-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2018; 7(4): 83-89

doi:10.5923/j.textile.20180704.01

Development of Software for the Adjustment of Maximum Color Variation in Auto Striped Knit Fabric

Faisal Ahmed 1, Md. Ibrahim Hossain 2, A. T. M. Faiz Ahmed 1, Dewan Murshed Ahmed 1

1Department of Fabric Engineering, Bangladesh University of Textiles, Tejgaon, Dhaka, Bangladesh

2Department of Knitting, Epyllion Group, Gazipur Sadar, Gazipur, Bangladesh

Correspondence to: Faisal Ahmed , Department of Fabric Engineering, Bangladesh University of Textiles, Tejgaon, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

In auto striped knit fabric, the number of courses in the repeat of the fabric is more than the number of feeders of the machine. Therefore a special type of machine is used to produce this type of fabric. The program plan for auto striped fabric production is a herculean task to do. The responsible personnel face a lot of challenges and difficulties in decision making while taking an order of auto striped fabric. Weather maximum utilization of machine capacity is possible or not, is it possible to modify the design to achieve maximum utilization of machine capacity, how to convince the buyer to accept the changed fabric design – are some of them. In our study, we have tried to present mathematical and analytical logic and formulas to make the designing process of auto striped fabric easy and highly accurate. In this project, we have developed a software solution which is capable of adjusting maximum colour variation in auto striped knit fabric. It is also capable of designing & simulating auto striped knit fabric and capable of performing necessary calculations as well. It will help responsible personnel to create program plan for auto striped fabric production easily, efficiently, effectively and precisely within a few minutes.

Keywords: Auto stripe, Knit fabric, Software, Knitting

Cite this paper: Faisal Ahmed , Md. Ibrahim Hossain , A. T. M. Faiz Ahmed , Dewan Murshed Ahmed , Development of Software for the Adjustment of Maximum Color Variation in Auto Striped Knit Fabric, International Journal of Textile Science, Vol. 7 No. 4, 2018, pp. 83-89. doi: 10.5923/j.textile.20180704.01.

Article Outline

1. Introduction

- Horizontal striping provides the facility to select one from a choice of several colored yarns at a machine feed position. Even without striping selection facilities, by careful arrangement of the packages of colored yarns on a large diameter, multi-feeder machine, and elaborate sequence of stripes having a depth that is repeated at each machine revolution, is obtained [1].Threads of different colors are combined in stripe form. If different dyed or contrasting colors are used at different feeds by supplying packages of colored yarn on a multi-feeder machine of a single jersey structure, a variety of horizontal stripes can be obtained on the surface of the knitted fabric [2].Horizontal Stipe can be of two types: Feeder Stripe and Engineering Stipe or Auto Stripe.When the number of courses in the repeat of the fabric is less or equal to the number of feeders of the machine, then the fabric is called Feeder Striped Fabric. Multiple fed single jersey machines with large number of feeds are usually employed for such patterns. Colored yarns are supplied alternatively in uniform manner [3].When the number of courses in the repeat of the fabric is more than the number of feeders of the machine, then the fabric is called Auto Striped Fabric. It is produced in a special type of machine usually with four or six fingers arrangement called Auto Striper or Engineering Striper Machine. This type of machine was introduced to increase the scope of striping. Selection of each striping finger is effected from a programmable microcomputer in which the design information is fed in. Solenoids above each striping finger are used to transmit striping instruction in accordance with the programme. It has an individual trapping and cutting of yarn at each finger [3].The auto striper machine is equipped with a striper device called Finger. The machine has usually 3, 4 or 6 fingers against each feeder. The fingers are centrally controlled either by a chain switch apparatus and rotating switch cams, or with the help of an electrical pre-selection and a mechanical rotary switch [4].

2. Materials and Methods

- We used Microsoft Visual Basic for the development of the software. It is a mature and rich integrated development environment (IDE). It includes the visual Windows Presentation Foundation designer codenamed "Cider", debugs at runtime, better IntelliSense support (fixes common spelling errors, corrects most forms of invalid syntax, and provides suggestions to class names when specified classes are not found).Visual Basic is a third-generation event-driven programming language and integrated development environment (IDE) from Microsoft for its Component Object Model (COM) programming model first released in 1991 and declared legacy in 2008. Microsoft intended Visual Basic to be relatively easy to learn and use. Visual Basic was derived from BASIC, a user-friendly programming language designed for beginners, and it enables the rapid application development (RAD) of graphical user interface (GUI) applications, access to databases using Data Access Objects, Remote Data Objects, or ActiveX Data Objects, and creation of ActiveX controls and objects.A programmer can create an application using the components provided by the Visual Basic program itself. Over time the community of programmers developed third party components. Programs written in Visual Basic can also use the Windows API, which requires external function declarations. [5]Microsoft started development on the .NET Framework in the late 1990s originally under the name of Next Generation Windows Services (NGWS). By late 2001 the first beta versions of .NET 1.0 were released. The first version of .NET Framework was released on 13 February 2002, bringing managed code to Windows NT 4.0, 98, 2000, ME and XP.Since the first version, Microsoft has released nine more upgrades for .NET Framework, seven of which have been released along with a new version of Visual Studio. Two of these upgrades, .NET Framework 2.0 and 4.0, have upgraded Common Language Runtime (CLR). New versions of .NET Framework replace older versions when the CLR version is the same.The .NET Framework family also includes two versions for mobile or embedded device use. A reduced version of the framework, the .NET Compact Framework, is available on Windows CE platforms, including Windows Mobile devices such as smartphones. Additionally, the .NET Micro Framework is targeted at severely resource-constrained devices [6]. Microsoft Access is a database management system (DBMS) from Microsoft that combines the relational Microsoft Jet Database Engine with a graphical user interface and software-development tools. It is a member of the Microsoft Office suite of applications, included in the Professional and higher editions or sold separately.Microsoft Access stores data in its own format based on the Access Jet Database Engine. It can also import or link directly to data stored in other applications and databases.Software developers, data architects and power users can use Microsoft Access to develop application software. Like other Microsoft Office applications, Access is supported by Visual Basic for Applications (VBA), an object-based programming language that can reference a variety of objects including DAO (Data Access Objects), ActiveX Data Objects, and many other ActiveX components. Visual objects used in forms and reports expose their methods and properties in the VBA programming environment, and VBA code modules may declare and call Windows operating system operations [7].

3. Results and Discussion

3.1. Results

| Figure 1. Parent Window |

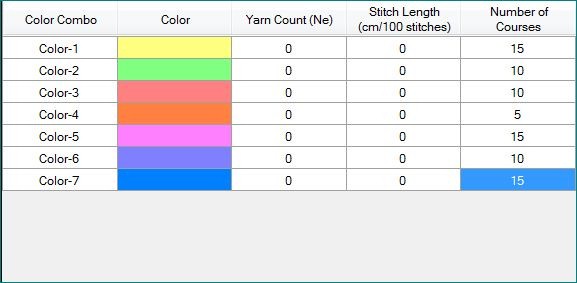

| Figure 2. Input Section |

| Figure 3. Selection of Number of Feeders |

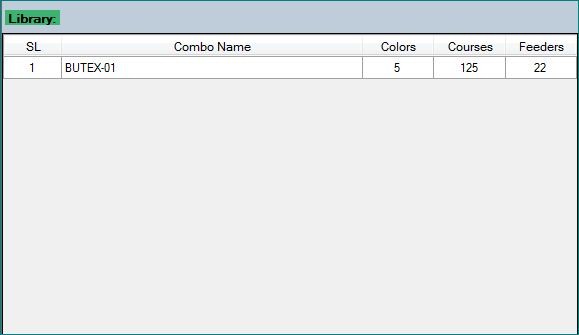

| Figure 4. Library |

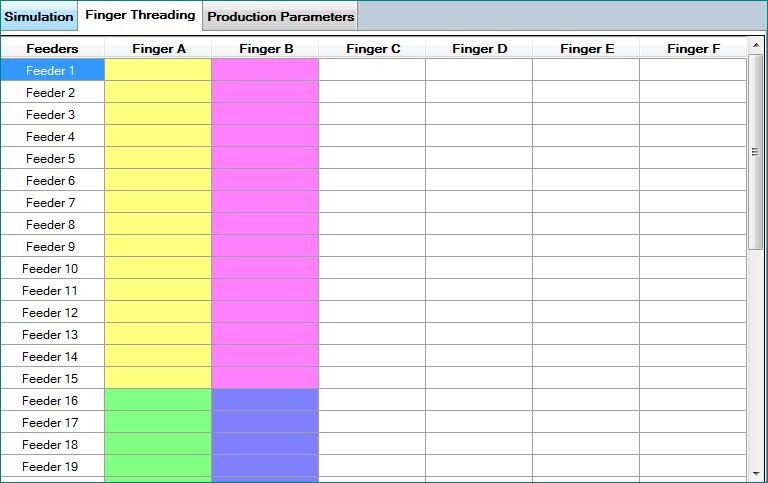

| Figure 5. Output Section (Simulation) |

| Figure 6. Output Section (Finger Threading) |

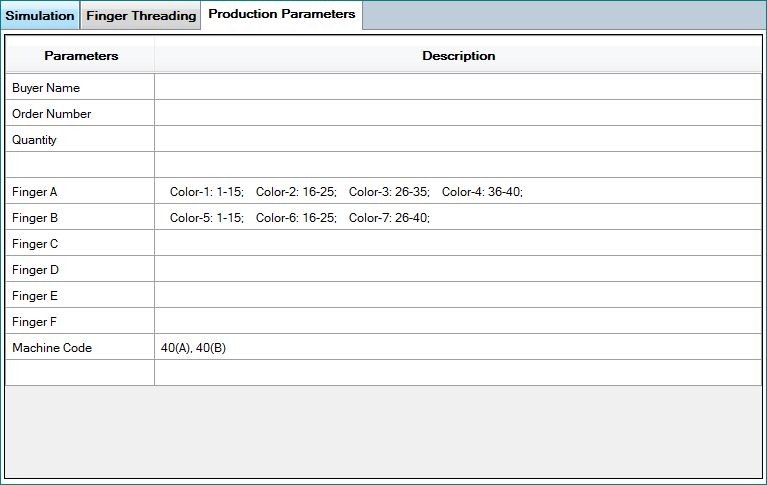

| Figure 7. Output Section (Production Parameters) |

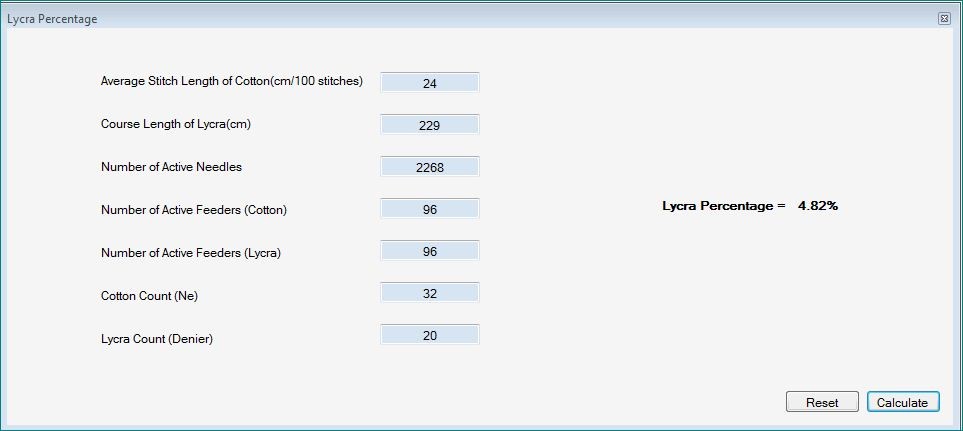

| Figure 8. Lycra Percentage |

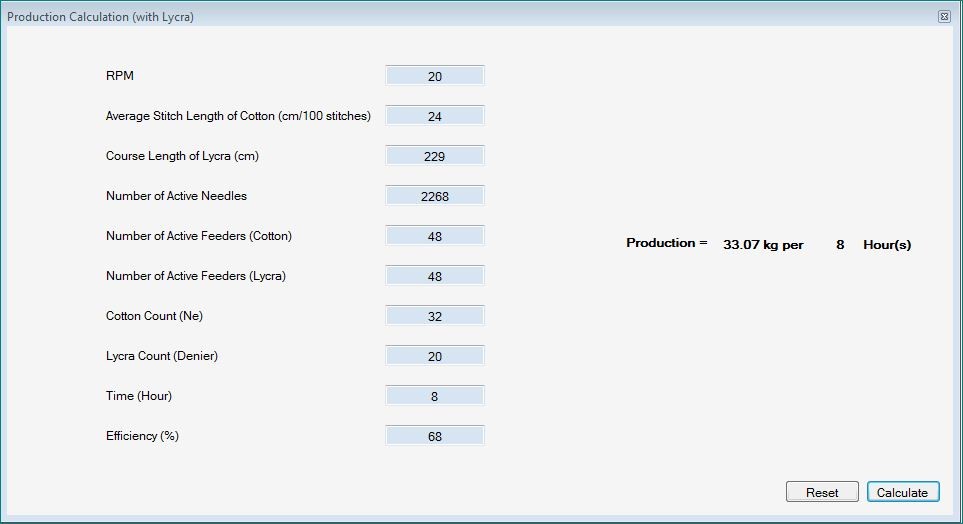

| Figure 9. Production Calculation (with Lycra) |

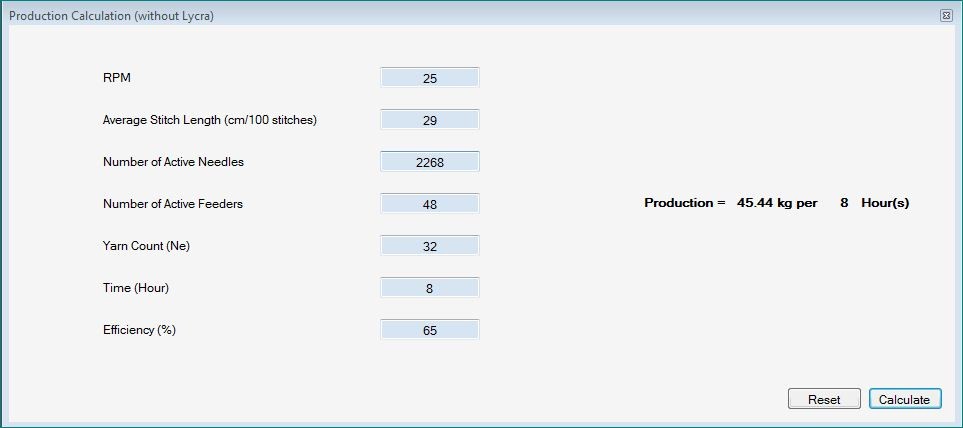

| Figure 10. Production Calculation (without Lycra) |

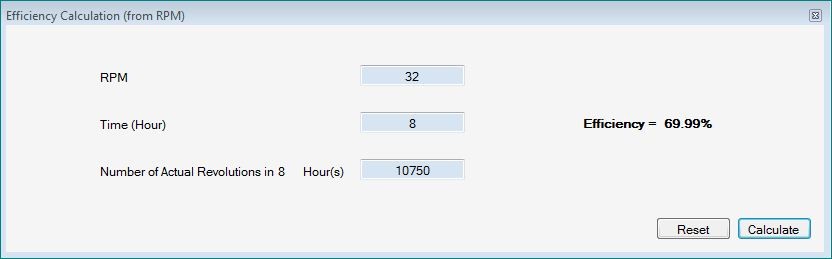

| Figure 11. Efficiency Calculation (from RPM) |

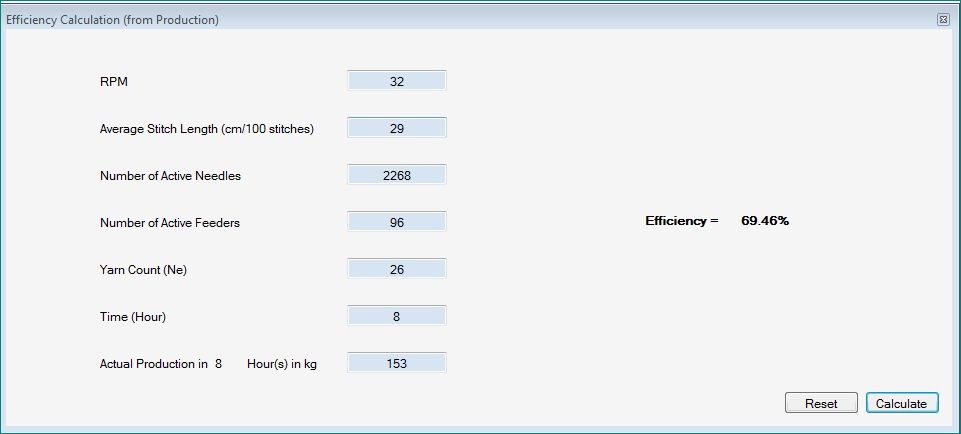

| Figure 12. Efficiency Calculation (from Production) |

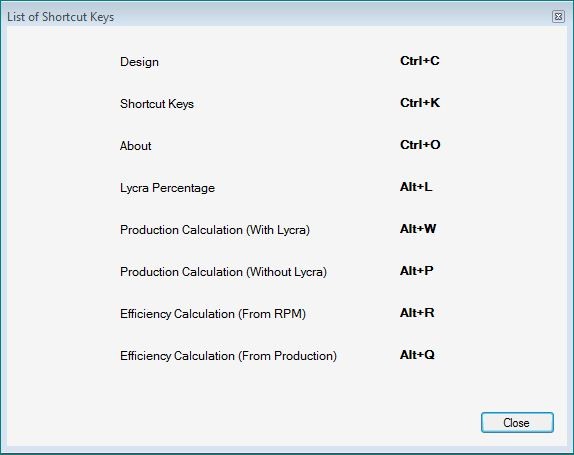

| Figure 13. List of Shortcut Keys |

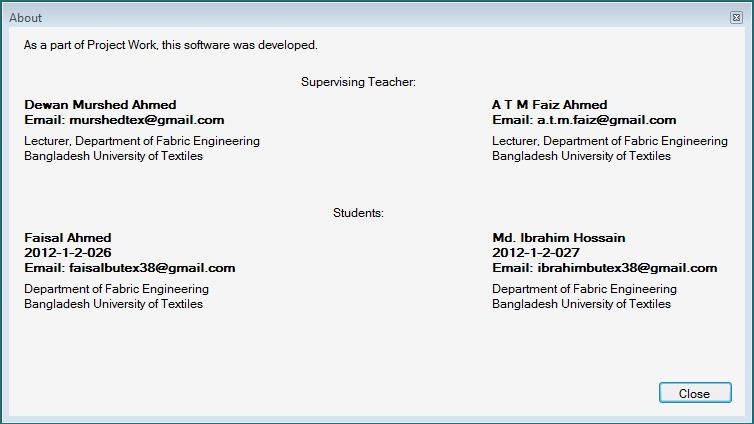

| Figure 14. About |

3.2. Discussion

- The software provides colour arrangement in the fingers, machine code and simulation from a few inputs. The colour arrangement and machine code it provides is highly accurate and reliable. For simulation it uses solid colours.The most important function it performs is the adjustment of maximum colour variation in auto striped knit fabric. Sometimes it may not possible to produce a particular design in a particular machine. In that case, adjustment of the design is necessary. Though the software does not provide true suggestion on design adjustment, it instantly provides suggestion on course adjustment.The software excels at many things but there are some areas for future improvement including – proper design adjustment, structural simulation instead of solid colour simulation, printing of simulated fabric, making interface more user friendly, adding more necessary calculations.

4. Conclusions

- In this paper we have discussed about software for the adjustment of maximum colour variation in auto striped knit fabric. The purpose of this project is to make the process of designing auto striped fabric simple, fast and highly accurate. The software will help to adjust maximum colour variation in auto striped fabric, will reduce human error, will provide colour simulation of the fabric and will perform necessary calculations so that the designer has the clear and proper idea about the finished product.

ACKNOWLEDGEMENTS

- We gratefully acknowledge the help & support from Md. Ashrafuzzaman, Deputy General Manager, Knit Asia Ltd., Shafipur (Kaliakoir), Gazipur, Dhaka, Bangladesh.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML