-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2023; 12(1): 15-21

doi:10.5923/j.textile.20231201.03

Received: Sep. 30, 2023; Accepted: Oct. 20, 2023; Published: Nov. 23, 2023

Textile Washing Process and Its Impacts

Mohammad Asad Bin Yousuf1, Abu Hashem Bin Yousuf2

1Skill Enhancement Facilitator and HR & Employee Development Consultant, 2nd MBA, University of Dhaka, 1st MBA, Stamford University of Bangladesh, PGDHRM, Bangladesh Institute of Management, BBA, Independent University of Bangladesh

2MBA, PGDHRM, BBA, Former Lecturer, School of Business, Prime Asia University, Dhaka, Bangladesh

Correspondence to: Mohammad Asad Bin Yousuf, Skill Enhancement Facilitator and HR & Employee Development Consultant, 2nd MBA, University of Dhaka, 1st MBA, Stamford University of Bangladesh, PGDHRM, Bangladesh Institute of Management, BBA, Independent University of Bangladesh.

| Email: |  |

Copyright © 2023 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Textile history is as old as human civilization which changed over time dramatically. The first initiatives of putting something on human body simply aims to cover shyness or to maintain minimum level of decency. Warm feeling in winter season and to process certain level of protection were two major additional objectives which were adopted by human during its evolution period. Slowly clothing has been enlisted as one of the five basic needs for survival. With time the core objective of clothing adopted many additional objectives besides meeting the basic human need. With time demand for different types of textile products has grown in all parts of the world. To meet the demand diversity of textile different mechanism has been adopted. Different mechanism which are being used today to modify the appearance of any textile product, washing process is one of the most significant one. Some of the garments wash process also creates many adverse impacts on ecosystem besides creating especial effects. As a result, it is essential to explore impacts of garments wash. This article explores textile washing process and washing impact on fabric texture, appearance, and lifespan. This article explores effectiveness of wet and dry wash process.

Keywords: Garments Finish, Cleaning Textile Products, Wet Wash Process, Dry Wash Process, Wet and Dry Wash Impact, Garments Wash, Garments Washing Process

Cite this paper: Mohammad Asad Bin Yousuf, Abu Hashem Bin Yousuf, Textile Washing Process and Its Impacts, International Journal of Textile Science, Vol. 12 No. 1, 2023, pp. 15-21. doi: 10.5923/j.textile.20231201.03.

Article Outline

1. Literature Review

- Textiles plays a very important role in all aspects of human lives and living from birth to death. Clothing and textiles reflect the materials and technologies available in different parts of the world during course of time. Textile is also termed as garments, cloth, or fabric. Basically, textile is flexible artificial material which is usually made up of either by natural or artificial fibers (thread or yarn) which is formed by weaving or knitting (textiles). In a simple word textile represents anything what usually human wear to cover fully or partial parts of their body and termed as clothing. Demand for clothing across globe has emerged over time. To support the enormous demand for clothing textile industry has evolved in different parts of the world. With time demand for different type of textile products has grown in all parts of the world. The textile industry was primarily concerned with the production and distribution of textiles but with time appearance and design of textile has become one of the core concerns of the textile manufacturer. To meet the demand diversity of the textile products different mechanism has been adopted in different phase of textile evolution. After using synthetic yarn instead of raw yarn, textile washing techniques has become one of most impactful technological advancement in the history of textile industry. To meet the unique demand of textile industry plenty of advanced technology has been adopted. Among the different mechanism which are being used today to modify the appearance of any textile product garments wash is one of most significant one. Human spend a major portion of their income on buying textile they like to wear. Therefore, it is essential for buyer, seller, and manufacturer to understand various washing process used in textile industry along with their characteristics and their impact on fabric status and ecosystem. Exploring washing impact on textile product will help readers and textile buyers to adopt adequate knowledge on garments wash process and its consequences.

2. Problem Statement

- In the era of globalization and advancement of technology human taste and demand of textile products changed dramatically across globe. To meet the unique taste of textile products textile industry has adopted different types of technology. Among the different technologies used to modify outlook, status, and appearance of textile products garments wash is majorly used one. Textile washing process is one of most advance technology used to modify the appearance and status of any fabric. As a result, textile buyers and users often get confused to determine which wash has what sort of impact on fabric status and which wash is best for fabric lifespan and environment as well.

3. Objective

- The main objective of this article can be divided into two broad classes. One is primary objective and another one is secondary objective.

3.1. Primary Objective

- Primary objective of this article is to explore different washing process used in textile industry.

3.2. Secondary Objective

- Secondary objective of this article is to explore impacts of various garments washing process on textile status, appearance, and lifespan.

4. Methodology

- This writing is formulated based on the descriptive exploration of the subject area which is backed by different theoretical data collected from books, published articles, journals, and online verified data sources. Different types and sources of data have been collected, analyse, and formulated in the right way to draw meaningful information.

4.1. Process Data Collection

- The data collection process of this article can be divided into two broad sources. The first source is primary data collection source and second one is secondary data collection source which are mainly derived to support the primary source of data. Primary data has been collected through in person conversation with industrial engineers, merchandisers, quality checkers, washing experts, chemist, technicians along with practical in person observation of the whole washing process. Face to face interview has been conducted over ten (10) Ready Made Garments Professionals working at different washing and textile miles. The secondary data has been extracted from different books, published online journals, online articles, newspaper news, research report, statistical reports, and other available databases. All the secondary data collection sources are citied in the refence section for further clarification of the readers.

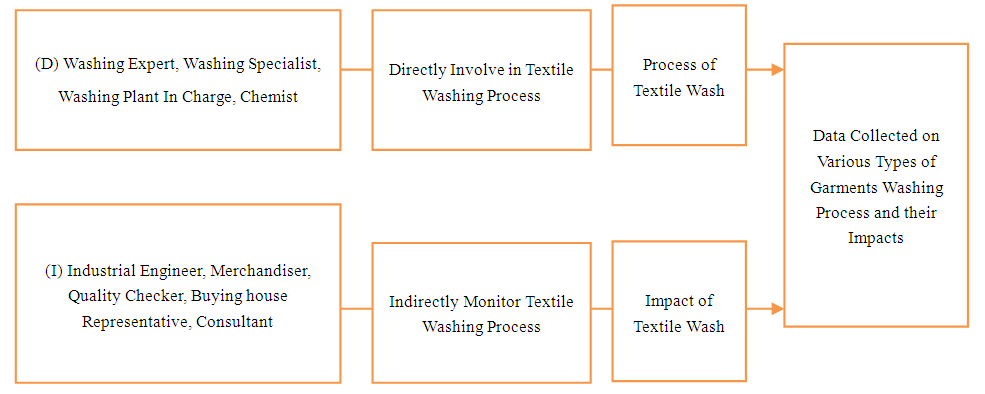

4.2. Conceptual Frame Work

| Figure 1. Conceptual Frame Work |

5. Exploring Textile Wash

- Textile wash is the technology used in textile industry to modify outlook, control size, enhance comfortability and create new fashionable look of any fabric or textile product or garments or apparels. Apart from cleaning and removing bad odor textile wash creates special impact on garments status. There are different washing techniques which are applied now a days to modify garments and meet buyer’s unique taste. Some of such washing also cable to enhance textile life span while a few may also diminish garments strength. In a broader sense garment washing can be termed as in any industrial apparel, washing is a technology which is used to modify the outlook, appearance, comfort-ability and design of textile or ready-made garments or apparels made from solid color dyed or pigment printed fabric (Islam, M. M. U., RMG Consultant & Researcher).

5.1. Objective of Textile Wash

- In a simpler sentence it can be said that Textile wash is mainly conducted to add more value to any textile or garments. The core objectives of textile wash are listed below:Eliminating Objective: 1. To remove bad odor, dirt, dust, waste, and any harmful materials from textile.2. To remove sizing materials and unexpected shrinkage from textile or garments.3. To eliminate any injurious foreign particles from textile.Controlling Objective:4. To control pH Value and to control fabric harness for human skin.5. To meet buyer requirements.Effect Creation Objective:6. To create fading effect / old look / vintage look.7. To create destroying, grinding, and tagging effects on textile.8. To increase the brightness and smoothness of any textile or garments.9. To change the appearance of any textile or garments.10. To make textile or garments wearable, soft and handy.11. To make special finish / effects on textile or garments.

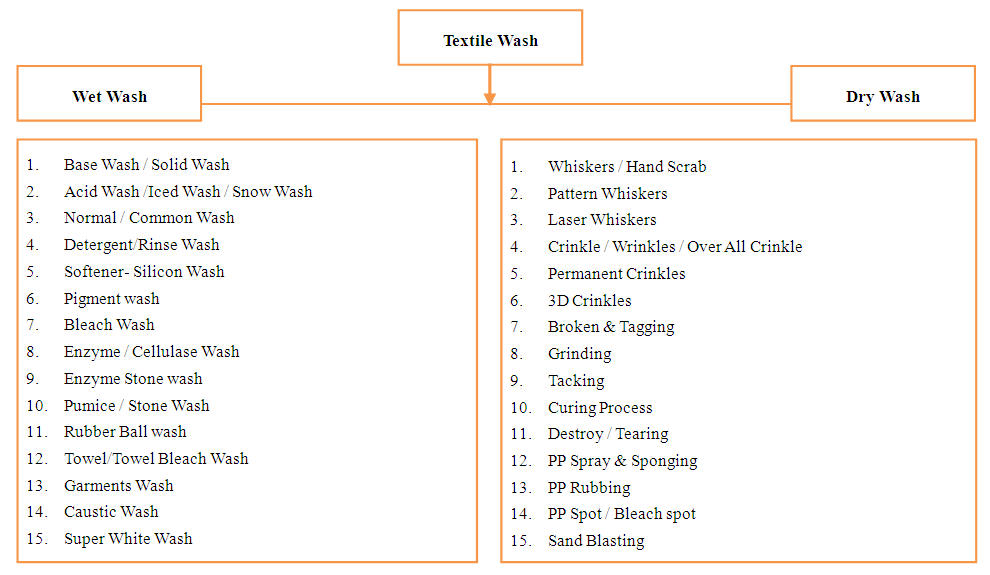

6. Different Types of Textiles Washing

- Various types of textile washing can be categorized into two broad classes. Different types of Textile washing are mentioned below:

| Figure 2. Different Types of Textile Wash |

6.1. Textile Wet Wash Process

- The wet wash process is the core wash treatment for any type of garments wash. Textile wet wash is also termed as chemical wash process which mainly use water and different types of chemicals to wash and modify any textile. Wet wash mainly aims to change or modify outlook, appearance, comfortability, and hands feel of any fabrics or textile. Along with modification wet washing also clean dirt and dust with water, chemical and soap.

6.2. Impacts of Wet Wash

- Wet wash is mainly carried forward to meet some specific objectives. The most common impacts of wet wash are mentioned below:• To remove dirt, dust, waste, and any harmful materials from textile.• To remove sizing materials and unexpected shrinkage from textile or garments.• To Control pH Value and eliminate any injurious foreign particles from textile.• To create fading effect / old look / vintage look on textile or garments.• To increase the brightness, softness and hands feel of any textile or garments.• To strengthens and enhance life span of any textile or garments.

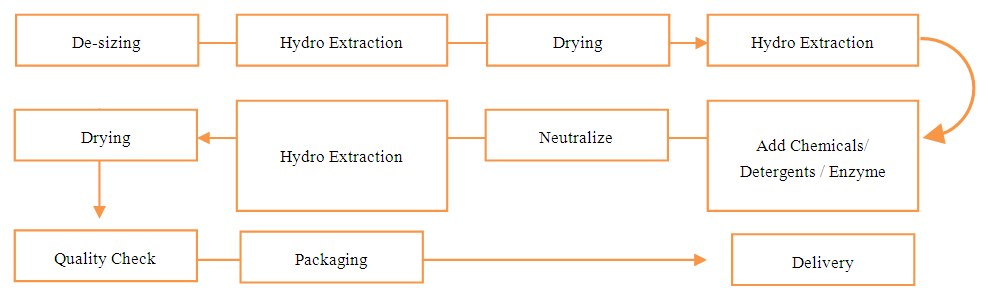

6.3. Process of Textile Wet Wash

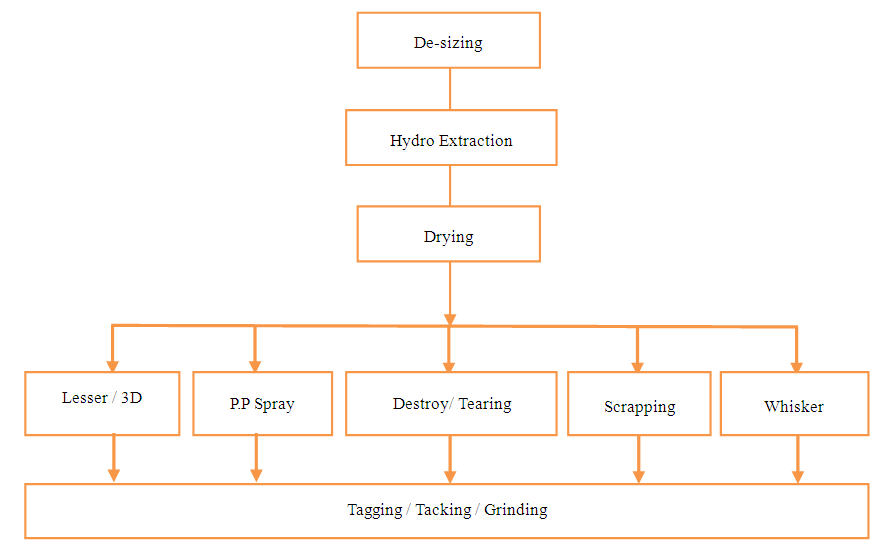

- Textile wet wash mainly involve set of steps to complete the whole process. It usually starts from de-sizing and ends at Hydro extraction and drying. Most essential steps of wet wash process are mentioned below:

| Figure 3. Process of Textile Wet Wash |

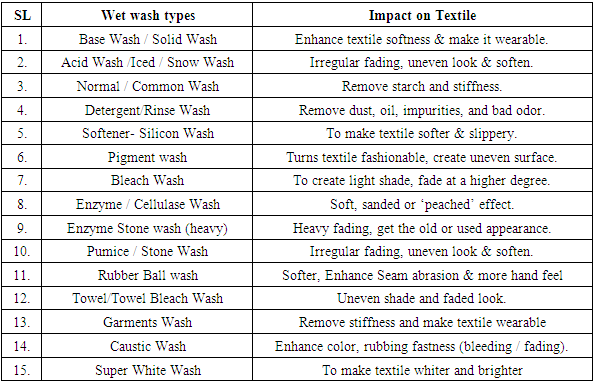

6.4. Different Types of Textile Wet Wash Process and Their Impact

- Impacts of different types of wet wash process is very crucial to understand and meet buyer requirements. A very brief idea of the impact of various wet wash process is mentioned below:

|

6.5. Textile Dry Wash

- The dry wash is an important factor in textile washing apart from wet washing. In dry wash process special finish or effects are created in textile without using water and in some extend chemicals as well. Dry wash is usually termed as mechanical process which do not used much of machineries and usually fully carried forward by human hand. Cost effectiveness especially for small order quantity is one of the finest attributes of dry wash.

6.6. Impacts of Dry Wash

- Dry wash in textile industry mainly carried forward to meet specific need of buyers(Kiron, M. I., Founder & Editor of Textile Learner). The most common impacts of dry wash are mentioned below:ü To create special finish and effects on textile or fabrics especially on denim.ü To create fading effect / old look / vintage look on textile or garments.ü To create Wrinkles Effects on Textile.ü To create tore effects.

6.7. Process of Textile Dry Wash

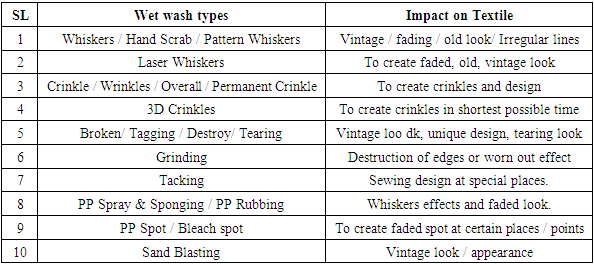

6.8. Different Types of Textile Dry Wash Process and Their Impact

- Impacts of different types of dry wash process is very crucial to understand and meet buyer requirements. A very brief idea of the impact of various dry wash process is mentioned below:

|

7. Discussion

- Garments washing is mandatory steps for all sorts of garments to remove bad odor, dirt, dust, oil, waste, and any other foreign particles from the surface of the garments. Some especial chemicals are used in garments wash to control shrinkage problem, pH value and harness of the any fabric. When it comes to denim fabrics textile industry uses various types of washing process only to create especial effects on the denim garments. Wet and Dry wash both aims to create especial effects on denim surface apart from removing dirt and dust. After denim gain its popularity at the late 1960s textile industry introduced many washings technology that can create special effects on textile specially on denim fabrics. At the starting of such journey, it begins with total manual processes. Later, to meet larger quantity of demand of buyer automated process evolved with time. Now wet wash process is very much essential to give special effects on large number of garments in the shortest possible of time. One of respondent who is washing expert quoted that wet wash is mandatory for all sort of garments and even for denim to complete the entire dry wash process certain wet wash is also required. One respondent also quoted at present garments wash has become an inevitable part of textile industry which have both affirmative and adverse impact on fabric status, human health, energy level and ecosystem.

7.1. Advantages of Garments Wash

- While discussing garments washing respondents highlight both merits and demerits of garments wash. Obviously, merits are many in number. Respondents address the positive sides of garments wash. Some of the most common advantages of garments wash are listed below:• Garments wash especially wet washing process turns garments wearable. Respondents clearly described how wet wash makes garments soft and give more hand feel effect. Wet wash turns garments wearable and smooth for human skin (Steven Toltz).• Garments wash remove bad odor, oil, dirt, dust, and any foreign particles from garments which is very essential for every garment (Abu Sayed). • Garments wash remove seizing materials from garments and improve garments lifespan. • Garments wash is good way to fix the discoloring effect of any garments. Garments wash fixed color and eliminate chances of certain shrinkage. • Garments wash is mandatory for controlling pH value of the fabric which eliminate all adverse impact of chemicals used in fabrics. • New Effects like faded or worn-out effect can be introduced to surface of the garments which creates new attractive fashion (Rasel's Blog).• To create different colour pattern and effects on fabrics.

7.2. Challenges of Garments Washing Process

- While discussing garments washing process some of the respondents also claimed that alongside of all the positives sides of textile washing process there are some negative aspects too. While emphasizing some of the major negative aspects of garments wash some of the respondent explained adverse impacts of wet wash process. Some of challenges of wet wash process are highlighted below: • Wet washing process consumed a good number of energy and water which is the biggest challenge for textile engineer. Textile researcher, engineer, and consultant are trying enormously to develop equipment’s what will give maximum output with minimum uses of water and energy. Globally every year over one trillion KWh of electricity is consumed to produce approximately sixty (60) billion KG of fabrics (Raja A. S. M., Arputharaj A., Saxena S., Patil P. G.). • Dumping waste water into earth and engrave destroyed garments in earth is creating a great challenge for our eco-system (Choudhury, A.) which needs to be addressed with proper waste management system. Survey conducted in Bangladesh by BUET found that from 2021 textile industries would be dumping a mind-boggling 20,300 crore liters of untreated wastewater annually into the waterbodies threatening fisheries, biodiversity, and groundwater storage (Mohammad Al-Masum Molla, Refayet Ullah Mirdha). • Alongside of energy uses a very disadvantage of wet wash process is the use of chemical which is very hazardous for both human and water world. Although different equipment and substitutes have evolved to protect both, human, earth, and water but the uses of such equipment’s are very significant amount. Textile Industry Responsible for 20% of Global Water Pollution (Isabelle Juillard Thompsen).• Workers who work at washing plants especially at dry wash factory often had problem with skins so proper precaution should be taken. Workers must wear and use personal protective equipment’s and dress while working in washing plant. Sand blasting can expose workers to extreme health hazards. Send blasting impact can be as devastating as death within months or years of starting work as a sandblaster (Textile Blog).• Creating any effects on garments surface reduce the lifespan of the garments as a result garments. Less lifespan means less use of garments and buying new garments means throwing old garments into the garbage can. Ultimately wastage garments are dumped into the earth which are creating a huge damage to eco system. Approximately one hundred billion textile are being produced across globe each year and as much as ninety two million tons of clothing ends up in landfills (Arabella Ruiz).Now textile experts, buyers and users are promoting sustainable garments wash process that will create minimum impact on eco system and maximize the life span of any textile product so that it creates less impact on earth. But these alternative approaches are not fully operational rather adopting in a test basis. Both garments’ producers and users must understand the challenge mother nature is facing due to enormous production and dumping of garments across world. Therefore, all forces must act together to ensure sustainability.

8. Recommendations

- A few of the respondent also suggested several ways out to minimize the adverse impact of textile washing especially on environment and human health. Some of most important way out recommended by industry experts are mentioned in the following:Recommendation for Wet Washing Process:Ø Use eco-friendly chemicals for textile wet wash.Ø Use substitute chemicals which usually have less environmental impact. Ø Adopt new technology / machine that can reduce energy consumption, in terms of water, electricity and gas. Use ozone wash so that water and energy can be saved. (Grau, P.) Ø Water treatment plant should be place at every washing plant so that amount of chemicals presence in washing water can be reduced before dumbing waste water.Ø Use dry wash instead of wet wash to reduce water consumption.Ø Recycle water for multiple uses in textile washing process.Ø An adequate number of research and technological development should be encountered to create sustainable textile washing process. Recommendation for Dry wash Process:Ø Use lesser and 3D technology instead of chemicals to reduce impact on environment.Ø Use Personal Protective Equipment’s (PPE) while doing dry wash process.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML