-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(2): 57-63

doi:10.5923/j.textile.20170602.05

Causes and Remedies of Garments Production Hampering in Textile Industries

Monoroma Hossain1, 2, Md. Shakhawat Hossain Rony1, 2, Santanu Das2, 3, Mithon Majumder1, 2, Md. Fazle Rabbi Khandaker1, 2, Yang Zhou1

1School of Textile Science and Engineering, Wuhan Textile University, Wuhan, China

2Department of Textile Engineering, Southeast University, Dhaka, Bangladesh

3School of Chemistry and Chemical Engineering, Wuhan Textile University, Wuhan, China

Correspondence to: Md. Shakhawat Hossain Rony, School of Textile Science and Engineering, Wuhan Textile University, Wuhan, China.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

This paper represents the causes of different problems and mitigation of production hampering that are identified through the investigation of surveying in different garments manufacturing factory in Bangladesh. Although Bangladesh is one of the largest garments manufacturing country in the world but it often fails to meet the ultimate production within the lead time. Production hampering is a major and common problem for garments industries. Lots of causes are observed for the production hampering. The problems that are involved with production are termed as production hampering factors. Production hampering is created because of target production without calculation adequately and uses of unfit machines. It has been identified from the investigation that, some worker related problems like unskilled worker, gossiping tendency and absence of worker are also the reason of production hampering. Most of time inadequate helper, lack of proper monitoring, unsuitable environmental condition are also the crucial facts. Existence of these problems, it is very difficult to produce quality product within the lead time. To cope up with the global challenges, we should to reduce the production hampering causes by implement some standard methods. The other important things are also explained in this article and that are the best possible solutions of the causes of production hampering factors.

Keywords: Garments, Production hampering, Quality product, Lead time, Causes and Remedies

Cite this paper: Monoroma Hossain, Md. Shakhawat Hossain Rony, Santanu Das, Mithon Majumder, Md. Fazle Rabbi Khandaker, Yang Zhou, Causes and Remedies of Garments Production Hampering in Textile Industries, International Journal of Textile Science, Vol. 6 No. 2, 2017, pp. 57-63. doi: 10.5923/j.textile.20170602.05.

Article Outline

1. Introduction

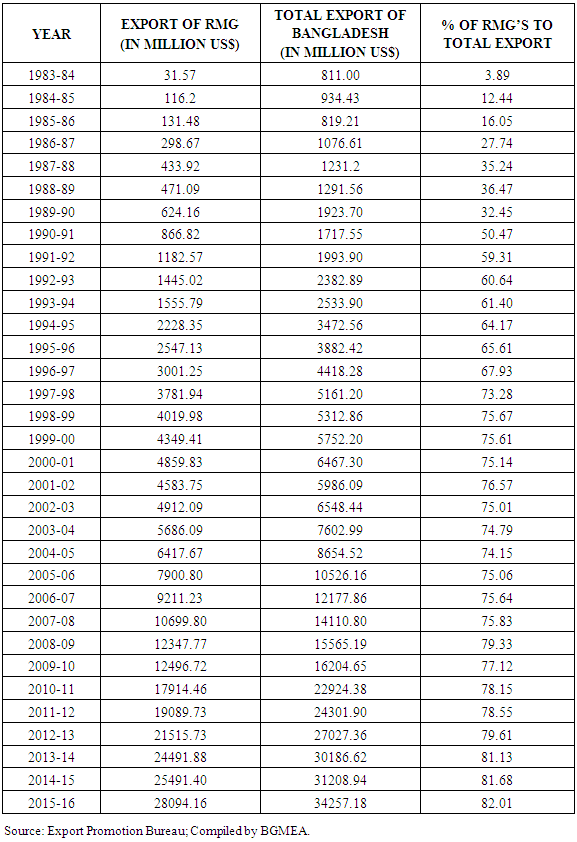

- Garments sector plays a vital role in Bangladesh. Now a day’s garments product is the number one export products in our country [1]. Few years ago jute was the golden fiber of Bangladesh. Now this place is replaced by the garment field. This section created a very large job market so people come to this area and stay with their giant pleasure [2]. Most of the workers were very poor but this sector removes their poverty. For this reason, it can be said that this zone is the God gifted sector for those people [3, 4].The output of garments per unit time (second, minute etc.) is an important factor in a garments industry [5]. A split second is very significant for garments production. Sometimes garments production does not meet up the target making due to some problems or barriers [6].The importance of the garment industry in the economy of Bangladesh is very high. Furthermore, the industry is expected to be the catalyst in the industrialization of Bangladesh, and has been declared as a thrust sector by the government [7]. However, this largest sector faces numerous problems, coupled with faulty government policies and a lack of fairness in competition from neighboring countries [8, 9]. The explosive growth of the RMG industry in the country, however, has not been supported by the growth of backward linkage facilities. Because of the inferior quality and supply of local fabrics, which are also non-competitively priced, the RMG industry is almost completely dependent on imported fabric [10]. As a result, the foreign exchange earning from the RMG industry is extremely low. This value addition could obviously be boosted if appropriate backward linkages were established in the textile industry. This paper highlights the problems and the frequency the problem occurrence and also the mitigation ways of these problems that will be very informative to increase the concern of the top management that will help to reduce the production hampering and increase the quality products. In 2015-2016 financial year 82.01% of the total export was from readymade garment industry Table 1 [11, 12].

2. Methodology

2.1. Instruments

- Different production oriented machine situated in the garments manufacturing units of Bangladesh named ABA group, Padma poly cotton knit fabrics limited and Beats fashion limited. Different sewing machines, cutting machines, inspection machines and finishing machines were used for this research available in the factory.

2.2. Methods

- Different sections production efficiency was taken into consideration for this research work. Idle time and lead time were closely monitored and analyzed. Technical skill of the employees especially the workers, machine idle time, environment of the workplace was also investigated strongly for attaining the most effective output through this work.

3. Results and Discussion

- Different problems that reduce the production hampering and also reduce the quality of products have been integrated together in this paper. The summary of problem occurring and the frequency of problem occurrence of different industries are analyzed. How production hampering occurs due to these problems has also been analyzed graphically. In a garments industry production problems may occur from different ways have also been integrated. This paper will reflect these production hampering problems and the remission ways to the top management of the industries and also be effective to take actions against these problems. Finally, this paper provides the mitigation ways against these problems.

|

3.1. The Effective Causes beyond the Production Hampering

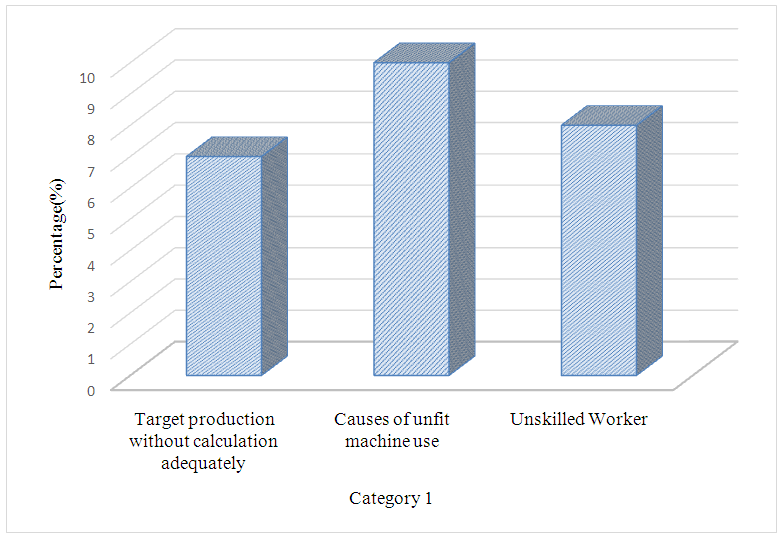

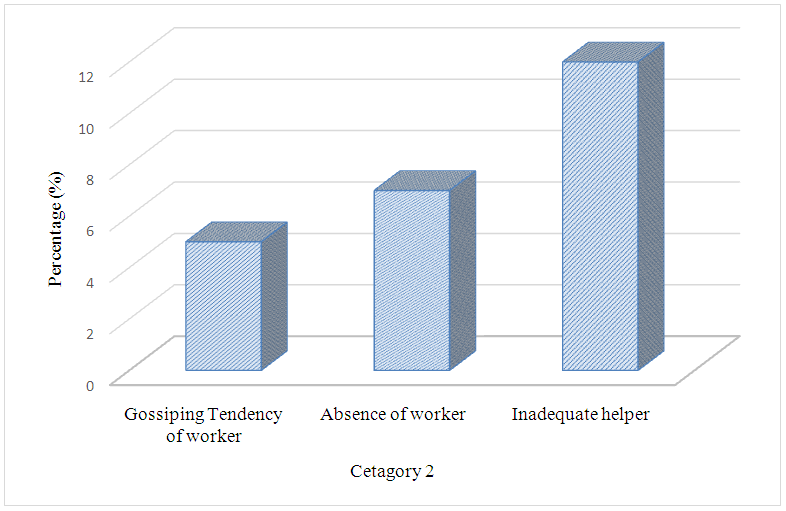

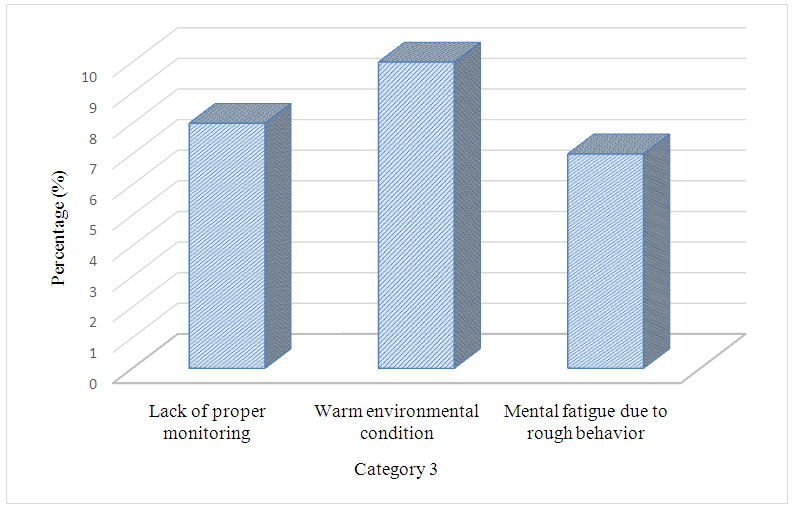

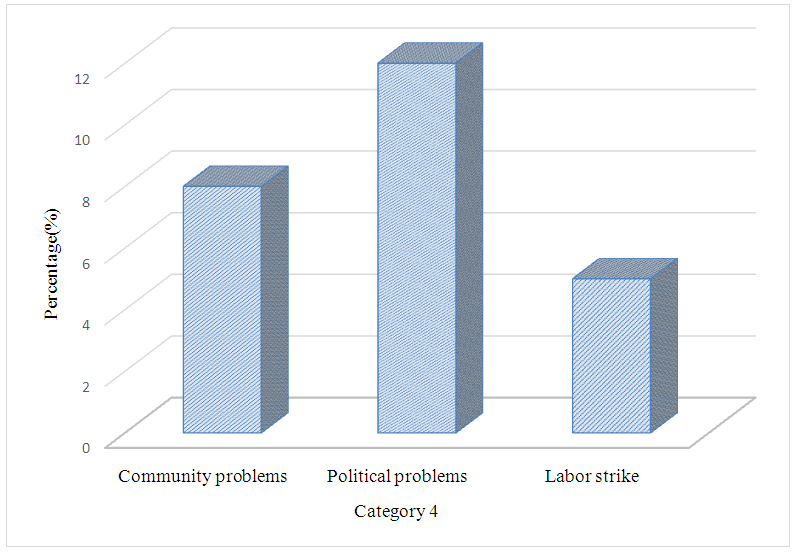

- I. Target production without calculation adequately Four things should be considered to calculate the actual target production such as machine efficiency, operation (different stitches according to lay out), floor conditions (external, internal), and workers efficiency. In most of the cases target production is calculated without considering these factors. As a result, SMV is not balanced properly, production jam occurs and it becomes a factor of production hampering.II. Causes of unfit machine use Most of the time unfit machines are used in the production line which causes many problems such as frequent breakage of sewing thread during sewing, frequent breakage of needle etc. It requires extra time to set the sewing thread. Also needle set in the machine requires more time. For this reason, SMV will increase and as usual it hampers production rate.III. Unskilled Worker In garments sector skilled worker is one of more important factor. Unskilled operators cannot adapt themselves with the skilled operators. In this case production jam occurs which industrially known as bottle neck theory and it’s a major cause of production hampering factors.IV. Gossiping Tendency of worker There is a bad tendency among most of the workers of the garments industry. They tend to gossip to each other during the production time. As a result, they cannot concentrate properly in their duty and they are not able to fulfill their line wise target. V. Absence of workerAbsence of worker in working day is common problem in garments industry. Sometimes workers remain absent due to illness and for other reasons. A common matter is found in the workers of garment industry is that some of the workers remain absent in the day after salary payment. As a result, the production is hampered and it becomes very difficult to fulfill the target of production.VI. Inadequate helperSometimes production is hampered due to the inadequate number of helper. Operators have to pass the cutting part from one table to another table. It requires an extra time and operators become failure to fulfill their target. It also causes of production hampering. VII. Lack of proper monitoring If the line responsible person is not aware about the production, the workers work as their own way. As a result, alteration of faulty garments increases during checking. It requires extra time to eradicate faults from the garments. It also hampers the production.VIII. Warm environmental condition In production floor ventilation system should kept properly. If the ventilation system is poor, then the workers fell uncomfortable during their work. For this reason, mental fatigue arises of workers. So they can not work properly. As a result, warm environmental condition is a vital cause of production hampering.IX. Mental fatigue due to rough behavior Sometimes line supervisors behave very roughly with the workers for silly faults. As a result, mental fatigue arises of the workers which results in tiredness, high rate of accident etc. X. Community problemsEverybody work as a team is important concern to increase the garment production. Lack of this type of attitude creates a lot of problems. Such as, they cannot work properly because of internal problems among them. The workers cannot be helpful with each other. The workers always look after others fault. The workers make quarrel with each other. Factory environment and production may fall. So lead time may increase.XI. Political problemsPolitical situation of our country is unstable. Hartal or strike is a common phenomenon of our country. During hartal or strike workers can not reach at their work place with in due time. As a result, the production goes down.XII. Labor strikeStrike is one of major problem created by the workers. Sometimes misunderstanding between factory management and workers create labor strike. On the other hand, sometimes factories make excessive delay in making payment of the workers. At that time the workers are influenced by their leader and stop working to notify their owners about wages. In some cases, the strike comes out a large volume that the workers act destructive works against the factory management and take place along the high way to create strike. As a result, the productions go down.Actually, the production of the garments floor is not calculated adequately. This is one of the most important causes of production hampering, which is by 7%. The use of unfit machines is responsible by 10%. The unskilled workers create problem by 8% shown in Figure 1.

| Figure 1. The causes of production hampering, category 1 |

| Figure 2. The causes of production hampering, category 2 |

| Figure 3. The causes of production hampering, category 3 |

| Figure 4. The causes of production hampering, category 4 |

3.2. Effective Ways for Remedies of Production Hampering

- I. Establishment of trustRely on between the employee and the employer is not simply important, but essential too for various reasons. When workers trust employer and feel comfortable to serve under a particular management, they do not like to change job and stay longer time in that company. This causes low labor turnover, keeps experienced labor for longer period of time, and thus reduces training cost and economies time all this avoids production loss, increase finally productivity and keeps lead time unchanged.II. Workers satisfactionWorkforce is the most important factor of a production system; providing satisfaction to worker is a matter of utmost importance. Highly unsatisfied workforce may become unruly, create unrest and may call for strike and violence. So every garments industry should follow a strategy to keep the workforce satisfied.III. Suitable working environment Garments factory must provide basic needs for a safe and healthy working environment including pure drinking water, restroom facilities, child care facilities, proper safety equipment’s etc. If the factory provides a comfortable and safe working environment for the workers then this results in less tiredness, low rate of accidents and less absenteeism. In return the factory attains better productivity.IV. Ensuring safety of the workersAll of the safety equipment’s should install properly in the garments industry. Proper installation of safety equipment’s can save the factories own property and lives by reducing the accident or occupational hazard and in return saves both production time and cost of treatment.V. Working hours In a factory working hours should be maximum 8 hours per day with one day off per week and also 12 hours’ overtime per week. As a result, the workers will get time for their self and they remain strong and energetic enough to do hard labor during there working time. Thus the productivity will increase automatically.VI. Salary and benefits The minimum wages that are determined by the government should be paid properly to the worker. Overtime wages should also be paid with the salary. All of the payment of the worker must be paid within 7 days of the following month. When the workers get the salary in due time they become satisfied and it results increasing productivity.VII. Proper maintenance of machinery In a factory machines should be properly installed by relevant experts who have long installation experience in this field. Proper maintenance of machinery is a must to avoid any accident due to the non fit machineries. Workers feel comfortable to work with a fit machine and the production rate is increased.VIII. Proper monitoring system All of the responsible persons involved with the production should be aware about the work which is running in the production floor. There must be a monitoring and evaluation system in order to check whether the system is running in right order or not; what are weakness, insufficiency or lacking etc. If any problems arise in the production floor immediate step should be taken to overcome the problem. IX. Arranging training programs Training makes human resource more efficient and makes business more competitive. Industrial management knowledge is most important for top and mid level employees and also for the workers while proper operations of machines by operators are crucial for increase productivity. Regular basis training can ensure both better industrial management environment and higher productivity.X. Proper management SystemSuccess of a garments industry depends mainly on its management system. Experienced manpower should be included in each department in a factory. This is because they know which work is to start earlier and which by the end of the program. The whole production system should be taken care of under the supervision of knowledgeable and experienced experts.

4. Conclusions

- Garment industries are the leading industrial area in Bangladesh but due to some production hampering problems the it often fails to reach the desired position. RMG sector contributes around 80% of total exports in Bangladesh garments industry. Although there are some problems in this sector, but it is not out of solution. It can be solved in many ways. This paper integrated some production hampering problems and also indicates some effective ways to reduce them. It is very difficult only for workers or management to solve these problems alone. All of the persons involved in the garments sector should come forward to eradicate the problems of production hampering. The top management and entrepreneur of any garments industry will be benefited by this paper to take challenges in the competitive world to reduce production hampering and increase quality of products.

ACKNOWLEDGEMENTS

- The Authors would like to express their cordial thanks to ABA Group Limited, Padma Poly Cotton Knit Fabrics Limited, and Beats Fashion limited, Bangladesh for delivering that efficient data, experience and substances to do this investigate. Authors are also appreciative to every section in garments for their encouragement to fruitfully accomplishment of this work. This article is successfully done by the support and co-ordination by all Authors.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML