On the other hand, the community cloud is created to be controlled and operated in a collection of organisations that have mutual profits while as, the combination of public cloud and private cloud will create the hybrid cloud[23]. According to Goscinski and Brock[24], and Gark[20], the three general types of cloud computing services models are categorised to: (1) Infrastructure as a Service (IaaS): The main computing resources for instance, the processing features, storage capabilities, selection of operation system, servers and networking fundamentals will be served to the users via the cloud providers such as Amazon web services and Salesforce; (2) Platform as a Service (PaaS): A platform for developing and operating the applications will be served to the users via the cloud providers such as Amazon’s EC2 offerings, IBM and Microsoft Azure, and(3) Software as a Service (SaaS): The users will have the opportunity to serve an application. While as, they don’t have any control on the processing features, storage capabilities, selection of operation system, servers and networking fundamentals. Additionally, the cloud providers for serving the Software as a Service (SaaS) are Google Apps comprising of Gmail, Google Calendar, Google Docs and also the Amazon.

4. Discussion on the Impact of Cloud Computing System to Precast Supply Chain Management

- As mentioned in the previous section of this paper, other than lack of communication between parties, poor on site coordination and complexities, same information is accessed, shared, analysed, processed, deployed and distributed within the precast construction industry. Accordingly, there will be productivity deterioration due to activities such as the designs are re-designed, scheduling are re-scheduled, resources are replaced, lists are altered, quantities are repeatedly counted and materials are substituted. Hence, the most important objective is to improve the coordination, team workings, more integration, enhanced communications and collaboration via the earlier parties participation within the precast supply chain phases as in design/build procurement which the architect and contractor participates in the project beginnings towards constructing continuous communication and enhancing the efficiencies.It is hoped that by proposing the cloud computing implementation, all precast supply chain parties and the project stakeholders, comprising of the owner, consultants, designers, engineers, manufacturers, general contractors, transporters, suppliers and sub-contractors will have the opportunity to more cooperate, integrate, improve the productivity and collaborate efficiently compared to the traditional approaches and processes. Furthermore, cloud computing technology will assist the users (businesses and individuals) to access, share and disseminate the data; applications and services from the various servers via the internet. Moreover, it assists the users to implement the applications with no concerns regarding to the installation which allows them on accessing to their various data through the internet on any computer or mobile devices. It should be signified that cloud computing utilisation allows the users by integrating storage, memory, processing capabilities and network bandwidth to have much efficient and effective implementation of information technology services which could significantly lower the costs. The final section will briefly discuss on the conclusions derived from this research.

5. Conclusions

- Cloud computing is a potential tool to support the precast construction supply chain management. The precast construction industry has specific characteristics of the supply chain phases and parties included compare to other major industries. Moreover, the precast construction industry is associated with many processes, various information and numerous parties which have single objective. Hence, to attain efficiently and effectively the precast construction project objectives based on the assigned time, specified budget and standard quality with considering the safety parameters, the choice and execution of the collaboration tools is highly significant. Consequently, cloud computing as a significant collaborative tool will improve the integration, communication and collaboration for the parties and stakeholders within the precast construction industry. Currently, with the improvements of mobile devices such as tablets and smartphones, speed enhancements of mobile applications and wireless communication tool have facilitated the cloud computing technology as the potential collaborative and information management tool within the precast construction industry. This study has accomplished in order to investigate and propose the fundamentals of cloud computing technology as valuable collaborative tools for assisting the precast supply chain procedures, activities, parties, connections and networks to develop and increase the opportunities for attaining improved competitive advantages within the precast construction industry.Finally, the study conducted in this paper is an initial survey that is a part of on-going research, which will ultimately endeavour to further improve the practices and utilisation of cloud computing as one of the major valuable construction collaboration tools.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML