-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2024; 13(1): 1-6

doi:10.5923/j.textile.20241301.01

Received: Jul. 14, 2024; Accepted: Aug. 19, 2024; Published: Aug. 30, 2024

Corn Husk Fiber- A Sustainable Fiber

Zinia Yasmin1, Nusrath Jahan Khanam1, Mayesha Maliha1, Tanzima Zoha Chowdhury1, Md. Jabed Hasan2

1Department of Textile Engineering, Primeasia University, Dhaka, Bangladesh

2Department of Industrial Engineering, Epyllion Style Ltd, Gazipur, Bangladesh

Correspondence to: Zinia Yasmin, Department of Textile Engineering, Primeasia University, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2024 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Corn grows in the world as the second-largest agricultural crop. Every single thing of the corn plant is useable. Corn husk is a by-product of corn plants. It has a high content of cellulose. It provides a large source of inexpensive cellulosic fiber and also a renewable natural fiber. This paper reviews on manufacturing process, fiber structure, cross-sectional diagram, fiber properties, and the end uses of corn husk fiber. The crucial awareness of the global environment opens a new direction for using corn husk fiber. It will be a good initiative with sustainable economic benefits.

Keywords: Corn husk, Cellulose, By-product

Cite this paper: Zinia Yasmin, Nusrath Jahan Khanam, Mayesha Maliha, Tanzima Zoha Chowdhury, Md. Jabed Hasan, Corn Husk Fiber- A Sustainable Fiber, International Journal of Textile Science, Vol. 13 No. 1, 2024, pp. 1-6. doi: 10.5923/j.textile.20241301.01.

Article Outline

1. Introduction

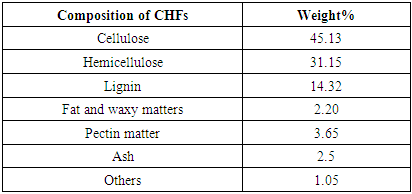

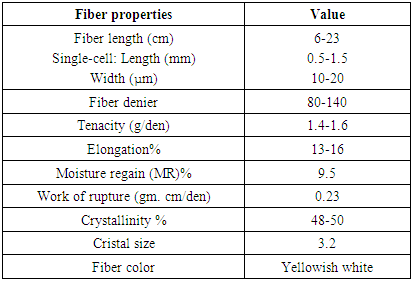

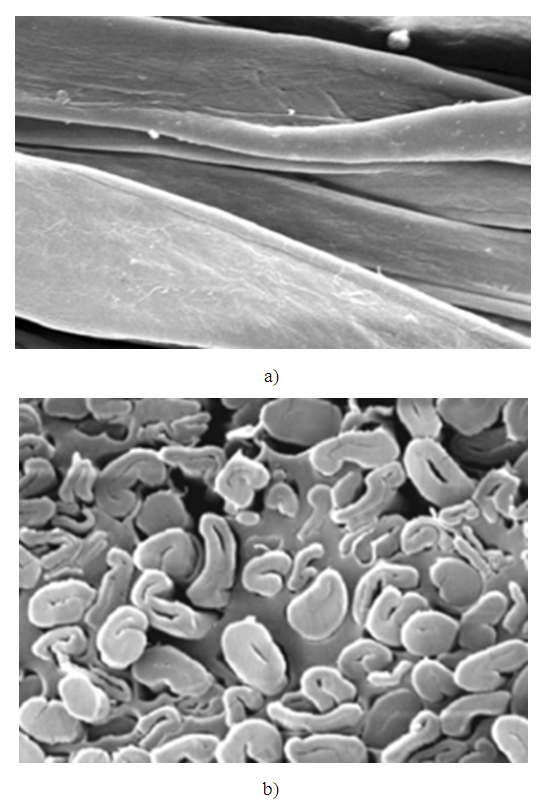

- Corn cultivation started about 10,000 years ago [1]. According to the International Grains Council (IGC) global corn production is 1.15 billion metric tons. The top three corn-producing nations are the USA, China, and Brazil. In the marketing year 2023-2024, the United States produced 32% or 389.7 million metric tons of corn which is one-third of the total corn production in the world [4]. Corn is produced as a low-cost crop worldwide for multifarious uses as food, feed, and industrial raw materials [3]. Corn husk fiber (CHF) is a natural lignocellulosic, renewable, and bio-degradable fiber obtained from the leafy outer cover of corn fruit [2]. This covering part of corn is known as corn husk. Corn is known as maize, a type of grass. The scientific name is Zea Mays. It grows 3-13 feet (1-4 m) high, with a tall central stalk and long leaf blades. Corn plants usually contain about 50 percent stalks, 23 percent leaves, 15 percent fruits, and 14 percent husk [2]. In most cases, the outer leafy skin of the corn fruits/cobs has been thrown away as waste which is almost the same as corn fruit [2]. The strongest part of the corn plant is the corn husk (CH) as it protects the seeds [5]. Generally, this husk is thin and flat like foliar leaves. CHFs are collected from the outer foliar leaves of fruit. It contains 80-87% (cellulose, and hemicellulose), and 6-7% lignin [2]. CHF is comparable with lignocellulosic fiber jute and other cellulosic fibers like cotton [10]. It has good pliability, moderate strength, durability, longevity, and high moisture retention properties [5]. It has less crystallinity, which enhances elongation properties and allows for chemical reactions [6]. CHFs as the new fabric are highly acceptable about their usefulness, appearance, durability, and eco-friendliness [23].

| Figure 1. a) Corn plant, b) Cross-sectional view of corn husk fiber |

| Figure 2. a) SEM view of CHF [10] b) SEM view of CHF cross-section [10] |

2. Materials & Methods

- Several research papers were gathered and reviewed. According to the information on the paper manufacturing process, fiber structure, properties, and uses were considered here.

2.1. Manufacturing Process

2.1.1. Harvesting and Husking

- Corn is harvested when the tassels at the end of the cob have started to dry out and turn brown after around eight weeks of planting. The corn fruit is picked up after the full maturity of corn cobs (except the top 2-3 leaves and the remaining leaves are completely dry) [7]. Machine harvesting process and hand harvesting processes are commonly used to break the corn fruits when there is a break in the weather, within two to three days without rain [8]. After harvesting the corn, husks are collected before grain threshing.

| Figure 3. Corn harvesting a) Hand harvesting b) Machine Harvesting |

2.1.2. Fiber Extraction Process

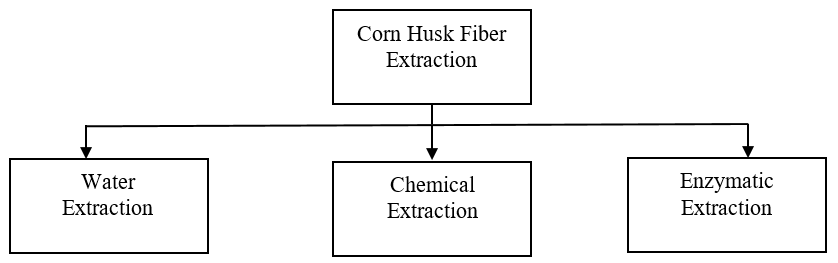

- Water extraction, chemical extraction, and enzymatic extraction, the three types of fiber extraction methods that have been found to collect corn husk fiber (CHF).

| Figure 4. Flow chart of CHF extraction |

2.2. Water Extraction

- Corn husk Fiber (CHF) extraction is performed with the action of water which is a conventional method. CHs are soaked in water for 15 days and the water is changed every two days [12]. This time allows micro-bacterial degradation to the CHs [9]. The micro-bacterial organisms de-lignified the cellulosic fiber. Then the fiber is washed with clean water several times to remove the dissolved residual matter. Then combed with a brush to align the fiber and dried for further use.

| Figure 5. Water extraction CHF [12] |

2.2.1. Chemical Extraction

- In this method, CH is subjected to a sodium hydroxide (NaOH) solution. CHs are immersed in 10% concentrated NaOH solution at 120°C for 60 minutes [10]. NaOH helps the CHs to degumming the fiber. After the separation of fiber, CHFs are thoroughly washed with running water to remove the degummed material [10]. Then treated with 0.1% acetic acid for neutralization and dried the fiber.

2.2.2. Enzymatic Extraction

- This method includes the CHs being dried first and then treated with pectinase enzyme. Dried CHs are kept in a sealed plastic bag with 1% enzyme solution at (40°-50°C) temperature for 72 hours [11]. After the treatment time, CHFs are rinsed thoroughly with clean water to remove dissolved gummy matter and dried the fiber.

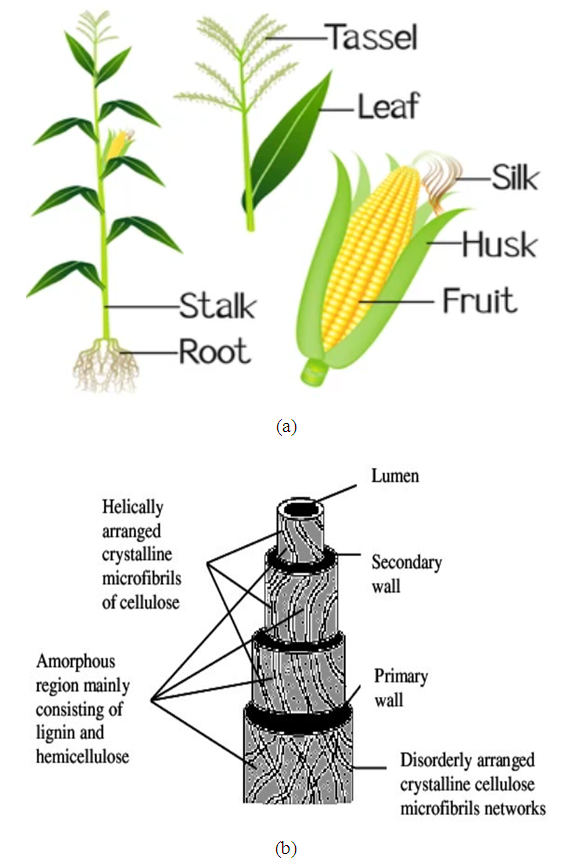

2.3. Chemical Composition of Corn Husk Fiber

- Corn husk fiber is a multicellular fiber that has a higher number of individual cells (cellulose, hemicellulose, and lignin) [13]. They are held together by binding substances. The chemical composition of corn husk fiber is as follows [14].

|

2.4. Physical Properties of Corn Husk Fiber

2.5. Effect of Alkali

- Concentrated NaOH treatment can cause weight loss of CHF. As the fibers extracted with sodium hydroxide are coarse and brittle, they require an enzymatic treatment to overcome the obstacles [15].

2.6. Effect of H2O2

- The strength of CHF is gradually decreased with the increase in concentration of hydrogen peroxide (H2O2). The preferable concentration of H2O2 is up to 2 g/l [15].

2.7. Effect of Temperature

- CHF has good resistance to boiling temperature with a slight change in yellowish color [15].

2.8. Flammability of CHF

- Corn husk fiber is highly flammable. This problem could be overcome with the treatment of flame retardant agents [16].

2.9. Thermal Properties of CHF

- CHF has an excellent thermal insulation property with low thermal conductivity. The thermal insulation is increased when treated with 10% NaOH solution [17].

2.10. Spinning of Corn Husk Fiber

- Corn husk yarn can be produced by the rotor and ring both spinning processes [27]. It should be blended with other natural or synthetic fibers as CHFs are coarse and comparatively less strong than cotton. Favorable spinnable blend ratio is maximum 50% or less to minimize the yarn breakage [27].

2.11. End Uses of Corn Husk Fiber

- 1. Corn husk fiber is used as yarn and fabric. Now fashion designers are interested in sustainable fabric from corn husks as CHF has biodegradability within 30 days [18]. CHF can be converted into fabric by knitting, weaving, and also denim [18].2. CHF can be used for thermal insulation due to low conductivity [17].3. It is used as reinforcement for manufacturing bio-composite [19]. 4. It is used as a bio-adsorbent of dyestuffs from aqueous solution [20].5. CHF is also used as a sound absorbent, due to excellent acoustic absorption properties [21].6. It can be used as a UV protector, due to the anti-oxidant properties of CH [22].7. CHFs are used to make toys.8. It is also used to make curtains, placemats, store items, handbags, and shoes (sneakers and espadrille) [23].9. It is used as a cosmetic item or cosmetic base like sunscreen lotion [20].10. CHFs are also used as home decorative items like wallpaper, flowers, rope, etc.11. CHFs could be used as biomass for different applications [24]. 12. CHF sheets could be used as sanitary napkins or diapers [25].

| Figure 6. CHF heat insulator sheets |

| Figure 7. CHF colored paper |

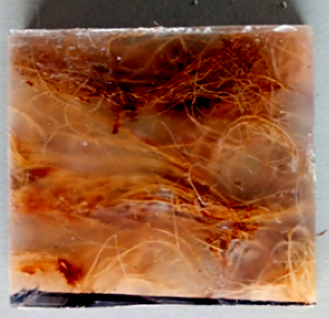

| Figure 8. CHF dyed fabric |

| Figure 9. CHF plant pot |

| Figure 10. CHF composite [19] |

| Figure 11. CHF doll |

| Figure 12. CHF rug |

| Figure 13. CHF bottle cover |

| Figure 14. CHF Rope |

| Figure 15. Storage basket |

| Figure 16. CHF brush |

| Figure 17. CHF handbag |

| Figure 18. CHF sanitary Napkin [26] |

| Figure 19. CHF flowers |

3. Conclusions

- Corn is now the third cereal crop in Bangladesh due to the high demand for the food, bakery products, and poultry industry as poultry feed. It can be harvested three times a year with very low requirements. Now Corn cultivation has increased ten times more in recent years. However, corn husk production is equal to corn fruits. The fiber extraction process from husk is simple. Chemically fiber extraction method required less time than the enzymatic and water extraction method. This fiber has similarities with other cellulosic fibers like cotton and jute. It could be blended with different types of cellulosic or synthetic fibers to get the desired properties yarn for various fashion and industrial uses. Hence, corn husk fiber could reduce the load on other cellulosic fibers (cotton, flax, jute) as its longevity, good aspects, and eco-friendliness.

ACKNOWLEDGEMENTS

- The authors are thankful to all the researchers who made their research work on corn husk fiber. Their research works help to gather knowledge in new diversified areas about corn husk fiber.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML