-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(5): 119-127

doi:10.5923/j.textile.20170605.01

Seam Performance Evaluation of Plain Fabric Using Different Dyes in Garments Dyeing

Nurunnabi1, Mohammad Abul Hasan Shibly1, Taslima Ahmed Tammana2, Md. Mahtabur Rahman3

1Department of Textile Engineering, National Institute of Textile Engineering and Research, Dhaka, Bangladesh

2Department of Textile Engineering, BGMEA University of Fashion and Technology, Dhaka, Bangladesh

3Anlima Textile Ltd, Dhaka, Bangladesh

Correspondence to: Nurunnabi, Department of Textile Engineering, National Institute of Textile Engineering and Research, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The seam performance, such as seam strength, seam slippage, and seam efficiency is an important factor of a garment. The durability of a garment depends on the longevity of a seam. Now a day’s fabric is dyed in the form of garments. So, it should be known about the seam properties how can it influenced after dyeing. The seam strength and seam elongation are the important factor for some purposes of end use such as domestic, decorative, functional, and protective, etc. So this study compares the longevity of seam before and after dyeing with alternative four dyes (direct dye, reactive dye, vat dye and pigment color) applied on sewn 100% cotton woven plain fabric which sewn by white colored polyester core spun thread (40/2 Tex). Dyed and undyed garment panels (specimen) are prepared along to the both in warp and weft direction for testing. In both warp and weft direction five samples of each group were taken for testing. The testing procedure was followed according to the ASTM method; D1683-04 and D5034. Seam performance evaluated in three different stages as grey panel, pretreated panel and dyed panel. In this study Universal strength tester was used for evaluation seam strength and seam slippage. The study was performed by taken 6.0 mm seam slippage to measure the breaking load. It was observed breaking load of the undyed garment panel were show higher strength than the dyed garments without seam opening. Here also discussed in details that, seam strength, seam slippage and seam efficiency not only influenced sewing thread, fabric construction, needle size, sewing machine condition etc. also dyestuffs can influence seam properties.

Keywords: Seam performance, Plain fabric, Dyed fabric, Breaking load, Universal strength tester

Cite this paper: Nurunnabi, Mohammad Abul Hasan Shibly, Taslima Ahmed Tammana, Md. Mahtabur Rahman, Seam Performance Evaluation of Plain Fabric Using Different Dyes in Garments Dyeing, International Journal of Textile Science, Vol. 6 No. 5, 2017, pp. 119-127. doi: 10.5923/j.textile.20170605.01.

Article Outline

1. Introduction

- The apparel industry generally produces a three-dimensional product from two-dimensional fabric. Apparel manufacturing process having some compulsory steps to finishing process in order to make a complete product. But stitch seaming is a common method that used world wide during converting garments from fabric (Solinger, 1989; Behera and Sharma, 1998). Seam found after stitching stage. And this seam is an important part of a garment, play an important role during wear. Seam strength, slippage, puckering, appearance has strongly influenced the seam performance and quality (Lindberg et al., 1960). A seam is generally formed by sewing machine and that should satisfy all the requirements of the end user (Rosenblad and Cednas, 1973; Stylios and Lloyd, 1990). From several studies, it clearly indicates that, seam is the most important parts of a garment and it is necessary to understand before apparel production. Seam quality insures by some aesthetic and functional performance after making a garment in the apparel industry. The functional performance includes strength, tenacity, efficiency, elasticity, elongation, flexibility, bending stiffness, abrasion resistance, washing resistance and dry cleaning resistance of the seam under some conditions of mechanical stress for a period of time (Mehta, 1985; Carr and Latham 1995; Glock and Kunz, 1995). Serviceability of apparel depends on seam strength, tenacity and efficiency. Seam should not be damaged during bending, shift and during folding. For this it should have proper elasticity, elongation, flexibility and low bending stiffness properties. Abrasion of seam also be found during wear, dry cleaning and washing. In this situation, it is expected that seam should have good abrasion and/ or washing and/ or dry cleaning. Consumer body as hand and eye also exhibits some aesthetic properties of a seam (Solinger, 1989; Carr and Latham, 1995; Glock and Kunz, 1995; Choudhory, 1995). A quality seam of a garment insures free from seam puckering, seam grin, distortion, unbalanced seam, loose seam, skipped stitches, etc. Faults free seam insure customer satisfaction and increase its acceptability. The apparel industry evaluates seam quality by using several dimensions from the consumer points of view (Kadolp, 1998).

2. Aim of Study

- To characterization of seam strength, seam slippage and shrinkage on cotton plain fabric before and after dyeing with different dyestuff like direct dye, reactive dye, vat dye and pigment dye.

3. Materials and Methods

3.1. Materials

- a. FabricWoven cotton plain fabric (

, G.S.M = 154)b. Sewing thread100% Spun polyester sewing thread (count: 40/2 Tex; sewing thread ply: 2; colour: white; finish: lubricant finish; sewing thread length: 2200 meter).c. Sewing needleNeedle size: metric 90; finish: chrome; point: thin ball (No.1/No. 23)) d. DyestuffsDirect dye, reactive dye, vat dye and pigment colour.e. EquipmentsSingle needle lockstitch sewing machine, Sample dyeing machine and Universal strength tester.

, G.S.M = 154)b. Sewing thread100% Spun polyester sewing thread (count: 40/2 Tex; sewing thread ply: 2; colour: white; finish: lubricant finish; sewing thread length: 2200 meter).c. Sewing needleNeedle size: metric 90; finish: chrome; point: thin ball (No.1/No. 23)) d. DyestuffsDirect dye, reactive dye, vat dye and pigment colour.e. EquipmentsSingle needle lockstitch sewing machine, Sample dyeing machine and Universal strength tester.3.2. Methods

- a. Specimen PreparationAccording to ASTM 1683-04 method, all samples was prepared. Each sample length was 350 mm and width was 100 mm. After that for seam preparation 200 mm length was marked and folded which length were 100 mm and sewn 2cm. Finally, the seam was prepared in both warp and weft direction.b. Pre-treatmentThe specimen was desized by neutral enzyme then scoured and bleached by using caustic and peroxide.c. Dyeing MethodAfter pretreatment specimen were dyed with direct, reactive, vat dye and pigment colour by using sample dyeing machine.d. Test MethodASTM D1683-04 method was used to measure, seam strength, unseam strength, seam slippage and seam efficiency.

4. Results and Discussions

4.1. Measurement of Breaking Load and Seam Slippage for Grey and Pretreated Fabric

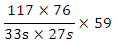

| Figure 1. Measurement of breaking load in kgf for grey and pretreated fabric |

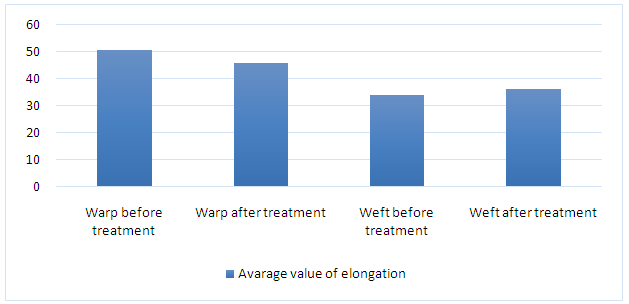

| Figure 2. Measurement of seam slippage for grey and pretreated fabric |

4.2. Measurement of Breaking Load and Seam Slippage for Pretreated and Dyed Fabric

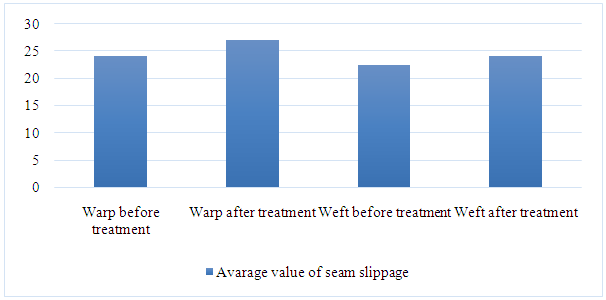

| Figure 3. Measurement of breaking load in kgf for direct dyed fabric |

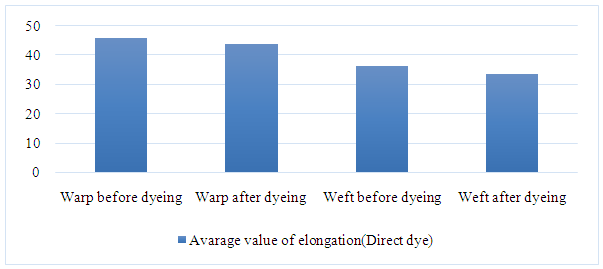

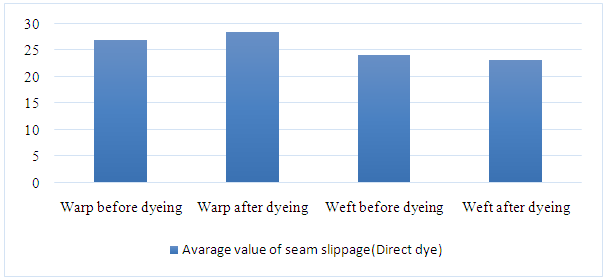

| Figure 4. Measurement of seam slippage in mm for direct dyed fabric |

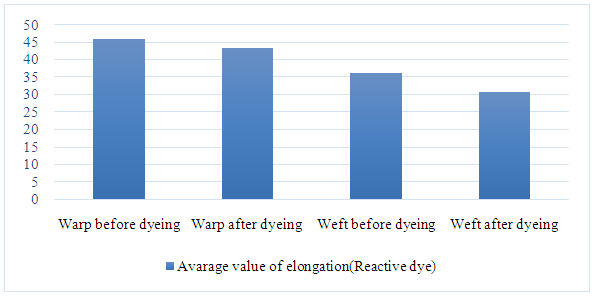

| Figure 5. Measurement of breaking load in kgf for reactive dyed fabric |

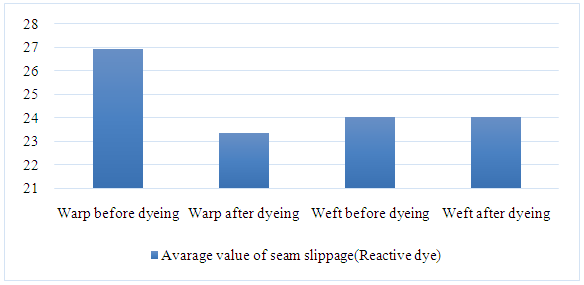

| Figure 6. Measurement of seam slippage in mm for reactive dyed fabric |

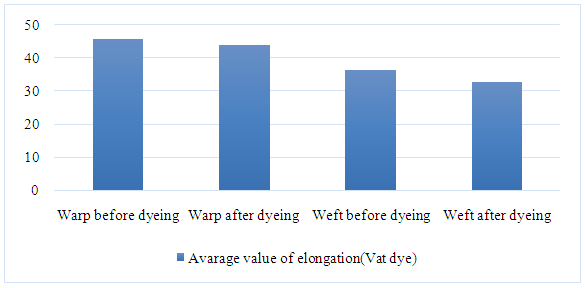

| Figure 7. Measurement of breaking load in kgf for vat dyed fabric |

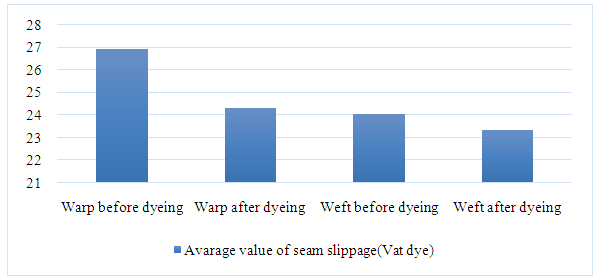

| Figure 8. Measurement of seam slippage in mm for vat dyed fabric |

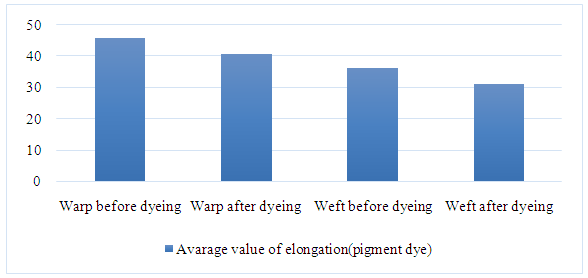

| Figure 9. Measurement of breaking load in kgf for pigment coloured fabric |

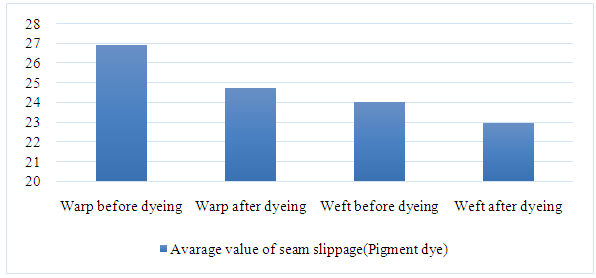

| Figure 10. Measurement of seam slippage in mm for pigment dyed fabric |

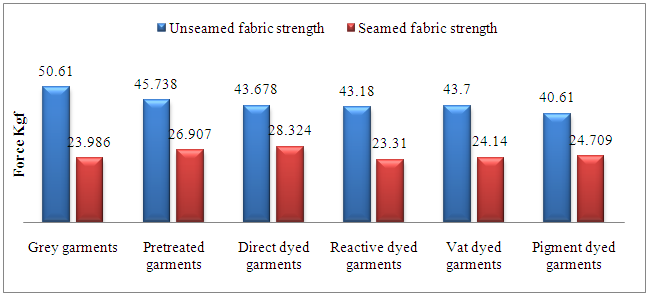

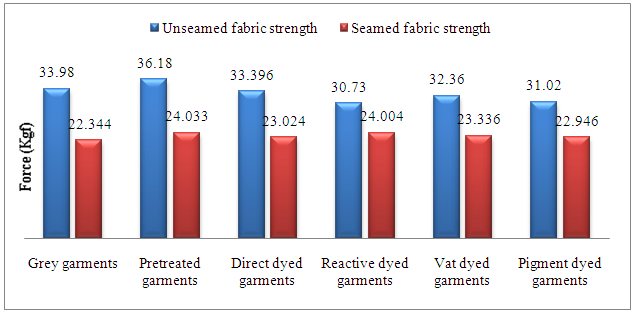

4.3. Comparison between Seam and Unseam Fabric Strength

| Figure 11. Comparison between seam and unseam fabric strength in warp direction |

| Figure 12. Comparison between seam and unseam fabric strength in weft direction |

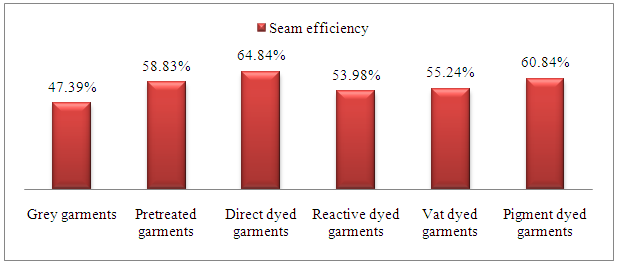

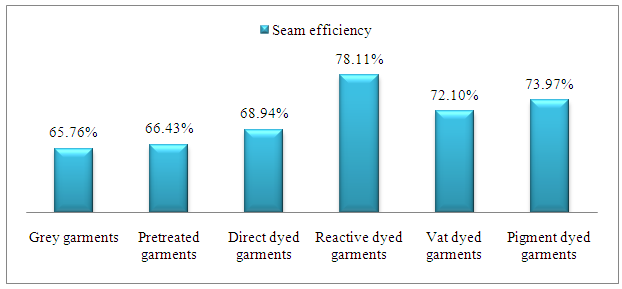

4.4. Comparison of Seam Efficiency of Fabric at Different Stages

| Figure 13. Comparison of seam efficiency at different stage in warp direction |

| Figure 14. Comparison of seam efficiency at different stage in weft direction |

5. Conclusions

- From the study, it is shown that the spun polyester thread seam strength is not falling down in pretreated process and dyeing process with four dyes, i.e. direct dye, reactive dye, vat dye and pigment color. For these dyes, polyester thread does not absorb dye, but for using cotton fabric the strength is varied and in case of some dye strength is raised and some cases are falling down. Here also notice that the unseam strength was better in direct dye, good in vat dye, moderately good in reactive dye and pigment also in the warp direction, but in case of weft direction the unseam strength was good in direct dye, moderately good in vat dye, moderately in pigment color and also reactive dye. The seam strength was good in direct dye, moderate in pigment color, vat dye, reactive dye in the warp direction, but in weft direction seam strength was higher in reactive dye, slightly moderate in vat dye, direct dye and pigment color. The seam efficiency was found higher in direct dyed garments, after then the value of seam efficiency of pigment, vat and reactive dyed garments are gradually decreased along in the warp direction. The weft directional garments are dyed with reactive dye was given better seam efficiency, moderate in pigment color and vat dye but lower in direct dye. Some fabric properties as ends per inch, picks per inch, yarn count and weave type playing a major role in the performance of the seam. With increase EPI and PPI, increase cover factor that’s show greater fabric strength and seam breakage.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML