-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(6): 143-147

doi:10.5923/j.textile.20170606.01

Effect of Wales Wise Increment of Tuck Loop on Fabric Width, Shrinkage, Spirality and Areal Density of Weft Knitted Fabric

Syeda Sanjida Wasim1, Jamal Uddin Ahmed2, MD. Al-Amin2

1Department of Fabric Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh

2Department of Textile Engineering, Southeast University, Dhaka, Bangladesh

Correspondence to: Syeda Sanjida Wasim, Department of Fabric Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Dimensional stability of knitted fabric is a key factor for garments manufacturing. To make the fabric dimensionally stable fabric width, shrinkage, spirality and areal density should be under tolerance limit. Knitted fabric structure plays an important role on dimensional properties. This paper focuses on the fabric width, spirality, areal density and shrinkage property of various derivatives of single jersey weft knitted fabric at both grey and finished state. Derivatives of knit fabric are manufactured with tuck loop incorporated with knit loop in wales direction. From the investigation it is seen that, with the increase of tuck loop in wales direction fabric width and areal density increases in both grey and finished state. It is also found that shrinkage and spirality of knitted fabric also changes with tuck loop percentage, but there is no linear relationship.

Keywords: Shrinkage, Spirality, Areal density, Wales, Dimentional stability

Cite this paper: Syeda Sanjida Wasim, Jamal Uddin Ahmed, MD. Al-Amin, Effect of Wales Wise Increment of Tuck Loop on Fabric Width, Shrinkage, Spirality and Areal Density of Weft Knitted Fabric, International Journal of Textile Science, Vol. 6 No. 6, 2017, pp. 143-147. doi: 10.5923/j.textile.20170606.01.

Article Outline

1. Introduction

- Knitting is the process of forming fabric by interlooping yarn in a series of intermeshed loops using needles. Knitted fabrics are preferred in many types of clothing because of its extensibility, lightweight, warmth, wrinkle resistance and ease of care [1]. The term knitting describes the technique of constructing textile structures by forming a continuous length of yarn into columns of vertically intermeshed loops [2]. Knitted structures are progressively built-up from row after row of intermeshed loops. The properties of a knitted structure are largely determined by the interdependence of each stitch to its neighbors on either side and above and below its [2]. As knit fabrics are produced on different machines with various conditions to produce different types of fabric, they bear different qualities [3]. Knitted fabric structures and finishing processes influence the physical properties and connected with the wearing properties of knitted garment [4]. Knit fabric structure and machine parameter has profound influence on the fabric width. The structure with tuck stitches is wider than the normal knit structures. The loop shape at the tuck stitch is distorted and has a wider base as the side wales are not pulled together [5]. The effect of fabric structure on the fabric width has been investigated by few researchers [6-8, 17]. Variable factors, namely linear density, twist factor, machine gauge and stitch length, influence the shrinkage to a variable degree, stitch length is the dominating factor [9]. If shrinkage can be controlled, fabric weight is predicted with high accuracy.Dimensional stability is very important to maintain the aesthetics of knitted products in the user ends. Different factors such as fiber characteristics, yarn parameters, machine parameters influence the dimensional characteristics of knitted fabrics [11]. Fabric shrinkage is a serious problem originating from dimensional changes in the fabric. Yarn is exposed to various tensions during knitting process and the relaxation process changes the dimension of the knitted fabric [12]. The effect of knit structures on fabric shrinkage has not been investigated enough [17, 10]. Spirality is a major problem of knit fabrics which is produced in circular knitting machines. Relaxation of torsional stresses cause dimensional distortions and instability in the knitted loop constructions. The effect of machine gauge, yarn and fabric properties on the spirality of single jersey knit fabrics has been analyzed by some researchers [13-15]. The study on spirality and shrinkage property with tumble and line drying method with different structures also have been done, but with different stitch length. [16] There have been few researches regarding the effect of knit structures with same stitch or loop length, on the spirality of the fabric [8].Presence of tuck loop in knitted fabric structure changes fabric dimensional characteristics. The aim of our study is to analyze the effect of tuck loop on fabric width, shrinkage and spirality at grey and finished state.

2. Material and Method

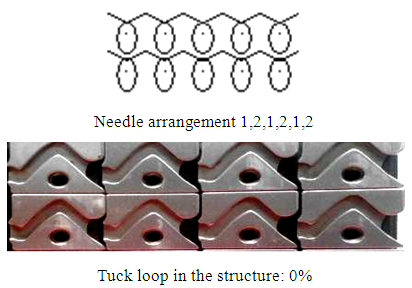

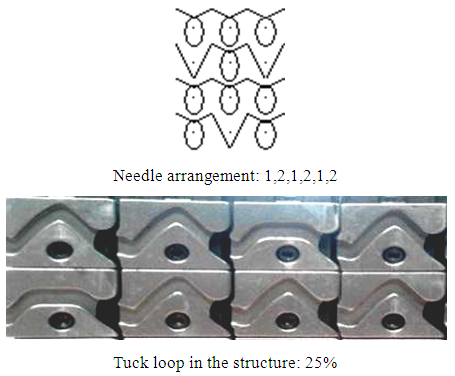

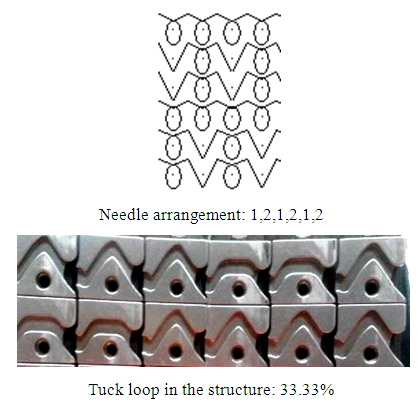

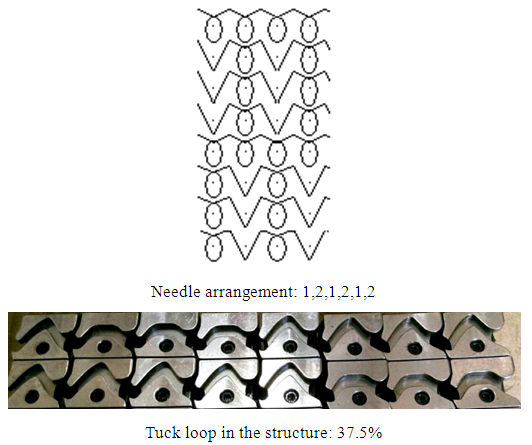

- Lacoste is common derivatives of plain weft knitted fabric, which have tuck loops and knit loops in its construction. Here four knitted samples are made having different percentage of tuck loops. The samples are shown here with their cam arrangement and needle arrangement (Figure 1-4).Single Jersey:

| Figure 1. Notation diagram, needle arrangement and Cam arrangement of Single Jersey |

| Figure 2. Notation diagram, needle arrangement and Cam arrangement of Single lacoste |

| Figure 3. Notation diagram, needle arrangement and Cam arrangement of double lacoste |

| Figure 4. Notation diagram, needle arrangement and Cam arrangement of triple lacoste |

3. Result & Discussion

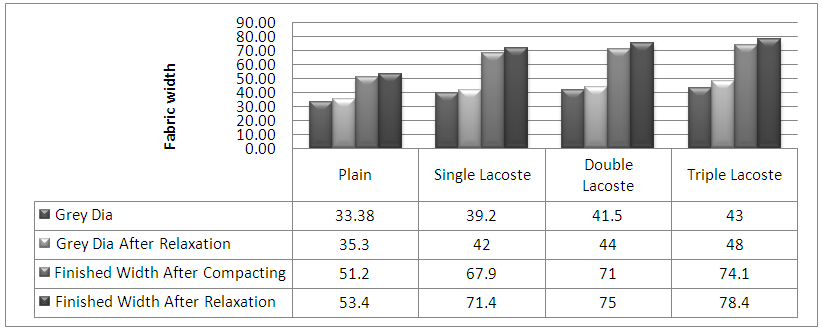

3.1. Effect on Fabric Width

- It is found that, with the increase of tuck loop percentage in wales direction, fabric width increases, which has been shown in Figure 5. As plain knitted fabric do not have any tuck loop, shows the list value. Triple Lacoste fabric having highest tuck loop (37.5%) among 4 samples shows the maximum width value.Plain fabric is created with all knit loop. In this fabric knit loops are locked by the other knit loops adjacent to it. The side limbs of the loops are not free. So after relaxation and finishing this fabric do not get enough opportunity to spread due it’s construction. On the other side, tuck loops have free limbs. Fabric having tuck loops can spread more than plain fabric after relaxation. For this reason, increasing number of tuck loop in fabric structure shows increasing value in fabric width.

| Figure 5. Effect of tuck loop on fabric width |

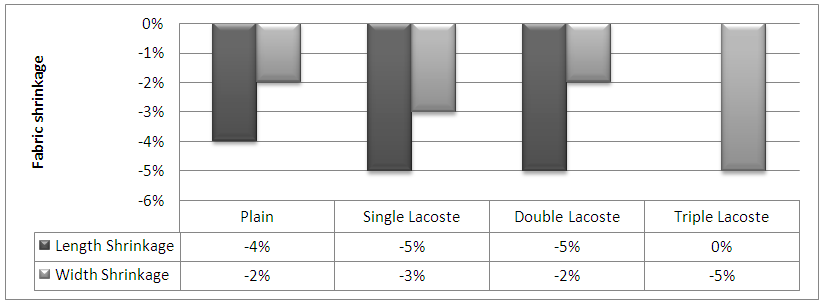

3.2. Effect on Shrinkage

- Knitted fabric structures do not show any linear relationship with increasing number of tuck loop. From figure 6 it is seen that single lacoste and double lacoste structure show highest shrinkage in length direction and Triple lacoste structure do not show any length shrinkage. On the other hand, width shrinkage is highest for Triple lacoste structure, where plain and double lacoste structure show minimum width shrinkage among four. All the structure shows shrinkage within tolerance limit (± 5%).

| Figure 6. Effect of tuck loop on fabric shrinkage |

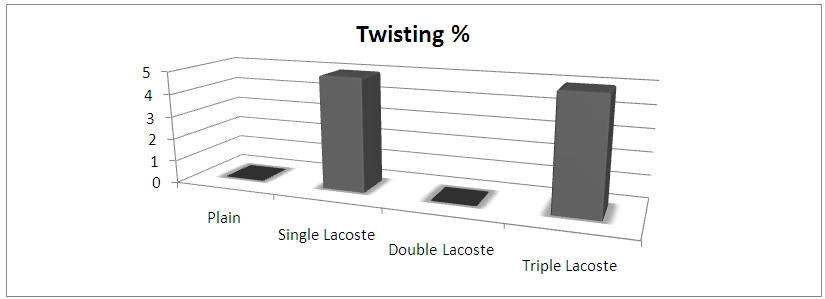

3.3. Effect on Spirality

- Spirality of different structures is shown in the figure 3. From figure 7 it is seen that plain and double lacoste structure do not show any twisting but single lacoste and triple lacoste fabric show 5% twisting.

| Figure 7. Effect of tuck loop on spirality |

3.4. Effect on Areal Density

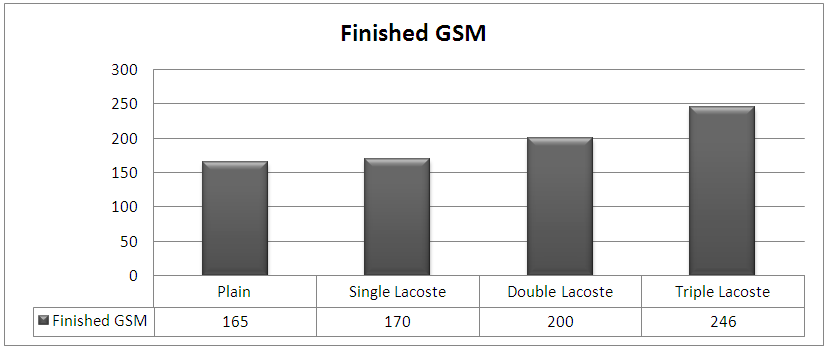

- Areal density of knitted structure changes with the change in the percentage of tuck loop. From figure 8 it is clear that areal density increases with the increase of tuck loop in knitted structure. Tuck loop accumulates yarn in the tuck place. For this reason number of loops increases per unit area, as a result areal density increases. With same yarn count, stitch length and machine specification, Triple Lacoste shows higher GSM than other fabrics, because it has maximum number of tuck loops in the repeat than other structures. As plain structure has no tuck loops, it shows lowest GSM.

| Figure 8. Effect of tuck loop on areal density |

4. Conclusions

- In this study the effect of tuck loop on fabric width in grey and finished state, shrinkage, spirality and areal density were investigated when yarn count, stitch length, machine gauge, machine diameter, dyeing and finishing procedures were same. From the investigation it was found that with the increase of tuck loop percentage in wales direction fabric width and areal density increases. But increasing number of tuck loop does not show any linear relationship with shrinkage and spirality.

ACKNOWLEDGEMENTS

- This research has been done in Micro Fibre Group, which is a 100% export oriented garments factory. Their Production and testing machineries has been used. This paper could be a guideline to the knitting department of the factory for further production development. We also like to acknowledge Safayat Hossain, student of Southeast University, who helped us to carry out the physical tests.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML