-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(3): 88-91

doi:10.5923/j.textile.20170603.02

Comparison of Several Cotton Yarn Properties before and after Conditioning

Khan Ayub Nabi, Abir Nafis, Hawlader Md. Ramij

Dept. of Textile Engineering, BGMEA University of Fashion & Technology, Dhaka Bangladesh

Correspondence to: Abir Nafis, Dept. of Textile Engineering, BGMEA University of Fashion & Technology, Dhaka Bangladesh.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This article summarizes the effect of yarn conditioning on several yarn properties like moisture content, tenacity, elongation at break and yarn hairiness. At the early stages of fibre to yarn manufacturing, the range of moisture content in the cotton fibre lies around the standard level but after yarn manufacturing which becomes lowered, which creates several negative impacts on different yarn properties. To avoid this incident, presence of exact amount of moisture in the fibres is ensured through yarn conditioning process. During this research, yarn made from different fibre lots were tested before and after conditioning to analyze how conditioning puts significant impact on moisture content, tenacity, elongation at break and hairiness of yarn. The result showed around 5% increase in moisture content, around 4 to 6% decrease in hairiness, 12 to 13% increase in elongation at break, and a significant change in yarn tenacity. Besides these, this article also provides some explanations behind each impact.

Keywords: Yarn conditioning, Moisture content, Tenacity, Elongation at break, Hairiness

Cite this paper: Khan Ayub Nabi, Abir Nafis, Hawlader Md. Ramij, Comparison of Several Cotton Yarn Properties before and after Conditioning, International Journal of Textile Science, Vol. 6 No. 3, 2017, pp. 88-91. doi: 10.5923/j.textile.20170603.02.

Article Outline

1. Introduction

- The aim of yarn conditioning is to ensure the presence of exact amount of moisture in yarn packages. After conditioning, different properties of yarn like tenacity, elongation at break, thermal conductivity, air permeability, pilling resistance etc. get improved [1]. Yarn conditioning also provides better performances of yarn in post spinning processes like warping, weaving, knitting etc [2].This article deals about four major yarn properties like moisture content, hairiness, tenacity and elongation at break and the analysis shows that how much these properties get influenced by yarn conditioning. During the experiment, yarns having same count from different lots were made. Above stated yarn properties were checked by using USTER Evenness Tester 3 and USTER Tensojet before and after conditioning to analyze the impact on stated above yarn properties [3].Sardag et al. did a research about the effect of conditioning on the tenacity properties of cotton and viscose yarn. They found significant changes after conditioning. Such as, after conditioning a 16 Ne at 80°C for 30 minutes they got 9.31% increase in breaking load and 2.16% increase in breaking tenacity [4].Kara et al. analyzed the effect of heat setting on polyester/Viscose blended yarn and found that yarn tenaciy increased around 15% after heat setting at 90°C. and an increase of 8% in terms of elongation at break [5].Ahmed et al. analyzed the tensile properties of different fabrics in different relative humidity and found that after increasing the relative humidity from 55% to 85% through conditioning, tensile strength of cotton fabric increased around 20% in warp direction and 33% increase in weft direction [6].Uzair Hussain et al. tested hosiery yarn and knit fabric after conditioning through different methods and found an increase in CLSP value and also around 60% increase in the bursting strength of knit fabric [7].

2. Materials and Methods

- During this experiment cotton fibres from three different lots were taken from CIS origin (Uzbekistan). The whole experiment was done at the spinning unit of Padma Textile Mills Ltd.Yarns of 30Ne count were produced. After that yarns were tested by Uster EvennessTester-3 and Uster Tensojet before and after conditioning (conditioning time 25 min, conditioning temp. 80-85°C).The objective of conditioning is to ensure the presence of necessary amount of moisture in order to achieve a lasting improvement in quality [8].Conditioning was done according to the vacuum steaming process. In this process, at first vacuum removes the air pockets and then water vapor is applied to the yarn packages in the form of steam in a vacuum condition, so that saturated steam can diffuse uniformly into the yarn cones [9-11].Uster evenness tester is equipment which is used to evaluate the quality parameters of sliver, roving and specially the yarn. This instrument determines the unevenness (U%), co-efficient of variation of the fibrous strand throughout the whole length, yarn hairiness, imperfection index (IPI) etc.Uster evenness tester evaluates the fibre strands by measuring capacitance where the fibrous strands are passed through two parallel plates of a capacitor and the changes of the capacitance due to the change of masses of the materials through the parallel plates are recorded [12].

| Figure 1. Uster Tester 3 |

| Figure 2. Uster Tensojet |

3. Results and Discussion

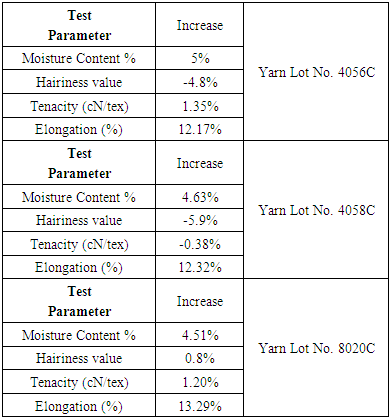

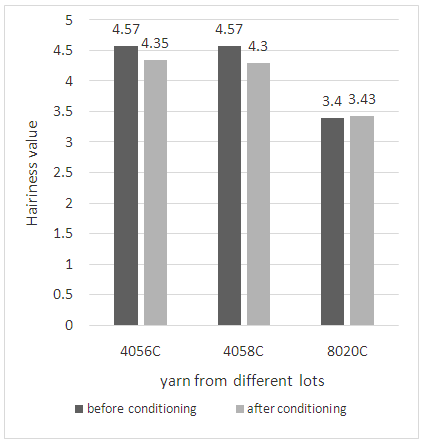

- The Table 1 shows the effect of conditioning on four key properties of yarn. Numerical values are shown at the table before and after conditioning. The negative signs indicate the percentage of deterioration after conditioning.

|

3.1. Effect of Conditioning on Moisture Content

- The major contributions of conditioning comes with the increase in moisture content of yarn as well as increase in the package weight. After conditioning the increase in the moisture content in different yarn lots are shown below. It is seen that after conditioning Moisture content has been increased about 5% for each yarn lot.During yarn conditioning, yarn packages are fed into the closed vessel of a yarn conditioning machine. Since conditioning machine applies saturated steam into the layers of yarn packages, a major rise regarding moisture content has been seen [14].

| Chart 1. Effect of conditioning on moisture content |

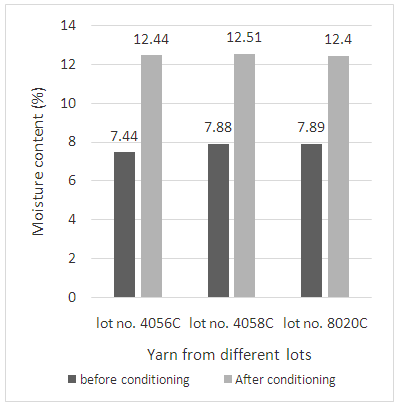

3.2. Effect of Yarn Conditioning on Yarn Hairiness

- Positive influences has seen regarding yarn hairiness value. It is seen among three yarn samples that, two of them shows a decrease in the hairiness value where other yarn show almost same result.Reduction of hairiness may occur due to the fact that, after conditioning, possibility of static electricity formation reduces which can render the repulsion of neighboring fibres [15]. Again after conditioning, cotton fibre obtains a favorable degree of softness which may also influence the reduction of hairiness after conditioning [16].

| Chart 2. Effect of yarn conditioning on yarn hairiness |

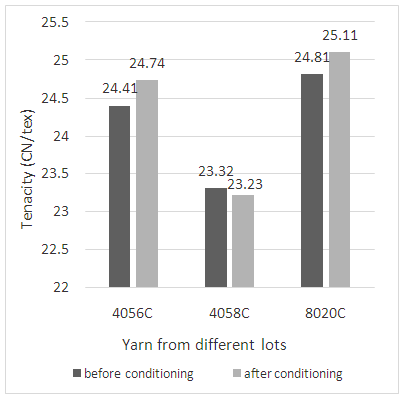

3.3. Effect of Yarn Conditioning on Yarn Tenacity

- Yarn tenacity also increases after conditioning. Among three yarns, two of them show an increase in the tenacity value, though one sample shows a very slight reduction in tenacity, but it is almost same to the tenacity value before conditioning.This fluctuation of tenacity value from the regular tendency may occur due to the improper instrument handling.The addition of tenacity occurs due to the swelling of screw shaped fibrils of cotton fibres. After conditioning, fibrils tend to untwist and unbend and simultaneously become pressed more efficiently against each other by swelling action which increases the resistance of fibres against any external force [17].

| Chart 3. Effect of yarn conditioning on yarn tenacity |

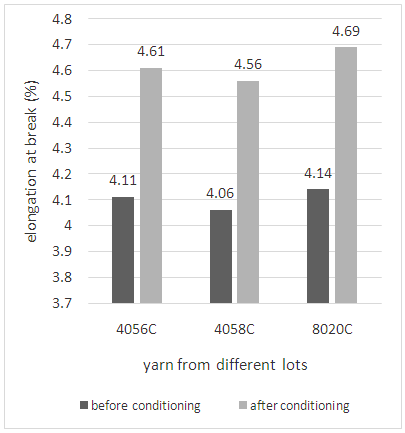

3.4. Effect of Yarn Conditioning on Elongation at Break of Yarn

- A dramatic addition is seen in the elongation at break of yarn. After analyzing data it is seen that in every cases conditioning process provides a 10-13% increase in the elongation at break value.During conditioning of cotton yarn, water vapor act as plasticizer by destroying the rigidity of cellulose structure of cotton fibre. After addition of moisture, cellulose molecules tend to move more freely with respect to other adjacent molecules. As a result cellulose structure becomes capable to change its shape more frequently against elongation [18].

| Chart 4. Effect of yarn conditioning on elongation at break of yarn |

4. Conclusions

- Yarn conditioning has an enormous impact on the physical properties of yarn. From this research work it is seen that, conditioning provides remarkable increase in, moisture content, elongation at break, and a significant decrease in yarn hairiness. In terms of tenacity, the increase of tenacity values was not so much significant. Researchers who want to do further research on this topic, as well as the people who are concerned with post spinning processes will be benefitted from this article also. Improvement in yarn properties after conditioning show their influences in post spinning processes.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML