-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(6): 148-152

doi:10.5923/j.textile.20170606.02

Recent Approach for Multifunctional Finishing of Cotton/Polyester Fabric Blends via Natural Products

E. M. R. Elzairy, W. A. Abdallah, S. M. Osman, M. A. M. Fouad

Faculty of Applied Arts, Helwan University, Cairo, Egypt

Correspondence to: M. A. M. Fouad, Faculty of Applied Arts, Helwan University, Cairo, Egypt.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Monochlorotriazinebetacyclodextrin (MCT-βCD) was used in this study as an eco-friendly chemical modifying agent for cellulose component contained in cotton/polyester fabric blends via covalently bonds. Inclusion of each vitamin E and Jojoba oils to the MCT-βCD grafted cellulose portion in the above blended substrate were made in order to verify that the cavities were available for inclusion compounds. The impart of UV-protection (UPF) and antibacterial efficiency functionality to cellulose component contained in cotton/polyester blends through permanent fixation of MCT-βCD onto cellulose structure followed by inclusion of certain natural antibacterial and UV-protection agent separately i.e. Jojoba oil and vitamin E oil proved to give very good results and follows the descending order: Jojoba > Vitamin E oils keeping other parameters constant. Herein, they are considered as promising reagents in textile functional finishing.

Keywords: Monochlorotriazinebetacyclodextrin (MCT-βCD), Vitamin E, & Jojoba oils, UV-protection, Antibacterial efficiency, Functional finishing

Cite this paper: E. M. R. Elzairy, W. A. Abdallah, S. M. Osman, M. A. M. Fouad, Recent Approach for Multifunctional Finishing of Cotton/Polyester Fabric Blends via Natural Products, International Journal of Textile Science, Vol. 6 No. 6, 2017, pp. 148-152. doi: 10.5923/j.textile.20170606.02.

Article Outline

1. Introduction

- Recently a great attention has been focused on functionalization of textiles to impart novel properties such as antibacterial efficiency and ultraviolet protection (UPF) using natural products to impart textile-users protection and safety as well as to complete in the tough global market place. Therefore, the main aim of this study was directed towards proper finishing formulation for functionalizations of cotton/polyester fabric blends to meet functional and environmental demands and to extend their high impart applicable properties. Herein, we report the feasibility to improve the UV-protection function of textiles against the harmful UV-radiation, especially the UV-A and UV-B the main cause of skin cancer [1] as well as antibacterial activity against the G+ve and G-ve bacterial using environment/especial natural products like Vitamin E and Jojoba oils. Monochlorotiazine-β-chorodextrin [MCT-βCD] was used to impart cellulose component contained in cotton/polyester blends nitrogen producing modified cellulose that capable to react with eco-friendly used finishing products to improve the extent of modified cellulosic structure, Dimethyloldihydroxyethyleneurea [DMDHEU] was used as a crosslinking agent along with magnesium chloride [MgCl2.6H2O] as metal salt catalyst. Type and concentration of the natural finishing agent as well as curing time were examined. Moreover, it may be said that post treatment of cellulose portion in the above mentioned blended fabric with MCT-βCD as well as DMDHEU is accompanied by noticeable increase in nitrogen content [%N] as a direct consequence of increasing the extent of loading the cationic active sites onto the fabric surface which capable to react with anionic eco-friendly finishing agent i.e. Vitamin E and Jojoba oils that loading negative charges through an electro-static interaction ionic-like linkage.

2. Experimental

2.1. Materials

- Mill-scoured and bleached Cotton/Polyester blend (70/30, 235 g/m3) woven fabrics were used throughout this work as Cotton/Polyester blend is more common in textile industry.Cavasol® W7MC, monochlorotriazine-β-cyclodextrin (MCT-βCD), [average molecular weight ≈ 1560, degree of substitution 0.3–0.6 per anhydroglucose unit, Wacker, Germany], Fixapret® ECO (modified dimethyloldihydroxy ethylene urea DMDHEU-BASF) were of technical grade. Jojoba oil was kindly provided by Ferquima. Vitamin E capsules 1000 were kindly provided by Pharcoin Egypt. Ethanol was purchased from Sinopharm Chemical Reagent Co. Ltd., China, and MgCL2 was analytical graded and provided by Merck and Fluka.

2.2. Methods

- For imparting multifunctional properties to cotton/polyester blended fabrics, novel finishing formulations have been established via two different applicable methods i.e.

2.2.1. Two-Stage Functional Finishing Process

- a- Pretreatment with MCT-βCDLoading of MCT-β-CD onto/within cotton/polyester blend.Fabric samples were impregnated in aqueous solution containing the MCT-βCD (0-20 g/L), DMDHEU as a crosslinker (20 g/L), MgCL2.6H2O as a catalyst (8 g/L) roll squeezed, and thermofixed at 170C for 3 min, thoroughly washed to remove untreated and any soluble by products and finally dried.b- Post-treatment with Jojoba oil and Vitamin E oilPortions of MCT-βCD loaded fabric samples were individually post treatment with Jojoba oil (0-2 m/L) and Vitamin E (0-2 m/L) at liquor ratio (1:20) for (1/2-2 h) at 75C in launder O-meter jars under continuous stirring. After functionalization, the post finished fabric samples were thoroughly washed with hot distilled water, rinsed with cold water and finally dried at ambient temperature.

2.2.2. All-in Functional Finishing Process

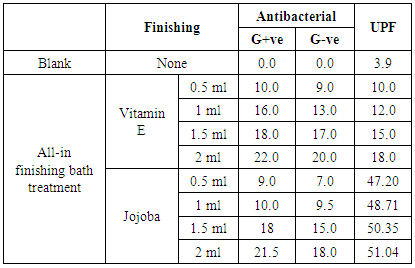

- Woven fabric samples were treated in the absence and presence of MCT-βCD (20 g/L) along with other additives i.e. cross linker (DMDHEU) and catalyst (MgCl2.6H2O) as well as environment antibacterial/ultraviolet protect finishing reagents at 170C for 60 seconds according to typical formulations and treatment conditions are given in the text.Each of the used finishing agent i.e. Jojoba and Vitamin E oils were incorporated in the treatment bath separately to compare and decide which one can achieve best results as illustrated in [table 2]. The above table signify that incorporation of vitamin E oil at the ambient finishing conditions attain very good results compared with jojoba oil especially for ultra-violet protection which achieves excellent grades.

2.3. Testing and Analysis

- Nitrogen content of the MCT-βCD loaded cotton/polyester fabric samples were determined by Vogel (1975).Antibacterial activity of the finished cotton/polyester fabric samples against G +ve (S.aureus) and G –ve (E.cloi) bacteria was assessed qualitatively expressed as zone of growth inhibition (ZI, mm) according to AATCC test method (147-1988).UV-protection factor (UPF) was determined according to the Australian/Newzeland standard (AS/NZS 4399-1996) [7].

3. Results and Discussion

- Attempts have been made to modify the crosslinking formulation via incorporation of Monochlorotriazine Betacyclodextrin [MCT-βCD] in the cellulose component in the blends as well as Dimethyloldihyroxyethylene urea [DMDHEU] to provide the new cationic active sites fixed to the finished fabric matrix for enhancing the substrate, substantivity for anionic used finishing agent i.e. Vitamin E and Jojoba oils.

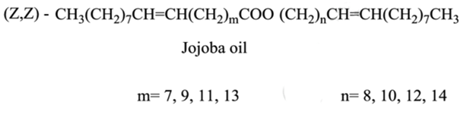

Chemical Structure of Jojoba oil

Chemical Structure of Jojoba oil

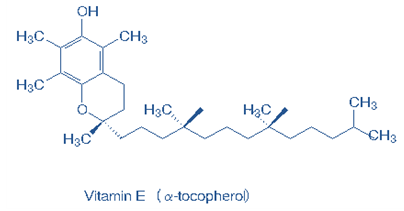

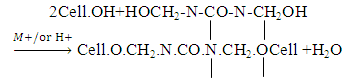

Structure of Vitamin EThe formation of crosslinking of cellulose hydroxyls with DMDHEU, thereby enhancing the %N is indicated as follows [6, 13].

Structure of Vitamin EThe formation of crosslinking of cellulose hydroxyls with DMDHEU, thereby enhancing the %N is indicated as follows [6, 13]. The present study was conducted to impart antibacterial and UV-protection properties to the obtained cotton/polyester fabrics through permanent portion of MCT-βCD onto the fabric structure followed by inclusion of certain antibacterial agents like Jojoba oil and Vitamin E oil within the immobilized cavities of the grafted MCT-βCD. Factors affecting the imparted antibacterial and UV protection activity of the finished cotton/polyester fabric such as type and concentration of Jojoba oil and Vitamin E oil as well as post treatment time were studied.

The present study was conducted to impart antibacterial and UV-protection properties to the obtained cotton/polyester fabrics through permanent portion of MCT-βCD onto the fabric structure followed by inclusion of certain antibacterial agents like Jojoba oil and Vitamin E oil within the immobilized cavities of the grafted MCT-βCD. Factors affecting the imparted antibacterial and UV protection activity of the finished cotton/polyester fabric such as type and concentration of Jojoba oil and Vitamin E oil as well as post treatment time were studied.3.1. MCT-βCD Concentration

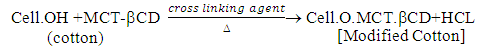

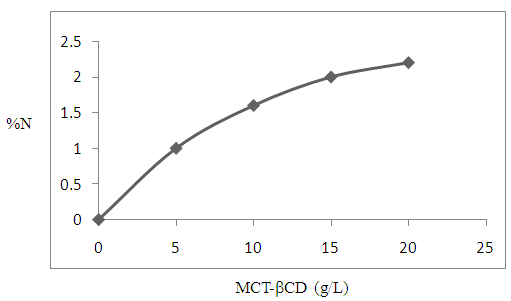

- As far as the change in the extent of modification of cotton/polyester fabric blends expressed as %N, as a function of the MCT-βCD concentration, [figure 1] demonstrates that: i) increasing MCT-βCD concentration up to 15 g/L results in a remarkable increase in the %N of modified cotton/polyester structure, ii) further increase in MCT-βCD concentration up to 20 g/L is accompanied by a marginal or no effect in the %N contentmost probably due to the unavailability and accessibility of cellulose active sites, i.e. –OH groups, as well as steric hindrance of grafted MCT-βCD thereby preventing further interactions with additional active sites at the fabric surface, especially at higher concentration.On the other hand, the enhancement in the %N of the MCT-βCD loaded cotton/polyester is a direct consequence according to the following scheme of reaction: [4, 8, 9].

In conclusion, the optimal concentration of MCT-βCD is 15 g/L, irrespective of the used applicable method.

In conclusion, the optimal concentration of MCT-βCD is 15 g/L, irrespective of the used applicable method. | Figure 1. Effect of MCT-βCD concentration on the nitrogen content (%N) of modified cotton/polyester samples |

3.2. Type and Concentration of Antibacterial Agent

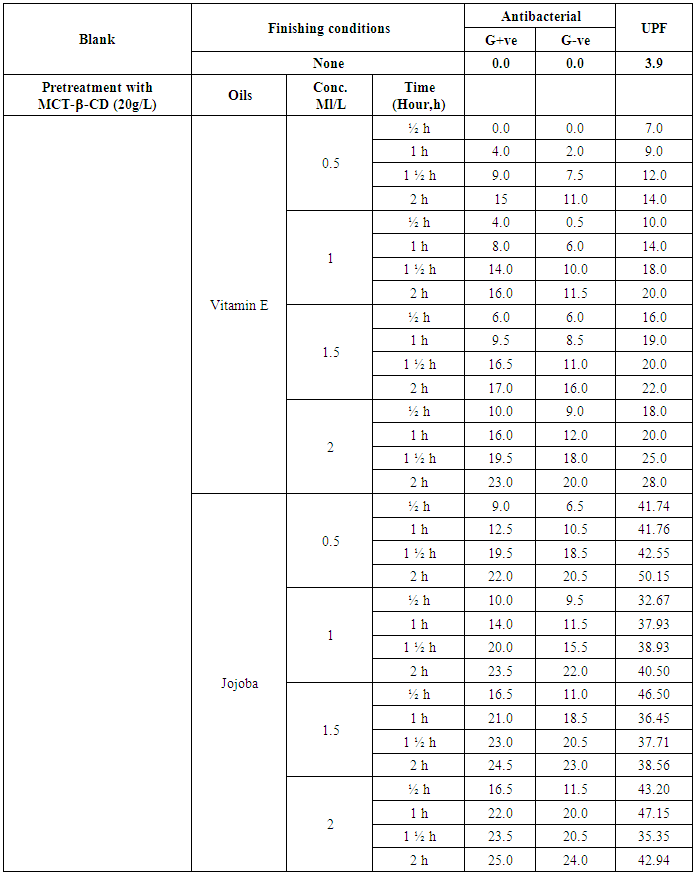

- The data in [table 1] demonstrate that i) the more concentration of antibacterial agent used, the greater the inhibition capacity against pathogenic G+ve and G-ve bacteria is, ii) the effectiveness of growth inhibition is governed by type of antibacterial agent and time of treatment process and follows the decreasing order: Jojoba oil > Vitamin E >> none, which reflects the differences among them in: extent of loading into the grafted MCT-βCD cavities, their active ingredients, mode of inhibition, and performance against the tested strains: G+ve> G-ve [3, 5, 14, 16].

3.3. Influence of UV-blocking Additive

- [Table 1] shows the UV absorption of the untreated cotton/polyester and Jojoba oil coated MCT-βCD grafted cotton/polyester substrates. The data so obtained signifies that, there is a great difference in the UV protection properties between the untreated and treated specimens, the results in table [1] reveal that the excellent UV protecting capacity of treated cotton/polyester substrate is at 2 h compared with other treated time, its high ability to absorb the harmful UV-B radiance with its aromatic units [2, 10]. ii) The effectiveness of growth inhibition is governed by type of UV protected agent as well as the time for treatment and follows the decreasing order Jojoba oil > Vitamin E oil>> none, which reflects the differences among them in extent of loading into the grafted MCT-βCD cavities, their active ingredients made of inhibition. Furthermore, The results in [table 1] revealed that inclusion of vitamin E oil into the MCT-βCD cavities brings about a remarkable enhancement in the antibacterial activity of the treated cotton/polyester specimens which can be attributed to the presence of an active phenolic moieties i.e. catechins in its structure which have the ability to damage and disrupt the cell membrane, thereby adversely affecting the growth survival of the hazardous bacteria [9, 11, 12, 15].On the other hand, the functional finishing properties of cotton/polyester specimens i.e. antibacterial activity and UV-protection [UPF] via two-stage process as recorded in [table 1] proved, generally, to give good results compared with the another one that used in the present study i.e., one-stage, «All-in », finishing method as indicated in [table 2].

|

4. Conclusions

- Ÿ The applicable two-stage method was used to impart the antibacterial and ultraviolet protection (UPF) functional finishing properties to cotton/polyester fabric blends through permanent fixation of monochlorotriazine beta-cycloddextrin (MCT-βCD) onto the cellulose structure in the blended fabric followed by inclusion of certain environmental finishing agent i.e. Vitamin E oil and Jojoba oil may be available. Moreover, all-in, i.e., one-stage finishing method was also used throughout the current study. Ÿ Compared with the above used two eco-friendly finishing agents, Jojoba oil exhibit better UV-protection capacity as well as antibacterial efficiency.Ÿ In general, compared to the above mentioned applied two finishing methods, the data in tables 1&2 confirm that the two stage finishing process proved to give the best one.Ÿ The present developed multifunctional finishing process can be applied on industrial scale.

References

| [1] | Abidi, N., Hequet, E., Tarimala, S., & Dai, L. L. (2007). Cotton fabric surface modification for improved UV-radiation protection using sol-gel process. Journal of Applied Polymer Science, 104, 111-117. doi: 10.1002/app.24572. |

| [2] | Babu, P. V. A., Sabitha, K. E., & Shyamaladevi, C. S. (2006). Therapeutic effect of green tea extract on oxidative stress in aorta and heart of streptozotocin diabetic rats. Chemico-Biological Interactions, 162, 114–120. doi:10.1016/j.cbi.2006.04.009. |

| [3] | Bajai, M., Gupta, P., & Bajai, S., K. (2013). Silver (I) ions loaded cyclodextrin-grafted-cotton fabric with excellent antimicrobial property. Fiber and Polymer, 11, 8-13. doi: 10.1007/s12221-010-0008-x. |

| [4] | Cabrales, L., Abidi N., & Hammad, A. (2012). Cotton fabric functionalization with cyclodextrins. Journal of Materials and Environmental science, 3, 561-574. |

| [5] | Holme, I. (2007). Innovative technologies for high performance textiles. Coloration Technology, 123, 59-73. doi: 10.1111/j.14784408.2007. 00064-.x. |

| [6] | Ibrahim, N., A. (1978). Ph.D. Thesis, EL-Azhar University, Faculty of Science, Cairo, Egypt. |

| [7] | Ibrahim, N., A., E-Zairy, W., R., & Eid, B., M. (2010). Novel approach for improving disperse dyeing and UV-protective function of cotton-containing fabrics using MCT-β-CD. Carbohydrate Polymers, 79, 839-846. doi: 10.1016/j.carbpol.2009.10.008. |

| [8] | Ibrahim, N., A., Abdalla, W., A., Elzairy, E., M., R., & Khalil, H., M. (2013). Utilization of monochloro-triazine-β-cyclodextrin for enhancing printability and functionality of wool. Carbohydrate Polymers, 92, 1520- 1529, doi: 10.1016/j.carbpol.2012.11.020. |

| [9] | Ibrahim, N., A., El-Zairy, E., M., R., & Eid, B., M. (2017). Eco-friendly modification and antibacterial functionalization of viscose fabric. the Journal of the Textile Institute, 108, 1406-1411. doi: 10.1080/00405000.-2016.1254583. |

| [10] | Kim, S. H. (2006). Dyeing characteristics and UV-protection property of green tea dyed cotton fabrics focusing on the effect of chitosan mordanting condition. Fibers and Polymers, 7, 255–261. doi: 10.1007/BF02875682. |

| [11] | Nassar, S., H. (2008). A comparative study for using different solvents in pretreatment fabrics and in corporation in printing paste. Journal of Applied Polymer Science, 108, 1064-1069. doi: 10.1002/app.27671. |

| [12] | Park, Y., Koo, K., Kim, S., & Choe, J. (2008). Improving the colorfastness of poly(ethylene terephthalate) fabrics with the natural dye of caesalpinia sappan L. wood extract and the effect of chitosan and low temperature plasma. Journal of Applied Polymer Science, 109, 160-166. doi: 10.1002/app.27899. |

| [13] | Shih, F., F., & Rowland, S., P. (1982). Catalysis of the Dimethylolethylene-urea-Cotton Cellulose Reaction with Three Different Metal Salts. Textile Research Journal, 52, 108-115. doi: 10.1177/004051758205200204. |

| [14] | Turaga, U., Sing, V., & Ramkumar, S. (2015). Biological and chemical protective finishes for texiles. In R. Paul (Ed.), Functional finishes for textiles (pp. 555–578). Oxford: Woodhead Publisher. Chapter 18. doi: 10.1533/9780857098450.2.555. |

| [15] | Uddin, F. (2014). Cellulose fibers: Antimicrobial finishing. In Munmaya K. Mishra (Ed.), Encyclopedia of biomedical polymer and polymeric materials (pp. 1–18). Taylor and Francis. doi:10.1801/E-EBPP-120049931. |

| [16] | Winder, L., Height, M., & Nowack, B. (2013). Comparative evaluation of antimicrobials for textile applications, Environmental International. 53, 62-73. doi:10.1016/j.envint.2012.12.010. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML