Farhana Yeasmin1, Md. Abdullah Al Mamun2, Md. Rokunuzzaman2

1Department of Textile Engineering, Atish Dipankar University of Science and Technology, Dhaka, Bangladesh

2Department of Textile Engineering, Mawlana Bhashani Science and Technology University, Tangail, Bangladesh

Correspondence to: Farhana Yeasmin, Department of Textile Engineering, Atish Dipankar University of Science and Technology, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2018 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

This research investigated the behavior of cotton knitted fabric dyed by natural dyes extracted from catechu. 100% cotton knitted single jersey fabric of 160 GSM were used and dyeing in neutral medium was preferred in this work. Synthetic mordanting agents were applied before the dyeing process to intensify natural dye fixation. Dyeing performance of the dyed samples were accessed for various dyeing conditions by evaluating several elementary parameters such as K/S value, color fastness to wash, color fastness to rubbing, color fastness to perspiration (both acidic & alkaline) and bursting strength of the samples. Here, it is observed that pretreatment of cotton fabric with potassium dichromate shows good dye fixation rate along with excellent fastness and fabric strength property. Finally the sample dyed by natural dyes were compared with a sample dyed by reactive dyes in terms of visual perception, economical perception, fastness and fabric strength property and against its anti-microbial property. The result elaborates the good potential of natural dyes as substitute for synthetic dyes in terms of dye fixation rate, fastness properties and anti-microbial property.

Keywords:

Catechu, K/S value, Fastness, Dye fixation, Bursting strength, Anti-Microbial

Cite this paper: Farhana Yeasmin, Md. Abdullah Al Mamun, Md. Rokunuzzaman, Comparative Study of Cotton Knitted Fabric Dyed with Natural Dyes Extracted from Catechu V/S Reactive Dyes, International Journal of Textile Science, Vol. 7 No. 3, 2018, pp. 65-68. doi: 10.5923/j.textile.20180703.01.

1. Introduction

Dyeing is a method which imparts beauty to the textile by applying various colors and their shades on to a fabric. Dyes are used for coloring the fabrics. Dyes are molecules which absorb and reflect light at specific wavelengths to give human eyes the sense of color. There are two major types of dyes - natural and synthetic dyes. Natural dyes are obtained from natural sources. Most are of plant origin and extracted from roots, wood, bark, berries, lichens, leaves, flowers, nuts, and seeds. Others come from insects, shellfish, and mineral compounds. Natural dyes were the only source of color for textiles, leather, basketry, and other materials until synthetic dyes were developed in the latter half of the nineteenth century [1]. Of the thousands of natural color substances, very few became significant commercially.The European Union, for example, has encouraged Indonesian batik cloth producers to switch to natural dyes to improve their export market in Europe [2]. Artists of the Arts and Crafts Movement preferred the pure shades and subtle variability of natural dyes, which mellow with age but preserve their true colors, unlike early synthetic dyes [3], and helped ensure that the old European techniques for dyeing and printing with natural dyestuffs were preserved for use by home and craft dyers. Natural dyeing techniques are also preserved by artisans in traditional. The discovery of man-made synthetic dyes in the mid-19th century triggered a long decline in the large-scale market for natural dyes. Synthetic dyes, which could be produced in large quantities, quickly superseded natural dyes for the commercial textile production enabled by the industrial revolution, and unlike natural dyes, were suitable for the synthetic fibers that followed.In the early 21st century, the market for natural dyes in the fashion industry is experiencing resurgence [4]. Western consumers have become more concerned about the health and environmental impact of synthetic dyes in manufacturing and there is a growing demand for products that use natural dyes cultures around the world.Some commercial use of natural dyes is a response to concerns about synthetic dyes and environmental pollution. Natural dyes are a renewable resource and contribute to rural economic development. Contrary to common assumptions, some natural dyes have excellent fastness to light, cleaning agents, water, and perspiration. Commercially available natural dye extracts facilitate color matching and make the dyeing process less involved.For successful commercial use of natural dyes, the appropriate and standardized dyeing techniques need to be adopted without scarifying required quality of dyed textiles materials. Therefore, to obtain newer shades with acceptable color fastness behavior and reproducible color yield, appropriate scientific techniques or producers need to be derived from scientific studies on dyeing methods, dyeing process variable, dyeing kinetics and compatibility of selective natural dyes. A need has also been felt to reinvestigate and rebuild the traditional processes of natural dyeing to control each treatment and pre-dyeing process (preparation, mordanting) and dying process variables for producing uncommon shades with balanced color fastness and eco-performing textiles.My work in this research is a small initiative with this journey to produce organic dyed textile product without scarifying required quality of dyed textiles materials. In this research dyes extracted from cutch root were used. Cutch is an important historical brown natural dyes that comes from the heartwood of the cutch tree (Acacia catechu). It is a very easy dye to use and it is both light-fast and wash-fast, as well as being inexpensive. Cutch is an excellent dye for cottons as it is high in tannins, and it is also suitable for silk and wool fabric dyeing.

2. Materials and Methods

2.1. Fabric

160 GSM light weight scoured, bleached knitted cotton fabric was taken. Scouring & bleaching was done in same bath and formulation for Scouring & bleaching involved 6 g/l of NaOH & 4 g/l H2O2 treated under pH 11.5 at 100°C for 1 hour.

2.2. Extraction of Dyes

A dark brown Cutch named as Black cutch (Acacia Catechu) was purchased from the local market to continue the working procedure. It was taken in power form.

2.3. Mordanting

Pre Mordanting Process Were Used To Observe The Effect Of Them On Dyeing Process. Mordanting Was Done By Using Alum, Copper Sulfate, Tartaric Acid, Ferrous Sulfate, Potassium Dichromate & Ammonium Sulfate At 100°C Temperature For 1 Hour At Neutral Medium And After That Bath Was Kept For 24 Hours. Then The Fabric Washed And Dried, Later Prepared For Further Dyeing.

2.4. Dyeing

After mordanting the fabric was dyed using shade% 10 at a temperature 60°C for 60 min. Dyeing was carried out at neutral medium and at a liquor ratio 1: 10. Here wetting agent was used in the dyeing process for removing the surface tension of water. After completing dyeing process the unfixed dyes were removed from the fabric surface using 1 gm/l ISO standard soaping agent. After that the fabric had been oven dried.

2.5. Color Strength Measurement

Color strength is frequently computed as ratio of K/S values by using the Kubelka-Munk equation with data color machine by using ultraviolet radiation.

2.6. Fastness Tests

The dyed material was tested for light, wash and rub fastness. All of them were done in both dry & wet condition and expressed by change in color & color staining both.

2.7. Bursting Test

In the test the fabric sample is clamped over the rubber diaphragm and the pressure in the fluid increased at such a rate that the specimen bursts within 20 ± 3 s. The extension of the diaphragm is recorded and next test is carried out with the same process. Bursting strength (Kpa), Bursting area (mm) and Bursting time (Sec) is recorded.

2.8. Anti-Microbial Activity Test

Catechu dyed fabric, Reactive dyed fabric and the raw fabric without dyeing was taken for observing the antimicrobial property of catechu dyed fabric and observing the result with reactive dyed fabric.Three strains of bacteria were used as test microorganisms. The bacterial strains included Gram-positive Bacillus licheniformis and Gram-negative Escherichia coli and Haemophilus. All microorganisms were clinical isolates, obtained from the Microbiology Laboratory at Department of Genetical and Bio-technology department, Dhaka University. All the cultures were maintained and sub cultured on nutrient agar medium.

2.9. Comparative Analysis between Natural & Reactive Dyeing

To compare the property of the fabric dyed with natural dyestuff catechu, a sample was prepared using reactive dyes. Samples were prepared based on the color obtained from dyeing with catechu dyes at 60° for 60 min and using the following formula. For Reactive dyeing:St. Yellow ED- 0.18%St. Red ED3B- 0.43%Rem. Blue SAM- 0.21%Glauber salt-40gm/lSoda ash-15gm/lDyeing Time- 60 minDyeing Temp- 60°CpH-11M:L -1:10After that, the natural dyed samples were compared with reactive dyed samples in terms of visual perception, economical perception, fastness property and its anti microbial property.

3. Results and Discussion

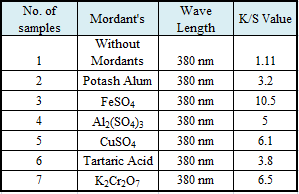

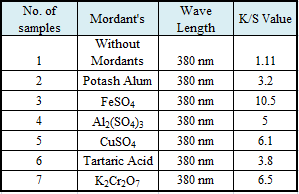

3.1. Determination the K/S Value

After dyeing color was visually inspected and found various shade of reddish brown color was produced while using different types of mordant. Maximum color strength 10.5 yield by using FeSO4, but it darkens the color and produce greenish red shade. CuSO4 and K2Cr2O7 produce excellent reddish brown color and also shows good color strength value 6.1 and 6.5 respectively.  | Figure 3.1. Visual evaluation of samples after dyeing |

Table 3.1. Effect on K/S value at different types of mordants

|

| |

|

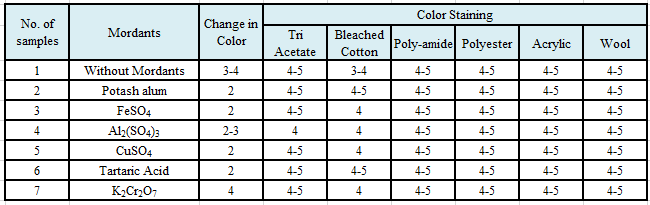

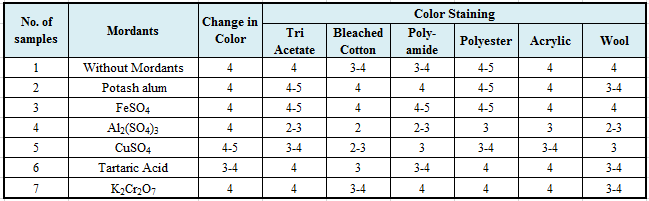

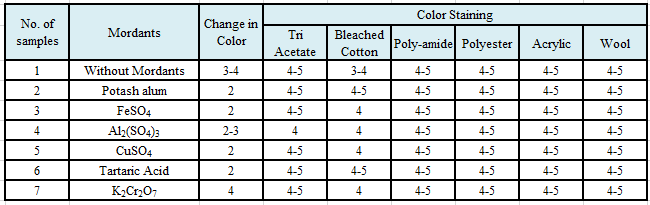

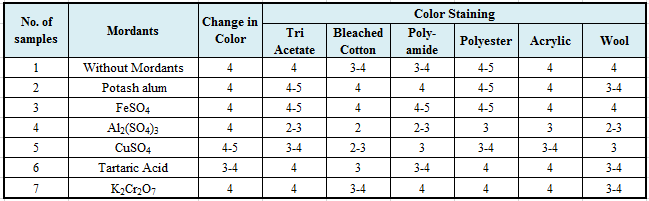

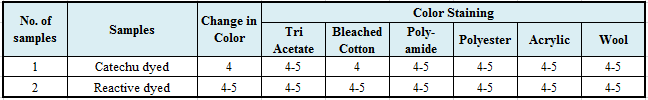

3.2. Evaluation of Color Fastness to wash

It was observed K2Cr2O7 has excellent wash fastness property, color staining 4-5 and change in color is 4. Potash alum, tartaric Acid, CuSO4 shows good color staining result with fair change in color result. Table 3.2. Evaluation of color fastness to wash

|

| |

|

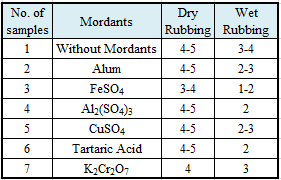

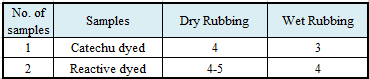

3.3. Evaluation of Color Fastness to Rubbing

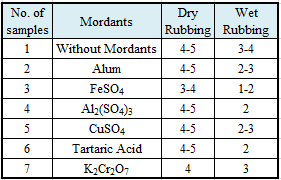

Among all samples pre mordantation with potash alum, tartaric Acid, CuSO4 and Al2(SO4)3 gives good result 4-5 for dry rubbing and moderate rubbing fastness 2-3. K2Cr2O7 exhibit good result in both dry and wet condition. Dry rubbing fastness result for using K2Cr2O7 is 4 and wet rubbing result is 3.Table 3.3. Evaluation of color fastness to rubbing

|

| |

|

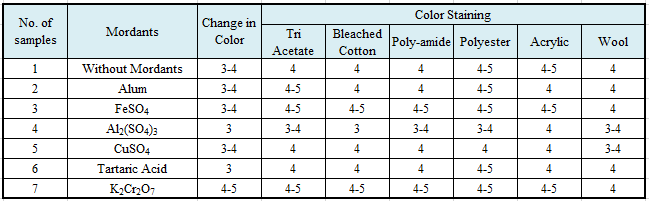

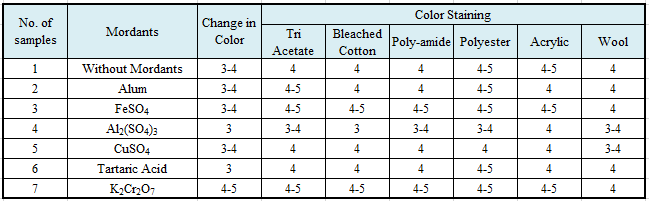

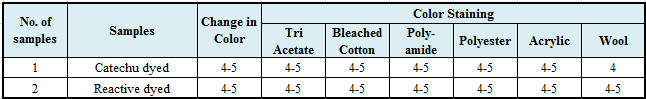

3.4. Evaluation of Color Fastness to Perspiration (Acidic Media)

K2Cr2O7 shows excellent fastness property 4-5 to perspiration in acidic medium. Using potash alum, FeSO4, CuSO4 shows good to moderate perspiration fastness in acidic medium.Table 3.4. Evaluation of color fastness to perspiration (acidic media) at different types of mordant’s

|

| |

|

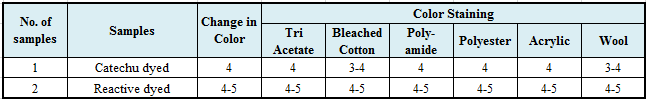

3.5. Evaluation of Color Fastness to Perspiration (Alkaline Media)

Here by it is observed that Potash alum, FeSO4, K2Cr2O7 and CuSO4 exhibit good color fastness property. Table 3.5. Evaluation of color fastness to perspiration (alkaline media) at different types of mordant’s

|

| |

|

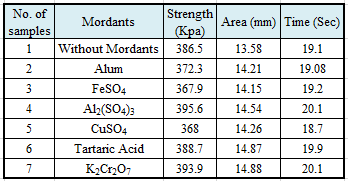

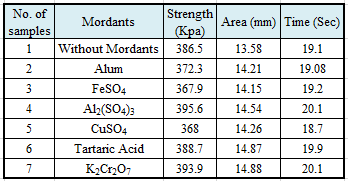

3.6. Evaluation of Bursting Strength

It was observed that fabric strength is for Al2(SO4)3 and K2Cr2O7 exhibit good fabric strength, 395.6 and 393.9KPA respectively. Mordanting with FeSO4, shows poor result 367.9KPA in comparison to others. Table 3.6. Evaluation of Bursting strength

|

| |

|

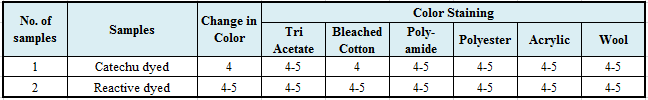

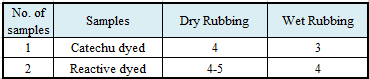

3.7. Comparative Analysis of Fastness Properties between Catechu Dyeing and Reactive Dyeing

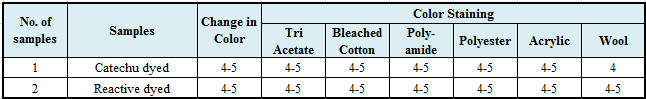

The fastness properties of natural dyed pre mordanting with K2Cr2O7 and reactive dyed samples are comparatively analyzed in this segment. Wash fastness, rubbing fastness and perspiration fastness in both alkaline and acid medium are depicted in the following tables. Table 3.7.1. Comparison of color fastness to wash of catechu & reactive dyed samples

|

| |

|

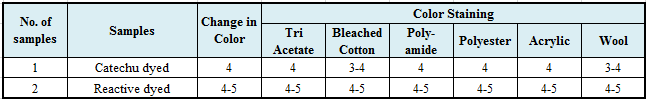

Table 3.7.2. Comparison of color fastness to rubbing of catechu & reactive dyed samples

|

| |

|

Table 3.7.3. Comparison of color fastness to perspiration (acid medium) of catechu & reactive dyed samples

|

| |

|

Table 3.7.4. Comparison of color fastness to perspiration (Alkali medium) of catechu & reactive dyed samples

|

| |

|

3.8. Comparative Analysis of Anti-Microbial Activity

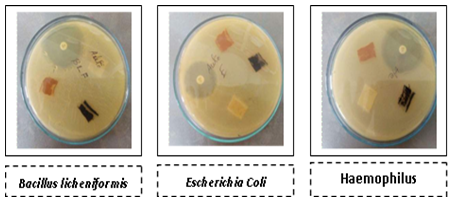

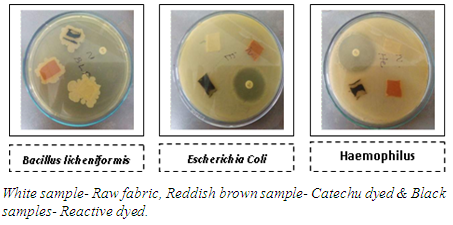

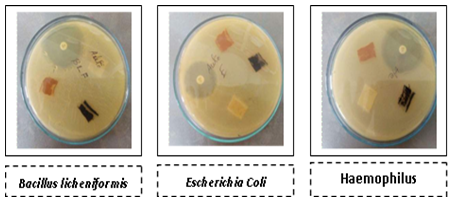

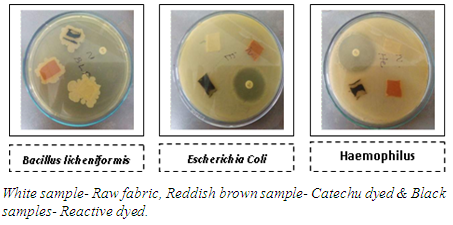

Among two sets of these samples fabric one set was sterilized and another set was without sterilization. In Sterilized set, no inhibition zone was produced. Here we found no difference between raw fabric, reactive dyed and catechu dyed samples and micro bacterium colony grown around the fabric and also within the fabric.In without sterilized zone no inhibition zone was produced, but here amazing result was observed for catechu dyed fabric. Here it is observed that bacterium colony was produced around and in between reactive & raw samples but for catechu dyed samples it couldn’t grow inside the samples which prove that fabric dyed with catechu has certain amount of anti-microbial properties. | Figure 3.2. Comparison of samples with sterilization |

| Figure 3.3. Comparison of samples without sterilization |

4. Conclusions

After evaluating different types dyed fabric which was pre mordanted using various types of synthetic mordanting agent, it is found using K2Cr2O7 is appreciable. Shade obtained using K2Cr2O7 is little bit darker and dark reddish brown shade is produced. Fabric shows good property along with high dye fixation rate 6.5 which is almost 4.5 times higher from general dyeing procedure of catechu dyes. Comparing the result obtained from dyeing with natural dyes obtained from Catechu and reactive dyes it may conclude that, catechu dyed fabric is more comfortable to wear due to its hygienic & anti-microbial properties with a slight limitation of color fastness.

References

| [1] | Sara J. Kadolph, “Natural Dyes”. Fashion history, Fashion and Clothing Industry. |

| [2] | Faizal, Elly Burhaini (October 29, 2011). "Indonesia told to produce more 'green' products". The Jakarta Post; November 9, 2011. |

| [3] | Goodwin; Page: 11, (1982). |

| [4] | The Biology of Gossypium hirsutum L. and Gossypium barbadense L. (cotton). www.ogtr.gov.au. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML