-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(2): 72-77

doi:10.5923/j.textile.20170602.07

Dyeing of Cotton with Tectona grandis Leaves and Terminalia arjuna Bark Extracts

Shailendra Rane1, Manish Hate1, Prashant Hande2, Ajitkumar BS2, Ajit Datar3

1Department of Chemistry, Ramnarain Ruia College, Mumbai, India

2Department of GNIRD, Gurunanak Khalsa College, Mumbai, India

3Shimadzu Analytical (India) Pvt. Ltd., Mumbai, India

Correspondence to: Shailendra Rane, Department of Chemistry, Ramnarain Ruia College, Mumbai, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This study is to find out a nontoxic, fast and eco-friendly colouring agents for cotton dyeing. Natural dyes of plant origin find use in the coloring of textiles, drugs and cosmetics, owing to their nontoxic effects, they are also used for various food products. But there is the drawback in natural dyes such as it fades out in washing, seasonal color variation, great difficulties in blending dyes, non-standardised techniques and inadequate degree of fixation and fastness properties dyes. The research effort devoted to natural dyes are negligible. If there had been significant research on the use of natural dyes, it is possible that they would have already been much more widely used than currently. The leaves of Tectona grandis Linn are used for dye production while in Terminalia arjuna,bark is good source of natural dyes [1]. Dyes were extracted from the Tectona grandis Linn, leaves and Terminalia arjuna bark, respectively and the dyeing behaviours of the color components on cotton were evaluated. The dyeing was carried out with and without the use of mordants and the colorfastness properties of the fabrics were determined. The absorbance (%) and color strengths (K/S) of the dyes were evaluated and the color changes were recorded in Hunter co-ordinates and converted to CIELab co-ordinates. It is seen that the fastness of all dyed samples to wet rubbing was very good but unmordanted dyed samples had very poor fastness to light and washing, though staining on adjacent fabric is not observed. Mordanting with alum improved the washing fastness to moderate levels and adding iron salt to alum further improved it to good and very good category. Both plant materials have good potential for use as a natural textile dye for cotton.

Keywords: Tectona grandis, Terminalia arjuna, Dyeing, Mordant, Colorfastness and CIELab

Cite this paper: Shailendra Rane, Manish Hate, Prashant Hande, Ajitkumar BS, Ajit Datar, Dyeing of Cotton with Tectona grandis Leaves and Terminalia arjuna Bark Extracts, International Journal of Textile Science, Vol. 6 No. 2, 2017, pp. 72-77. doi: 10.5923/j.textile.20170602.07.

Article Outline

1. Introduction

- India is a country with large, diverse ethnic societies and also rich in biodiversity. There are 45,000 species of wild plants out of which 9,500 species are reported as ethnobotanically important species [2]. Of these 7,500 species are in medicinal use including indigenous health practices. About 3,900 plant species are used by ethnic community as food (root and tubers, leafy vegetables, bulbs and flowers, fruits), fiber, fodder, and other species are used for extraction of gum, resins, dyes and perfume [3].Since the advent of widely available and cheaper synthetic dyes in 1856 having moderate to excellent color fastness properties, the use of natural dyes having poor to moderate wash and light fastness has declined to a great extent. However, recently there has been revival of the growing interest on the application of natural dyes on natural fibers due to worldwide environmental consciousness.For successful commercial use of natural dyes, the appropriate and standardized dyeing techniques need to be adopted without scarifying required quality of dyed textiles materials. Therefore, to obtain newer shades with acceptable colorfastness behaviour and reproducible color yield, appropriate scientific techniques or producers need to be derived from scientific studies on dyeing methods, dyeing process variable, dyeing kinetics and compatibility of selective natural dyes. A need has also been felt to reinvestigate and rebuild the traditional processes of natural dyeing to control each treatment and pre-dyeing process (preparation, mordanting) and dyeing process variables for producing uncommon shades with balanced color fastness and eco-performing textiles.Natural dyes are obtained from plants and animals with minimal chemical processing. This class of dyes is recognized to be eco-friendly and less likely to be poisonous as compared to man-made dyes [4-6]. Because of being less hazardous and more eco-friendly, natural dyes are considered safer to use as compared to their man-made counterparts [7, 8].For the commercial use of natural colorants the appropriate extraction, purification and characterization of color pigments from specific plant extracts are of utmost importance along with the studies related to their stability, toxicity and also standardization of natural dyes. It is therefore expedient in this regard that, a systematic study of selected plant colorants is to be carried out in order to explore their applications in various fields like food, cosmetics and textile.

2. Material and Methods

2.1. Plant Material and Sample Preparation

- Tectona grandis leaves and Terminalia arjuna bark were collected from thane district of Maharashtra. Herbariums of Tectona grandis and Terminalia arjuna were prepared and authenticated from MS University (Vadodara). The materials collected were washed under running tap water. The plant kept for drying in oven at temperature 40±2°C. The dried material was powdered through mixer and then sieved through ASTM sieve (85/BS sieve) separately and was kept in separate airtight containers.

2.2. Fabric

- Commercially scoured and bleached, ready for dyeing mercerized 100% cotton fabric of plain weave obtained from Century mills was used for dyeing experiments. Fabric were rinsed in water, cut into 10x10 cm pieces and weighed.

2.3. Dyes

- The water extract of dried and powdered Tectona grandis leaves and Terminalia arjuna bark were used for dyeing.

2.4. Dyes Extraction

- Required quantity of powdered dye was soaked overnight (about 16 hours) in distilled water (M: L ratio was 1:10) in a conical flask. The flask was then kept in a shaking water bath and temperature of the bath was increased to 60°C and maintained at that temperature for 15 minutes. Plant material was then filtered out by filtering through a sintered glass crucible (G-1) and the residue was washed using the of fresh distilled water and the liquor was filtered. Both the filtrates were combined and the volume was made to volume (200 ml for every 10 g dye used) in a measuring cylinder and used as such for dyeing.

2.5. Mordanting

- Pre-mordanting method was followed. Potash alum and its 50:50 mixture with ferrous sulphate were used as mordant. Prior to treatment with metallic mordants, cotton fabric pieces (10x10 cm each) were mordanted with aqueous tannic acid solution [5% on weight of the fabric (o.w.f.) basis] i.e. 5gm mordant 100 g-1 in a cooling bath [9, 10]. Fabric pieces were introduced into an almost boiling tannic acid solution in a conical flask which was then kept on a shaker for 45 minutes without supplying any further heat. The fabrics were then removed from the solution, squeezed and then immersed in aqueous solution of either potash alum alone or in a 50:50 mixture of alum and FeSO4 -ferrous sulphate (10% o.w.f.) for 30 min at room temperature (about 27°C) on a shaker. Material to liquor ratio for all mordanting experiments was 1: 20. At the end of the treatment period, the fabrics were removed from the solution, rinsed well with water and air dried.

2.6. Dyeing

- Dyeing was performed with the aqueous dye extracts prepared above to 80% shade (o.w.f.) with weight of powdered plant material being taken as the weight of the dye. Thus for each 10x10 cm fabric sample piece, 80 ml dye extract corresponding to 4g powdered plant material was used for dyeing. As the material to liquor ratio of 1: 16 was used, the dye extract prepared above was used as such for dyeing. Two dyeing temperatures viz. 60°C and 100°C were used for each dye and the dyeing was carried out in stainless steel beakers (100 ml capacity) on an Infrared beaker dyeing machine (Infra color from M/s R.B. Electronic and Engg. Company, Mumbai). Each dyeing experiment was carried out in duplicate i.e. two 10x10 cm cotton fabric samples from each of the three different pretreatments viz unmordanted, premordanted with tannic acid followed by alum and premordanted with tannic acid followed by alum and ferrous sulphate were taken up for dyeing.Dyeing was started at room temperature (27°C) and the temperature of the dye bath was raised to the required temperature viz. 60°C and 100°C at the rate of 3°C/min. and once the temperature was achieved, it was maintained for 45 min. The beakers were then allowed to cool down to about 45°C, opened, dyed samples were squeezed and removed from the dyebath, rinsed thoroughly with water and air dried. Though color obtained was light, the dyeing was uniform.

2.7. Characteristic of Dye Extracts

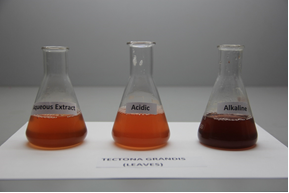

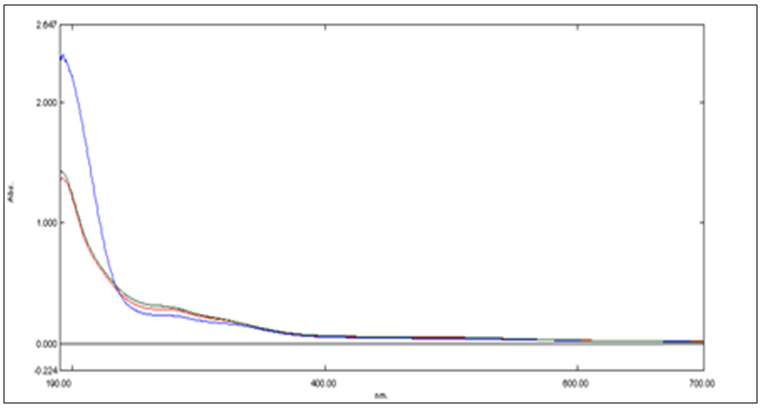

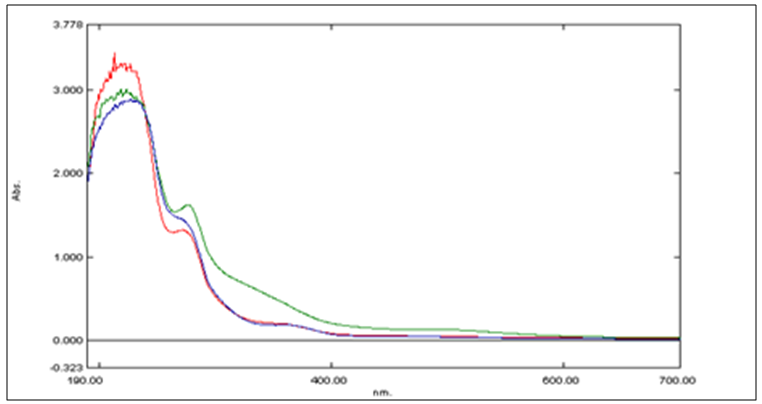

- Dye extract was prepared in a similar way but larger amount of extracting solvent (water) was used. 0.5 g plant material extracted with 100 ml water. Extracts were made to 250 ml in a measuring flask and its pH was recorded. Parts of these extracts were made acidic by adding acetic acid or alkaline by adding sodium carbonate and uv-visible spectrum of all these extracts were recorded on Shimadzu UV 1800 spectrophotometer after a further 10 times dilution.

3. Evaluation of Dyed Samples

- Dyed samples were evaluated for the color parameters and colorfastness properties.

3.1. Color Parameters

- Reflectance data of all dyed samples at various wavelengths in the visible region was analysed on Spectrascan 5100 computerized color matching system (Premier Colorscan). The CIELab color parameters of these samples were calculated from this data by the software. Wavelength of maximum absorption max and Color strength (K/S) values at max were also calculated by the software.

3.2. Evaluation of Colorfastness Properties

- Colorfastness properties of dyed samples were evaluated by the following standard methods,i) Colorfastness to washing- IS/ISO 105- C 10: 2006 (Test no. 2) [11]ii) Colorfastness to wet rubbing- IS 766: 1988iii) Colorfastness to light- IS 2454: 1988 (up to Blue wool standard 4)

4. Results

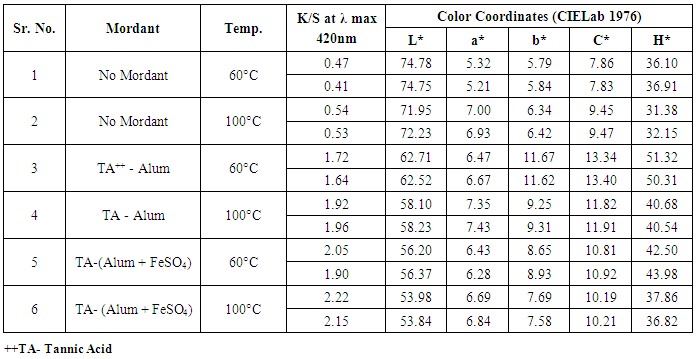

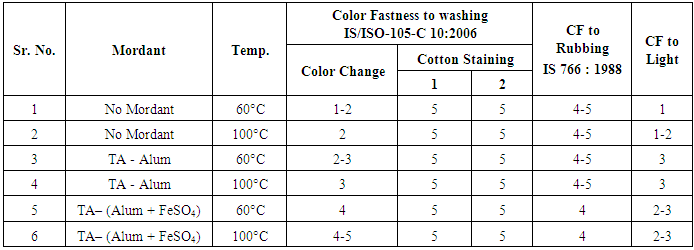

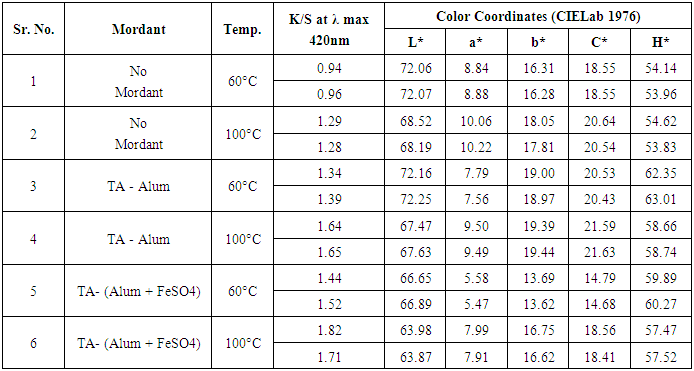

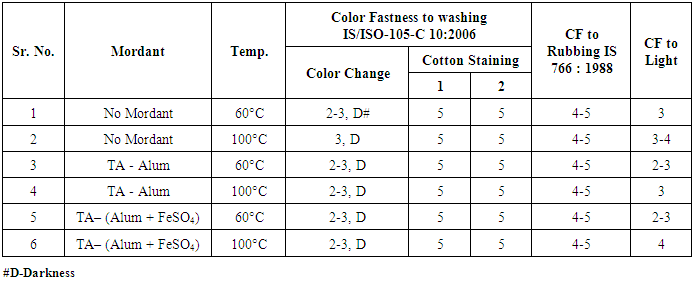

- Wavelength 420nm is having maximum absorbance in visible range for both the dyes, hence it was selected for the analysis. The K/S value at this wavelength was calculated by the software. Color parameters and color fastness properties of cotton fabrics dyed with Tectona grandis leaves extract and with Terminalia arjuna (Bark) extract are mentioned below.

|

|

|

|

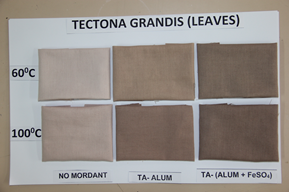

| Figure 1. Cloths dyed with Tectona grandis leaves extract |

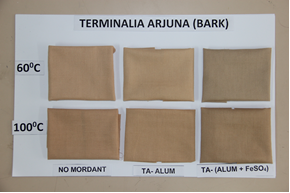

| Figure 2. Cloths dyed with Terminalia arjuna bark extract |

| Figure 3. Aqueous dye extracts from Tectona grandis |

| Figure 4. Aqueous dye extracts from Terminalia arjuna |

| Figure 5. UV-VISIBLE spectra of Tectona grandis leaves extract at different pH |

| Figure 6. UV-VISIBLE spectra of Terminalia arjuna bark extract at different pH |

5. Discussion

5.1. Dyeing of Cotton with Tectona grandis Leaves

- Color parameters of cotton fabrics dyed with Tectona grandis leaves are listed in Table 1. Dyed fabric in this case was also of light color as seen by low K/S values. However, mordanting has resulted in comparatively higher improvement in color strength values which is also exhibited by the greater reduction in L values. Higher dyeing temperature has resulted in higher color strength of dyed samples for this plant material also which indicates requirement of higher dyeing temperature by dye components for exhausting onto cotton as well as their good thermal stability. Mixture of alum with iron salt has proved a better mordant than alum alone for obtaining higher color strength. Positive a* and b* values of the dyed samples indicate redness and yellowness of dyed samples. Wavelength of maximum absorption for all samples for this material was also 420 nm denoting the yellowish shade of dyed samples. Chroma (C*) values of these samples were lower than the chroma values observed for Terminalia arjuna dyed samples which indicates comparatively weaker total color of these samples.Colorfastness properties of these dyed samples are presented in Table 2. It is seen that the fastness of all dyed samples to wet rubbing was very good but unmordanted dyed samples had very poor fastness to light and washing, though staining on adjacent fabric is not observed. A higher dyeing temperature did not have much effect on fastness to light for this material but it improved the fastness to washing. Mordanting with alum improved the washing fastness to moderate levels and adding iron salt to alum further improved it to good and very good category. Mordents had a beneficial effect on the lightfastness also but alum alone was found better in this aspect.

5.2. Dyeing of Cotton with Terminalia arjuna Bark

- Table 3. contains the color parameters of cotton fabrics dyed with the extract of Terminalia arjuna bark. It is seen that the color strength (K/S) values of all samples are low which is also evident from their light color. Samples dyed at boil were darker in comparison to those dyed at 80°C for all treatments as their K/S values were higher. This shows that the dye components require higher temperature for exhausting onto cotton material and these are stable at higher temperature. Unmordanted sample had the lowest color strength and Tannic acid and alum plus ferrous sulphate mordanted samples had. the highest color strength values. Their L values were also lowest indicating darker shade as higher is the L value, lighter is the shade. Positive a* and b* values indicate redness and yellowness of dyed samples. Wavelength of maximum absorption for all samples was 420 nm which again denotes yellowish shade of dyed samples.Table 4. contains the colorfastness properties of these dyed samples. Washing fastness of all samples was moderate and similar but it is worth noting that the samples instead of fading have become darker and there is no staining on adjacent cotton fabrics. Therefore a soaping treatment after dyeing can increase the fastness to washing of these samples. All samples showed excellent fastness to wet rubbing. Unmordanted dyed samples showed medium fastness to light. Better fastness was observed for samples dyed at boil for all treatments. Alum mordanting had a slight adverse effect on this property whereas a mixture of iron and alum mordant had a positive effect when dyeing was carried out at boil.

6. Conclusions

- Ÿ The plant extract was successfully used for dyeing of cotton fabrics with good fastness properties using mordants. The depth of the dyeing can be improved with proper experimental procedure and hence can be used as ready to use natural dye for clothing. Ÿ The percentage crude dye yield resulted from evaporation of dye plant extracts and color fastness tests indicated that the said dye plant under this study have considerable potential for application as a source of natural dye for cotton fabrics dyeing. Both the studies are very reliable as well as reproducible.Ÿ A systematic study of extraction, characterization and improving the properties of the dye is must to minimize the cost investment, yield maximization and dye purity. The dyes are eco-friendly and safe only when they are easily biodegradable, having no health hazard effects and eco-label. The dyes extracted from Tectona grandis leaves and Terminalia arjuna bark provide such beneficial properties.

ACKNOWLEDGEMENTS

- The authors are gratefully thank to CIRCOT (Central Institute for Research on Cotton Technology) and Shimadzu Analytical (India) Pvt. Ltd. for granting permission to use their facility for current research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML