-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2017; 6(1): 1-6

doi:10.5923/j.textile.20170601.01

Effect of Gamma Radiation on Cotton Fabric with Chitosan to Improve the Mechanical Properties

Md. Kamrul Hasan Munna1, Adindu Chisom Chinyerenwa2, Md. Kamruzzaman3, Md Anwar Hossain4, Md. Kawshar Ahamed5, Md. Abdul Wahab6

1Department of Textile Engineering, City University, Dhaka, Bangladesh

2Department of Textile Engineering, Federal University of Technology Owerri, Nigeria

3Department of Wet Processing Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh

4Department of Textile Engineering, Mawlana Bhashani Science & Technology University, Dhaka, Bangladesh

5Department of Textile Engineering, Prime Asia University, Dhaka, Bangladesh

6Department of Textile Engineering, South East University, Dhaka, Bangladesh

Correspondence to: Md. Kamruzzaman, Department of Wet Processing Engineering, Bangladesh University of Textiles, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

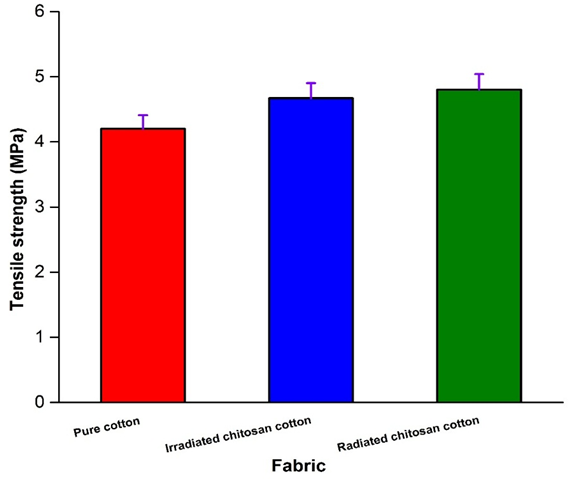

In this investigation modification of cotton fabric with chitosan was done by the application of gamma radiation to improve the mechanical properties of cotton fabric. From the prawn shell chitin is prepared. Chitosan is prepared from deacetylation of chitin and dissolved in 1% acetic acid solution and radiated at 30KGy Co-60 gamma radiation. Radiated chitosan solution is cross-linked with scoured cotton fabric with the help of citric acid and NaHPO4 used as catalyst. Cross-linked chitosan-cellulose solution is radiated at 1kGy through Co-60 gamma radiation. FTIR analysis was carried out for radiated cross-linked chitosan-cellulose for the improvement of the functional group of cotton. In order to augment the tensile strength and elongation percentage of pure cotton, irradiated chitosan cotton fabric and radiated chitosan cotton fabric was also evaluated and results showed that significantly improved their properties.

Keywords: Gamma radiation, Cotton fabric, Chitosan, Tensile strength, Elongation

Cite this paper: Md. Kamrul Hasan Munna, Adindu Chisom Chinyerenwa, Md. Kamruzzaman, Md Anwar Hossain, Md. Kawshar Ahamed, Md. Abdul Wahab, Effect of Gamma Radiation on Cotton Fabric with Chitosan to Improve the Mechanical Properties, International Journal of Textile Science, Vol. 6 No. 1, 2017, pp. 1-6. doi: 10.5923/j.textile.20170601.01.

Article Outline

1. Introduction

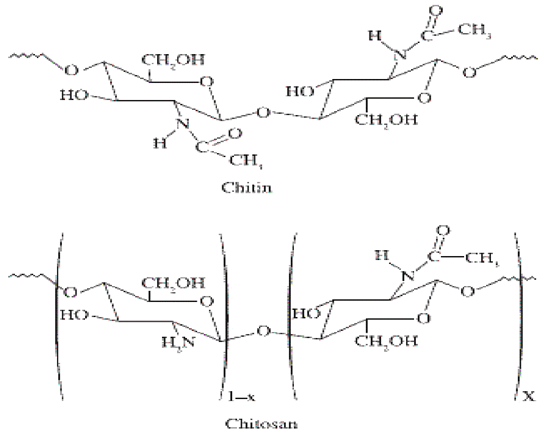

- The development of era in the fabric marketplace has led scientists and researchers to expand novel finishes to feature excessive cost on different fabric substances. It changed into a brand new window for researchers to advent and explore new research fields which consist of geotextiles, flame retardant textiles, insect repellent textiles, aroma textiles, medical textiles, smart textiles, antibacterial textiles, and nano textiles. Latest traits in the fabric industry are particularly targeted on bodily and chemical changes on floor of fibers and fabrics. One of a kind chemical and organic techniques were used electively to improve or impart everlasting functional traits at the surface of fabric substances. However, some of these chemicals are poisonous and once in a while high priced [1].Chitin and chitosan are extensively flexible and promising bio materials. The deaectylated chitin spinoff, chitosan is more useful and bioactive polymer. In spite of its biodegradability, it has many reactive amino aspect corporations, which offer opportunities of chemical modifications [2]. There isn't always a sharp boundary inside the nomenclature distinguishing chitosan from chitin, when chitin is deacetylated over about 60% it turns into soluble in dilute aqueous acids and is referred to as chitosan. Chitin is the primary element inside the shells of crustaceans, along with shrimp, crab, and lobster. It is observed in exoskeletons of mollusks and bugs, and in the cell walls of some fungi [3]. Deacetylated spinoff of chitin is called chitosan. It is the second maximum ample polysaccharide discovered on the planet next to cellulose. There isn't a pointy boundary within the nomenclature distinguishing chitosan from chitin [3]. Chitin is a polysaccharide of animal origin located abundantly in nature and characterized by way of a fibrous structure. It bureaucracy the premise of the main constituent of the outer skeleton of bugs and crustaceans like shrimp, crabs and lobster [4]. Chitin and chitosan are naturally occurring ß-1,4-linked linear polysaccharides much like cellulose as proven in Figure 1. Chitin has the same backbone as cellulose, however it has an acetamide organization on the C-2 function rather than a hydroxyl group and its molecular weight, purity, and crystal morphology are depending on their assets [2]. Chitosan is a vulnerable base and is insoluble in water, but soluble in dilute aqueous acidic solutions underneath its pKa (~6.3), wherein it is able to convert glucosamine devices (-NH2) into the soluble protonated shape (-NH+3). The solubility of chitosan depends on its biological beginning, molecular weight and degree of acetylation [5]. Chitosan is found in some fungi, but its quantity is so constrained that it's far particularly produced commercially by means of alkaline deacetylation of chitin [6]. Huge quantities of crab and shrimp shells were abandoned as wastes via global seafood groups. This has led to vast medical and technological hobby in chitin and chitosan as try to utilize those renewable wastes. Chitosan has become the favored business form of those substances, as it's miles more tractable to solution tactics than chitin. The fabric enterprise maintains to search for eco-friendly tactics that substitute for poisonous fabric chemical substances and decrease dyes in dye house wastewater. The use of chitosan as a textiles chemical may be substantially beneficial inside the view of the usage of deserted seafood wastes. The major issues of chitosan are its loss of the antimicrobial pastime below alkaline conditions due to its lack of the cationic nature and its negative durability, whilst applied to fabric fabric, due to its loss of robust bonding with fabrics [3].

| Figure 1. Schematic representation of the chemical structure of the chitin and chitosan |

2. Experimental

- MaterialsPrawn shell was supplied from Bangladesh Atomic Energy Commission. Chitosan prepared from it. NaOH, HCl was used for the preparation of chitosan. Acetic Acid used to dissolve the chitosan. For cross-linking chitosan with cotton fabric citric Acid and NaHPO4 was used. Mymun fabric confined DBL institution, Bangladesh provides the cordial guide with the aid of providing 100% scoured cotton fabric of GSM 120.

3. Methods

- Preparation of chitosan solutionFirstly 1% Acetic Acid solution was made. 0.5% Chitosan dissolved in 1% Acetic Acid solution. For the uniformity of solution it is stirred for 30minutes and heated at 50°C. Prepared solution is radiated by Co-60 gamma ray at 30KGy.Fabric Sample PreparationScoured fabric was dried at 60°C for 5min. Cotton fabric was cut with the scissor in a rectangular form and each pieces of fabric weight was 2.8gm. Cross-Linking of Chitosan with Cotton fabric Chitosan is cross-linked with cotton fabric by using Citric Acid and NaHPO4 used as catalyst. For cross-linking fabric is soaked into chitosan solution for 30min. Fabric is soaked into both irradiated and non-irradiated chitosan. After soaking fabric was squeezed and dried at 80°C. Dried sample was radiated by Co-60 gamma radiation at 1 kGy. In case of cross-linking two samples are cross-linked with radiated chitosan and another four sample is cross-linked with non-radiated chitosan.Analysis of functional Group using Fourier Transform Infrared Spectroscopy (FTIR)The FTIR spectrum of cotton fabric without radiated chitosan and after treatment of radiated chitosan was recorded by using fourier transform infrared spectroscopy (Brukar vertex 100, Germany) to identify the functional group of cotton fabric after radiated chitosan deposition and without chitosan treatment. A thin pallet of potassium bromide containing magnesium peroxide and the spectrums were recorded over 4000- 400 cm-1.Test ProcedureTensile strength of cotton fabric, radiated chitosan cotton fabric, irradiated chitosan cotton fabric was measured by following ASTM-D-5035(1995) method using Instron tensile tester (Model No. 5565) [14]. According to ASTM D5034-09(2013) method elongation of cotton fabric, radiated chitosan cotton fabric, irradiated chitosan cotton fabric was done.

4. Results and Discussion

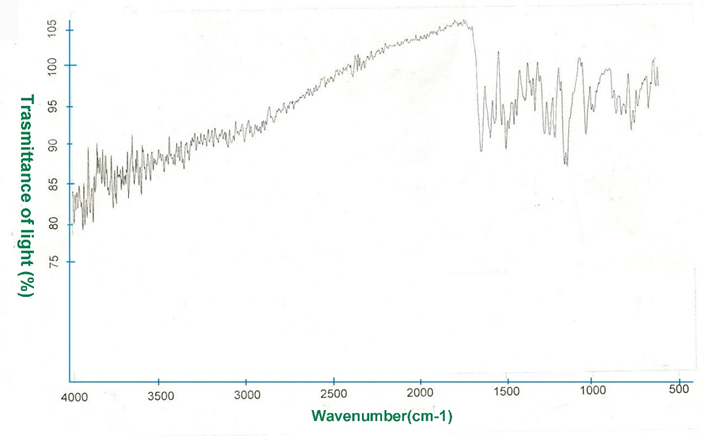

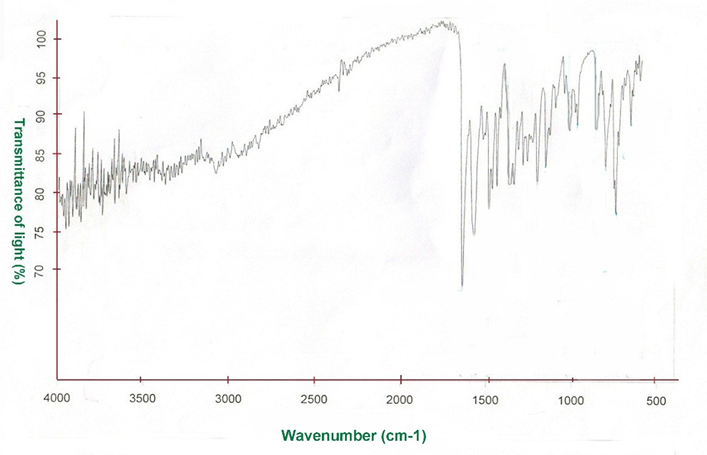

- Analysis of functional Group using Fourier Transform Infrared Spectroscopy (FTIR)FT-IR transmission spectra of pure cotton fabric, radiated chitosan cotton fabric was studied. In transmission mode the spectra were measured by KBr pellets made of finely cutand ground fabric. As a result the spectra showed only characteris-tic peaks of cellulose which is the major component of cotton fiber. But raw cotton also contains some impurities such as waxes, pectins etc. which are not detectable by transmission mode [16] (Figure 2). The spectrum of pure cotton extract showed peaks at 2918 and 2849 cm−1 corresponding to the asymmetric and the symmetric stretching of methylene (CH2) groups in long alkyl chains. This finding supports the work done by Chung et al. [17]. These peaks are responsible for the presence of waxes. Other impurities such as pectins showed characteristic peak in the region 1600-1800 cm−1. The spectrum obtained from pure cotton fabric and radiated chitosan cotton fabric was different. Figure 2 shown that in the peak of 3400 cm-1 there was a medium stretch which indicates that in this position amino group was present and in the peak of 1665cm-1 and 3332 cm-1 corresponding to the C=O vibrations groups in the carbonyl structure and O-H stretching vibrations.

| Figure 2. Analysis of functional group of pure cotton fabric from FTIR test |

| Figure 3. Analysis of functional group of radiated Chitosan treated cotton fabric by FTIR test |

| Figure 4. Tensile strength of pure cotton fabric, irradiated chitosan cotton fabric (1 kGy) and radiated chitosan cotton fabric (1 kGy) |

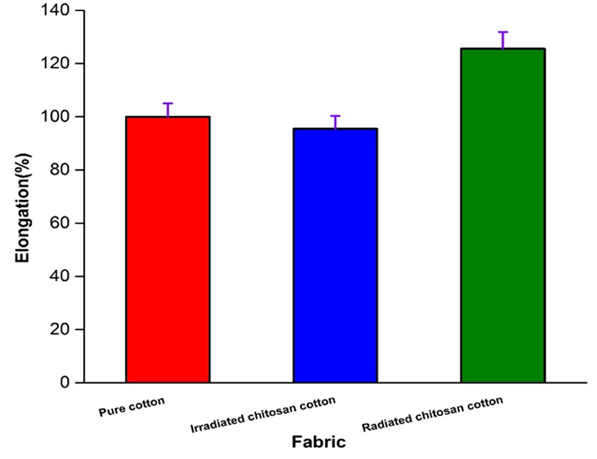

| Figure 5. Pure cotton fabric, irradiated chitosan cotton fabric (1 kGy) and radiated chitosan cotton fabric (1 kGy) elongation% |

5. Conclusions

- Cotton fabric was subjected to gamma radiation which was prepared by using solution of chitosan to investigate mechanical properties of cotton fabric. FTIR analysis showed that intermolecular interactions exist between cotton and chitosan. Cross-linking is increased between cotton and chitosan by gamma radiation. For the influence of gamma radiation chitosan cotton fabric not only exhibits significant change in the tensile strength but also reveals magnificent elongations properties.

ACKNOWLEDGEMENTS

- Special gratitude for cooperation during research work by managing research material in the Institute of Radiation and Polymer Technology (IRPT), Bangladesh Atomic Energy Commission, Dhaka, Bangladesh.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML