-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2023; 12(1): 10-14

doi:10.5923/j.textile.20231201.02

Received: Feb. 21, 2023; Accepted: Mar. 15, 2023; Published: Apr. 23, 2023

Evaluation of Enzyme Wash on Denim Fabric by Varying Conditions and Chemical Composition

Md. Mahbubur Rahman, Md. Mazharul Helal, Suraiya Ireen, Md. Mutasim Uddin, Dr. Jagannath Biswas

Textile Engineering Department, Green University of Bangladesh, Dhaka, Bangladesh

Correspondence to: Md. Mahbubur Rahman, Textile Engineering Department, Green University of Bangladesh, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2023 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Jeans are regarded as an elegant casual attire for both men and women. Denim jeans come in a wide variety of styles, yet they are always constructed of the same material. Denim fabrics are cleaned to give them a distinctive look, feel, and style. Denim washing is a cosmetic procedure that improves a fabric's suppleness and comfort. Denim cloth can be washed with a variety of enzymes. Denim finishers are currently employing cellulase enzyme to speed up the abrasion process. Several kilograms of stones can be replaced with a tiny amount of enzyme. The amount of enzyme used has an effect on the characteristics of the denim fabric. Cellulase operates on the fabric surface and breaks it down, smoothing it out. This aids in the prevention of pill formation. This study examines denim washing process improvements from three perspectives: product quality, process quality, and pollution. Garment quality must be verified against stated and unstated needs when washing to improve customer satisfaction. Cost reduction, productivity enhancement, waste reduction, and resource optimization are all aspects that influence process quality. Enzyme washing is better for the environment than using chemicals to wash garments. As enzymes are biodegradable, they break down rather than staying in the water system. After enzyme washing, denim properties such as tensile strength, stiffness, drape, and color change were examined.

Keywords: Denim, Garments Washing, Enzyme, Cellulase, Eco-friendly

Cite this paper: Md. Mahbubur Rahman, Md. Mazharul Helal, Suraiya Ireen, Md. Mutasim Uddin, Dr. Jagannath Biswas, Evaluation of Enzyme Wash on Denim Fabric by Varying Conditions and Chemical Composition, International Journal of Textile Science, Vol. 12 No. 1, 2023, pp. 10-14. doi: 10.5923/j.textile.20231201.02.

Article Outline

1. Introduction

- Denim is a strong, harsh and heavy weight cotton fabric. Therefore, denim garments are inherently uncomfortable to wear. Denim is made by dyeing the surface of the warp yarn while leaving the core of the warp yarn white during the manufacturing process. Denim fabrics have a high density and a high mass per unit area, and they are also difficult to wear. As a result, uncomfortably stiff denim garments require a finishing treatment to make them soft and smooth, thereby increasing the wearer's level of comfort. Washing is one of the most widely used finishing treatments [1].Denim is the only fabric that has earned widespread acceptability among all textile items. People of various ages, classes, and genders have utilized it widely. Denim jeans finishing is one of the most often used finishing treatments with a lot of practice. As these treatments significantly influence the look and comfort of the garments, various efforts are made in this respect [2].Enzymes have been found to be capable of replacing harsh chemicals, catalyzing reactions, and operating in mild circumstances. These are biodegradable, safe to use, easy to control, and pollution prevention. Pollution prevention includes water conservation, chemical reuse, waste minimization, waste recovery, effluent control, and environmental hazard control. Therefore, enzyme wash is an environmentally friendly washing technique [3]. In denim fabric, enzyme washing is a process that involves the use of enzymes to produce softness and comfort as well as lustre and a faded appearance. Enzymes break down the cellulose fibers on the surface of the denim fabric, which are then removed during the washing process. During the enzyme washing process, a small amount of indigo dye and cellulose fibers from the fabric's surface are removed [4]. Additionally, it is a popular method of garment washing as it has some notable benefits. To mitigate the negative effects of stone wash, garments are washed with enzymes.If the denim fabric is treated with commercial cellulase, pectinases and xylanases individually and in combination at various concentrations, then the smoothness of the fabric surface significantly improves and it becomes soft [5]. Various cellulose degrading enzymes are available nowadays and these can be produced commercially. Enzyme degrades the fabric's surface cellulose fibers and removes them during washing. Among the two traditional enzymes used to treat denim garments (amylase, which hydrolyses starches, and pectinase, which degrades cotton cellulose in a variety of ways), there is another enzyme that can be used to attack specifically the molecule that produces the blue indigo color, rendering it ineffective against other types of dyes. Endoglucanases randomly hydrolyse chains, cellobiohydrolases hydrolyse cellobiose from polymer ends, and cellobiases hydrolyse cellobiose to glucose. During cellulose degradation, these enzyme components work in concert. Cellulase finishing and washing effects are always used in processes involving strong mechanical action on fabric [6]. Comparing to the traditional stone wash, enzyme provides a more softened hand feel to the fabric while also retaining the fabric's strength and durability. It can prevent the formation of fuzz and pills on the fabric's surface, while increasing the smoothness, lustre, and uniformity of the color, as well as improving the handle and durability of the fabric. Additionally, it has the potential to reduce the intensity of abrasion on the fabric [7].Cellulase is a multicomponent enzyme system that consists of endoglucanases (EGs) that randomly hydrolyse cellulose chains, cellobiohydrolases (CBHs) that hydrolyse cellobiose from polymer ends, and cellobiases that hydrolyse cellobiose to glucose. All of these enzyme components work in concert to degrade cellulose. However, the slow kinetics of enzymatic degradation of crystalline cellulose (such as cotton cellulose) enables the improvement of fabric and fiber properties without causing undue damage. During the enzymatic treatment, the indigo that has been removed from the denim fabric may reappear on the white yarn of the fabric. This is referred to as back-staining, and it has the potential to completely ruin the appearance of a denim garment. When it comes to bio-stoning enzymes, abrasive activity and back-staining are important characteristics to look for. There have been some studies on back-staining that have focused on the mechanism of indigo redeposition on denim garments as well as the reduction of its effect, but it still continues to be a problem for the manufacturer of denim clothing [8].The purpose of the study was to improve garment quality, process productivity, and inclusion of enzymes instead of harmful chemicals. Compliance with legal requirements and regulations is important in preventing pollution by using biodegradable materials. Additionally, raising awareness about customer trends, denim washing, chemical and enzyme usage, washing conditions, etc. are actively considered in this study.

2. Materials and Methods

2.1. Materials

- The raw material for this study was “Denim” fabric made from 100% cotton fiber. The GSM (Grams per Square Meter) of the sample fabric was 415 (Average of three sample). The sample weight was 10 grams. The samples were enzyme washed by using these following chemicals: acid enzyme, detergent, neutral enzyme, anti-back staining agent, desizing agent, acetic acid, cationic softener. The machineries that were used to perform the experiment was sample dyeing machine, padding mangle (squeezer), electrical balance, heater, kettle, agitator, pot, beaker, and stand.

2.2. Methods

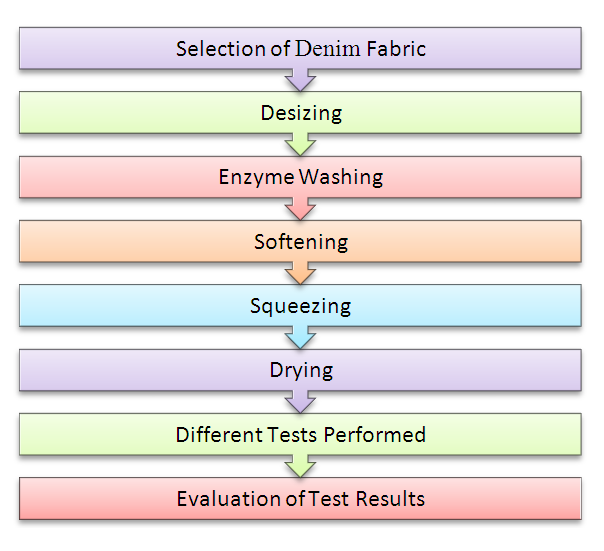

- In this study, the enzyme washing is done under different conditions i.e., changing parameters. The variables are enzyme (acid enzyme and neutral enzyme), water (changing the amount of water) and temperature (varying the temperature). Four types of samples were prepared for the evaluation & the total number of samples were 4*3 = 12.Type 01: Standard Sample (Washed with Acid Enzyme)Type 02: Washed with Bio Polish EnzymeType 03: Washed with Lower Liquor ConcentrationType 04: Washed with Lower TemperatureThe overall process flow is shown here

| Figure 1. Process Sequence of the Study |

3. Results and Discussions

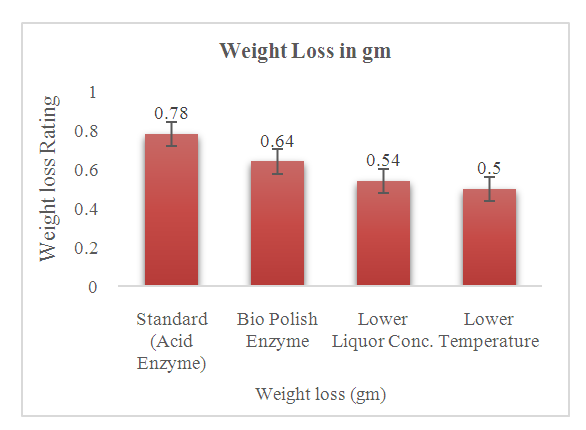

3.1. Weight Loss Due to Wash

- Electric balance is used to perform this test.

| Figure 2. Weight loss due to wash |

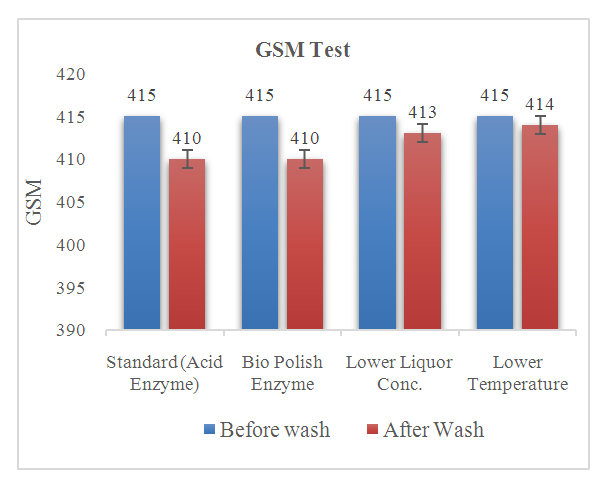

3.2. Change in GSM (Grams per Square Meter)

- GSM cutter and cutting board is used to perform this test.

| Figure 3. GSM Test |

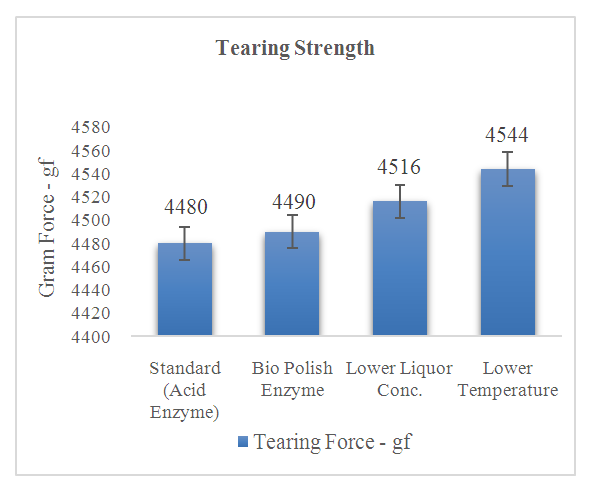

3.3. Tearing Strength Test

- Elmendorf Tearing Tester is used to measure the tearing force.

| Figure 4. Tearing Strength Test |

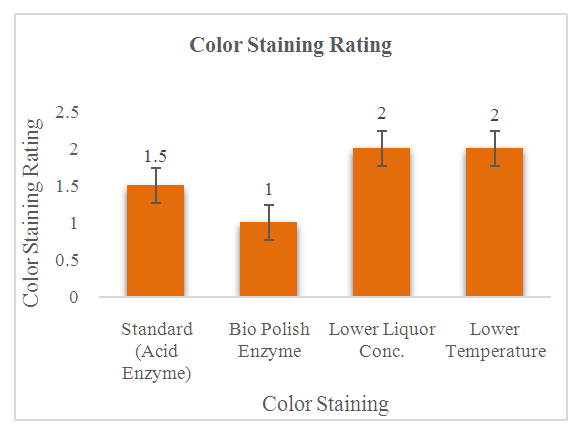

3.4. Color Staining Due to Garment Washing

- Grayscale of color staining is used to evaluate the color staining of the samples.

| Figure 5. Color staining due to garment wash |

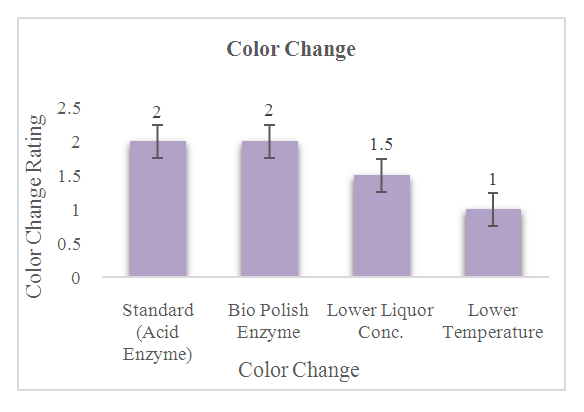

3.5. Effect of Washing on Color Shade of Denim Fabric

- Grayscale of color change is used to evaluate the shade of the samples.

| Figure 6. Effect of washing on color shade of denim fabric |

4. Conclusions

- Washing of denim garments with various chemicals and other mechanical actions has become the most demanding and popular finishing process all over the world in recent years. Aside from its enticing appearance, it is also responsible for imparting a variety of aesthetic and functional properties to denim fabric, such as softness, comfort, and others. This research demonstrates how to improve garment quality and process productivity. It suggests that hazardous chemicals be replaced with biodegradable enzymes. It is a preferential demand to save the environment by preventing pollution. For such purpose, strict adherence to legal standards and regulations takes precedence. The promising results made it possible to replace chemicals and it has been found that the quality and outlook of enzyme wash slightly varies from one to another. If there is a significant change on parameters and enzyme characteristics, there might be notable differences between the samples. By analysing all the findings from the study, it can be said that the standard sample performed averagely good in every aspect and the bio polish enzyme sample performance was relatively poor. The rest two sample’s performance was good but not good enough. However, as per the requirement of buyer, the parameters can be changed to get the desired outlook with an eco-friendly manner in enzyme wash of denim pants.

ACKNOWLEDGEMENTS

- The authors are grateful to the Department of Textile Engineering, Green University of Bangladesh for providing lab facility.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML