Asif Shahriar

Department of Textile Engineering, Daffodil International University, Dhaka, Bangladesh

Correspondence to: Asif Shahriar , Department of Textile Engineering, Daffodil International University, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

This study is based on calculation of standard minute value (SMV) of T-shirt by determining the manpower and machine allocation for particular target. It seems that there are some differences between target production and actual production. In some cases target production was higher than that actual production while in some cases the other way round .i.e. actual production was higher than target production. It may also happed due to wrong data that lead to calculation of target production. It was also observed that SMV of a T-shirt increased in terms of decorative garments and there is a decrease of productivity. On the other hand SMV was relatively for the less decorative garments so that their productivity increased.

Keywords:

SMV, T-Shirt, Operation Breakdown, Work Study, Line Balancing

Cite this paper: Asif Shahriar , The Optimization of Knitted T-Shirt for Rapid Production Process, International Journal of Textile Science, Vol. 8 No. 1, 2019, pp. 16-25. doi: 10.5923/j.textile.20190801.03.

1. General Introduction

A T-shirt (or T shirt, tee-shirt, or tee) is a style of shirt. A T-shirt's defining characteristic is the T shape made with the body and sleeves. It is normally associated with short sleeves, a round neck line known as a "crew neck", and no collar.Typically made of cotton fibers knitted in a jersey stitch, they have a distinctive soft texture compared to woven shirts. The majority of modern versions have a body made from a continuously woven tube, on a circular loom, so that the torso has no side seams. The manufacture of T-shirts has become highly automated, and may include fabric cutting by laser or water jet.The T-shirt evolved from undergarments used in the 19th century, through cutting the one- piece "union suit" underwear into separate top and bottom garments, with the top long enough to tuck under the waistband of the bottoms. With and without buttons, they were adopted by miners and stevedores during the late 19th century as a convenient covering for hot environments.Objects of the Project Work× To calculate the SMV of T- shirt. × To determine line balancing× To determine operational sequence of the manufacturing process of T-shirt × To develop the target of the manufacturing process× To increase the productivity of the company × To make proper distribution of SMV× To make better utilization of man, machine and materials

2. Methodology

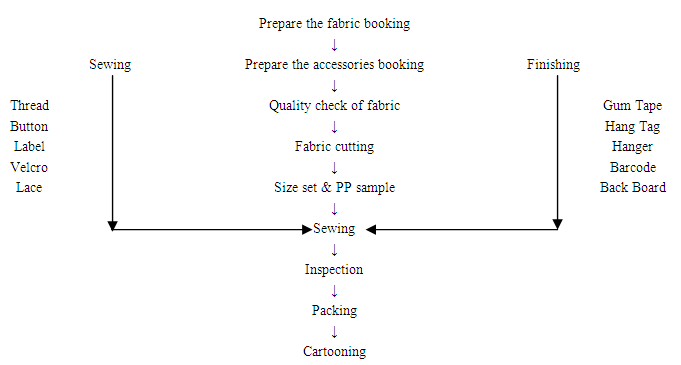

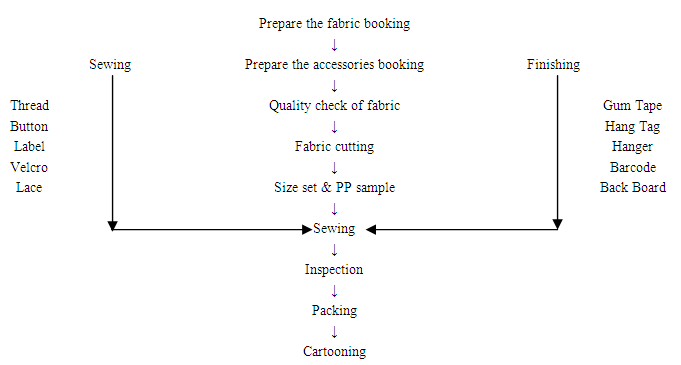

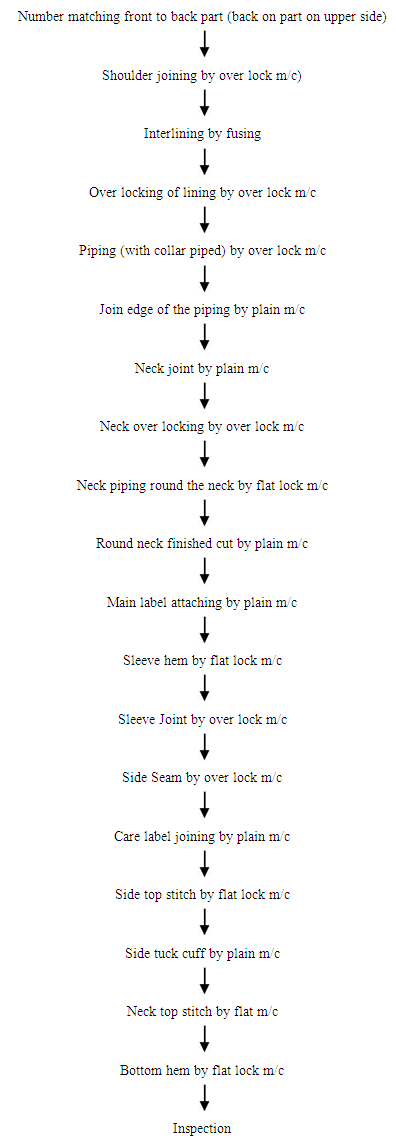

Production of a Knit T-shirtIn sewing section there are various types of product are produced such as T-shirt, polo shirt, tang top, Hollywood style, jersey top, jacket, hoody jacket, under wear, trouser, sportswear, swimming wear and so on. The production details of a knit T-shirt is given below’Tools used in Cutting Section:ü Pattern paperü Measuring Tapeü Scissorü Pencilü Eraserü Curve RulerMethod of making t-shirt:First of all a pattern is required. This was adopted from an existing shirt. A size 4 t-shirts sample from vintage sew for Toddler was used. The patters of the sample were adopted from the pattern book available in Knit Asia ltd. The patterns were then traced onto freezer paper. It can be seen on close looking that the wrong size was traced first. What happened there is not rembered by me but it was one of the two tracings I have of this pattern. Front, back, sleeve and background- these are the 4 pieces my pattern has.A pretty big piece of fabric is owned by me, so to waste the least amount of fabric and also be able to manage the whole thing one pattern piece was cut out by me at a time. The front is started first – the center from the edge needs to be on placed on the fold of the fabric. By looking closely at the fabric it is made sure by me that tiny knit stitches are running straight (not at an angle) with fold line. Also, the stretch of this fabric is going up and down in the photo, or across the body of the t-shirt front and back pattern pieces. Your knits are wanted to be cut out with the stretch going the right way.Then the same is done with back by me. First the small amount of scrap is cut off from the front and the fabric was refolded wide enough to do the back. Here my cute pattern weights can be seen. My patterns are not pinned by me- pattern weights and rotary cut around the edges of the patterns can be seen. Scissors can be used in absence of rotary cutter. My scissors need to be sharpened and a new rotary blade is needed- cutting this out wasn’t as easy and fun as it should have been.The sleeve is again refolded; so enough width to lay out the sleeve pattern is available. Can the long straight line be seen? It’s the pattern grain line and should line up with the grain of the fabric. In other words, line up with straight up and down lines of knitted stitches in the fabric. If a t-shirt was found twisting around your body when you were wearing it- it was cut off again. It’s not hard to make sure your fabric and patterns are on grain when you’re cutting.Neckline ribbing- this fabric is laid out with the stretch going left to right. The pattern piece is laid on the fold. A cotton/lycra rib knit is used for this piece, if main shirt fabric is ribbed or fairly stretchy, the same fabric can be used for the neckline. This shirt fabric is a jersey that’s not really stretchy enough to go over my boy’s head and not have stitches pop right away.Sewing:Sewing step 1: Place front and back pieces together with right sides facing. Match the pieces up at the shoulder and pin them if you want. Here they are serged together. Before I had a serge I would sew the seam, then zigzag the edges together because I don't like unfinished edges.Sewing step 2: Pin the top center of the sleeve to the shoulder seam.Pin the front and back edges of the sleeve seam. This is kind of difficult to show in a photo.Sewing step 3: Fold the shirt so the front and back line up and the sleeve edges line up. Starting at the sleeve hem edge, and all at once, sew the sleeve edges together, then the front and back together at the sides. Do both sides.Sewing step 4: Sewing the neckband on is explained here in T-shirt.Sewing step 5: Fold the sleeve edges and bottom edge up once and stitch in place. I have a "why you don't need a free arm to sew hems of small sleeves".To make a T-shirt Single jersey knitted fabric for body, Rib for neck, Sewing thread, Pattern paper, Measuring Tape, Scissor, Pencil, Eraser, Curve Ruler etc are required. The various component of a T-shirt are neck, front part, back part, sleeve and hem. Flow Chart of Making T-shirt

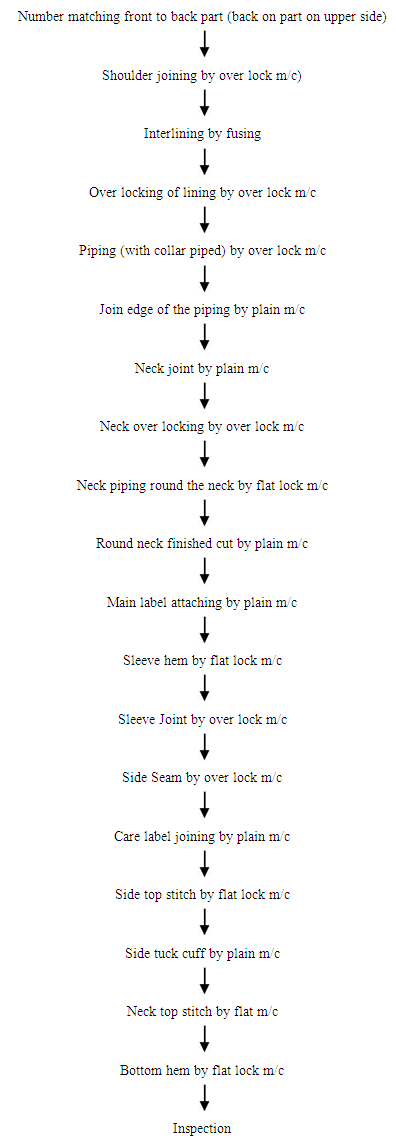

Flow Chart of Making T-shirt MACHINE SEQUENCE OF T-SHIRT MANUFACTURE PROCESS:

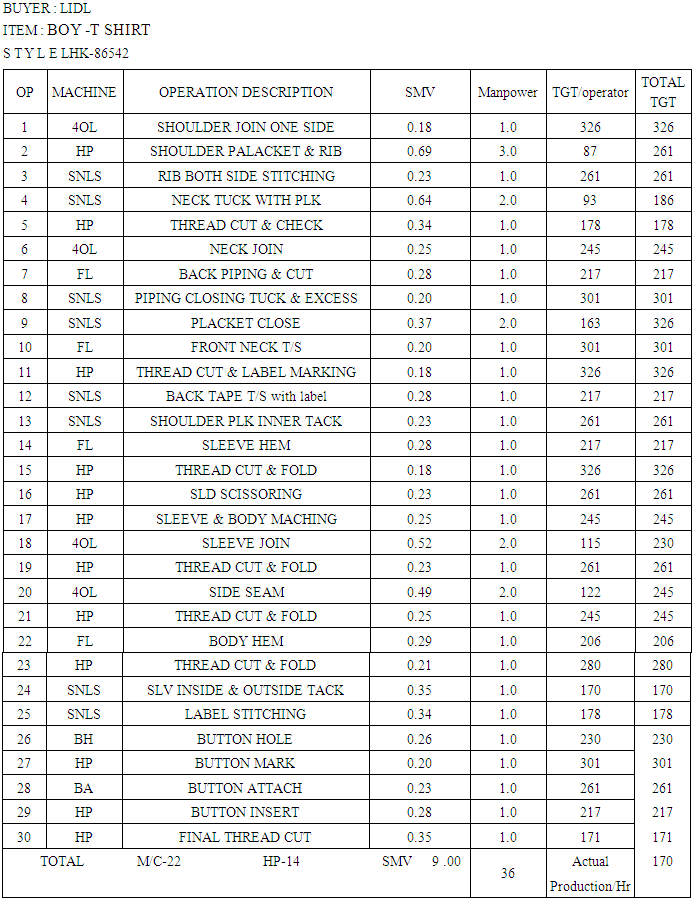

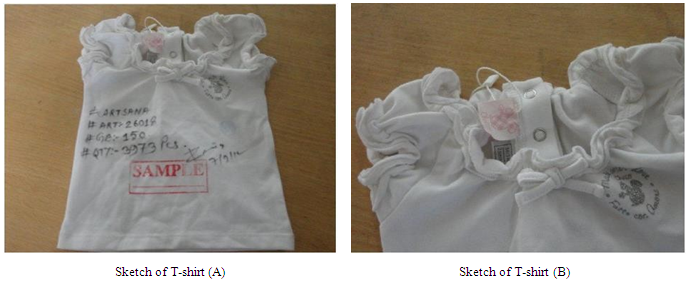

MACHINE SEQUENCE OF T-SHIRT MANUFACTURE PROCESS: Study on T-Shirt:Figure of T-Shirt (Item-1)

Study on T-Shirt:Figure of T-Shirt (Item-1) Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.

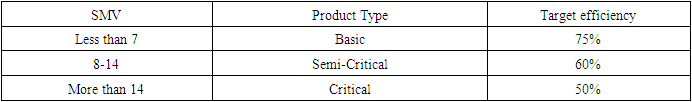

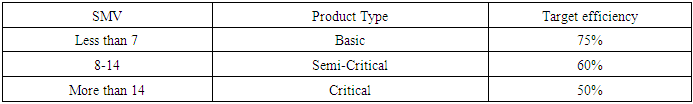

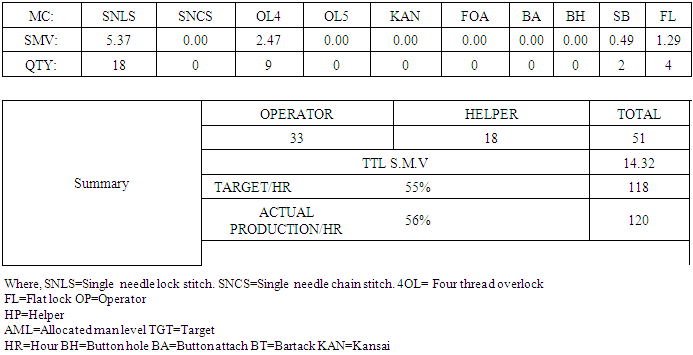

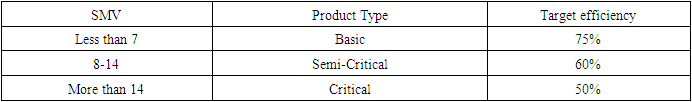

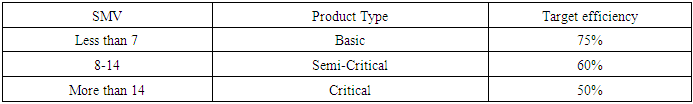

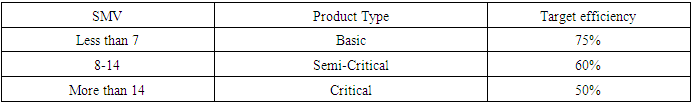

Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.Table 1. SMV Wise Target Efficiency

|

| |

|

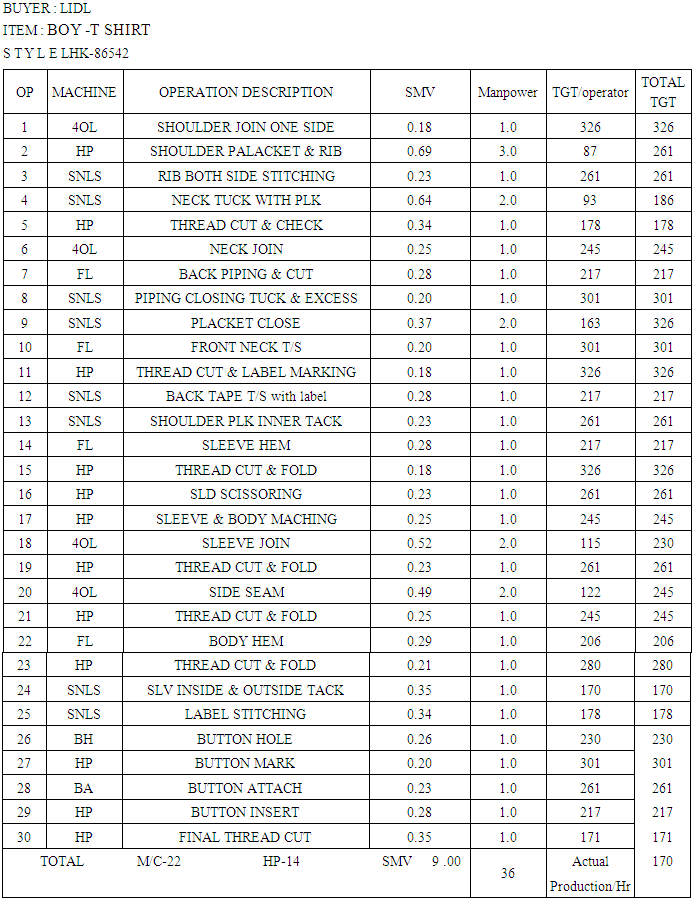

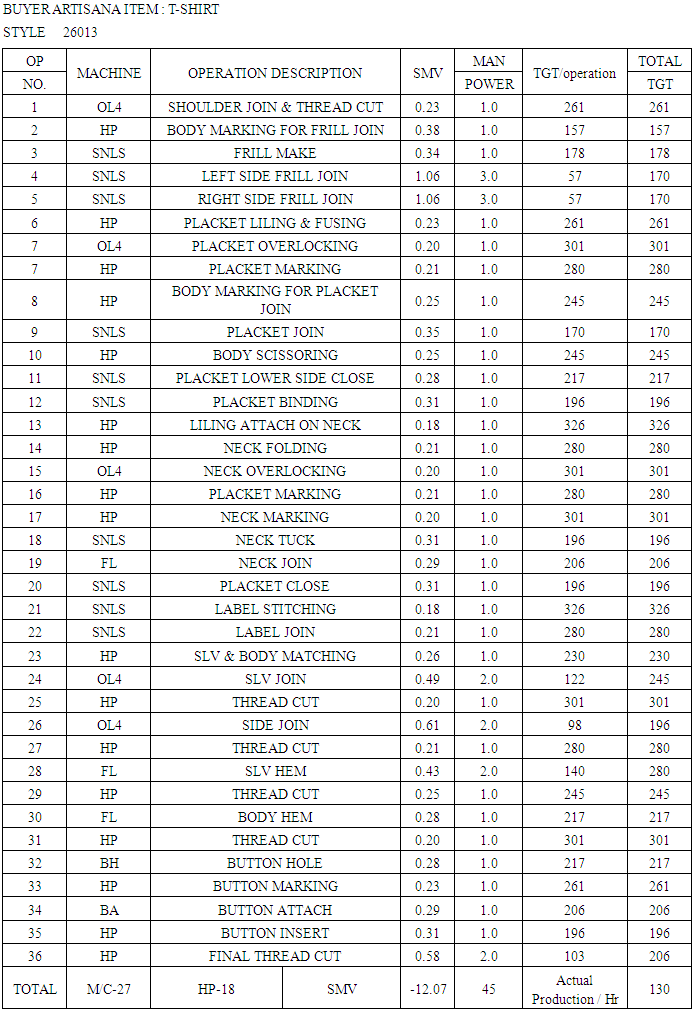

Table 2. Operation Bulletin

|

| |

|

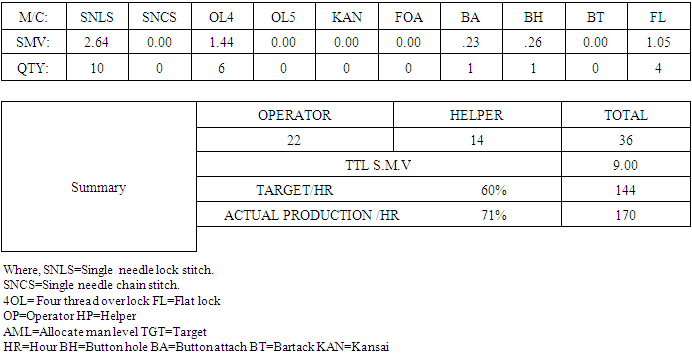

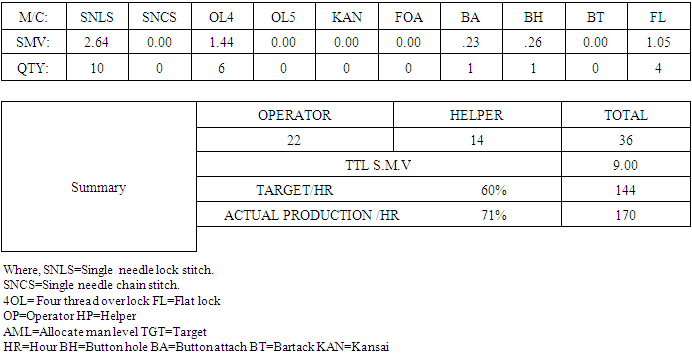

Calculation of Target/hrsFormula:60% Efficiency Target= Manpower X Working Minute X Expected Efficiency Percentage/SMV60% Target = 60 X 36 X 0.60/ 9.00 =144Where, 1hrs=60 minTotal Manpower = 36Expected efficiency =60% SMV=9.00Per hrs target = 144Table 3. Summary of man, machine, SMV, target per /hrs & expected efficiency

|

| |

|

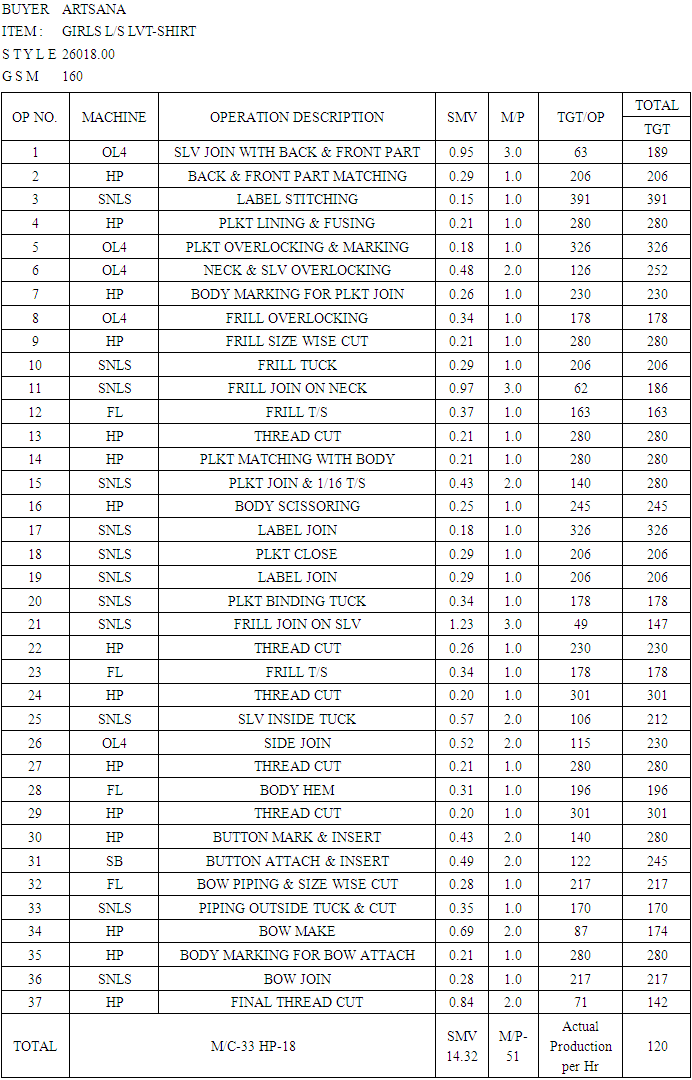

Study on T-ShirtThis T-shirt make S/J fabric & operation bulletin make man, machine, SMV, target per/hrs & expected efficiency. Where this t-shirt order from buyer – artsana, style no -26018.Figure of T-Shirt (Item-2) Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.

Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.Table 1. SMV Wise Target Efficiency

|

| |

|

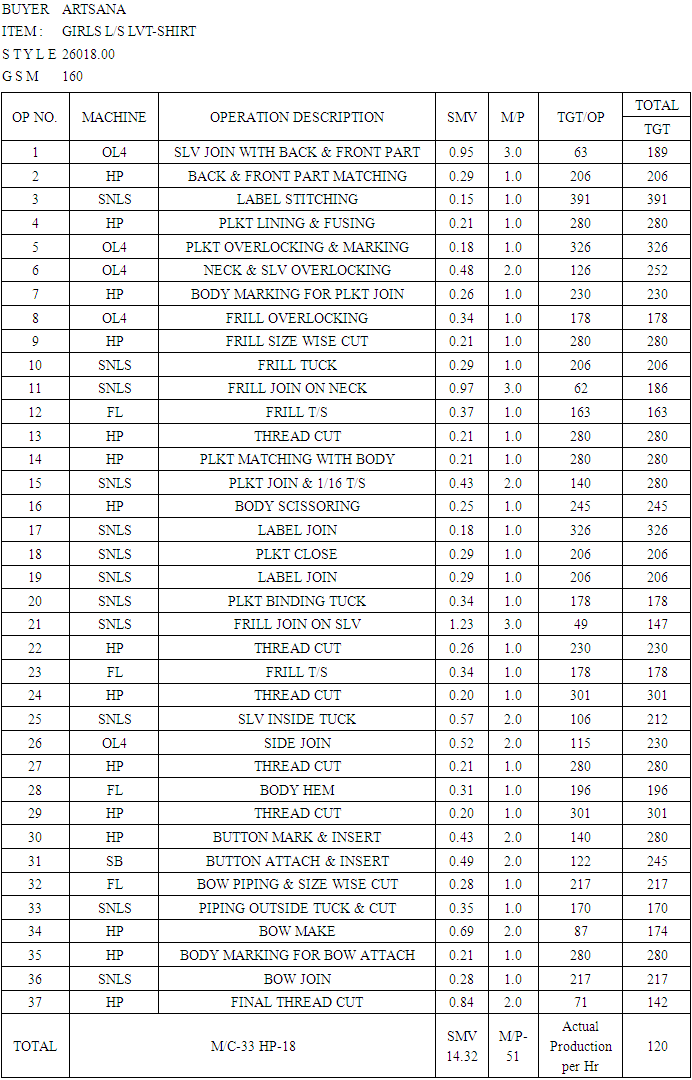

Table 2. Operation Bulletin

|

| |

|

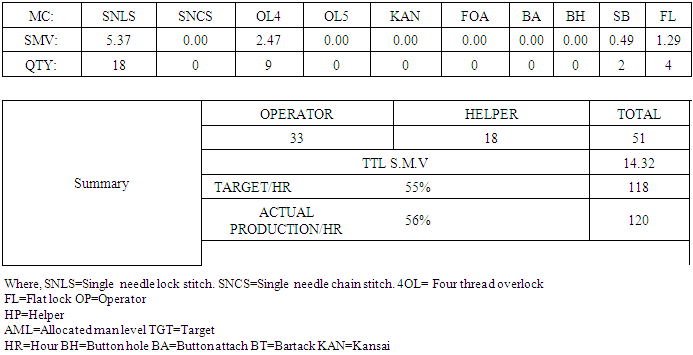

Calculation of target/hrs:Formula:55% Efficiency Target= Manpower X Working Minute X Expected Efficiency Percentage/SMV55% Target= 60 X 51 X 0.55/ 14.32=118Where, 1hrs=60 minTotal Manpower = 51Expected efficiency =55% SMV=14.32Per hrs target = 144Table 3. Summary of man, machine, SMV, target per /hrs & expected efficiency

|

| |

|

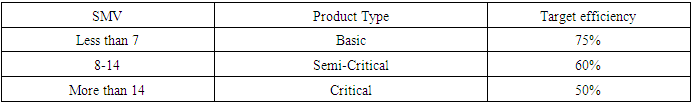

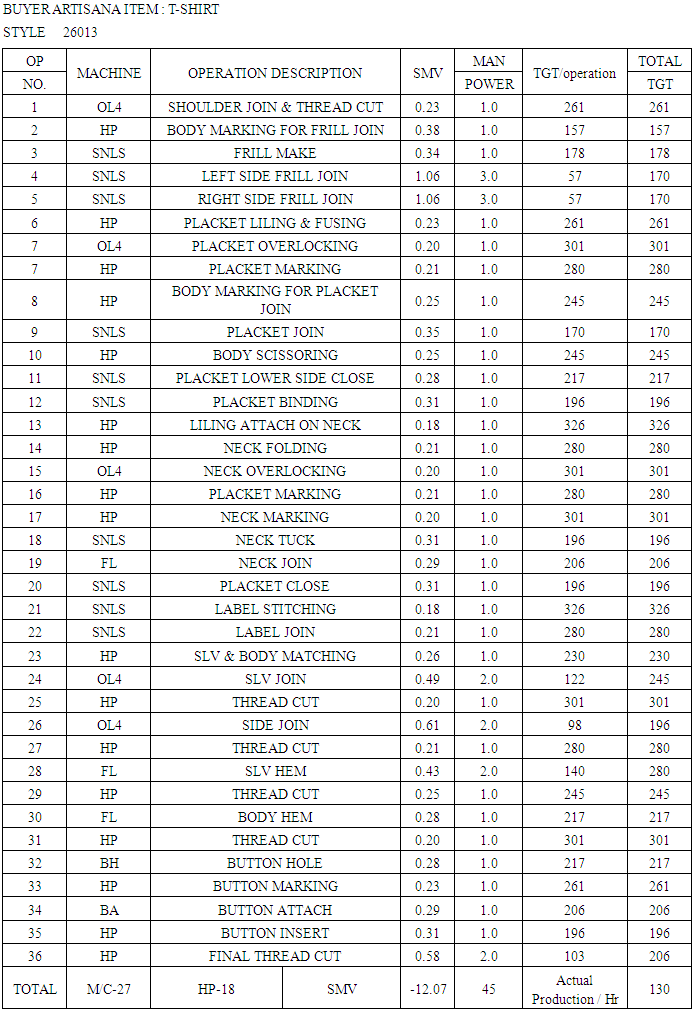

Study on T-shirtThis T-shirt make S/J fabric & operation bulletin make man, machine, SMV, target per/hrs & expected efficiency. Where this t-shirt order from buyer – artsana, style – 26013.Figure of T-Shirt (Item-3) Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.

Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.Table 1. SMV Wise Target Efficiency

|

| |

|

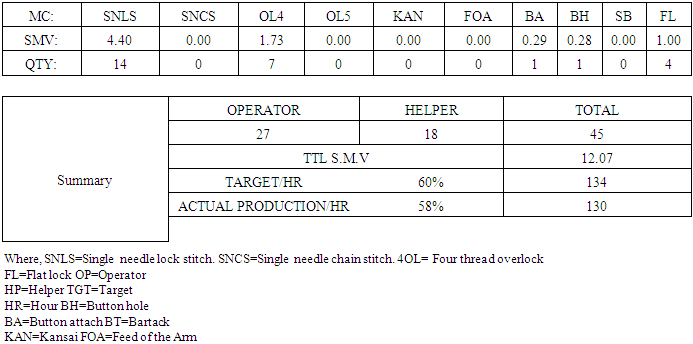

Table 2. Operation Bulletin

|

| |

|

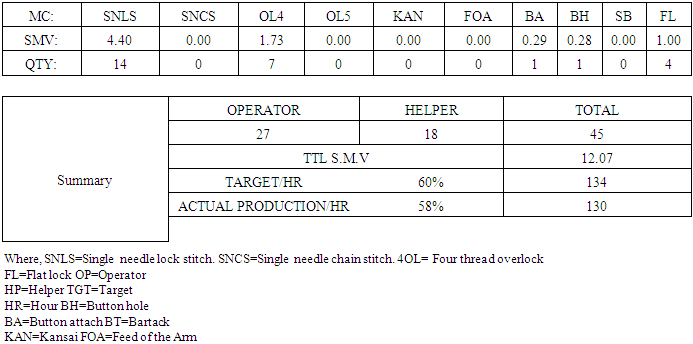

Calculation of Target/hrs-Formula:60% Efficiency Target= Manpower X Working Minute X Expected Efficiency Percentage/SMV60% Target= 60 X 45 X 0.60/ 12.07=134 Where,1hrs=60 minTotal Manpower = 45 Expected efficiency =60%SMV=12.07Per hrs target = 134Table 3. Summary of man, machine, SMV, target per/hrs & expected efficiency

|

| |

|

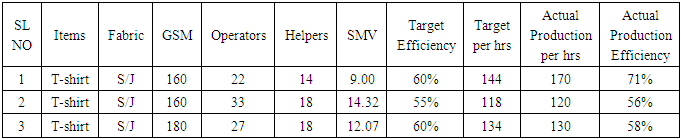

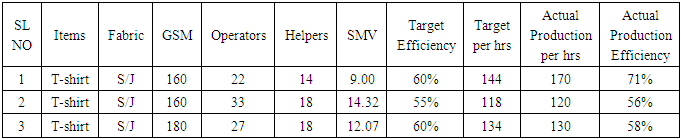

Table 4. Summary of production details of the three garments

|

| |

|

3. Results & Discussion

Explanation for Different Target Efficiency Basic Type ItemsIt can be seen in tables 1, 2, 3 that the number of processes are less than that of semi-critical and critical type product. The tables also show that the time required for machine setup and technical support are less than semi-critical and critical type product. It is also seen in that tables the time for products are also less than semi-critical and critical type product.Semi-Critical Type Items:It can be seen in tables 1, 2, 3 that the number of processes are more than basic type product. The tables also show that the time required for machine setup and technical support are more than basic type product. It is also seen in that tables the time for products are also less than basic type product.Critical Type Items:It can be seen in tables 1, 2, 3 that the number of processes are more than basic & semi-basic type product. The tables also show that the time required for machine setup and technical support are more than basic & semi-basic type product. It is also seen in that tables the time for products are also more than basic & semi-basic type product.Effect of SMV on ProductionIt can be seen in table 4 that as the SMV decreases production increases and vice versa.Effect of SMV on OperatorIt can be seen in table 4 that as the SMV increases operator also increases.

4. Conclusions

It seems that there are some differences between target production and actual production. In some cases target production was higher than that actual production while in some cases the other way round .i.e. actual production was higher than target production. It may also happed due to wrong data that lead to calculation of target production. It was also observed that SMV of a T- shirt increased in terms of decorative garments and there is a decrease of productivity. On the other hand SMV decreased on the less decorative garments. As a result productivity of garments is increased. Above discussion it is clear that current SMV calculation is the key factor for garments productivity.

References

| [1] | RahmanMizanur, (Thursday, 06 December 2012). RMG sector: Secret of success and causes of unrest, senior vice- p resident (IBBL). |

| [2] | Berg Achim, November 2011, Principal, McKinsey’s Frankfurt, Co-coordinator, McKinsey’s Apparels, Apparel, Fashion & Luxury Practice. |

| [3] | Mücella G. Güner, Can Ünal, Department of Textile Engineering, Faculty of Engineering, University of Ege, Izmir, Turkey, Line Balancing in the Apparel industry Using Simulation Techniques, FIBRES & TEXTILES in Eastern Europe April / June 2008, Vol. 16, No. 2 (67), p-75. |

| [4] | Glock, R. E. & Kunz, G. I. (1995). Apparel Manufacturing-Sewn Product Analysis, Prentice Hall, New Jersey, p:4. |

| [5] | Chuter, A. J. (1988). Introduction to Clothing Production Management, Blackwell Science, Oxford, pp. 60-63. |

| [6] | Cooklin, G. (1991). Introduction to Clothing Manufacturing, Blackwell Science, Oxford, p. 104. |

| [7] | Tyler, D. J. (1991). Materials Management In Clothing Production, BSP Professional Books Press, London. |

| [8] | Eberle, H., Hermeling, H., Hornberger, M., Kilgus, R., Menzer, D., Ring, W., (2004). Clothing Technology, Beuth-Verlag GmbH, Berlin. |

| [9] | Glock, R. E. & Kunz, G. I. (1995). Apparel Manufacturing-Sewn Product Analysis, Prentice Hall, New Jersey, p: 4. |

Flow Chart of Making T-shirt

Flow Chart of Making T-shirt MACHINE SEQUENCE OF T-SHIRT MANUFACTURE PROCESS:

MACHINE SEQUENCE OF T-SHIRT MANUFACTURE PROCESS: Study on T-Shirt:Figure of T-Shirt (Item-1)

Study on T-Shirt:Figure of T-Shirt (Item-1) Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.

Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given. Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.

Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given. Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given.

Target EfficiencyEvery garments factory has a policy to have the idea about target efficiency in advance. In fact this gives an opportunity to get the idea about time required to get certain production in advance. In table-1 the target efficiency for various SMV is given. Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML