-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2019; 8(2): 31-37

doi:10.5923/j.textile.20190802.01

Physical Change of Various Knitted Fabrics by Stentering & Compacting

Asif Shahriar

Department of Textile Engineering, Daffodil International University, Dhaka, Bangladesh

Correspondence to: Asif Shahriar , Department of Textile Engineering, Daffodil International University, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In my thesis I wanted to show different type of physical property changes due to different Type of machine applied in different type of fabric structure. Here I have worked with knitted fabric and also used knit finishing machine. In my thesis I have given some technical data and some valuable information how we can follow the buyer instruction and maintain proper use of machine to constant physical property of the fabric. Knitted fabric is not dimensionally constant, so we have to maintain shrinkage as well as maintaining the dia and GSM. Here I have shown comparison between machine to machine and the variation between fabric to fabric.

Keywords: Knit Fabrics, GSM, Shrinkage, Stentering, Compacting

Cite this paper: Asif Shahriar , Physical Change of Various Knitted Fabrics by Stentering & Compacting, International Journal of Textile Science, Vol. 8 No. 2, 2019, pp. 31-37. doi: 10.5923/j.textile.20190802.01.

Article Outline

1. Introduction

- The study that reported in this thesis basically a survey type work. For proper data collection and analyzing I have gone Different knit composite factory. For my thesis I have used stenter machine and compacting machine. But this machine cannot found in lab because they are so expensive. That why I have worked in the floor during production running. So some information may be incorrect or missing. But I have tried hard to give them accurate value.In my thesis I want to explain about changes of Dia, GSM and Shrinkage in different structural fabrics. Here I also discuss to follow buyer requirement what type to decision we have to take for machine and also fixing shrinkage issue.Here I have also discuss about how shrinkage may vary by changing Dia and overfeed of a stenter.

2. Equipment Needed for the Test

- 1. Knitting machine for different type of fabric such as Single Jersey, Interlock and Lacost fabric.2. De-watering Machine with Squeezer3. Stenter Machine4. Compactor Machine5. GSM Cutter6. Spectrophotometer etc

3. Experimental Details

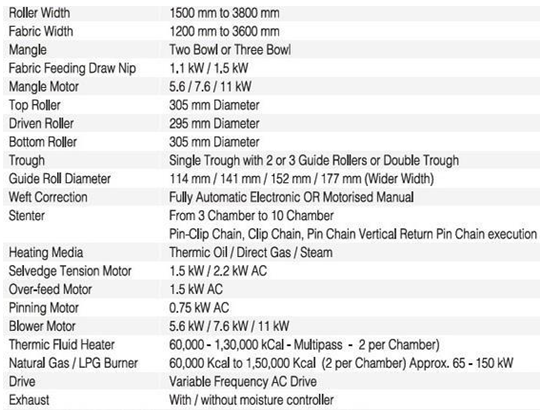

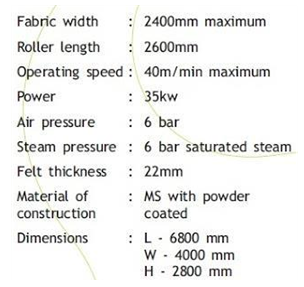

- Technical Data of Stenter Machine:

Technical Data of Open Width Compactor:

Technical Data of Open Width Compactor:

4. Factor Consideration

- Shrinkage control:-Shrinkage is controlled by proper over feeding.-To apply less or more over feed speed fabrics reduce along to length and increase along to width. Maximum 70 – 75% shrinkage is controlled by using it.GSM Control:- GSM is also controlled by applying proper over feeding speed.- If over feed is more than GSM is also more.- If Over feed speed is less then GSM is also is less.- If Dia is more than GSM of the fabric will less.- If Dia is less than the GSM of the fabric will more.N.B: If GSM of the fabric is OK then shrinkage is also OK.Dia Control:- Dia is controlled by dia controlling meter scale.- If any fault, GSM of the fabric is reduced then to increase the GSM of the fabric dia will have to be reduced (2 – 3) inch.- If Over feed speed is more thanDia of the fabric will be more.- If Over feed speed is less thenDia of the fabric will be less.- If length is more than width of the fabric is reduced.- If length is less then width of the fabric is more.N.B: Fabric speed is controlled on the fabric dia. Here, Dia less or More fully depends on yarn count and buyer order. Dia is done less or more by using expander rod.

5. Effect of Different Machines on Different Structural Fabrics

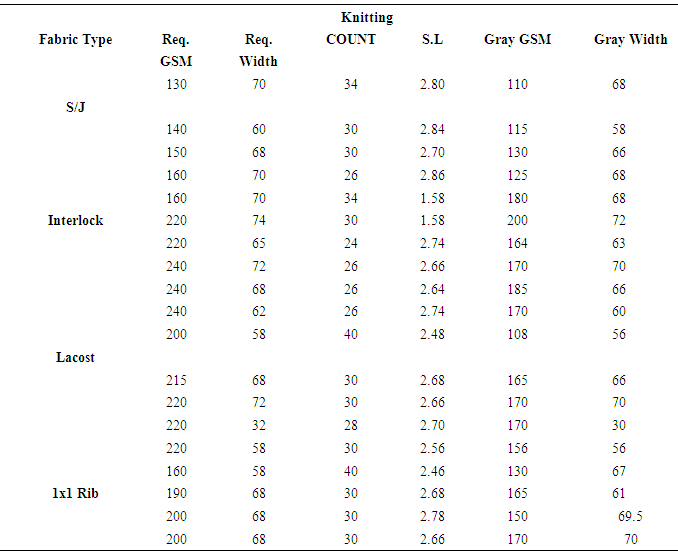

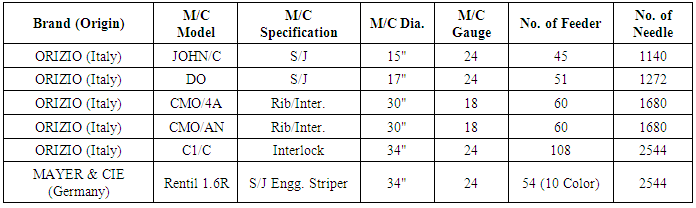

- Effect of different fabric structure by using Knitting Machine:Specification of Knitting Machine:

|

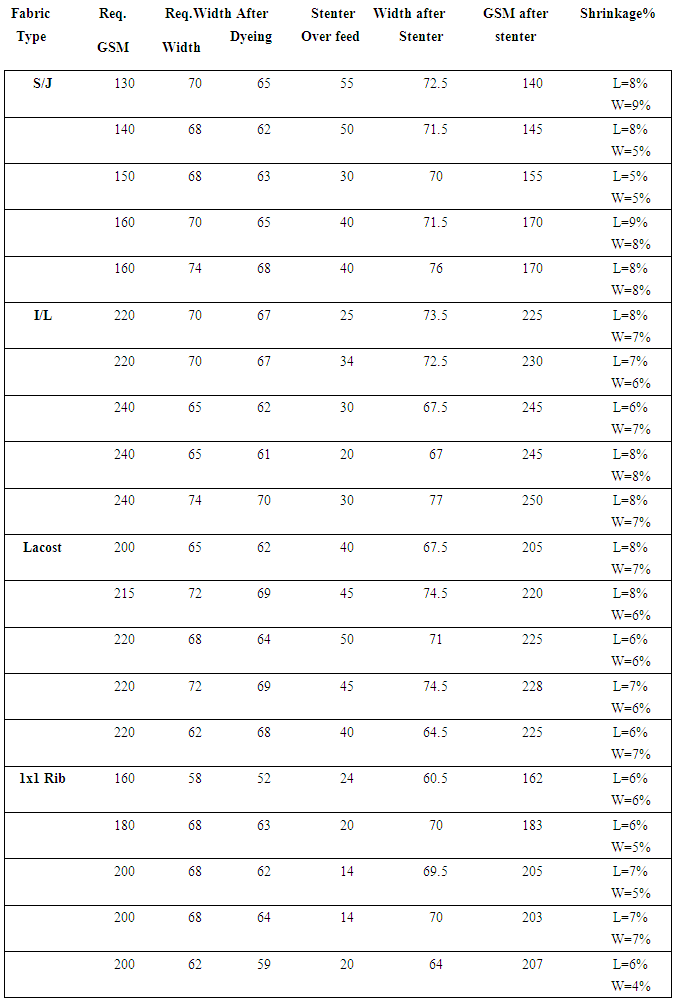

6. Using Stenter Machine

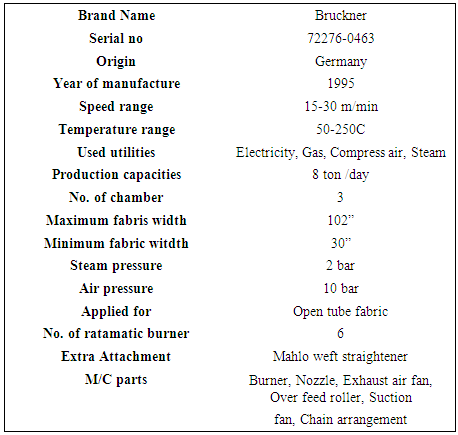

- Specification of a Stenter Machine:

|

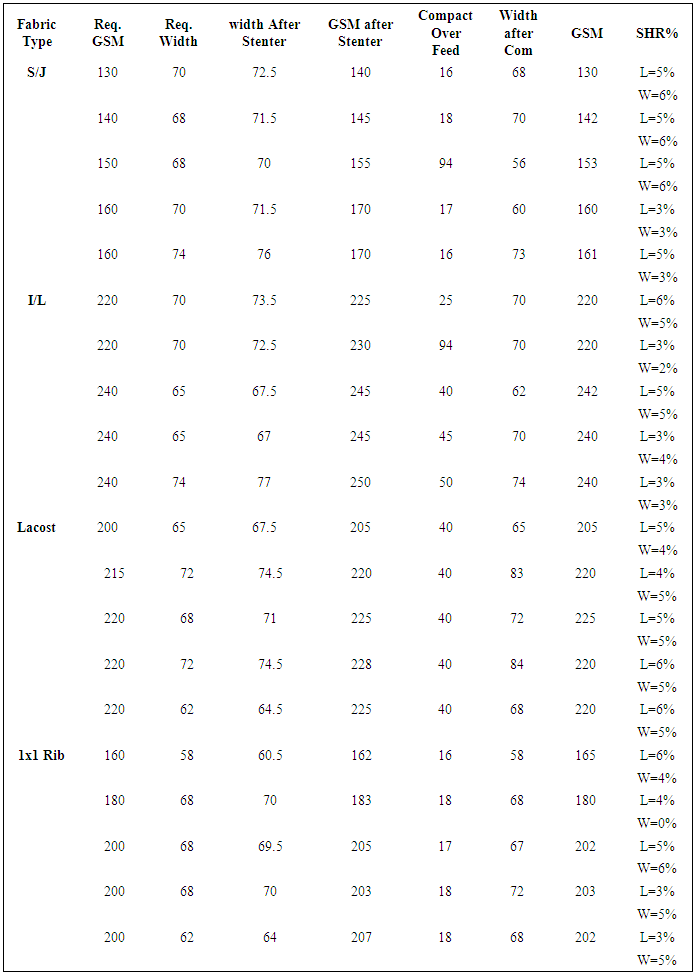

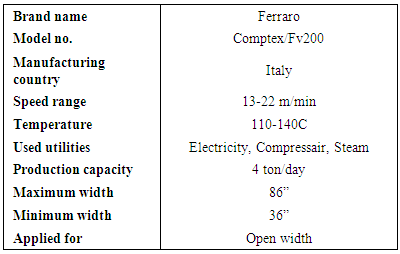

7. Using Compactor Machine

- Specification of Open Width Compactor Machine:

|

8. Discussion of Result

- Required GSM VS Finished GSM:It can be seen in Table 2 that knitting GSM is always less than finished GSM for all types and structures of fabrics, because after knitting fabric need to be dyeing and finishing. If dyestuff added in the fabric, its GSM must be increase and after softener added as finishing process GSM also increases. To follow the buyer requirement for GSM we have to look after the gray GSM very well. If GSM is more than buyer require GSM, the will not pay for excess weight and factory will face problem.Effect of steter:Effect of stenter on width: It can be seen in Table 1 that if tension applied to the fabric widthwise its Dia will be increase but shrinkage will be increase. As we have to follow buyer require width, we have to look after the shrinkage as well. If width increase shrinkage will be high and higher shrinkage means lower quality for garments. So we have to give Over Feed in order to increase dia and for better shrinkage.Effect of stenter on GSM: It can be seen in Table 1 that for following buyer requirement GSM; we have to look for dia of the fabric and also shrinkage of the fabric. If GSM is less quality of the fabric will also be decrease. To keep constant GSM Dia, Shrinkage and Overfeed must be perfectly follow-up.Effect of stenter VS fabric structure: It can be seen in Table 1 that different types of fabric have different type of nature. For example Single Jersey fabric GSM maintain is difficult rather than 1x1 RIB and Interlock fabric. Dia controlling and shrinkage controlling may vary for different structure fabric. Sometime less overfeed needed for other fabrics rather than single jersey. This happens because of their structural behavior. Single jersey fabric is more flexible than other structural fabric, so speed of fabric processing also varies.Effect of Compacting:Effect of compactor on width: It can be seen in Table 3 that if tension applied to the fabric widthwise its Dia will be increase but shrinkage will be increase. As we have to follow buyer require width, we have to look after the shrinkage as well. If width increase shrinkage will be high and higher shrinkage means lower quality for garments. Compactor usually increases Dia by compaction using blanket, so here width must be shorter than stenter.Effect of compactor on GSM: It can be seen in Table 3 that for following buyer requirement GSM, we have to look for dia of the fabric and also shrinkage of the fabric. If GSM is less quality of the fabric will also be decrease. Compactor usually increase the GSM by compaction with blanket, so GSM must be good after stentering.Effect of compactor VS fabric structure: It can be seen in Table 3 that different types of fabric have different type of nature. For example Single Jersey fabric GSM maintain is difficult rather than 1x1 RIB and Interlock fabric. Dia controlling and shrinkage controlling may vary for different structure fabric. For compacting machine parameter may varies for fabric to fabric. For single jersey high compaction pressure applies and other fabrics low pressure applies due to their structure.

9. Conclusions

- The work reported here provide various important conclusion regarding processing in stenter and compacting machine. Some of the important findings are as follows;Finished GSM of fabric must be higher than gray GSM, because due to some process such as Dyeing and Finishing GSM increases. After dyeing process it is very important to follow the operation of stenter machine in case Dia. GSM and shrinkage, without proper maintain Dia or GSM shrinkage cannot be control.In compacting machine compaction must me proper follow up so that here GSM not over than buyer requirement and Dia and Shrinkage report must be good.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML