-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Energy and Power

p-ISSN: 2163-159X e-ISSN: 2163-1603

2014; 4(1A): 1-10

doi:10.5923/s.ep.201401.01

Nanoparticle Counts Emissions of Trucks: EURO 3 with and without DPF Compared to EURO 4 and EURO 5

Andreas Mayer1, Markus Kasper2, Jan Czerwinski3

1TTM, Technik Thermische Machinen, Fohrhölzlistrasse 14b, 5443 Niederrohrdorf, Switzerland

2VERT Association, 5400 Brugg, Switzerland

3AFHB, Laboratory for IC-Engines and Exhaust Emission Control, University of Applied Sciences, 2500 Biel-Bienne, Switzerland

Correspondence to: Jan Czerwinski, AFHB, Laboratory for IC-Engines and Exhaust Emission Control, University of Applied Sciences, 2500 Biel-Bienne, Switzerland.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Investigations of emissions from three modern HD vehicles (HDV) were carried out on a chassis-dynamometer. One of the vehicles uses PM-Kat and is certified according to EURO4. The second one is EURO5 compliant and uses SCR. The third one is was a EURO3 HDV, which was tested with and without VERT-certified DPF. The investigation focussed on solid particles in the mobility size range of 10-400nm. The instruments were SMPS, NanoMet, PASS and ELPI. Sampling conformed to PMP for SMPS and NanoMet, PASS and ELPI were used with FPS-dilution. Metallic emissions were measured using ICP-MS. Also measured were inherent secondary emissions, especially NO2 and NH3. Compared to EURO3 without DPF a moderate curtailment of nanoparticle emissions was observed for the majority of operating points for EURO4 with PM-Kat and EURO5 with SCR. However, at full load the EURO5 engine emitted higher concentrations than a EURO3 engine without DPF. A stochastic particle release was observed from the PM-Kat of the EURO4 engine. Its penetration scatter was very much dependant on the soot burden and the testing history. Compared to a EURO3 engine with a DPF conforming to VERT criteria, both modern engines EURO4 and EURO5 emitted 100-500 times more nanoparticles. Very good results of the gaseous emissions – a significant reduction of NOx – showed the EURO5 engine. There were no deleterious effects observed due to the SCR. The concentrations of NH3 and N2O remained close to the detection limit. However, the EURO4 engine emitted rather high concentrations of NO2 at about half load range. Emissions of Vanadium with EURO5 and Platinum with EURO4 were low in both cases, even below detection limit.

Keywords: Nanoparticles, DPF… Diesel Particle Filter, Retrofitting DPF on Trucks, Emissions HD Diesel

Cite this paper: Andreas Mayer, Markus Kasper, Jan Czerwinski, Nanoparticle Counts Emissions of Trucks: EURO 3 with and without DPF Compared to EURO 4 and EURO 5, Energy and Power, Vol. 4 No. 1A, 2014, pp. 1-10. doi: 10.5923/s.ep.201401.01.

Article Outline

1. Introduction

- Solid state particles occur in IC-engine exhaust at concentrations of 107 – 108 particles per cm3. Their pertinent size range is about 10 - 400 nm and the average size is 60 – 80 nm. Particles of this size intrude the alveoli. Subsequently, they rapidly infiltrate the cell membranes and are transported into human organs, even penetrating the blood/brain barrier and the placenta-barrier. Apart from causing cancer, nanoparticles may trigger a variety of diseases, e.g. cardiac infarct, Alzheimer and Parkinson decease[1]. In 1989 the WHO classified these particles as carcinogenic. Indeed, P. Pott observed soot to be carcinogenic already in 1775 during his famous studies with chimney sweeps. Researchers and authorities in occupational health[2] recognised the importance of particle size as early as 1910. Environmental legislation mandates minimizing such emissions using the best available technology BAT,[3].Separation into solid state particles and condensed droplets, characteristic for IC engine exhaust when cooling down, is reliably done using the PMP-measuring method evaluated by UN-ECE-GRPE in 2002-2006[4].European legislation, for IC-engine exhaust, initially specified the EURO-1 particle emissions limits in 1992 using the US EPA definition of PM, dating from 1982. PM is a metric that does not differentiate according to particle size or chemical composition. Hence, it is not well suitable for toxicity evaluations. The Swiss metric for DPF-evaluation is the number concentration of solids in the nanoscale range[6].European Union legislation also does not limit secondary noxious pollutants, unlike the US Clean Air Act 202 which precludes the release of poisonous by-products[5], when deploying new technologies. Since 1990, the Swiss also require testing of possible secondary emissions if there are catalytic processes involved in the engine exhaust[7]. DPF retrofit of construction equipment or off road vehicles is only acceptable when the filter systems comply with both the filtration and secondary emission criteria according to best available technology.Meanwhile, European emission criteria have been tightened but the PM metric is still inappropriate. The EU assumes that curtailing particle mass automatically decreases the number of particles also. To answer the question whether reducing mass does automatically reduce particle concentration or not, two representative HDV certified according to EURO4 and EURO5 were selected. Their nanoparticle and secondary emissions were compared to a corresponding EURO3 vehicle with and without DPF. The fundamental question was: “Are DPFs, complying with the VERT standard, still necessary in future despite the emissions progress from EURO3 to EURO4 and EURO5 engines?”

2. Test Vehicles

- Test-vehicle EURO-3Manufacturer: Mercedes BenzType: 1846 LS-O3Engine: OM 4001 LA.III/9Power rating: 355 kW at 1695 rpmMaximum torque:2335 Nm at 1196 rpmPrior usage: 49,051 kmEmission reduction: Retrofit DPF by HJS CRT-system, sinter-metal-filter(VERT No. B159/03.05)Test-vehicle EURO-4Manufacturer: MANType: TGA 18.430 4XBLSEngine:D 2066LF 11, EURO-4Power rating: 316 kW at 1900 rpmMaximum torque:2212 Nm at 994 rpmPrior usage: 31,196 kmEmission reduction: EGR cooled, PM-KatPM-Kat is a bypass-filter system where at clean conditions about 50% of the gas flow is through a metal fibre filter fleece layer. The flow ratio varies with soot load. Regeneration is with NO2 from an upstream oxidation catalyst[12].Test-vehicle EURO-5Manufacturer Mercedes BenzType 1896-LS EURO-5Engine:OM 5001 LA.V5Power rating: 348 kW at 1796 rpmMaximum torque:2221 Nm at 1097 rpmPrior usage: 2,863 kmEmission reduction: SCR with Adblue TechnologyFuelCommercial Diesel fuel as per SN 181 160-1:2005Sulphur content: 10 -15 mg /kg fuelEURO4 and EURO5 substantially curtailed particulate mass emissions PM compared to EURO3. The PM limit is diminished from 100 mg to less than 20 mg/kWh within the ESC driving cycle. Engines do not “smoke” any more. However, tailpipes are still blackened by soot. Moreover, NOx limits were curtailed tremendously. Nevertheless, the permissible NO2/NO ratio is yet unspecified. The EURO5 and EURO3 tests were performed sequentially. The EURO-4 vehicle was tested some months later.

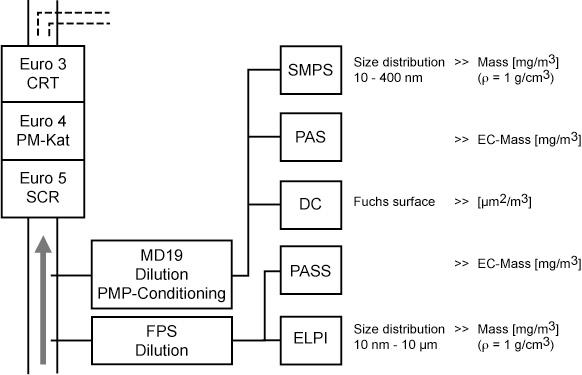

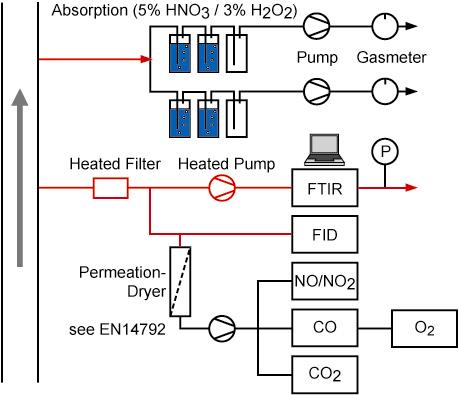

3. Test Set-up and Instrumentation

- Chassis-dynamometer of LARAG AG, Wil, SwitzerlandThis test bed can be set to any steady state operating point of the engine within the entire operating range. Load steps can be performed including free accelerating conditions. Determination of gaseous emissionsConcentrations of CO2, CO, NO2 and NO were determined in the heated and permeation dried gas using non-dispersive IR analysis (NDIR) and a two-channel chemo-luminescence analysis (CLD). To avoid loss of substance due to permeation-drying, volatile organic substances, hydrocarbons, N2O, NH3 SO2 were determined in the hot and humid exhaust using flame-ionisation spectroscopy (FID) and Fourrier Transform Infrared Spectrometry[25]. Determination of metallic emissionsThe EURO-5 vehicle (SCR equipped) was tested for emissions of Vanadium, the EURO-4 vehicle (PM-Kat equipped) was tested for emissions of Platinum. Over the entire driving cycle, an aliquot proportional to volume of exhaust was absorbed in acid aqueous solution, which was finally analyzed using plasma-mass spectroscopy (Q-ICP-MS).Particle-analyticsThe following measuring methods were used:• SMPS (TSI)• NanoMet with PAS and DC sensors ( Matter Engineering)• PASS (AVL)• ELPI ( DEKATI)Sampling for SMPS and NanoMet was performed acc. to PMP. The sampling line was heated to 300°C, to prevent condensation and diluted using the MD19 rotating disc diluter (ME) at ratios of > 100[21].FPS (DEKATI) injector dilution was used for PASS and ELPI because of the higher sampling gas volume, dilution ratio was 30-70 and the sampling line was not heated.These measurement methods were selected for the following reasons:SMPS is a widely used method for the fine analysis of size distributions. Its disadvantage is the limitation to the size range of at maximum 1000 nm. Consequently agglomerates, to be expected in partial filters, cannot be observed[9]. SMPS can also be used to calculate overall particle volume and, applying unit density (1g/cm3) particle mass. The SMPS is not suitable for transients.

| Figure 1a. Schemes for measuring: particle-analytics |

| Figure 1b. Gas- and metal-analytics |

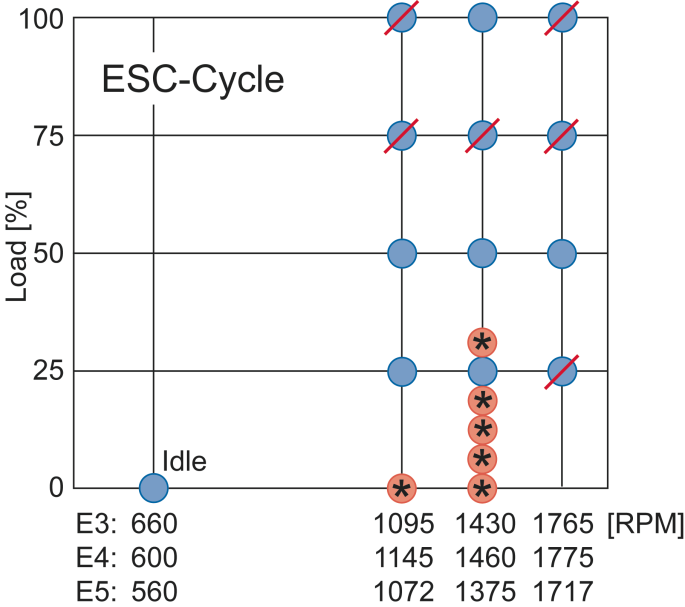

4. Operating Points

5. Particle Emissions at Steady State

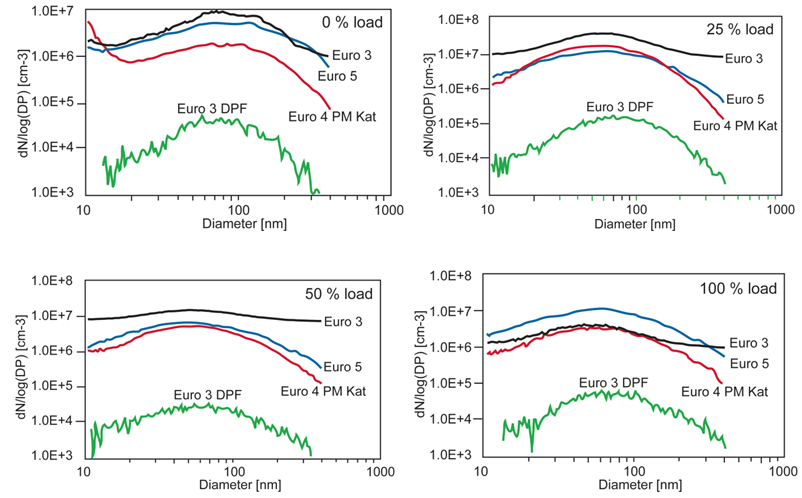

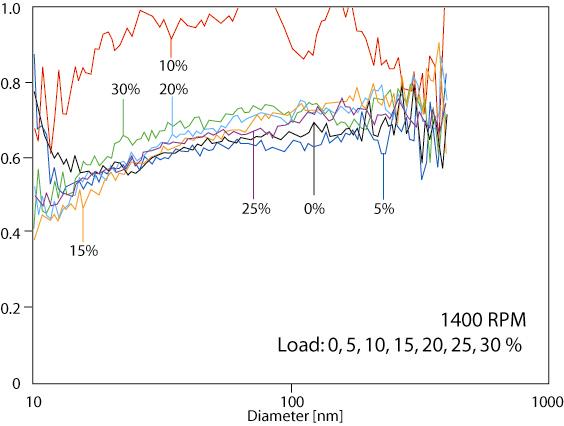

- Figure 3 shows particle size distributions, measured with SMPS of the four HDV candidates investigated at zero-load, at 25% load, at 50% load and at full load, all at 1400 rpm. Decisive for the cycle are the three part-loads. Evidently, both EURO4 and EURO5 are distinctly improved compared to EURO3. This effect is more pronounced for larger particles, in the size range 200-400 nm, than for smaller particles. This agrees with the agglomeration model, when concentration of primary particles is diminished. Large particles dominate particle mass, which is reduced by a factor of 5 from EURO3. The overall response of EURO4 and EURO5 is quite similar.3 observations deserve attention:§ At full load, EURO-5 without any filtering aftertreatment emits more nanoparticles than EURO-3. § The poor behaviour of the PM-Kat is evidenced by the increasing penetration with reducing size.§ Deploying a DPF complying with the VERT-standard enables 2 to 3 orders of magnitude (100-500 times) less nanoparticle emissions than the very latest HDVs .Results for EURO-5 were well repeatable. Average standard deviation SDV for SMPS upstream DPF was 5.3%, downstream DPF at very low concentrations 47.2%, which is excellent. Average standard deviations for DC and PAS upstream DPF were 6.7% and 5.5% respectively. With EURO4, equipped with PM-Kat, repeatability at low loads was not achievable (Figure 4). There was a rather large variation in the penetration (= 1 – retention rate) of the PM-Kat system, for both large and small particles. Moreover, filtration failed completely at 10% load. Further increase of the engine load enabled a recovery of the system to retention rates of 30-50%. Apparently, reaching higher temperatures the system had regenerated itself and thereby regained its filtration capability.Retention characteristics of the PM-Kat-system obviously are not reproducible in the range of low loads. The dynamics of regeneration and antecedents influence filtration in unpredictable ways. This is a problem of stochastic stability.

| Figure 3. Emissions of ultrafine particles in the nanoscale range at 1400 rpm at different loads of all 4 test candidates (with SMPS and PMP-sampling) |

| Figure 4. PM-Kat: Penetration at 1400 rpm and low load (recorded with SMPS) |

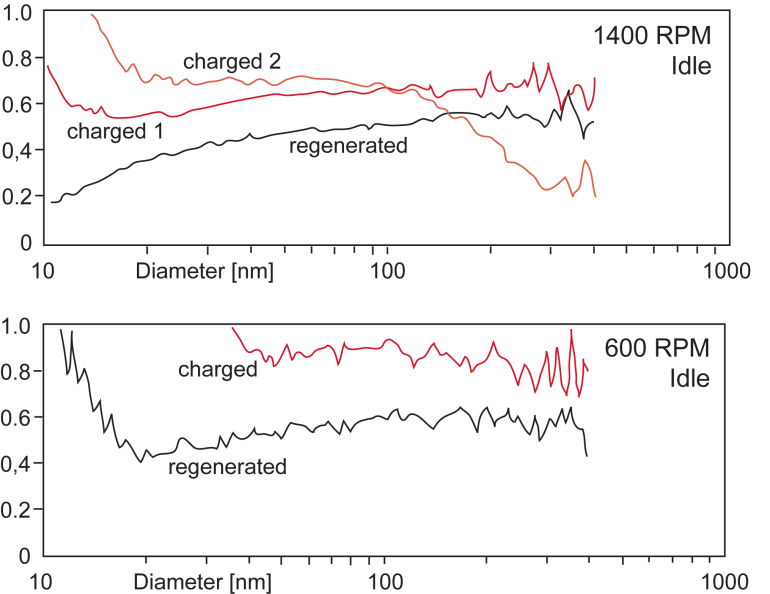

6. Soot Burden Effects in EURO4 PM- Kat

- PK-Kat is a partial filter. When the filter is clean, about half of the exhaust gas passes the filter, the rest leaves the system unfiltered through the bypass holes (that’s why such filters are also called “open filter systems”). When the filter is storing soot the flow-ratio bypass/filter increases due to the increase of the filter back pressure. Accumulating soot at low temperatures, where regeneration is not active has therefore a strong influence on the filtration rate. A soot deposit remains exposed to the main flow and blow-off can occur.A similar effect is well known in deep-bed filters (foam-filters, fibre-filters etc.). Increasing the soot burden reduces filtration, finally approaching a zero filtration rate where back-pressure remains fairly constant and the incoming particle mass is almost the same as out-flowing. However, the size spectrum is shifted towards larger particles, due to agglomeration[9, 10]. This effect is best demonstrated at zero-load. Particle emission is low. However, the regeneration capability is low too, because the catalytic activity is negligibly small, i.e. soot burden would increase. Such operating conditions are not typical for the load profile of utility vehicles. Nevertheless they are realistic and should be considered as a “worst case” as shown in Figure 5.At idle conditions (lower diagram) a freshly regenerated filter exhibits an average filtration rate of about 40%, albeit there is some distinct weakness in the range of small particles. At low soot rates, some hours elapse till the filtration rate drops towards zero. There is an increasing release of very small particles, and more particles may exit than enter the filter.

7. Formation of Volatile Particles within the EURO-4 PM-Kat System

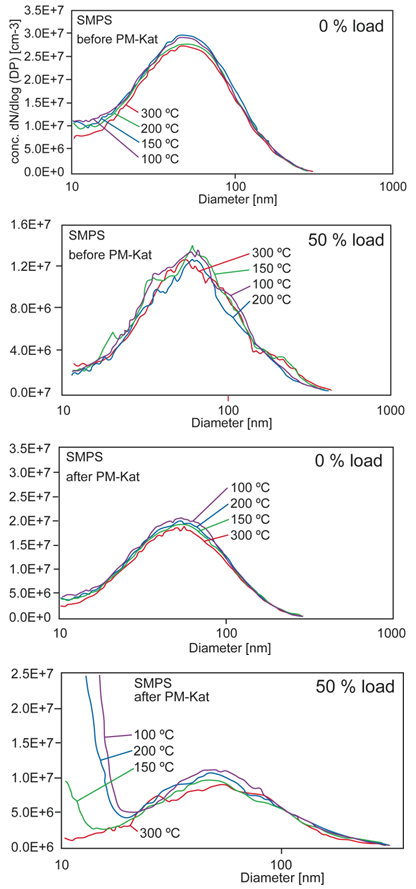

- The following figures are size distributions for various sampling system temperatures of the exhaust prior and after the PM-Kat system. The influence of sampling temperature on size distribution was investigated.

| Figure 6. Thermographs, sampling before and after the PM-Kat at 1400 rpm at 2 different loads. (Recorded with SMPS). Sampling system temperature was varied between 100°C and 300°C |

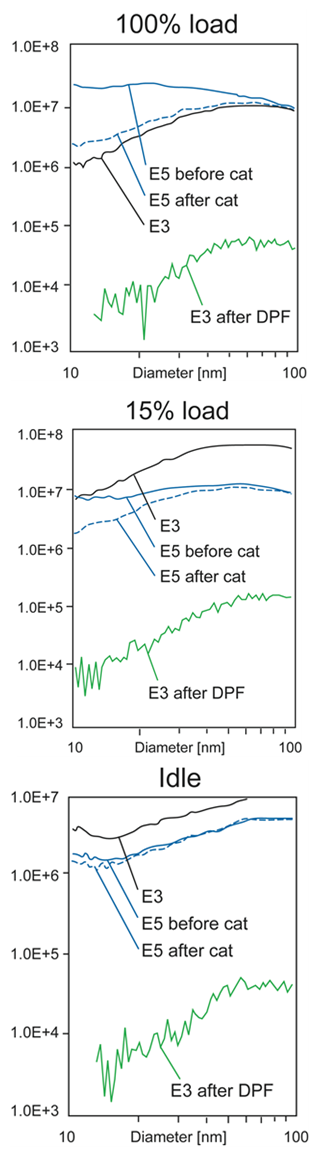

8. EURO5 SCR: Peculiarities of Emissions

- Several publications[13, 22] report emissions of additional ultrafine particles when using SCR with urea/water-solution (=Adblue) injection. The EURO5 vehicle was tested with and without Adblue injection. Some of the results are presented in Figure 7 and shown for the size range up to 100 nm.

| Figure 7. Influence of Adblue injection on ultra-fine particle emission (recorded with SMPS) |

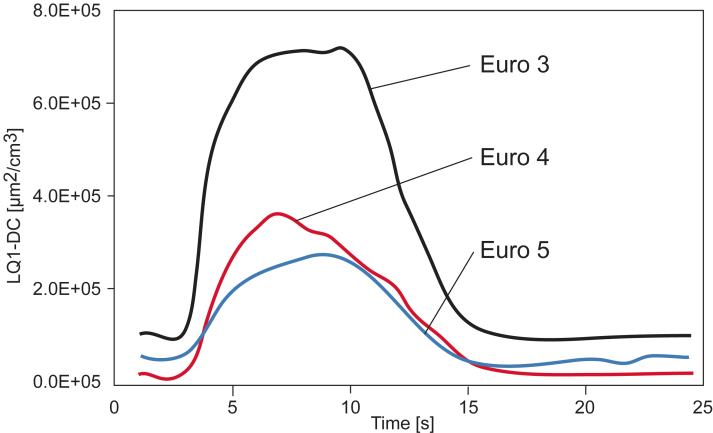

9. Particle Emissions in Acceleration

- The free acceleration is tested as follows. Starting from stable idling, the accelerator-pedal is suddenly kicked down fully, i.e. the engine accelerates its internal mass to full load. This is a very critical situation for smoke formation, which may exhibit the lag of the turbo-charger as well.

| Figure 8. Free accelerations, recorded with DC sensors of the NanoMet-system, averaged over 5 accelerations |

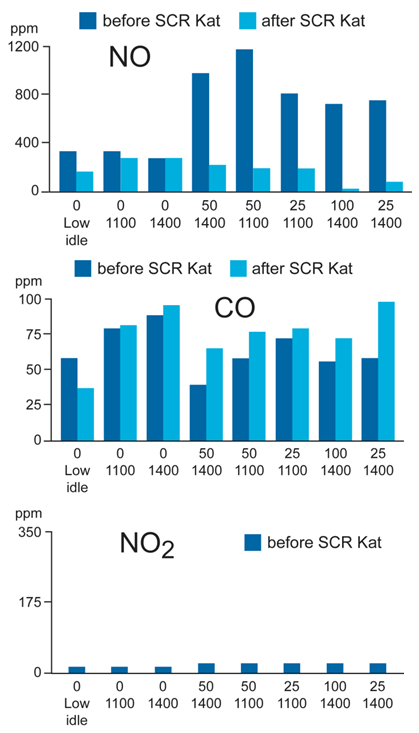

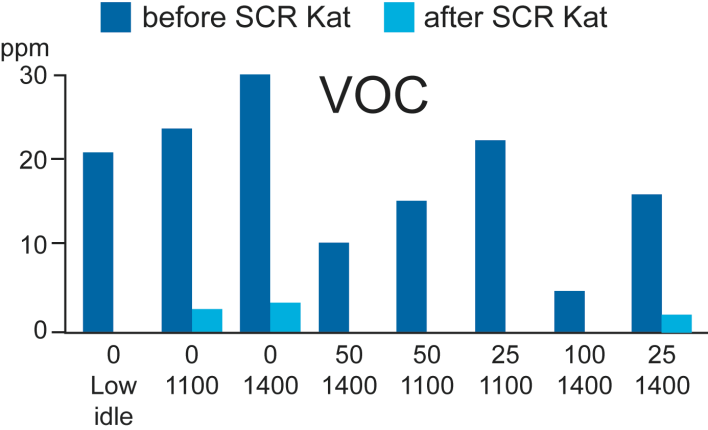

10. Gaseous Emissions with EURO 5 SCR

- Operating points were selected in function of load. Emissions shown are before and after the SCR catalyst, with Adblue injection active.

| Figure 9a. Gaseous emissions from the EURO5 HDV |

| Figure 9b. Gaseous emissions from the EURO5-HDV |

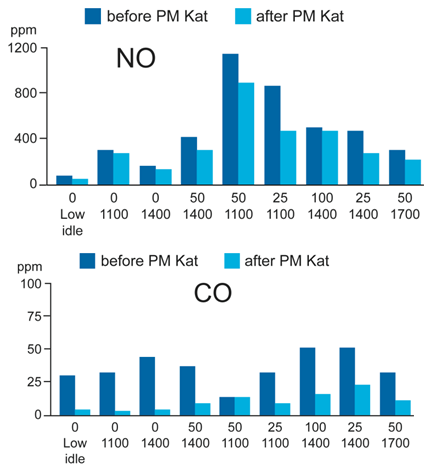

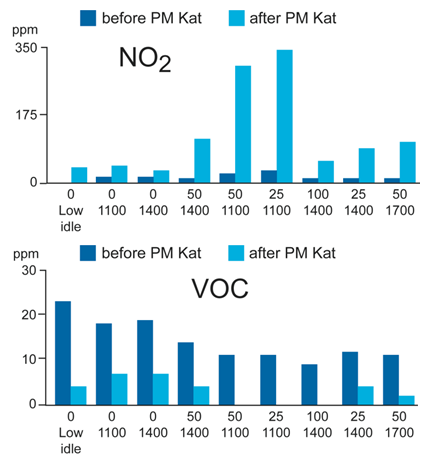

11. Gaseous Emissions with EURO4 PM-Kat

- The usual response of Pt-coated oxidation catalyst, as is well known for CRT systems, is observed on EURO-4[15]: CO and HC are efficiently converted. Their concentrations are one magnitude lower than the limit. Some NO is transformed to NO2 as soon as the exhaust temperature exceeds 240°C. At higher temperatures, the conversion rate decreases due to chemical equilibrium. The availability of NO2 is a prerequisite for reliable functioning and continuous regeneration of the PM-Kat. However, there is high NO2 slip, which may become a serious penalty[14].

12. Emission of Metal Paricles

- The average concentration of Vanadium in the exhaust gas was 102 ng/m³. This is clearly above concentration in ambient air of 0.8-2.4 ng/m³[16]. But it is below the WHO limit of 1000 ng/m³, which is the regarded to be the threshold for health effects[26]. Emissions of Platinum were below detection limit of 7 ng/m³. This is remarkably low as modern three-way catalysts are reported[17] to emit up to 100 ng/m³.

| Figure 10a. Gaseous emissions of the EURO4 HDV |

| Figure 10b. Gaseous emission of the EURO4 HDV |

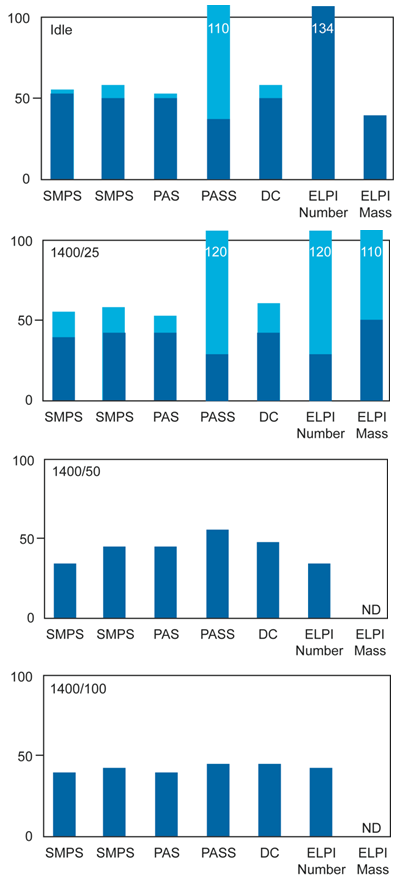

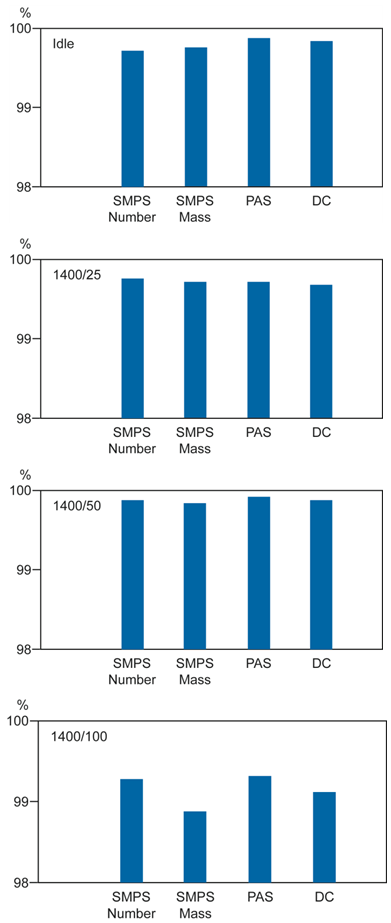

13. Comparison of Particle Measurement Methods

- Figure 11 shows the filtration rate of a HJS sinter-metal DPF complying with VERT standard at 4 different operating conditions, varying load. Data of SMPS (number and mass), PAS and DC were determined for 4 operating points. The filtration rate is at about 99.8% at light load and gradually decreases to 99% for the highest space velocity at full load. This statement is valid both for the number as well for the mass criteria, according to SMPS and to EC (PAS-signal) and for the Fuchs surface (PAS-signal). The results of all the sensors and instruments agree well with each other. That demonstrates both a very stable operation of the filter and a high repeatability of all used measuring systems.

| Figure 11. Filtration rate of the DPF retrofitted EURO3- vehicle |

14. Conclusions and Outlook

- The study shows that modern EURO4 and EURO5 vehicles release moderately fewer particles compared to EURO3, at almost all operating conditions. This is valid over the entire size range, albeit the reduction at larger particle size is better. There is no evident change of the mean particle size (mobility diameter) from EURO3 to EURO4/5. Furthermore, the particle emissions of the EURO5 SCR-concept are well repeatable. That is also true for EURO3, with and without DPF. In contrast, EURO4 with PM-Kat is unstable. At operating conditions where 30-40% filtration was measured, zero filtration was measured when approaching the same operation point after a different testing history. This confirms published evidence of filtration strongly depending on soot burden and engine operating point. There are also doubts about long-term stability, due to catalyst aging and irreversible adhesion of ash particles. NOx reduction of the EURO-5 SCR is impressive and ammonia slip is minimal. This is better than the EURO4 vehicle that exhibits a substantial NO2 slip. Emissions of metals are small in both concepts. Both concepts, EURO4 and EURO5 need further improvement. BAT-particle filters should be used. Thus emission of solid nanoparticles can match or surpass the EURO3 with DPF-retrofit.

ACRONYMS

- BAT

Best Available TechnologyDC

Best Available TechnologyDC Diffiusion Charging (Aerosol Sensor ME)DPF

Diffiusion Charging (Aerosol Sensor ME)DPF Diesel Particulate FilterEC

Diesel Particulate FilterEC Elemental CarbonELPI

Elemental CarbonELPI Electric Low Pressure Impactor (DEKATI)FPS

Electric Low Pressure Impactor (DEKATI)FPS DEKATI dilution systemHDV

DEKATI dilution systemHDV Heavy Duty VehicleICP-MS

Heavy Duty VehicleICP-MS Induct. Coupled Plasma Mass Spectrometry PAS

Induct. Coupled Plasma Mass Spectrometry PAS Photoelectric Aerosol Sensor (ME)PASS

Photoelectric Aerosol Sensor (ME)PASS Photo Acoustic Soot Sensor (AVL)PMP

Photo Acoustic Soot Sensor (AVL)PMP Particle Measurement Program (UN-ECE)PM-Kat

Particle Measurement Program (UN-ECE)PM-Kat Partial Filter Catalysed (MAN)SMPS

Partial Filter Catalysed (MAN)SMPS Scanning Mobility Particle Sizer (TSI)VERT

Scanning Mobility Particle Sizer (TSI)VERT Swiss Particle Filter Certification Sceme

Swiss Particle Filter Certification Sceme Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML