Santanu Das1, 2, Monoroma Hossain2, 3, Md. Shakhawat Hossain Rony2, 3, Md. Mehedi Hashan2, 3, Ashique Ul Haque1, 2, Mithon Majumder2, 3

1School of Chemistry and Chemical Engineering, Wuhan Textile University, Wuhan, China

2Department of Textile Engineering, Southeast University, Dhaka, Bangladesh

3School of Textile Science and Engineering, Wuhan Textile University, Wuhan, China

Correspondence to: Md. Shakhawat Hossain Rony, Department of Textile Engineering, Southeast University, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

This article focused on rib and interlock knit fabric structures which detected relationships among the GSM (Gram per square meter), count and stitch length. Textile industries face some common problems regarding the selection of accurate GSM, count and stitch length to produce a quality oriented knit fabric. Here, both the empirical and experimental data were compared with each other to verify through an equation where if the stitch length and count increases then the GSM decreases. This is due to the relation among GSM, count and stitch length; where GSM is inversely proportional to the count and stitch length. This study is based on grey GSM of knit fabric where yarn counts used were 28Ne, 30Ne, 32Ne for (1x1) rib, and 34Ne, 36Ne, 40Ne used for (1x1) interlock. In the investigation, we have compared both the theoretical as well as the practical implications from the industry and we have also tried our best to emphasize on the adjustable points of fabric GSM, count and stitch length directly or indirectly. This study establishes an acceptable result which would be preferable for the effective use and would also facilitate for carrying out further activities related with this research.

Keywords:

Count, GSM, Stitch length, Rib and Interlock Fabrics, Weft Knitting

Cite this paper: Santanu Das, Monoroma Hossain, Md. Shakhawat Hossain Rony, Md. Mehedi Hashan, Ashique Ul Haque, Mithon Majumder, Analyzing Technical Relationships among GSM, Count and Stitch Length of (1x1) Rib and (1x1) Grey Interlock Fabric, International Journal of Textile Science, Vol. 6 No. 2, 2017, pp. 64-71. doi: 10.5923/j.textile.20170602.06.

1. Introduction

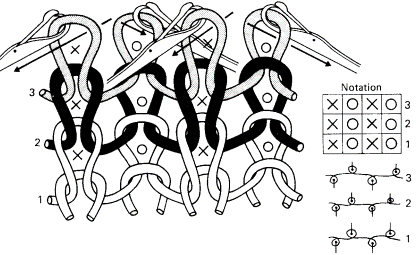

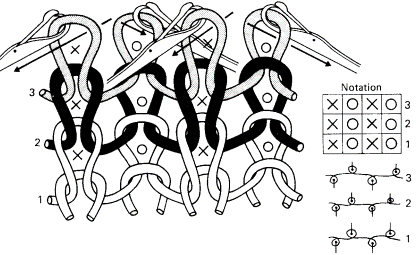

Knitting is a method of converting yarn into fabric by interlacing loops, which are formed with the help of needles to produce knit fabric [1]. There are two basic structure of knitting process technology, weft and warp knitting [2]. Weft knitted fabrics can be produced in both flat or tubular form [3]. In a weft knitted structure the thread runs in the horizontal direction and loops can be made using one thread. Weft knitted fabric is generally highly elastic and highly drape able, which make it suitable for a wide range of apparel applications. Weft knitted fabric is porous and comfortable both for outer garments and undergarments [4]. On the other hand, warp knitting which is done by machine, the work progresses length wise, through the intermeshing of loops in the direction of wale. In a warp knitted structure each loop in the horizontal direction is made from different thread. The main advantage of warp knitted cloth is that, it is not easy to unravel. However, these fabrics are not as elastic as weft knitted fabrics. Knitted fabric specification which are related to knitted fabric production [5]. In case of knitted fabric specification count, GSM and stitch length is mainly considered [6].The common problem of all industries is to produce knitted fabrics of required those specifications. Other specification like fabric width, thickness is generally maintained in industries. So, some technical problem arises when an order comes which never produced in before. The object of this study is to find out easy process or method to take decision about the selection of yarn count, loop length and GSM for producing rib and interlock fabric. This article estimated as relation among count, stitch length and GSM of rib and interlock fabric [7, 8]. Rib fabric A double-knit fabric in which the rib wales or vertical rows of stitches intermesh alternatively on the face and the back of the fabric. Rib knit fabrics have good elasticity and shape retention, especially in the width [9, 10].PropertiesŸ The appearance of face and back are identical.Ÿ Fabric length wise and width wise extensibility is approximately that of single jersey.Ÿ Fabric does not curl at edges.Ÿ Fabric thickness is approximately twice than single jersey.Ÿ There are two series of knitted loops arranged into two parallel in a course.Ÿ Combination of Wales of face loop and back loop are present on the both side of the fabric.Derivatives of Rib StructureŸ 1x1 ribŸ 2x2 ribŸ Half cardign Ÿ Full cardignŸ Swiss double piqueŸ France double piqueŸ 4x2 rib | Figure 1. (1x1) Rib knitted structure |

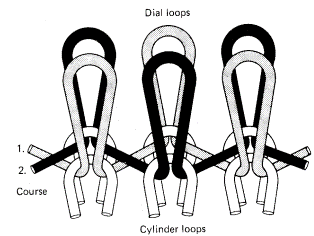

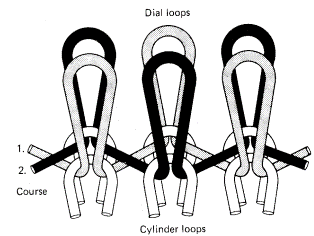

Interlock fabricIn knitted fabric, loops are locked to each other and loops are identical. The stitch variation of the rib stitch, which resembles two separate 1x1 ribbed fabrics that are interknitted. Plain interlock stitch fabrics are thicker, heavier, and more stable than single knit construction [7, 11].PropertiesŸ Interlock the technical face of plain on both side so the appearance of face and back are same.Ÿ The Wales of each side re exactly opposite to each other and are locked together.Ÿ Widthwise and length elongation are approximately same as single jersey.Ÿ The fabric does not curl at the edges.Ÿ The fabric can be unraveled from the knitted last.Ÿ Two yarns must be removed to unravel a complete repeat of knitted course.Ÿ Fabric thickness is approximately twice than that of single jersey.Derivatives of Interlock StructureŸ 1x1 interlockŸ Jersey card, etc. | Figure 2. (1x1) Interlock fabric structure |

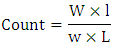

Stitch length The length of yarn required to produce a complete knitted loop is known as stitch length or loop length. Stitch length is a length of yarn which includes the needle loop and half the sinker loop on either side of it. Loop exists in course in course length and it is that which influence fabric dimension and other properties including weight. Take a fabric and mark with pen 100 wales for single jersey and 50 wales for rib and interlock fabric. Then open the course and measure the length in cm scale and divided this data by 10 and measure stitch length [12].Fabric GSMThe GSM is one kind of fabric specification which is very important for a textile engineer for understanding and production of fabric. GSM means gram per square meter that is the weight of fabric in gram per one square meter. By this specification compare the fabrics in unit area which is heavier and which is lighter. | Figure 3. GSM cutter |

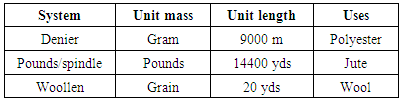

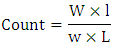

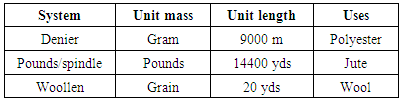

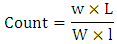

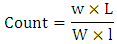

For measuring GSM, fabric sample is cut by GSM cutter. Weight is taken by electric balance. By this way we get the weight in gram per one square meter fabric [13]. Here GSM of the fabrics by the GSM cutter is obtained by the multiplying the sample weight with 100. CountCount is numerical expressions which express or indicate the fineness or coarseness of yarn used in textile. According to Textile intuition, count is a number indicating the mass per unit length or the length per unit mass of yarn. Here, count has two systems indicate coarseness and fineness of yarn [14]. Count is mainly two types-Ÿ Indirect system Ÿ Direct system Direct systemIn this system the count of yarn expresses the number of weight units in one length unit. This system the count is higher than the yarn is coarser. This system is used for thrown silk, artificial silk, jute etc. [15]. Count calculation formula is- Here, W = the weight of sampleL = the length of samplew = the unit weight in systeml = the unit length in system

Here, W = the weight of sampleL = the length of samplew = the unit weight in systeml = the unit length in systemTable 1. Direct count system

|

| |

|

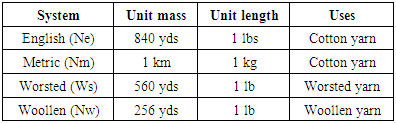

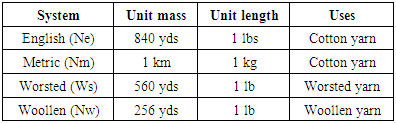

Indirect System In this system the count of yarn expresses the number of length unit in one weight unit. This system the count is higher than the yarn is finer [14, 16]. This system is generally used for cotton, worsted, woollen, linen [17]. The yarn count calculation formula is- Here, W = the weight of sampleL= the length of samplew = the unit weight in systeml= the unit length in system

Here, W = the weight of sampleL= the length of samplew = the unit weight in systeml= the unit length in systemTable 2. Indirect Count System

|

| |

|

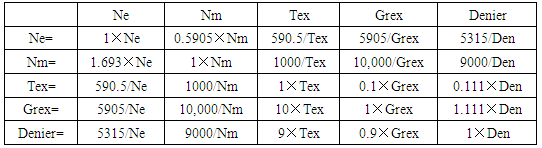

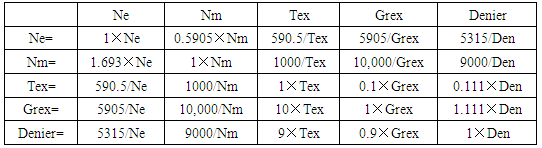

Whenever the type of count is not mentioned with the count, it is understood that is the English count because this count is widely used and known as English cotton count [18, 19]. Now let’s see the count conversion table which helps to calculate the count from any system of count.Table 3. Count conversion table

|

| |

|

2. Materials and Method

2.1. Materials

100% cotton knit fabric was used for (1x1) rib and (1x1) interlock fabric. The Fabrics were collected from Cotton Club BD Limited of Bangladesh. Count of the collected fabrics was 28, 30 and 32 used for the rib and interlock fabrics were used 40, 36 and 34 count.

2.2. Instruments

GSM cutter was used for taking the GSM of the grey fabric. Centimetre scale was used for measuring the stitch length. An electric balance used for taking the weight of the fabrics. Jiunn long circular knitting machines were used for manufacturing the fabric.

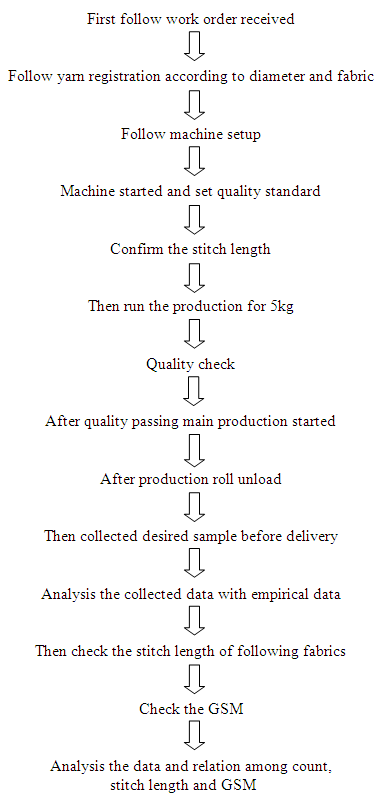

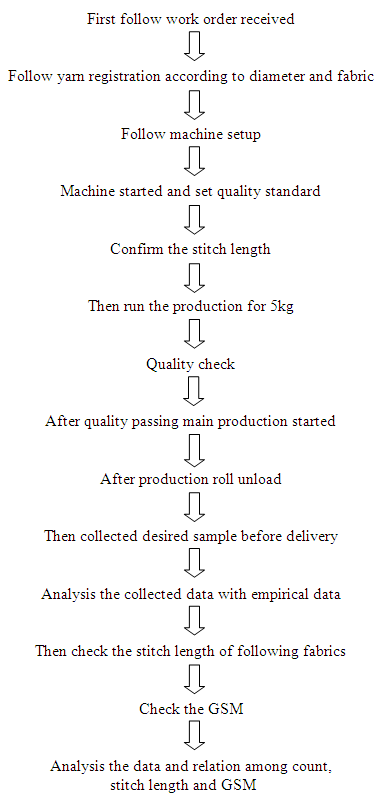

2.3. Method

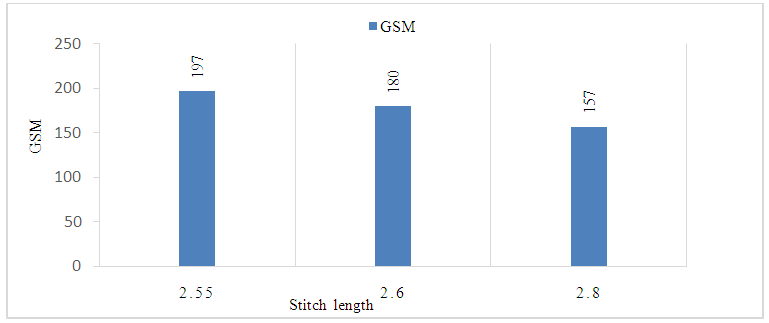

For this study, need to collect many data and analysis those data and relation among count, stitch length and GSM. The working procedure is given below-

| Figure 4. Stitch length measurement of grey fabric |

3. Result and Discussions

For this analysis 3 samples collected with 3 types of different count with 3 types of different stitch length for both (1x1) rib and (1x1) interlock fabrics.

3.1. Experimental Calculation for GSM Measurement

Collect sample (Rib and Interlock fabric) by G.S.M cutter and weighted from the balance. Then multiply this weight with 100/m2.For 1x1 rib fabrics, form balance we get 1.97-gram grey fabricSo, grey GSM = 1.97gm×100/m2 =197 gm/m2Same as, 1.80 gram and 1.57-gram grey fabric we found GSM 180 and 157.For (1x1) interlock fabrics, form balance we get 2.11-gram grey fabricSo, grey GSM = 2.11 gm×100/m2 =211 gm/m2Same as, 2.07 gram and 2.10-gram grey fabric we found GSM 207 and 210.

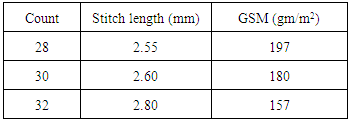

3.2. Experimental Calculation for Stitch Length Measurement

Take a fabric and mark with pen 50 wales for rib and interlock fabric. Then open the course and measure the length in cm scale and divided this data by 10 millimetre and measure stitch length.For (1x1) rib fabrics, measurement 50 wales length in same course 25.5 cm.So, stitch length = 25.5/10 mm = 2.55 mm.Same as, when 50 wales length 26 cm and 28 cm then find the stitch length 2.6 mm and 2.8 mm.For (1x1) interlock fabrics, measurement 50 wales length in same course 14.6 cm.So, stitch length = 14.6/10 mm = 1.46 mm.Like as above, when 50 wales length 16.6 cm and 18.0 cm then find the stitch length 1.66 mm and 1.8 mm.

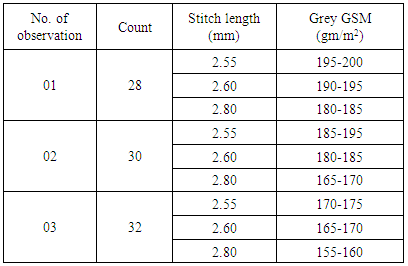

3.3. Analysis of Rib Fabric

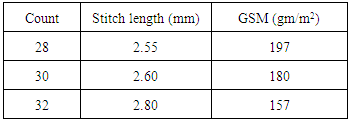

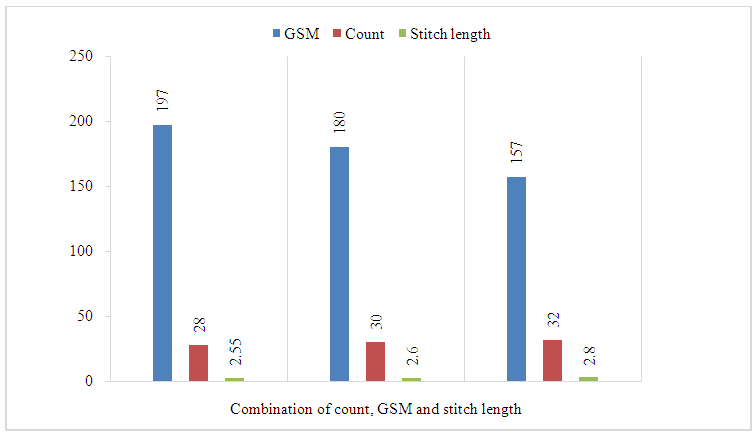

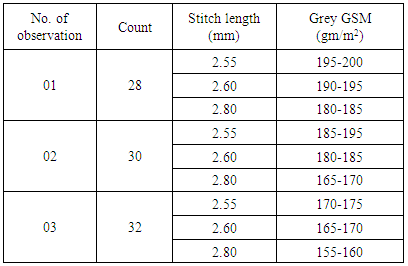

This analysis for (1x1) rib fabric and showing relation among GSM, count and stitch length. Here 28, 30 and 32 count are selected and also stitch length 2.55 mm, 2.60 mm and 2.80 mm are selected.Table 4. Count, stitch length and GSM of (1x1) rib fabrics

|

| |

|

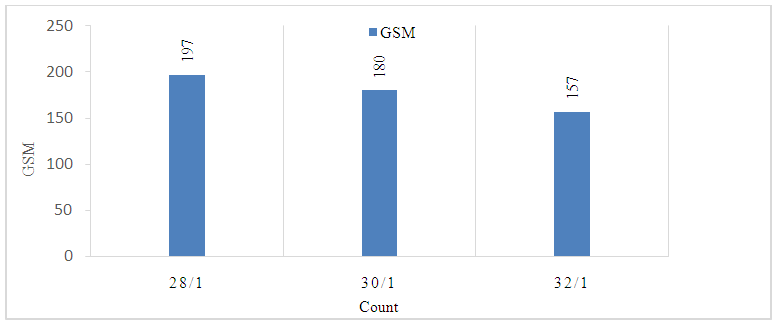

As shown in Figure 5 when the count 28, 30 and 32 then the GSM is respectively 197, 180 and 157.  | Figure 5. Relationship between count and GSM of rib fabric |

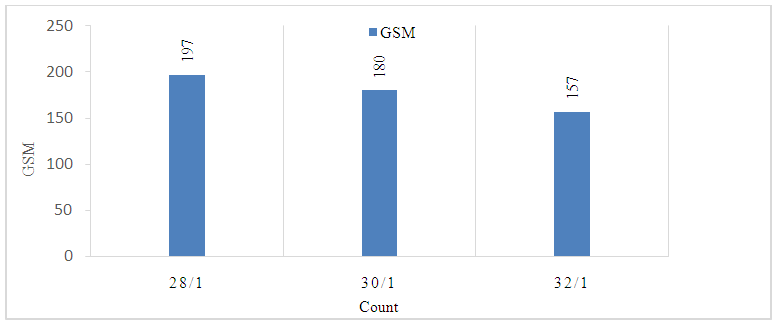

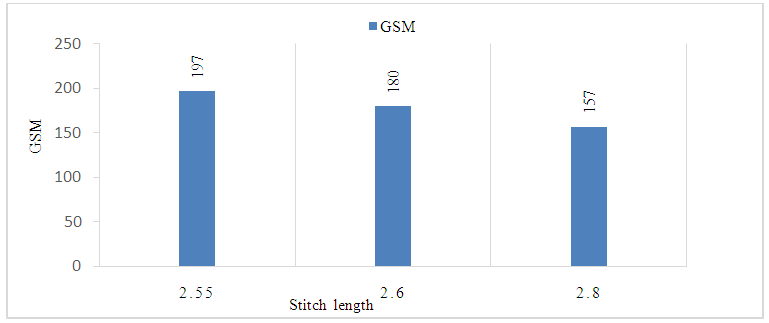

In Figure 6 when the stitch length 2.55 mm, 2.60 mm and 2.80 mm then the GSM is respectively 197, 180 and 157. | Figure 6. Relationship between GSM and stitch length of rib fabric |

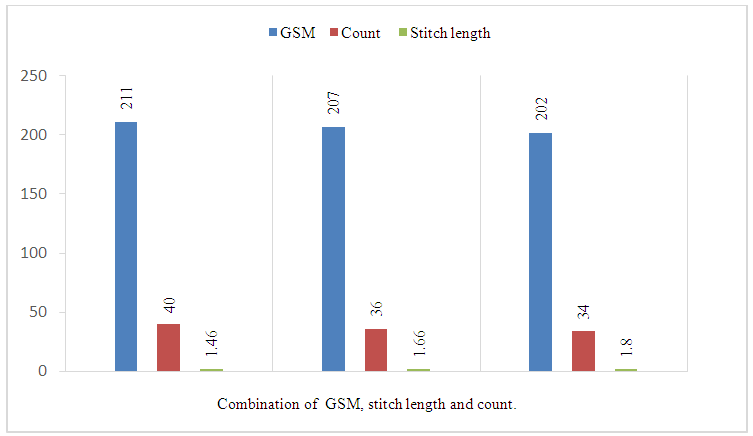

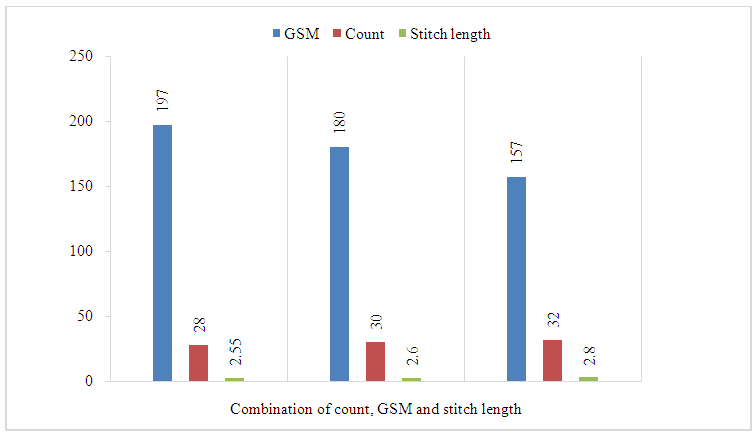

Figure 7 shows the combination between Figure 5 and Figure 6 and when the count 28, 30 and 32 stitch length is respectively 2.55mm, 2.60mm and 2.80mm then the GSM is 197, 180 and 157.  | Figure 7. Relationship among GSM, stitch length and count of rib fabric |

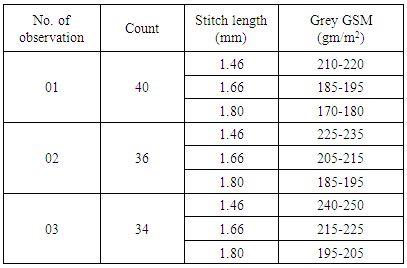

3.4. Analysis of Interlock Fabric

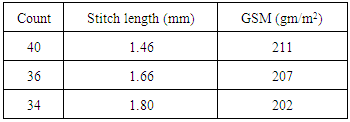

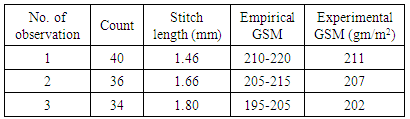

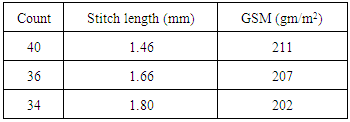

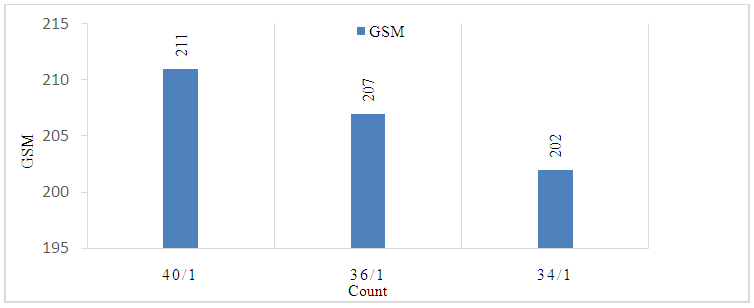

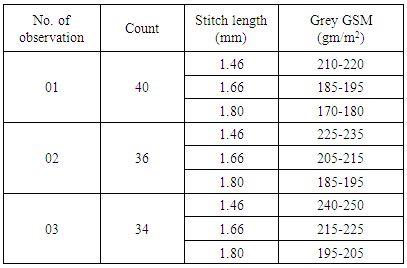

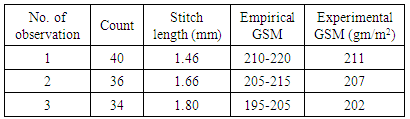

In case of this analysis for (1x1) interlock fabric and also showing relation among count, stitch length and GSM. Here 40, 36 and 34 count is selected and also stitch length 1.46, 1.66 and 1.80 are selected.Table 5. Count, stitch length and GSM for (1x1) interlock fabrics

|

| |

|

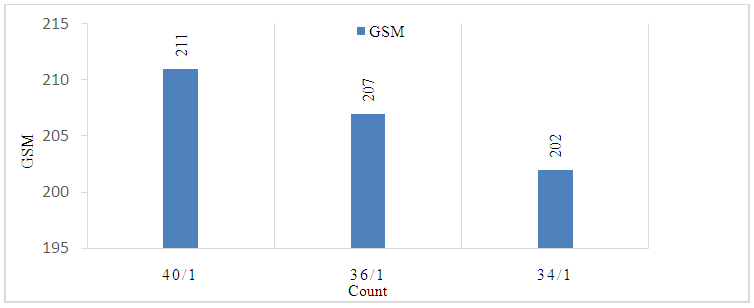

Figure 8 indicates, when the count 40, 36 and 34 then the GSM is respectively 211, 207 and 202. | Figure 8. Relationship between GSM and count of interlock fabric |

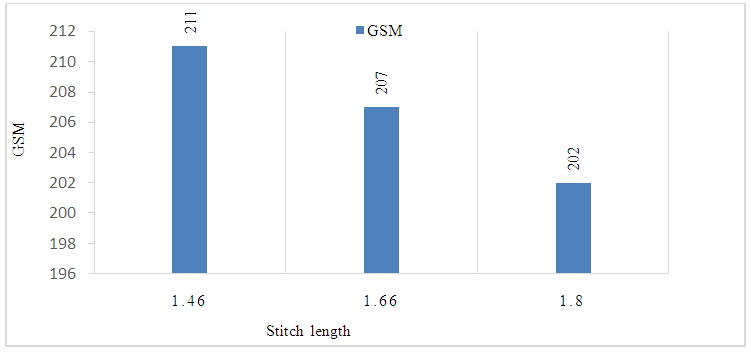

From Figure 9 when the stitch length 1.46 mm, 1.66 mm and 2.80 mm then the GSM is respectively 211, 207 and 202. | Figure 9. Relationship between GSM and stitch length of interlock fabric |

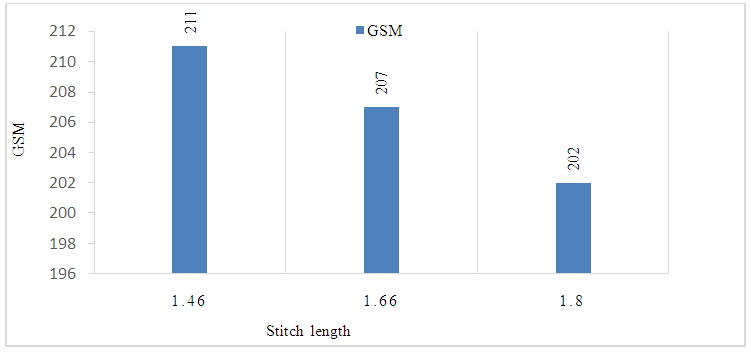

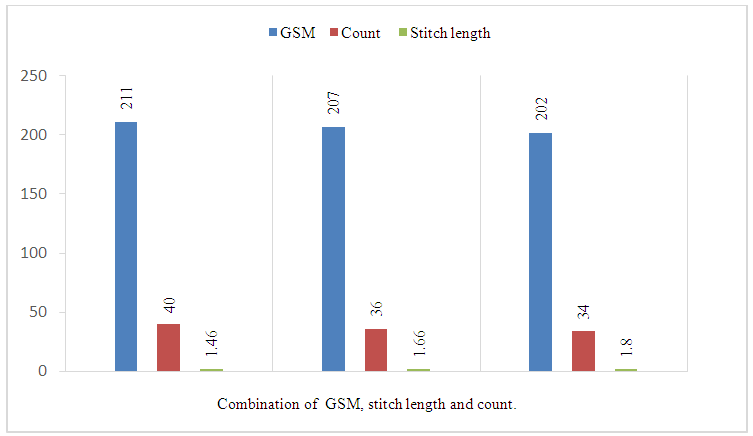

In Figure 7 when the count 40, 36 and 34 stitch length is respectively 1.46 mm, 1.66 mm and 1.80 mm then the GSM is 211, 207 and 202. According to experimental data some empirical data collected for (1x1) rib and (1x1) interlock fabric from factory which are given below-Table 6. Empirical data of 1x1 rib fabrics

|

| |

|

Table 7. Empirical Data of 1x1 interlock fabrics

|

| |

|

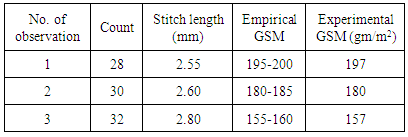

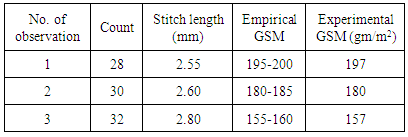

Table 8. Comparison between empirical and experimental GSM of 1x1 rib fabrics

|

| |

|

| Figure 10. Relationship among GSM, stitch length and count of interlock fabric |

Findings from the Table 8 when count 28 and stitch length 2.55 mm then our experimental GSM is 197 where factory experienced GSM range is 195-200. Same as for the count 30 and 32 the stitch length 2.60 mm and 2.80 mm then our experimental GSM are comparatively 180 and 157, where empirical GSM range is 180-185 and 155-160. From this table we can find, the empirical data and our experimental data are almost same. That means for rib fabric, this experiment is accurate.Table 9. Comparison between empirical and experimental GSM of 1x1 interlock fabrics

|

| |

|

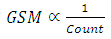

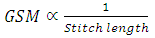

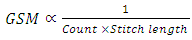

As shown is Table 9 when the count 40 and stitch length 1.46 then our experimental GSM are 211 where factory experience GSM range is 210-220. Same as when the count 36 and 34 the stitch length 1.66 and 1.80 then our experimental GSM are 207 and 202 where empirical GSM range is 205-210 and 200-205. From this table we can find, the empirical data and our experimental data are almost same. That means for interlock fabric, this experiment is accurate. For both 1x1 rib fabric and 1x1 interlock fabric, from Table 6, Table 8 and Table 7, Table 9 easily say that, when count is increases then GSM will be decreases. Here stitch length is fixed. | (1) |

And also it was investigated that when the stitch length increases then GSM decreases. Here, count is fixed. | (2) |

At last, from above equations (1) and (2) we found equation (3). Now it has been definitely say that when stitch length and count Increases then the GSM will be decreases. When yarn count and stitch length both are variables. That’s means,  | (3) |

4. Conclusions

It is need not to mention that GSM, count and stitch length is very essential parameters which control all the properties of weft knitted fabric. Mainly stitch length and count plays vital role in knit fabric structure. This study about only (1x1) rib and (1x1) interlock fabric and from the analysis find a complete idea about selection GSM, count and stitch length which is important when produce rib and interlock fabric in industries. Form the above mentioned data it has been identified that when stitch length and count Increases then the GSM will be decreases. Here yarn count and stitch length both are variables. From the analysis, it also gives idea about grey stage of knit fabrics, that source will show better performance for the proper selection of count and stitch length for accurate GSM.

ACKNOWLEDGEMENTS

The Authors are obliged to Cotton Club BD Limited, Bangladesh for their cooperation and encouragement by providing necessary equipment and materials to complete the experiment. Authors are also grateful to all staff, shift in charge and operators for their help and support for significant completion of the research paper.

References

| [1] | Chen, H.-C., K.-C. Lee, and J.-H. Lin, Electromagnetic and electrostatic shielding properties of co-weaving-knitting fabrics reinforced composites. Composites Part A: applied science and manufacturing, 2004. 35(11): p. 1249-1256. |

| [2] | Ellison, J.R., Warp knit weft insertion fabric and plastic sheet reinforced therewith. 1986, Google Patents. |

| [3] | Burrow, S.W. and D.P. Nobile, Low contamination swab employing tubular knit fabric. 1993, Google Patents. |

| [4] | Harrison, J.M. and R.R. Varin, Mesh knit fabrics having electrically conductive filaments for use in manufacture of anti-static garments and accessories. 1988, Google Patents. |

| [5] | Ramakrishna, S., Characterization and modeling of the tensile properties of plain weft-knit fabric-reinforced composites. Composites Science and Technology, 1997. 57(1): p. 1-22. |

| [6] | Rameshkumar, C., et al., Comparative studies on ring rotor and vortex yarn knitted fabrics. Autex Res. J, 2008. 8: p. 100-105. |

| [7] | Oğlakcioğlu, N. and A. Marmarali, Thermal comfort properties of some knitted structures. Fibres & Textiles in Eastern Europe, 2007. 15(5-6): p. 64-65. |

| [8] | Ramachandran, T., G. Manonmani, and C. Vigneswaran, Thermal behaviour of ring-and compact-spun yarn single jersey, rib and interlock knitted fabrics. 2010. |

| [9] | Smirfitt, J., 19—WORSTED 1× 1 RIB FABRICS PART I. DIMENSIONAL PROPERTIES. Journal of the Textile Institute Transactions, 1965. 56(5): p. T248-T259. |

| [10] | Kurbak, A., Geometrical models for balanced rib knitted fabrics part I: conventionally Knitted 1× 1 rib fabrics. Textile Research Journal, 2009. 79(5): p. 418-435. |

| [11] | Araujo, M.d., R. Fangueiro, and H. Hong, Modelling and simulation of the mechanical behaviour of weft-knitted fabrics for technical applications. Autex Research Journal, 2004. 4(2). |

| [12] | Kane, C., U. Patil, and P. Sudhakar, Studies on the influence of knit structure and stitch length on ring and compact yarn single jersey fabric properties. Textile Research Journal, 2007. 77(8): p. 572-582. |

| [13] | Islam, M.A. and A. Haque, Selection of suitable machine gauge by considering the GSM, shrinkage and spirality of single jersey knit fabric. Research Journal of Science and IT Management, 2014. 3(3): p. 50-55. |

| [14] | Özdil, N., A. Marmaralı, and S.D. Kretzschmar, Effect of yarn properties on thermal comfort of knitted fabrics. International journal of Thermal sciences, 2007. 46(12): p. 1318-1322. |

| [15] | Hamilton, J., 40—A Direct Method for Measuring Yarn Diameters and Bulk Densities Under Conditions of Thread Flattening. Journal of the Textile Institute Transactions, 1959. 50(12): p. T655-T672. |

| [16] | Shyong, E., Textile design system and method. 1991, Google Patents. |

| [17] | Scardino, F.L. and W.J. Lyons, Fiber Surface Properties in Relation to Linear Assemblies During Processing 1: Part II: Results on the Cotton and Woolen Systems; Other Studies. Textile Research Journal, 1967. 37(11): p. 982-988. |

| [18] | Aggarwal, S., A Model to Estimate the Breaking Elongation of High Twist Ring Spun Cotton Yarns: Part I: Derivation of the Model for Yarns from Single Cotton Varieties. Textile Research Journal, 1989. 59(11): p. 691-695. |

| [19] | El Mogahzy, Y.E., R. Broughton Jr, and W. Lynch, A statistical approach for determining the technological value of cotton using HVI fiber properties. Textile Research Journal, 1990. 60(9): p. 495-500. |

Here, W = the weight of sampleL = the length of samplew = the unit weight in systeml = the unit length in system

Here, W = the weight of sampleL = the length of samplew = the unit weight in systeml = the unit length in system Here, W = the weight of sampleL= the length of samplew = the unit weight in systeml= the unit length in system

Here, W = the weight of sampleL= the length of samplew = the unit weight in systeml= the unit length in system

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML