-

Paper Information

- Next Paper

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(2): 43-48

doi:10.5923/j.textile.20170602.03

Supply Chain Operation Model in Terms of Raw Material in Bangladesh Apparel Industry

Mahmuda Akter1, Md. Haris Uddin2

1Assistant Professor, Department of Apparel Engineering, Bangladesh University of Textiles, Bangladesh

2Merchandiser, SQ Group Ltd., Bangladesh

Correspondence to: Mahmuda Akter, Assistant Professor, Department of Apparel Engineering, Bangladesh University of Textiles, Bangladesh.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The main objectives of this study are to highlight the importance of supply chain operation model in respective of raw materials in Bangladesh apparel manufacturing industries, which is the main export earning product of Bangladesh. In apparel manufacturing industry, various parties are involved in a chain process like the suppliers, manufacturers, and buyers. Each stage consists of sourcing, procurement, manufacturing, replenishment; customer order is incompatible with the next stage. The conceptual model has been provided by this study helps apparel manufacturer to make the cost effective working process of collecting raw materials as well as reduce the time period. This operation model of raw materials creates scope to optimize the supply chain working procedure of this industry. The work load of merchandising will be reduced by implementing this model practically, which help to create efficient team and also helpful to remove obstacles which are faced by merchandising team during apparel production. Thus, they can meet up the buyer’s critical path schedule and export within the lead time. Finally, this model will help to enhance the production process flow.

Keywords: Apparel Industry, Merchandising, Operation Model, Raw, Material, Sales & Distribution, Supply Chain

Cite this paper: Mahmuda Akter, Md. Haris Uddin, Supply Chain Operation Model in Terms of Raw Material in Bangladesh Apparel Industry, International Journal of Textile Science, Vol. 6 No. 2, 2017, pp. 43-48. doi: 10.5923/j.textile.20170602.03.

1. Introduction

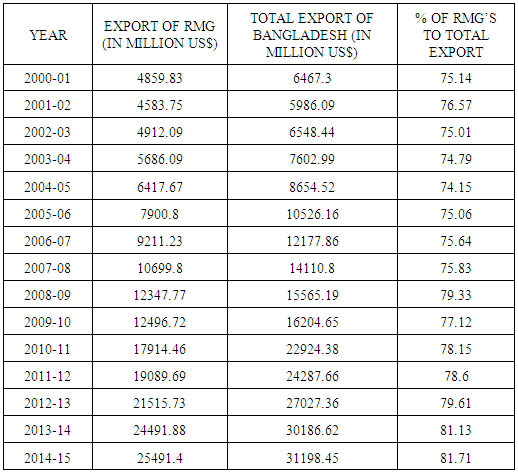

- About 60 million1 to 75 million people are involved in the textile, apparel and footwear sector worldwide (2014). It has been found that about three quarters of apparel industry workers worldwide are female. [1]The world’s women’s wear industry 2014 is worth 621 billion USD (497 billion EUR)The men’s wear industry is worth 402 billion USD (322 billion EUR)The children’s wear industry is worth 186 billion USD (estimated) (149 billion EUR). In 2014 World Garment Exports value was 708 billion USD (567 billion EUR); 412 billion USD (330 billion EUR). [3]In 2011 report of top Garment Producing Countries Bangladesh was in second position and they export 20% of their product to US market. [3]At present Bangladesh is one of the biggest apparel exporters in the world and its export volume is increasing day by day. There are 5000 apparel manufacturing in Bangladesh where 4 million people are directly involved. From below export report, we can easily find the contribution of apparel industry in Bangladesh which contribute 81.71% (25491.4 Million US $) of total export.

|

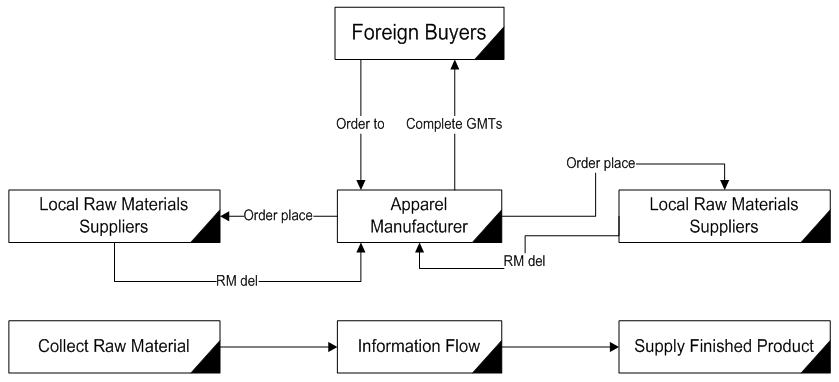

| Figure 1.1. Business Structure and Raw Materials Suppliers [12] |

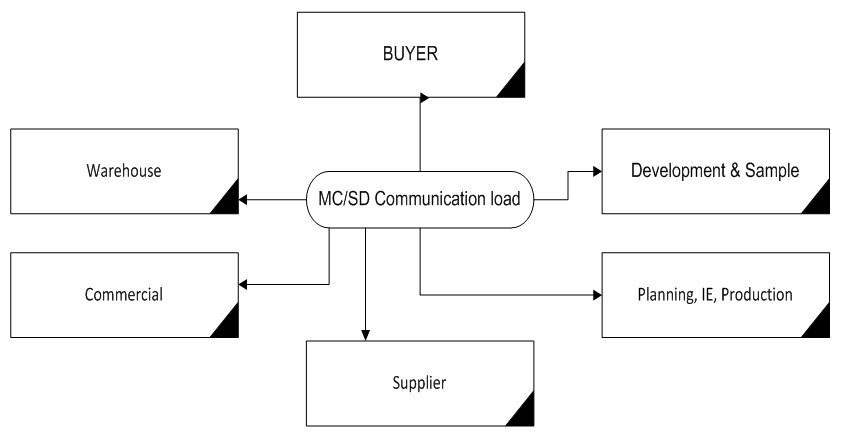

| Figure 1.2. Merchandiser/Sales & Distribution communication load |

2. Methodology

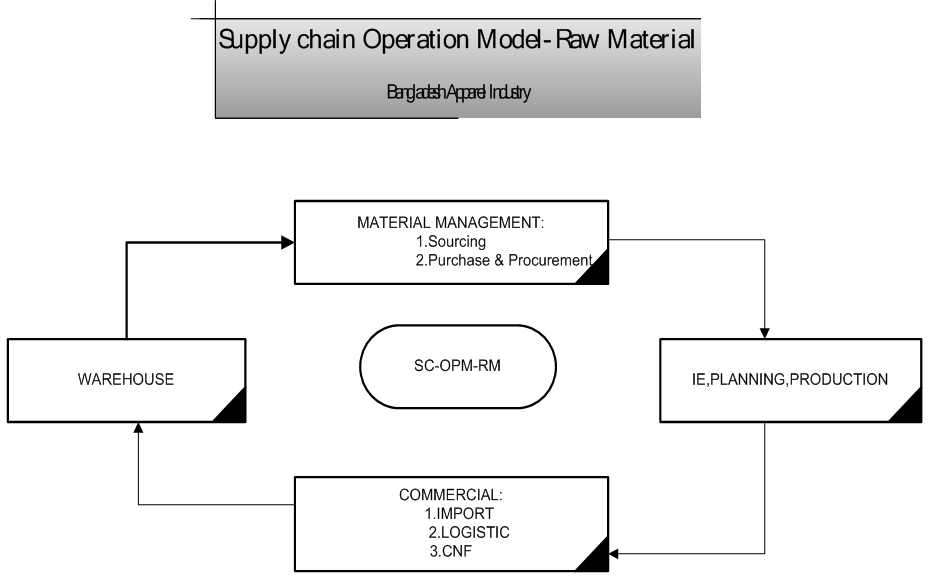

- A widespread literature survey has been undertaken in order to review the current condition of supply chain, growth and development in the apparel industry. In this study we have collected both primary and secondary data, primary data were collected from renowned garments factory of Bangladesh and secondary data were collect from different books, journal, publications and internet.Supply Chain Operation Model in terms of Raw Material (SC-OPM-RM)The RMG industry is highly dependent on imported raw material. About 90% of woven fabrics and 60% of knit fabrics are imported to make garments for export. That’s why this industry has taken maximum lead time to process an order [8]. In Bangladesh, the lead time for apparel export varies between 90-120 days. [6]Raw Materials:1. Fabric Item: In apparel industry fabric takes maximum lead time because of its manufacturing process. Because fabric is a planar textile structure produces by interlacing yarns, fibers, or filaments [13]. In Bangladesh, we use two types of fabric (Woven, Knitted). At present, we have to procure 90% of woven 60% of knitted fabrics from foreign supplier because of buyer nomination and our in-house limitation of manufacturing facilities. All of the fabric items are in input process because garment production mostly depends on fabric. [13]2. Non-Fabric Accessories: Non-fabric items are accessories and packaging material, which are needed during apparel production i.e.: Label, Thread, Button, Zipper, Elastic, Hangtag ticket, Drawcord, Eyelet etc.Intangible operation model of supply chain of apparel industry of Bangladesh in terms of Raw Materials are represented in below figure 2.1 in RMG sector, all the Bangladeshi garment companies are subcontractor. Areas of supply chain in apparel industry for raw materials are below:Material Management: the entire working process of material management consists of raw material Sourcing and Purchase & Procurement team. Sourcing is started from the sampling or development stages. In these stages the sourcing team has to do following activities as per proposed model. They are:Ÿ Receive RM Requirements from Development / Sample teamŸ Receive buyer approved Artwork/physical sample/ technical pack whatever available at Merchandiser/ Sales & Distribution team.Ÿ Sourcing Supplier (multiple 2or 3)Ÿ Place sample order bookingŸ Collect & submit sample to MC/SD/Buyer whatever requireŸ Collect approval from MC/SDŸ Select supplierŸ Confirm price, lead time and business terms & condition.In Bulk stages, Purchase & Procurement team do the following activities:Ÿ Receive details order sheet/Check list/Budget sheet from MerchandiserŸ Take consumption from related department (CAD, IE, Pattern)Ÿ Check consumption with merchandiser provided BOM (ERP or, Checklist)Ÿ Check current stock status of RM with warehouse or, ERP systemŸ Prepare booking (System generated or Manual) & proceed to selected supplierŸ Receive PI from supplier with expected RM Delivery dateŸ Collect garments delivery date from MC and Production plan from Planning TeamŸ Update material Plan to Planning, Merchandising, warehouse teamŸ Create ERP or Other’s system PO against PI and take PI approval from Head of SC or, authorized personŸ PI pass with PO to commercial (import) team to proceed payment (LC, TT as per policy)Ÿ Payment proved (LC, TT draft) pass to supplierŸ Follow up ETD with supplier and collect necessary shipping documentsŸ Pass shipping documents to commercial (Logistic, CNF)Ÿ Follow up with commercial (Logistic, CNF) until RM in-houseŸ Check RM receive and Inventory status with warehouseŸ Take trims card from warehouse and check quality reportŸ Check RM transaction (Issue, Transfer) with warehouseŸ Take RM stock or, closing balance from warehouse after garments deliver to Buyer/Retailer Ÿ Assess supplier half yearly or, yearly basis and take business facilities from supplierŸ Analyze RM stock and report to Head of Supply Chain with appropriate reason and recommendation. IE, Planning, ProductionThe activities of IE team as per proposed operation model of raw materials are to provide consumption of accessories like: Sewing thread, Elastic, Different type of tapes etc.Planning & Production team provide their production plan to material management so that they can plan a better raw material plan which will helps to meet garments delivery date as per buyer.Commercial: The activities of commercial team as per proposed operation model of raw materials are to proceed payment and confirm it to material management, Logistic and CNF support so that raw materials in-house on time.Warehouse: In this model warehouse activities is most import because they have to provide stock report to material management before placed booking to raw material suppliers, properly maintain stock label, on time Inventory, raw materials receive, quality check by warehouse quality team, submit trims card to material management.Based on above below is the proposed Supply Chain Operation Model in terms of raw material in Bangladesh apparel industry.

| Figure 2.1. Supply Chain Operation Model in terms of Raw Material (SC-OPM-RM) in Bangladesh apparel industry |

3. Conclusions

- The Apparel Manufacturing Industry is a major and vital business sector in Bangladesh overall economy. If we look at the apparel export rate from at the beginning from 2000’s to 2015’s then we can easily know the evolution of this process. But the Supply Chain process in Apparel Manufacturing Industry is scattered in point of view of Bangladesh which is lagging behind in the international competition. To be more competent in the Global apparel industries Bangladesh have to maintain standard Supply Chain procedures. If the Bangladesh apparel manufacturing Industry would follow this operation model of raw material which prescribed in this exploratory research then it will be more effective to establish good position in the global apparel market. This paper designates further frontiers for forthcoming researchers as well as practitioners those are involved with apparel manufacturing Industry.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML