-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2020; 9(1): 21-24

doi:10.5923/j.textile.20200901.04

Received: Aug. 22, 2020; Accepted: Sep. 10, 2020; Published: Sep. 15, 2020

Analysis of Seam Strength and Efficiency for 100% Cotton Plain Woven Fabric

Md. Rafiul Islam, A. K. M. Ayatullah Hosne Asif, Abdur Razzaque, Abdullah Al Mamun, Md. Maniruzzaman

Department of Textile Engineering, Mawlana Bhashani Science and Technology University, Santosh, Tangail, Bangladesh

Correspondence to: Abdullah Al Mamun, Department of Textile Engineering, Mawlana Bhashani Science and Technology University, Santosh, Tangail, Bangladesh.

| Email: |  |

Copyright © 2020 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The purpose of this study was to investigate the seam performance for commercially available 100% cotton plain woven fabric. The eminence of seam is characterized by strength of the seam, the elongation of seam and efficiency of the seam. Seam strength along with seam efficiency can contribute as important factor in determining the durability of a garment. Seam strength is related to the type of seam, the strength, efficiency of the seam and the seam density as well. Specifically, 100% cotton plain woven fabric was used for seam performance analysis because of its availability in market. Four different types of stitch structures along with three types of sewing threads like Ne 40s/2, 50s/2, and 60s/2 were used. Seam strength and efficiency of plain woven fabric was changed consecutively with different stitch types in conjunction with increasing stitch density and more specifically, maximum seam strength and efficiency were observed at cotton plain woven fabric for four thread overlock stitch structure together with 12 stitches per inch rather than others. Seam that contains more stitches per inch illustrates more seam strength and efficiency.

Keywords: Seam, Sewing Thread, Stitch Density, Woven Fabric, Tensile Strength

Cite this paper: Md. Rafiul Islam, A. K. M. Ayatullah Hosne Asif, Abdur Razzaque, Abdullah Al Mamun, Md. Maniruzzaman, Analysis of Seam Strength and Efficiency for 100% Cotton Plain Woven Fabric, International Journal of Textile Science, Vol. 9 No. 1, 2020, pp. 21-24. doi: 10.5923/j.textile.20200901.04.

Article Outline

1. Introduction

- The nature of the fabric affects not only the durability of the garments, but also the simplicity of which the shell framework may be constructed out of smooth fabric [1]. The requirements of the fabrics for the manufacturing of clothing can be regarded in terms of primary and secondary consistency characteristics [2]. The main consistency characteristics are the static physical proportions and the secondary characteristics are the reactions of the cloth to the dynamic force applied [3]. Stitches are accustomed to be a part of the clothing element along and seams characterize the form of the outfit for wear and typically for ornamental functions. These factors along with their performance properties improve the quality of the clothing [4]. The quality of the fabric affects not only the quality of the clothing, but also the ease with which a smooth structure can produce a shell structure [5]. More attention has been given in current years to the design, comfort and fitness of apparel in the textile industry. The most important features required from a garment are consistency, durability, serviceability, aesthetics and compliance. Style and aesthetic beauty are also relevant to consumers perception [6]. Clothing manufacturers are mainly interested in the tributary appearances of the fabric and focus on the quality of the seam during the manufacturing and production of clothing while applied to active coerce [7].At present, the garment industry has adopted various parameters to evaluate the seam performance of commercial fabrics, such as the seam efficiency which is used to assess seam durability [8]. It should be noted that the durability of the seam represents the relationship between the strength of the seam and the strength of the fabric. Predicting the performance of a seam on a fabric based on the properties of the fabric and the sewing parameters, has been considered by many researchers; indeed, many studies have been conducted to predict the effect of seam performance [9] [10]. Specifically, seam drops a line to the fabric components to ensure the durability of the best products [11]. The visual and technical requirements of dress depend on various specifications [12]. The design and competence of the seams depend on the stitch and fabric forms, the stitch width, the configuration of the sewing machine and the consistency of the sewing threads while the seam output of the garment depends on the structural and mechanical properties of the fabric along with the strength, extensibility, protection, flexibility, beauty and quality of the seams [13]. The fabric with the proper seam class enhances the serviceability and resilience of functional features of clothing [14]. Seam strength affects the functional and aesthetic performance of the clothing in terms of reliability and durability [15]. Clothing manufacturers set standards as guidelines for product development, and these standards are based on customers' preferences [16] [17]. Tensile strength and stitching properties are key performance indicators to guarantee whether the end product is suitable for end-use [18] [19].

2. Experimental Methodology

2.1. Material

2.1.1. Fabric

- The fabric selected for this experiment was 100% cotton pain woven fabric. The GSM (gram per square meter) of the fabric was 104, EPI (Ends per Inch) and PPI (Picks per Inch) were comprised about 114 and 64 respectively along with warp yarn count and weft yarn count were both accounted for 70s/1 Ne.

2.1.2. Sewing Parameters

- To continue this study, four different types of stitches were used (lockstitch, three thread flatlock stitch, four thread overlock stitch and chain stitch). Different sewing machines (Brand name: Juki, Kansai, Yamato) were employed to produce these stitches. Stitch density was accounted for 6, 8, 10 and 12 and needle size was 14.

2.1.3. Sewing Thread Specification

- For this experiment, three different types of sewing thread count was used like 40s/2, 50s/2 and 60s/2 Ne respectively. All of the threads were spun polyester with double ply formation. Besides these materials, the following materials were also used-• Measuring Tape• Electronic balance• Tensile Strength Tester (James heal)• Scissor and tailoring chalk

2.1.4. Tensile Strength Testing Machine Specification

- • Name: Titan Universal Strength Tester• Model No.: Titan5• Company: James Heal (Richmond Works)• Origin: United Kingdom

| Figure 1. Universal Tensile Strength Testing Machine (James Heal) |

2.2. Methodology

- The experiment was performed by ASTM method for sample preparation and testing. Five samples from each stitch type (lockstitch, four thread overlock, three thread flatlock and chain stitch) along with sewing thread count (40s/2, 50s/2, 60s/2 Ne) with different stitch density (6, 8, 10, 12) were employed to conduct the study. Then Sewn fabrics were tested for seam strength and efficiency on James heal tensile strength testing machine at a speed of 305 mm/min and 75 mm gauge length as per ASTM-D1683 standards [20]. Five tests were conducted consecutively in warp direction for each sample. The tensile strength of un-seamed fabric was measured by James Heal tensile strength testing machine and the result was found about 702N. For seam strength testing, the sample of (10×10) cm2 was cut from the base fabric and sewn in warp direction with seam allowance of 1 inch. Seam efficiency was measured by following formula: Seam efficiency (%) = (Seamed fabric tensile strength / Un-seamed fabric tensile strength) × 100

3. Results and Discussion

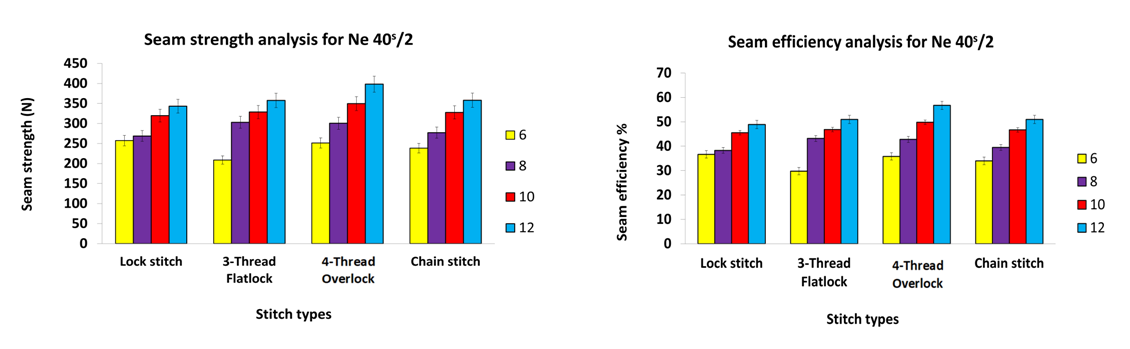

3.1. Determination of Seam Strength and Efficiency for Ne 40s/2

| Figure 2. Seam strength and efficiency for Ne 40s/2 |

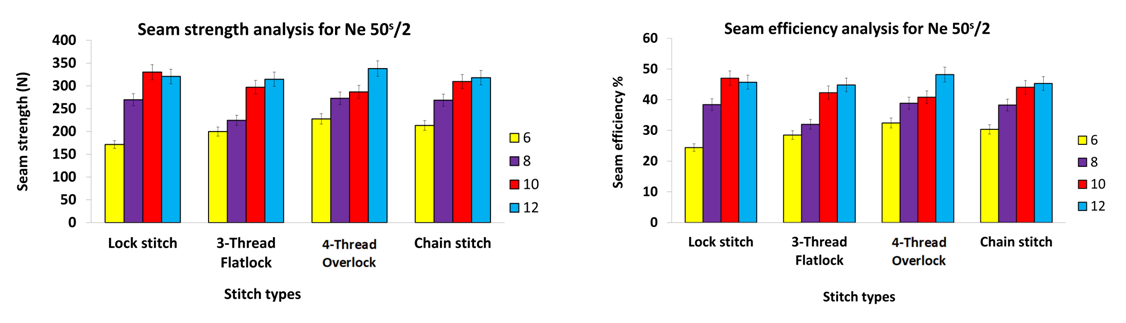

3.2. Analysis of Seam Strength and Efficiency for Ne 50s/2

| Figure 3. Seam strength and efficiency analysis for Ne 50s/2 |

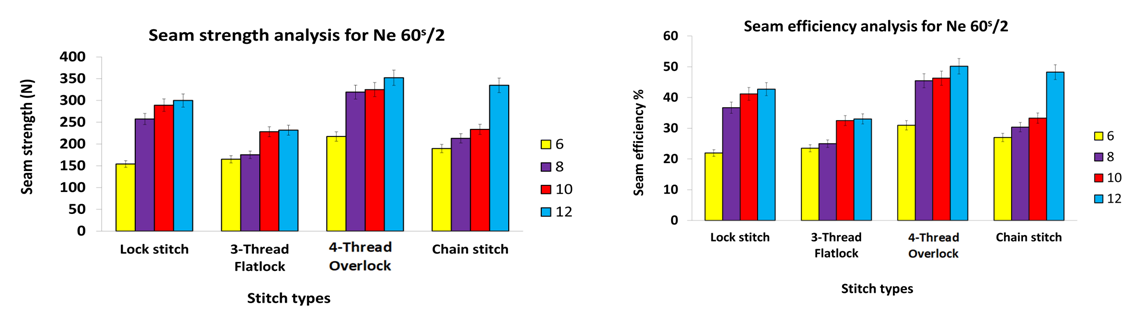

3.3. Formulation of Seam Strength and Efficiency for Ne 60s/2

| Figure 4. Seam strength and efficiency analysis for Ne 60s/2 |

4. Conclusions

- In this work, 100% cotton plain woven fabric was used to understand seam performance in context with seam strength and efficiency because this kind of fabric is commercially available around the world more than any other fabrics. Three different types of sewing thread along with four different types of stitches in warp direction and four different stitch density were used to measure seam performance. It has been clearly noticed that, seam strength and efficiency increased while surging the stitch density upon different stitch structures like lockstitch, three thread flatlock stitch, four thread overlock stitch and chain stitch for 100% cotton plain woven fabric. Among the stitch density 6, 8, 10 and 12; 6 SPI was recorded as low quality due to smaller number of stitches present in seam line which results in meagre seam strength along with efficiency. By increasing the amount of stitch density like 8, 10, 12; for each type of stitch structures like lockstitch, three thread flatlock, four thread overlock, chain stitch; overlock stitch encompasses seam structure by means of several threads to latch individual edge averting it from fraying successively and for 12 SPI, it shows the best performance than other stitch density in case of Ne 40s/2 rather than other counts. Based on the results of this study, apparel manufacturers will be mindful about the use of suitable threads and stitches for garments sewing. Such kind of knowledge will help consumers and manufacturers to achieve the desired results from end products in terms of the seam.

Compliance with Ethics Requirements

- This article does not contain any studies with human or animal subjects performed by any of the authors.

ACKNOWLEDGEMENTS

- The authors gratefully acknowledge the Research Cell of Mawlana Bhashani Science and Technology University for financial support of this work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML