-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2022; 11(1): 12-18

doi:10.5923/j.textile.20221101.03

Received: Jun. 6, 2022; Accepted: Jun. 22, 2022; Published: Jul. 15, 2022

Impact of Garments Washing Defects on the Economy of Bangladesh

Engr. Md. Eanamul Haque Nizam , Khalid Hassan , Jabedul Islam , Shajib Islam , Md. Ibrahim Khan , Md. Ashikuzzaman

Department of Textile Engineering, Bangladesh University of Business and Technology-BUBT, Mirpur-2, Dhaka, Bangladesh

Correspondence to: Engr. Md. Eanamul Haque Nizam , Department of Textile Engineering, Bangladesh University of Business and Technology-BUBT, Mirpur-2, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2022 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Garment washing is currently a very popular industry in Bangladesh and around the world. Bangladesh has received a lot of orders in various industries because of its enormous popularity. As a result, the long-term viability of these industries must be ensured. The cost of manufacture and lead - times are critical factors in ensuring the long-term viability of these industries. The research team chose 20 factories to collect data from that to address some of the study's questions. The research team devised an eight-question questionnaire to learn more about the current state of these industries, as well as to identify new problems, causes, and solutions to these problems. Their subjects were the general manager of the factory, the production manager, and the technician. Finally, the research team has made some proposals for resolving these issues and ensuring long-term viability.

Keywords: RMG, Washing, Economy, Bangladesh

Cite this paper: Engr. Md. Eanamul Haque Nizam , Khalid Hassan , Jabedul Islam , Shajib Islam , Md. Ibrahim Khan , Md. Ashikuzzaman , Impact of Garments Washing Defects on the Economy of Bangladesh, International Journal of Textile Science, Vol. 11 No. 1, 2022, pp. 12-18. doi: 10.5923/j.textile.20221101.03.

Article Outline

1. Introduction

- Normally garments washing means cleaning of dirty garments with soap or detergent. But industrial garments washing is a technology which is used to modify the outlook, appearance, comfortability, and design of the ready-made garments made from solid color dyed or pigment printed fabric is called garment washing. Without proper knowledge of washing, we cannot give proper looking which is asked by the buyers in recent years. Garments washing is a new trend in Bangladesh, but it has 50 years prior history. Now washing includes bringing different shades, dry processes, dyeing and so many process according to the buyer’s requirement [1]. Garment wash is done in denim fabrics to produce a color fading effect with or without patchiness, seam puckering, hairiness, crinkles, de-pilling, stabilized dimensions, and soft hand feel. It is one of the most popular processes which is applied in garments to enhance the garments. For the first time, the concept of garments washing technology was developed by Jack Spencer for the brand Lee. Stonewash was first developed by Francois Giraud and the sandblasting process was developed in 1988 by several branded companies in Italy. Primary garment washing is classified into two types, these are- Dry process or Mechanical process and Wet process or chemical process [2]. Garments washing is the process to improve hand feel, appearance, and better outlook of garments. That’s why washing plays a vital role in garments manufacturing. Because of various washing defects, the rejection of garments increases [3]. Garments washing defect 16 types. Some of these defects are the most common. We need to reduce the rate of washing defects/faults at a minimum level. Rejection increases the cost of overall manufacturing. This has a great impact on the economy of Bangladesh. Many defects appeared to us in denim manufacturing sectors in Bangladesh during the washings. The rising of washing defects affects the whole process of denim garments manufacturing. In Bangladesh, denim washing defects increase wastages of raw materials and other equipment's which is related to denim production. Similarly, this defect reduces the production of denim garments, which affects the production cost and price of the final products. As a result, the production cost of the final denim products also increases. As the production cost increased due to denim washing defects. So, the price of the final denim goods will increase automatically. Finally, for this contention, the consumer will give more money for final goods of denim garments, which affects the total financial cycle or system in Bangladesh. If denim washing defects don't be found during denim washing, and then it will help the economic growth of whole production (shown in Figure 1). Whereas, if denim washing defects found during denim washing. Then it will restrict the economic increase of all productions (shown in Figure 1). These defects also affect the international financial cycle like Bangladesh [4].

| Figure 1. Methodological Framework |

1.1. Objectives of This Study

- In this study, the research team select 300 Washing factories in different zone of Bangladesh specially Gazipur, saver and Mirpur for investigating this situation. Finally, the research team takes some Snap for showing the real scenario of the factories and prepare the final project as an outcome.

2. Material and Method

2.1. Materials

- • Washing Factory (20 from different zone)• Factory Employ (Labor, Technician, GM)• Different type of Buyer (H&M, Puma, Zara)• Washing Machine (Modern and traditional)• Survey data (Primary and secondary)

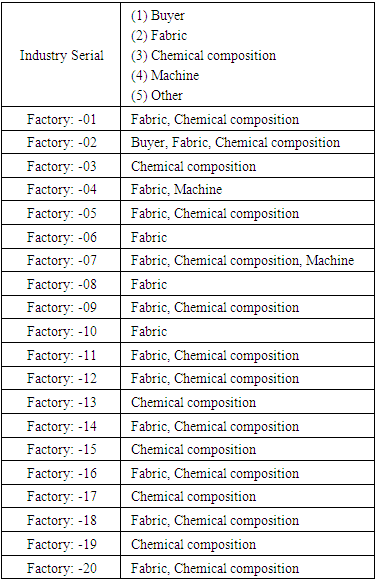

2.2. Methodological Framework

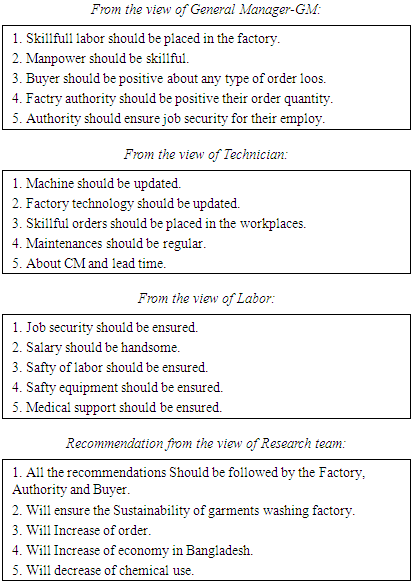

- At first, the research team analyse and try to find the defects theoretically. The research team has found 16 defects (washing) theoretically. The research team pick 20 factories according to product types. After collecting their feedback, they found 03 (three) new defects according to his comments. In most factories everyone is satisfied with the salary and job. The team analyse graph to show maximum and minimum defect. As a result of washing defect, order loss has occurred. After finding the results and recommendation, some suggestions from the view of the GM, Technician & factory owner, and the buyer finally the research team has recommended the factory owner, buyer the way to sustainability of this sector.

3. Results and Discussions

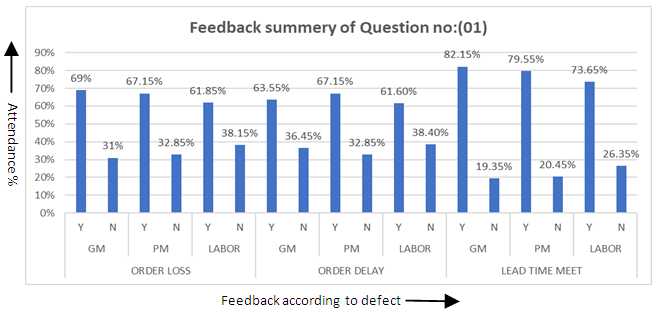

3.1. Question Number 01: Which Kind Impact do You Face Because of Washing Defect?

| Graph 1. Feedback summery of Question number 01 |

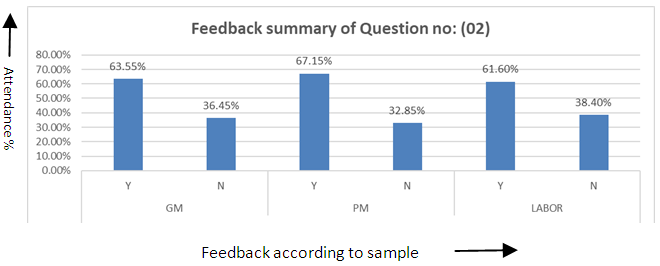

3.2. Question Number 02: What You Think? The Problem Can Effect on the Economy of Bangladesh?

| Graph 2. Feedback summery of Question number 02 |

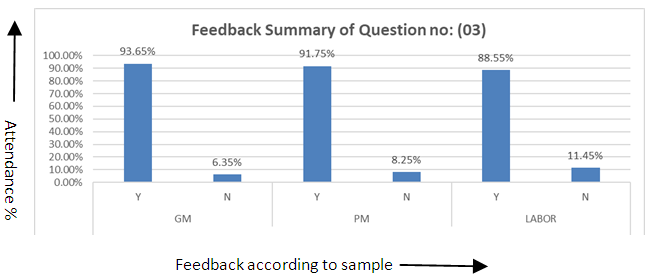

3.3. Question Number 03: Is It Possible to Solve All These Problems by Our Exiting Manpower?

| Graph 3. Feedback summery of Question no 03 |

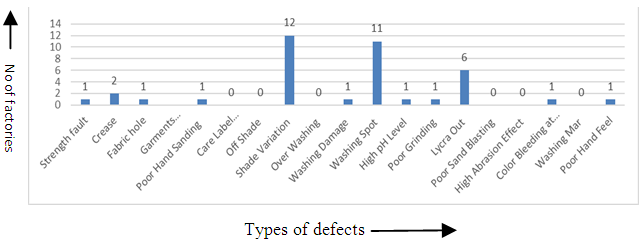

3.4. Question Number 04: In Garments Washing. Which Type of Defects You Commonly Seen?

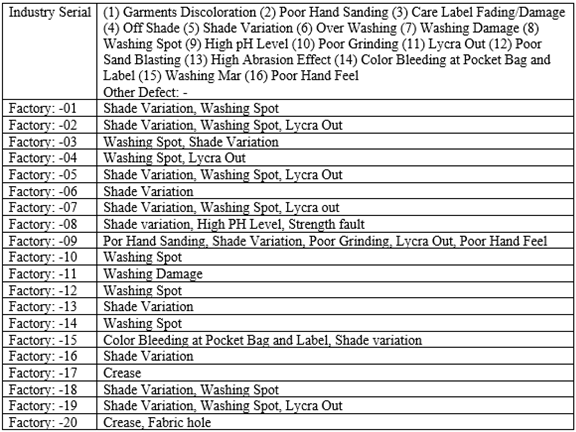

|

| Graph 4. Feedback summery of Question number 04 |

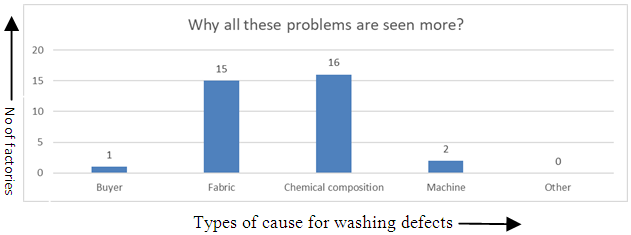

3.5. Question Number 05: Why These Types of Problems are Seen More?

|

| Graph 5. Feedback summery of Question no 05 |

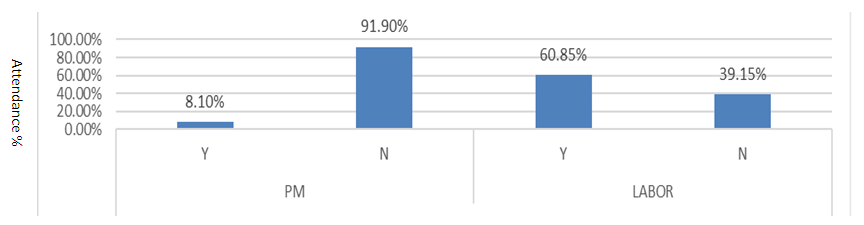

3.6. Question Number 06: Do You Face Health Problem During Working in the Washing Sector?

| Graph 6. Feedback Summery of Question no 06 |

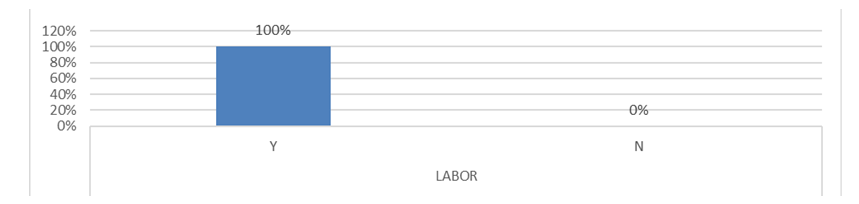

3.7. Question Number 07: Do You Satisfied to Work in the Sector?

| Graph 7. Feedback summery of Question no 07 |

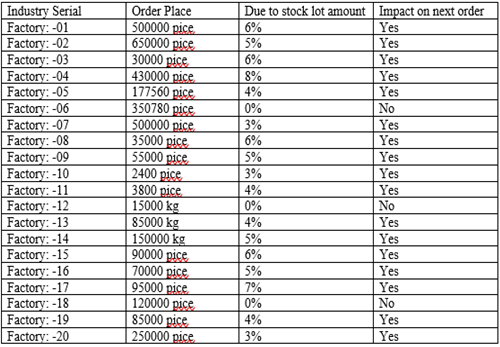

3.8. Question Number 08: Impact of Washing Defect on the Total Production

Stock lot: - Maximum washing factory store stock lot after completing the order. This is the wastages % of different washing factories. Next order: - Maximum of the factory effect in the next order due to huge stock lot and defects problem.

Stock lot: - Maximum washing factory store stock lot after completing the order. This is the wastages % of different washing factories. Next order: - Maximum of the factory effect in the next order due to huge stock lot and defects problem.4. Conclusions and Recommendations

- Garments washing is the process to improve hand feel, appearance, and better outlook of garments. That’s why washing plays a vital role in garments manufacturing. Because of various washing defects, the rejection of garments increases [5,6]. Maximum number of washing factories has huge stock lot problem up to 10% [7,8]. So, The Factory, Authority and Buyer should implement the CSR to sustain of garments washing factory in future. Decrease of chemical use that can Increase the next order. In total income of Bangladesh washing factory directly and indirectly related to the total economy of Bangladesh. Finally, the research team recommend all the recommendations to increase the economy of Bangladesh.Modern technology in washing sector can reduce the worker. But production quantity will high, and cost consumption will be reduced.

4.1. Recommendations

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML