Muhammad Abu Taher, Md. Mostafizur Rahman, Muhammad Ashfak Jahangir, Md. Shipan Mia, Ashaduzzaman

Department of Textile Engineering, Southeast University, Dhaka, Bangladesh

Correspondence to: Ashaduzzaman, Department of Textile Engineering, Southeast University, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

In this study we have done study on knit fabric faults and their causes. In Textile industry faults are frequently occurred and stitch length has a direct effect on these faults. For changing the stitch length at same count at three same diametric double jersey knitting machine on same Rib structure we found the effect of stitch length on common Knit fabric faults. Changing of stitch length gradually increases or decreases the amount of some major faults on knit industry such as Hole/Cracks, Loops/Drop stitches, Lycra out, Knots & etc. For this study, we collected different samples of common knit fabric faults & some quality inspection sheet done in 4-point system method from a reputed Textile Industry. Firstly, we analyzed the data from the quality inspection sheets and then we have analyzed how changing of stitch length affects on the increasing or decreasing of majorly occurred faults on grey knit fabric.

Keywords:

Knit Fabric, Knitting Fault, Causes, Remedies, Inspection

Cite this paper: Muhammad Abu Taher, Md. Mostafizur Rahman, Muhammad Ashfak Jahangir, Md. Shipan Mia, Ashaduzzaman, Study on Different Types of Knitting Faults, Causes and Remedies of Knit Fabrics, International Journal of Textile Science, Vol. 5 No. 6, 2016, pp. 119-131. doi: 10.5923/j.textile.20160506.01.

1. Introduction

Knitting is one of the important industrial sectors of Bangladesh. The maximum share our export oriented RMG is originated from knit fabrics Export means quality; we must ensure 100% quality of our export oriented RMG products. [1] Due to increasing demand for quality knitted fabrics, high quality requirements are today greater since customer has become more aware of “non-quality “ problems, in order to avoid fabric rejection , knitting mills have to produce fabrics of high quality, constantly [2, 3]. Detection of faults during production of knitted fabric with circular knitting machine is crucial for improved quality and productivity any variation to the knitted process needs to be investigated and corrected. The high quality standard can be guaranteed incorporating appropriate quality assurance. Industrial analysis indicate that quality can be improved, and defect cost minimized, by monitoring the circular knitting process. [3][4], Detection of faults during production of knitted fabric with circular knitting machine (CKM) is crucial for improved quality and productivity. Any variation to the knitting process needs to be investigated and corrected. The high quality standard can be guaranteed by incorporating appropriate quality assurance. Industrial analysis indicate that product quality can be improved, and defect cost minimized, by monitoring of the circular knitting process (Jearranai and Tiluk), 1999.Many researchers have applied computer vision to improve inspection method of human vision in textile products, in most of them, the image of knitted garments had been considered to specify the faults features. Others work aimed to classify defects in knitted fabrics by using image analysis and neutral network algorithm or fuzzy logic. All these methods are not completely reliable because image analysis of knitted fabrics involves difficulties due to the loop structures and yarn hairiness, compare to woven fabrics consisting of neat warp and weft yarns. Knitted fabric faults can also be detected by inspecting yarn input tension and loop but only few types of faults are concerned by these methods.Human inspection by using knitted fabric inspection machines remains today the most used way to classify faults after knitting and after finishing [5]. Generally, faults are classified by type and by frequency in the inspected knitted roll. The inspection assessment permits to appreciate fabric quality. The judgments of fabric quality depend on faults tolerance levels fixed by each knitter and could be in some cases subjective because it is often based only on the number of faults and not on fault size and gravity [6].[7]. A new inspection method was proposed in order to classify faults and help knitter to appreciate more objectively fabric quality.

2. Matrial and Methods

In order to evaluate objectively, the knitted fabric roll quality, a fault index (FI) for each fault type was defined. Classically, during inspection only the number and the fault type are taken into account to judge fabric quality, but fault gravity and fault size are generally not considered. Fault length and fault frequency inside the fabric roll were measured and introduced in the expression of fault index:

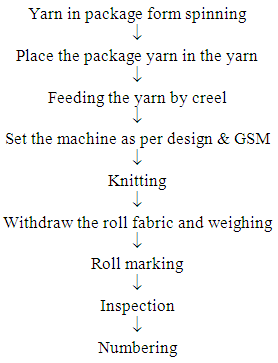

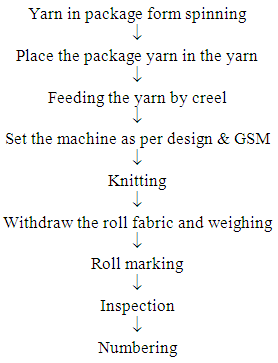

2.1. Process Flow Chart for Knitting

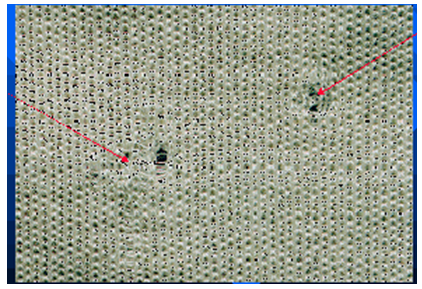

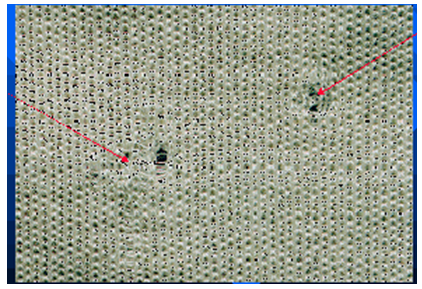

2.2. Drop Stitches (Holes)

Drop Stitches are randomly appearing small or big holes of the, same or different size, which appear as defects, in the Knitted fabrics.Causes:Ÿ High Yarn Tension Ÿ Yarn Overfeed or UnderfeedŸ High Fabric Take Down TensionŸ Obstructions in the yarn passage, due to the clogging of eyelets, yarn guides & tension discs, with wax & fluff etc.Ÿ Defects like; Slubs, Naps, Knots etc.Ÿ Incorrect gap between the Dial & Cylinder rings. | Figure 1. Drop Stitches (Holes) |

Remedies:Ÿ Ensure uniform yarn tension on all the feeders, with a Tension Meter. Ÿ Rate of yarn feed should be strictly regulated, as per the required Stitch Length.Ÿ The fabric tube should be just like a fully inflated balloon, not too tight or too slack.Ÿ Eyelets & the Yarn Guides, should not have, any fibers, fluff & wax etc. stuck in them. Ÿ The yarn being used, should have no imperfections, like; Slubs, Neps & big knots etcŸ The gap between the Cylinder & the Dial should, be correctly adjusted, as per the knitted loop size.

2.3. Barriness

Causes:Ÿ High Yarn Tension Ÿ Count Variation Ÿ Mixing of the yarn lots Ÿ Package hardness variationRemedies:Ÿ Ensure uniform Yarn Tension on all the feeders.Ÿ The average Count variation in the lot, should not be more than ± 0.3Ÿ Ensure that the yarn being used for Knitting is of the same Lot / Merge no.Ÿ Ensure that the hardness of, all the yarn packages, is uniform, using a hardness tester.

2.4. Streakiness

Causes:Ÿ Yarn slippage on the IRO Pulley, due to the yarn slipping in & out from underneath the IRO Belt, due to a tilted IRO Pulley. Ÿ Worn out IRO belts, yarn guides & eyelets etcŸ Faulty winding of the yarn packages Ÿ Yarn running out of the belt, on the IRO Pulley.Remedies:Ÿ Ensure very smooth, clean & obstruction free passage of the yarn, through the eyelets, yarn & tension discs etc. Ÿ No cuts or rough surfaces, in the Porcelain Eyelets, Yarn Guides & the Yarn Feeder holes etc. Ÿ Flawless winding of the, Yarn Package (The yarn coils should unwind smoothly, without any obstruction) Ÿ The yarn should be running under the IRO belt, between the belt & around the IRO pulley.

2.5. Snarls

Snarls appear on the fabric surface, in the form of big loops of yarn getting twisted, due to the high twist in the yarn (Unbalanced twist yarn).Causes:Ÿ High, twist in the, yarn.Ÿ Hosiery yarns are soft twisted. High, twist in the yarn, is the cause of snarling.Ÿ (Snarls cause, fabric defects & needle breakages)Remedies:Ÿ Ensure using Hosiery Yarns, of the recommended T.P.M. only.Ÿ (Hold a few inches of the yarn in both the hands, in the form of a ‘U’. Ÿ The yarn has a balanced twist, if it doesn’t tend to rotate or turn, in the form of a snarl. Ÿ (Such yarn can be used for Hosiery applications.)

2.6. Contaminations

Causes:Ÿ Presence of dead fibers & other foreign materials, such as; dyed fibers, husk & synthetic fibers etc. Ÿ Dead Fibers appear in the fabric, as a result of the, presence of excessive immature Cotton fibers, in the Cotton fiber crop. Ÿ Dead fibers do not pick up color during Dyeing. Ÿ Presence of the foreign materials, in the, staple fiber mixingŸ (Kitty, Husk, Broken Seeds, dyed fibers & fibers like Poly Propylene, Polyester, Viscose etc) Ÿ Dyed & other types of fibers flying from the adjacent Knitting machines cling, to the yarn being used for knitting & get, embedded in the Grey Fabric. Remedies:Ÿ Use rich fiber mixing for the yarns, to be used for Knitting, in order to have less dead fibers, appearing in the fabric. Ÿ Rigid control measures in the Blow Room, to prevent the mixing of foreign matters in the Cotton mixing.Ÿ Segregate the Spinning & Knitting Machines, with Plastic Curtains or Mosquito Nets, to prevent the fibers flying from the neighboring machines, from getting embedded in the yarn / fabric.

2.7. Spirality

Spirality appears in the form of a twisted garment, after washing. The seams on both the sides of the garment displace, from their position & appear on the front & back of the garment.Causes:Ÿ Spirality is caused, by the Twisting Torque as a result, of the high yarn T.P.M.Ÿ Hosiery yarns are soft twisted, whereas the Warp yarns are hard twistedŸ Uneven Fabric Take down tension, on the Knitting machine.Ÿ Unequal rate of Fabric feed on the Stenter, Calender& Compactor machines.Remedies:Ÿ Use the Hosiery yarns of the recommended TPM level for KnittingŸ (Hosiery yarns are soft twisted, in comparison to the Warp yarns)Ÿ Fabric pull or the Take Down tension, on both sides of the grey fabric tube, on the knitting machine, should be equal. Ÿ Ensure uniform rate of feed of the dyed fabric, on both the edges, while feeding the fabric to the Calendar, Compactor or Stenter machines.  | Figure 2. Spirality Faults |

2.8. Needle Lines

Causes:Ÿ Bent Latches, Needle Hooks & Needle stemsŸ Tight Needles in the groovesŸ Wrong Needle selection (Wrong sequence of needles, put in the Cylinder or Dial)Remedies:Ÿ Inspect the grey fabric on the knitting machine for any Needle lines.Ÿ Replace all the defective needles having, bent latches, hooks or stems.Ÿ Remove the fibers accumulated in, the Needle tricks (grooves).Ÿ Replace any bent Needles, running tight in the tricks.Ÿ Check the Needle filling sequence in the Cylinder / Dial grooves (tricks).

2.9. Sinker Lines

Causes:Ÿ Bent or Worn out SinkersŸ Sinkers being tight in, the Sinker Ring grooves Remedies:Ÿ Replace, all the worn out or bent sinkers, causing Sinker lines in the fabric. Ÿ Sinker lines are very fine & feeble vertical lines, appearing in the fabric.Ÿ Remove the fibers, clogging the Sinker tricks (Grooves)

2.10. Oil Lines

Causes:Ÿ Fibers & fluff accumulated in the needle tricks, which remain soaked with oil.Ÿ Excessive oiling of the, needle beds.Remedies:Ÿ Fibers, accumulated in the needle tricks, cause the oil to seep into the Fabric.Ÿ Some lubricating oils are not washable & cannot be removed during Scouring.Ÿ Oil lines appear in the fabric, in the lengthwise direction, even after dyeing. Ÿ Remove all the Needles & the Sinkers of the machine, periodically. Ÿ Clean the grooves of the Cylinder & Dial of the machine thoroughly, with petrol. Ÿ Blow the grooves of the Cylinder, Dial & Sinker ring, with dry air after cleaning.

2.11. Surface Hairiness & Piling

CausesŸ Abrasion due to the contact with rough surfacesŸ Excessive surface hairiness caused, due to the abrasive tumbling actionŸ (Fabric friction in the Tumble Dryer)Ÿ Rough Dyeing process & abrasive machine surfaces (Soft Flow Machine tubes, Tumble Dryer drum etc.)Ÿ Reprocessing of the fabric is, also a major cause of piling.Remedies:Ÿ Avoid using the Tumble Dryer.Ÿ (Control shrinkage by maximum fabric relaxation & over feed in the processing)Ÿ Regularly inspect the fabric contact points on all the machines, for any rough & sharp surfaces. Ÿ (Rectify, if found rough)Ÿ Avoid repeated reprocessing of the fabrics.Ÿ Use anti pilling chemical treatments for the fabrics, prone to pilling.

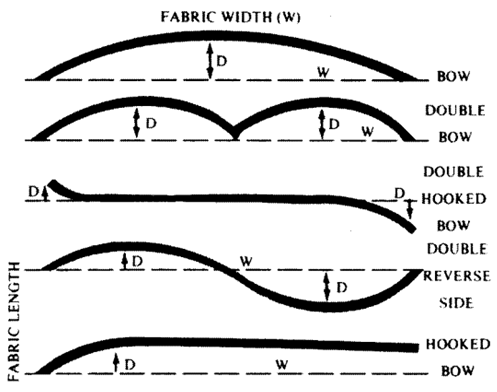

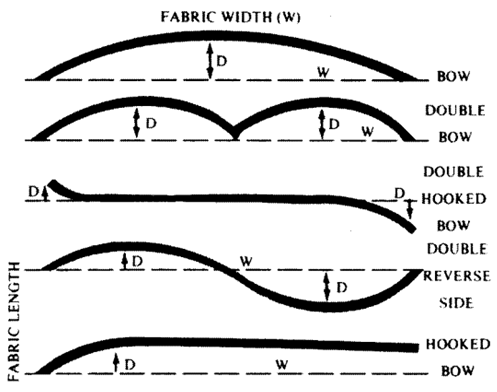

2.12. Bowing

Bowing appears as, rows of courses or yarn dyed stripes, forming a bow shape, along the fabric widthCauses:Ÿ Uneven distribution of tensions, across the fabric width while, dyeing or finishing the fabric.RemediesŸ Bowing can be corrected, by reprocessing the fabric feeding it from the opposite end. Ÿ A special machine (MAHLO) is also available for, correcting the bowing in the knitted fabrics | Figure 3. Fabric Bowing |

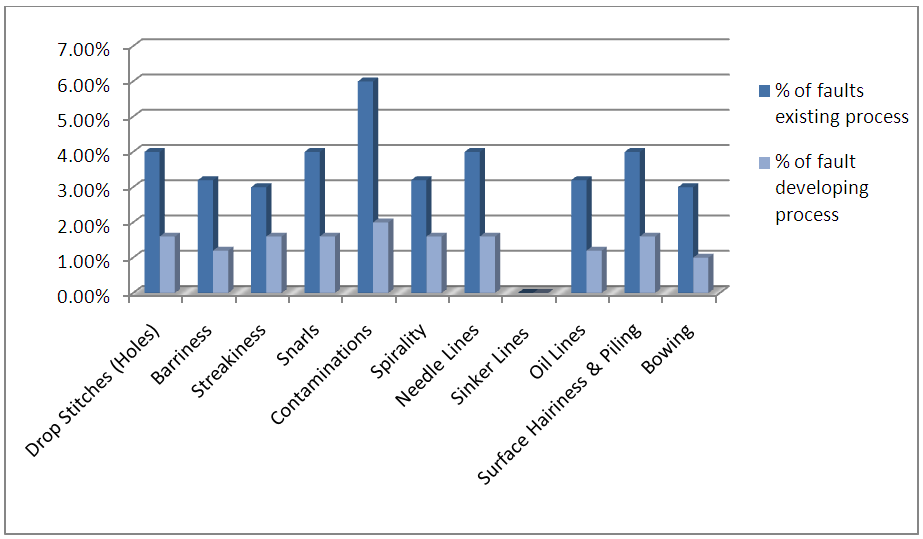

3. Survey Result & Analysis

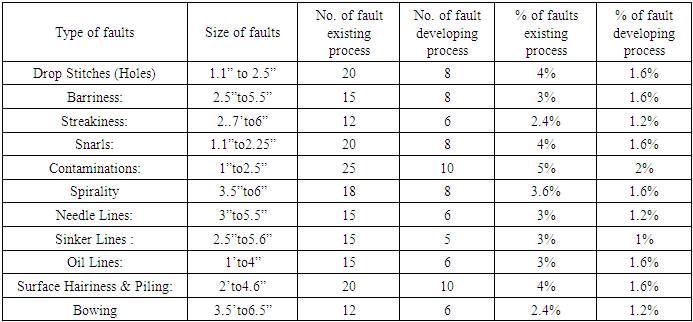

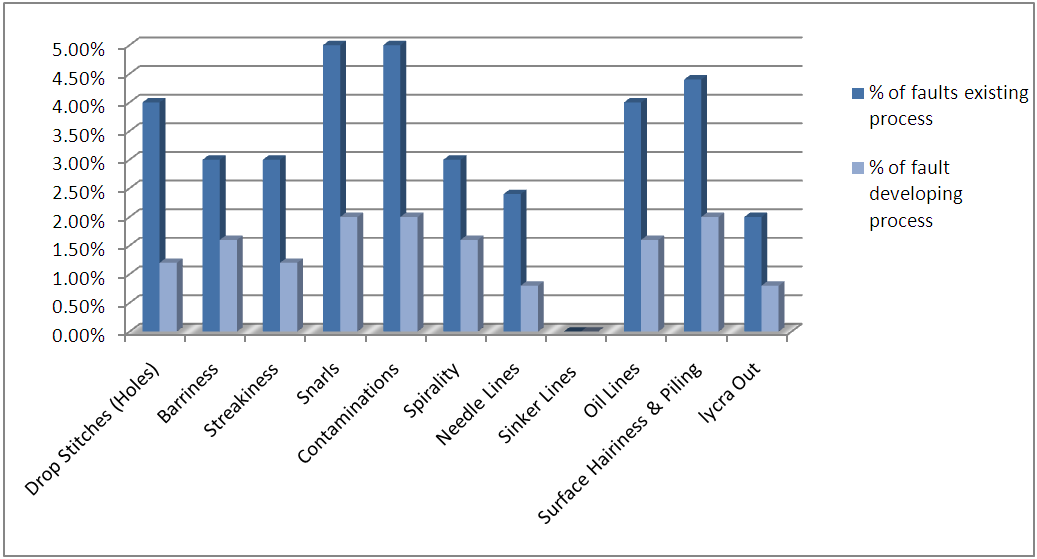

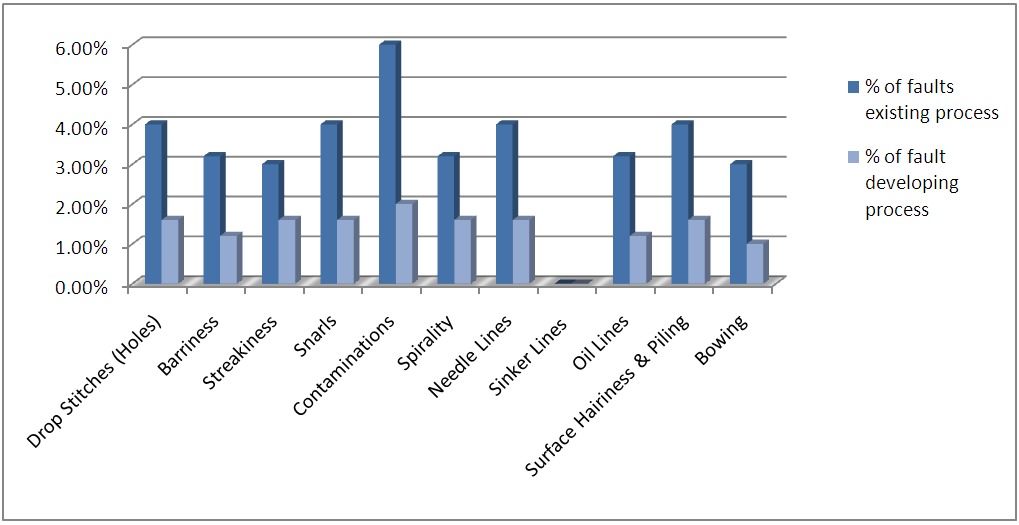

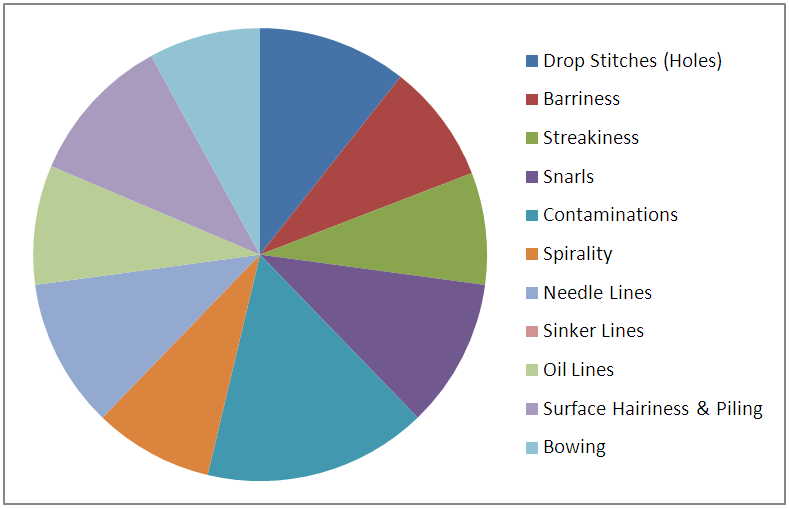

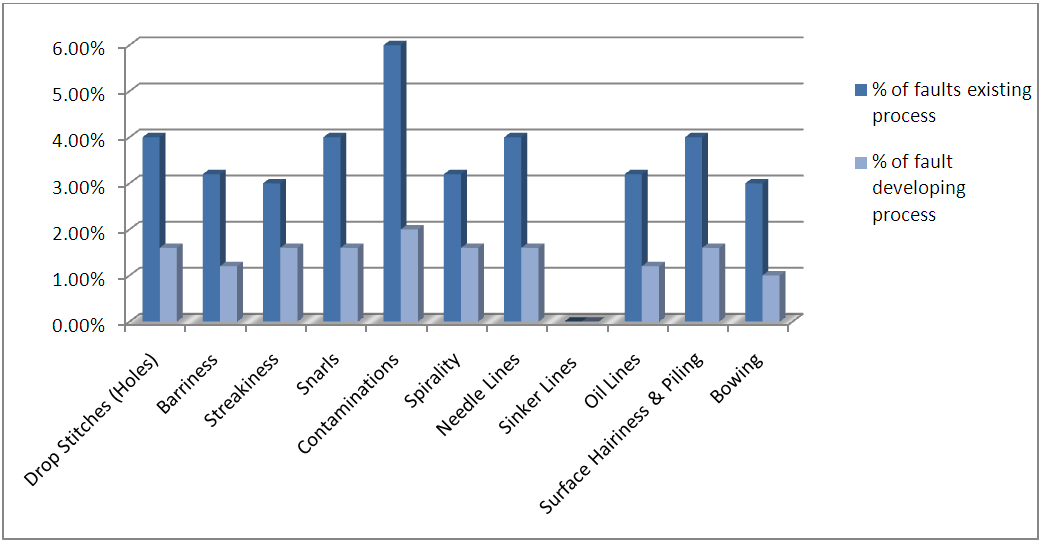

Here we see the major knit faults percentage (%) for various types of knit fabric in existing process and developing process where we can minimize the existing faults percentage (%) in a Lot by taking the above remedies which are discussed earlier.

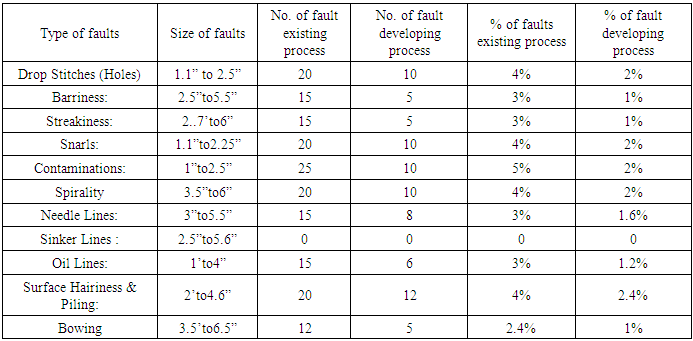

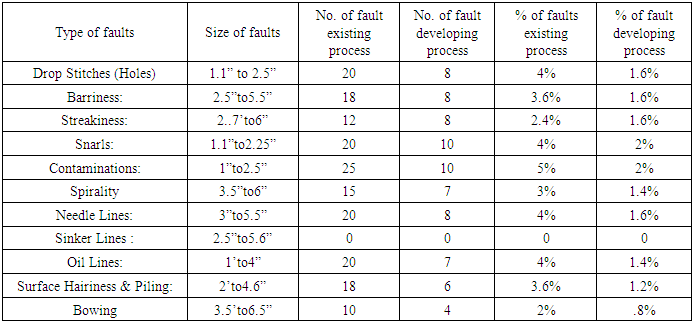

3.1. For Single Jersey: (500 Meter)

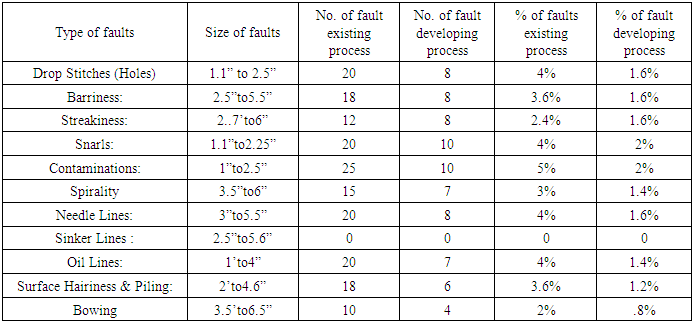

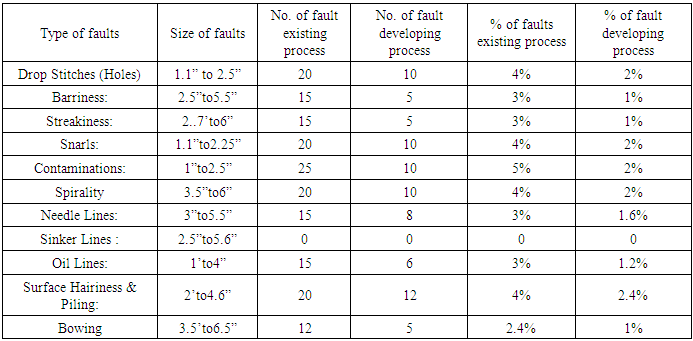

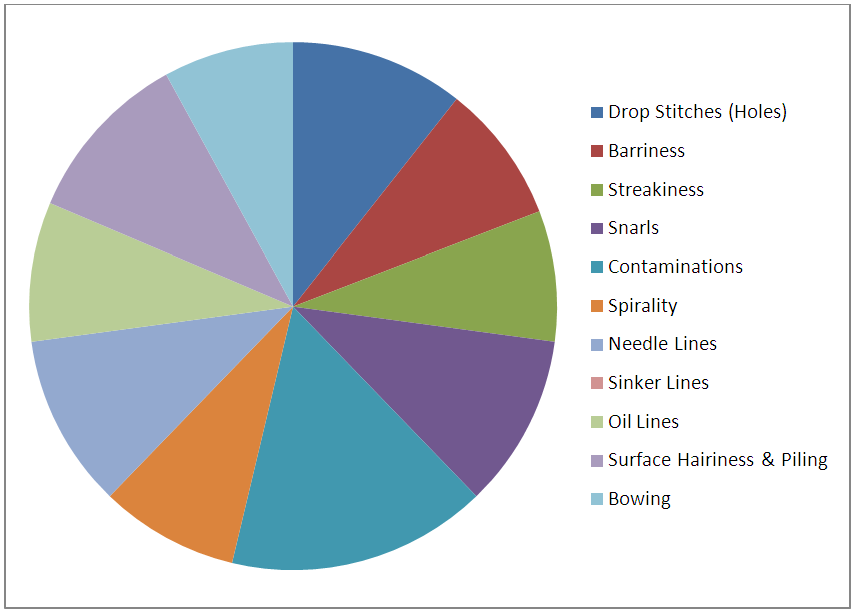

Table 1. Fault of single jersey fabric (500 meter)

|

| |

|

| Figure 4. Major knitting fault of single jersey fabric |

Calculation:% of fault in existing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 20,So the no. of fault in 100 meter fabric is = (20x100)/500 = 4%The rest fault percentage is calculated in the same way.% of fault in developing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 10So the no. of fault in 100 meter fabric is = (10x100)/500 = 2%The rest fault percentage is calculated in the same way.

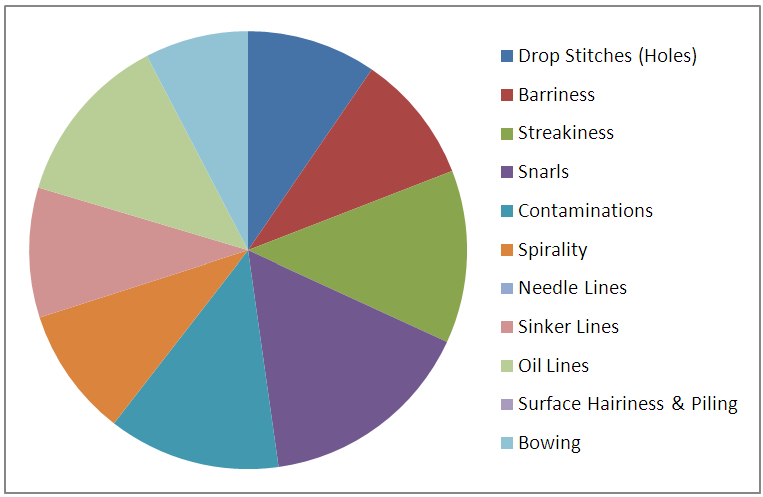

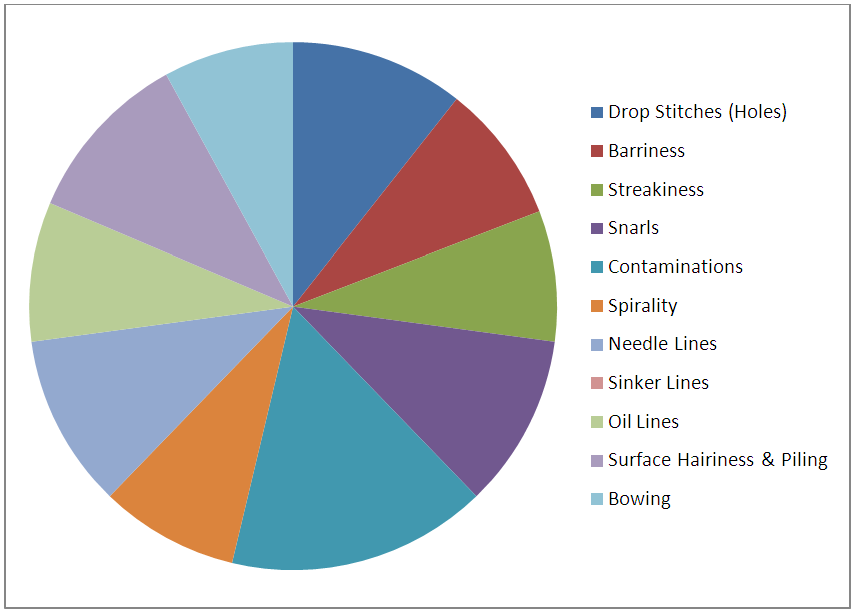

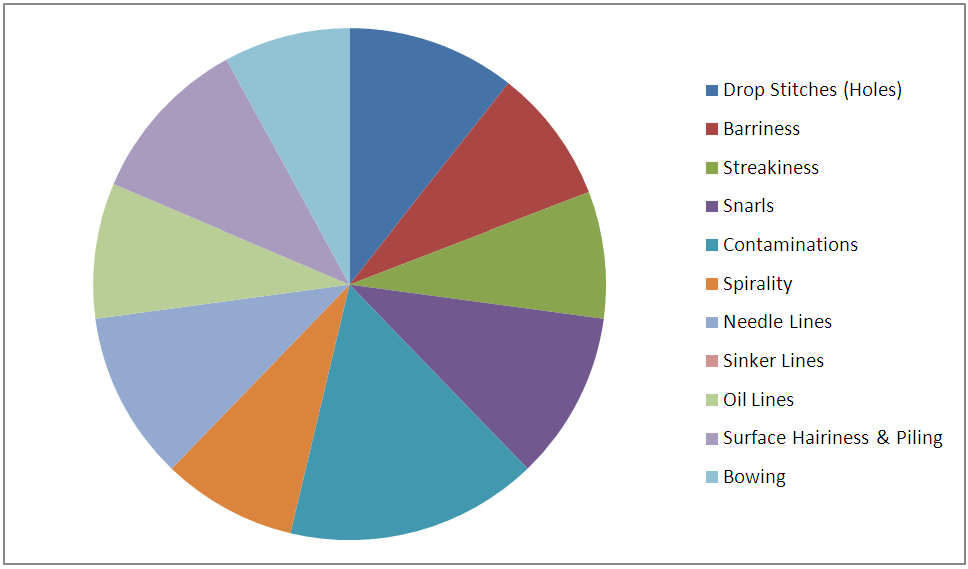

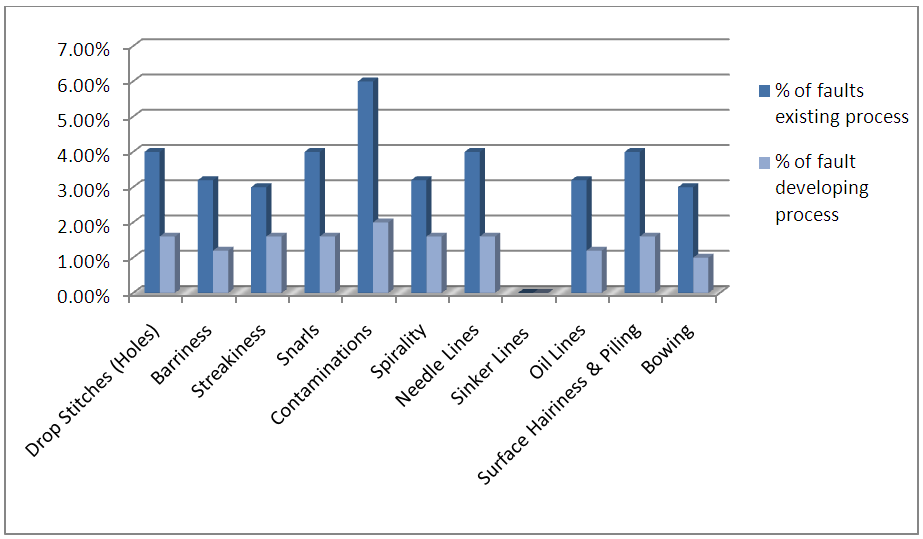

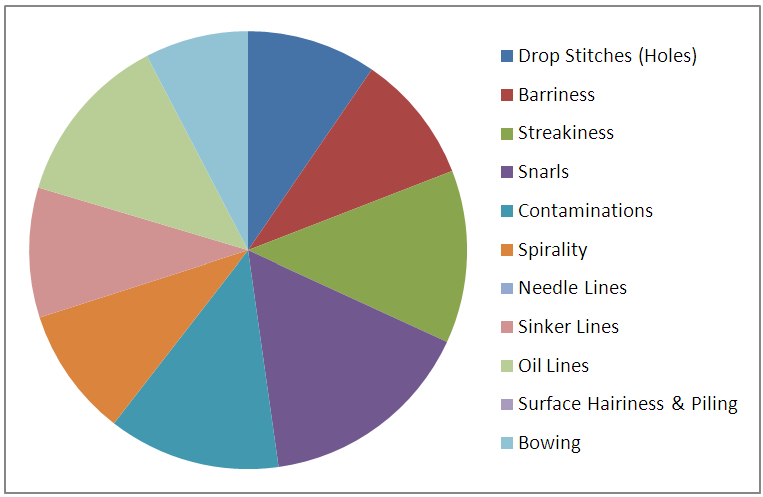

3.1.1. Percentage of Knitting Faults in s/j Fabric

| Figure 5. Percentage of dyeing faults in s/j fabric |

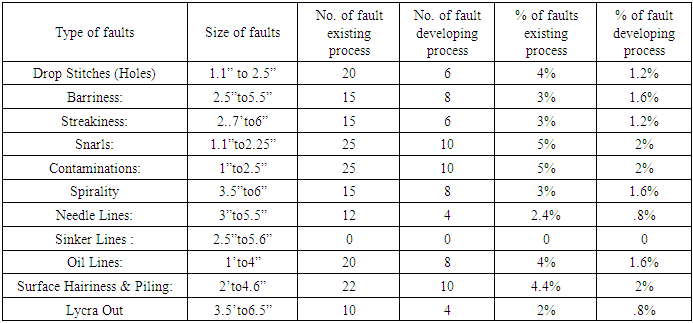

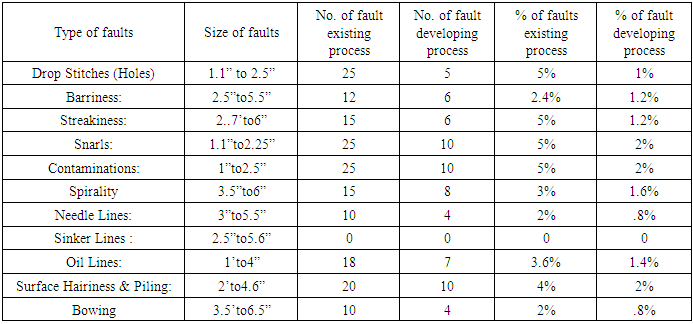

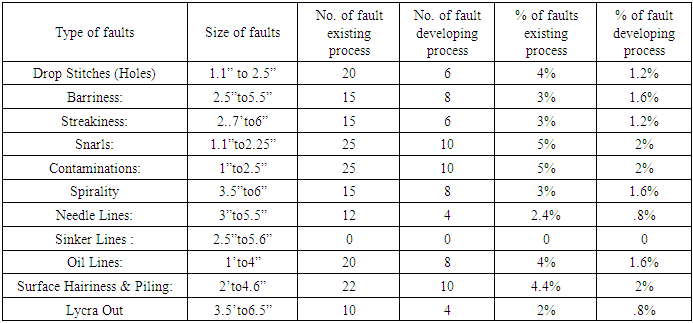

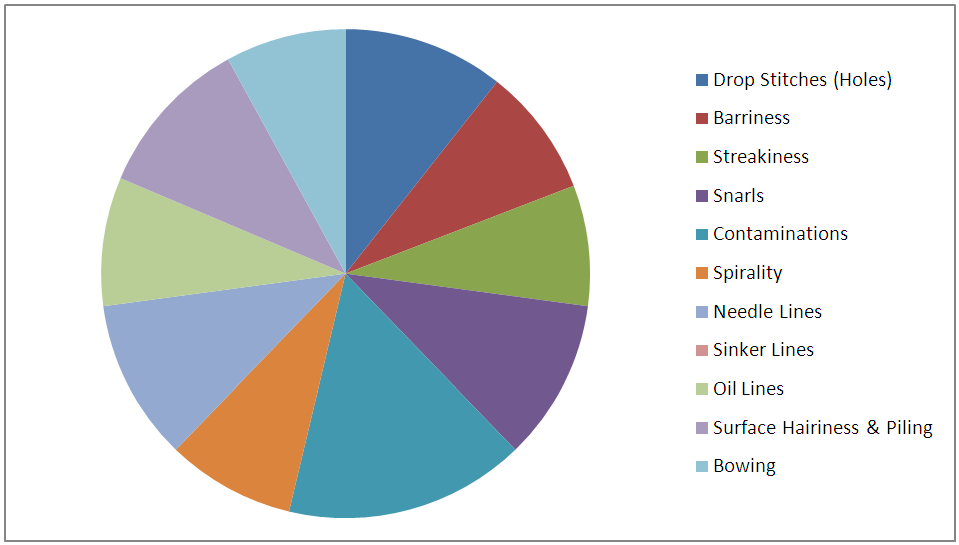

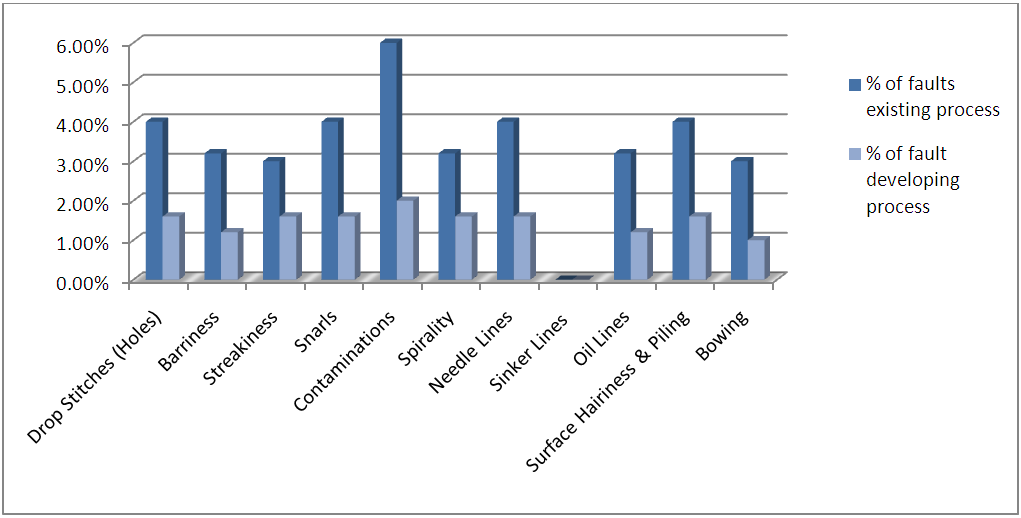

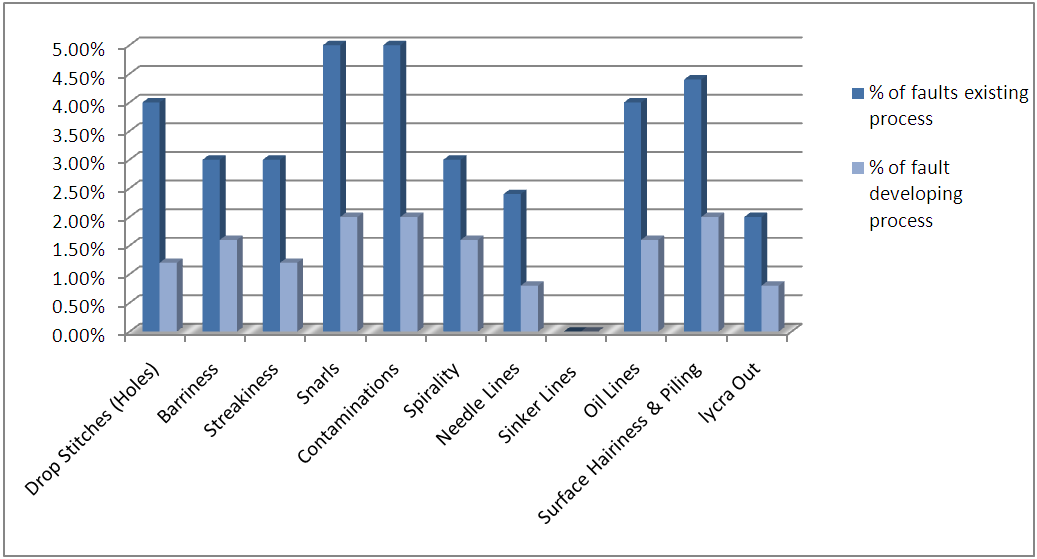

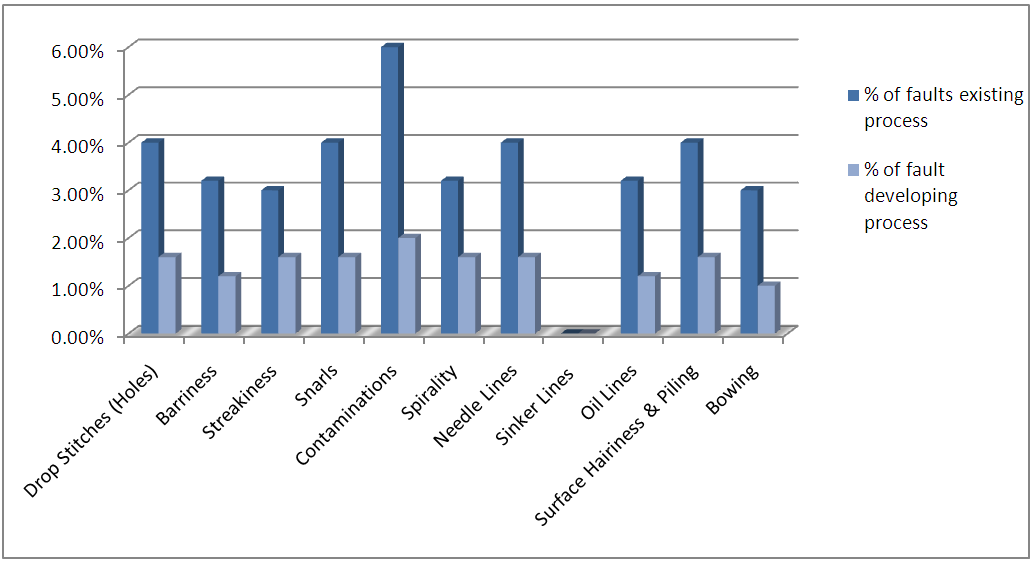

3.2. For Rib Fabric: (500 Meter)

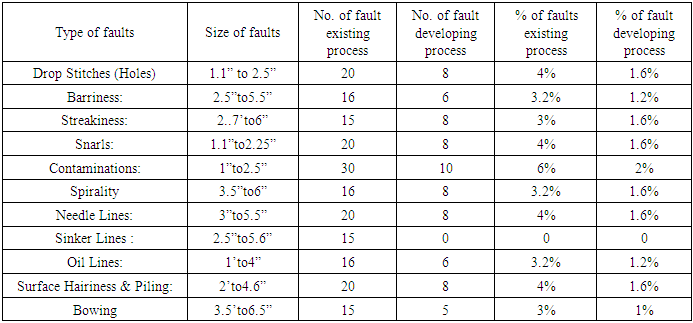

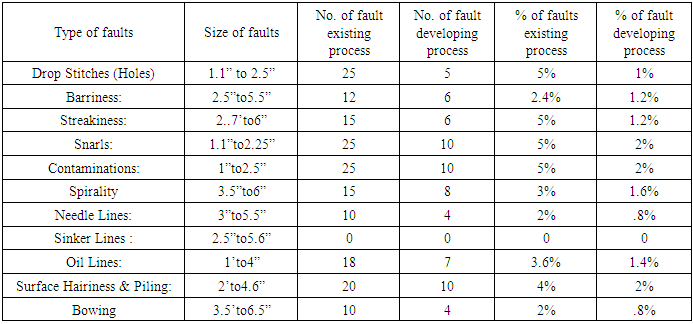

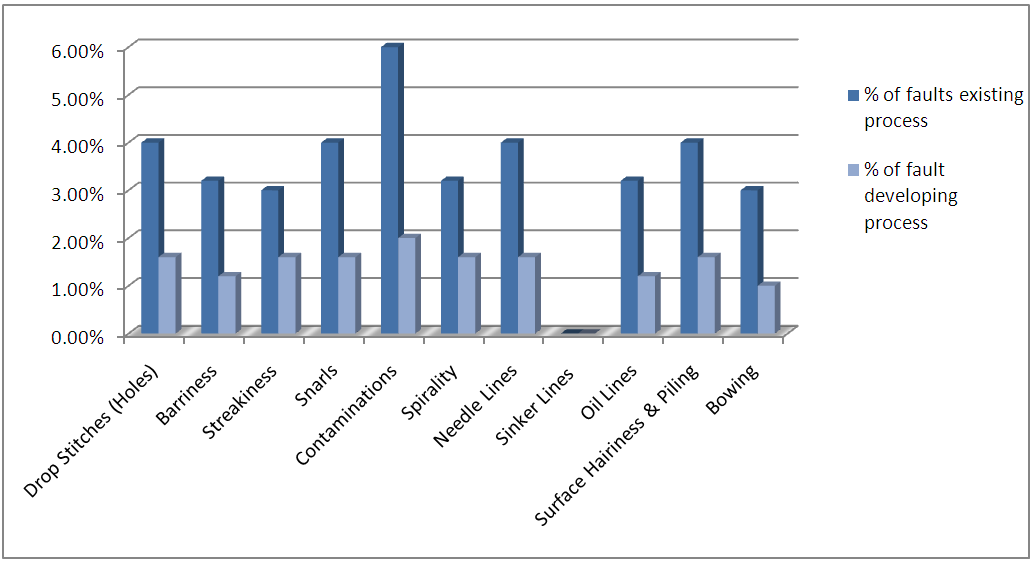

Calculation:% of fault in existing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 20,So the no. of fault in 100 meter fabric is = (20x100)/500 = 4%The rest fault percentage is calculated in the same way.% of fault in developing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 6So the no. of fault in 100 meter fabric is = (6x100)/500 = 1.2%The rest fault percentage is calculated in the same way.Table 2. Fault of rib fabric (500 meter)

|

| |

|

| Figure 6. Major knitting fault of rib fabric |

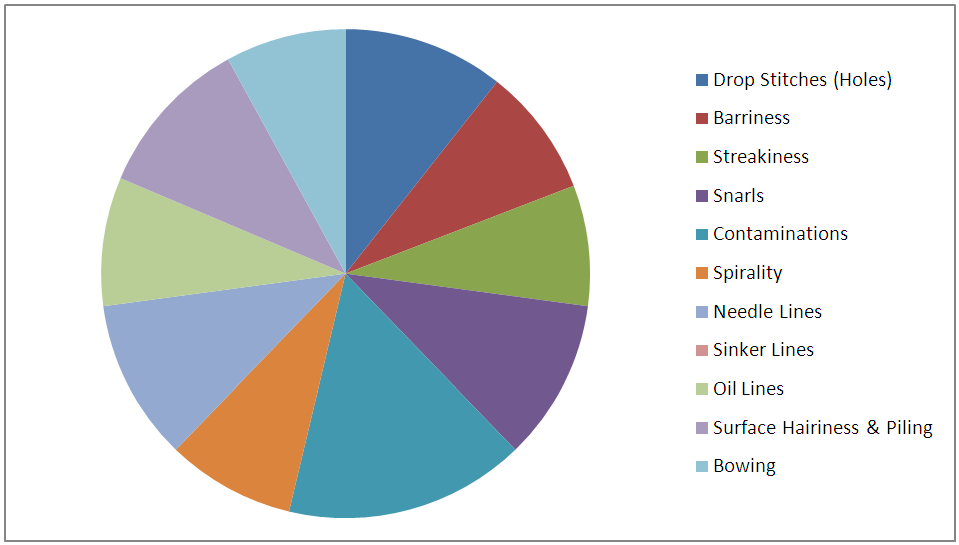

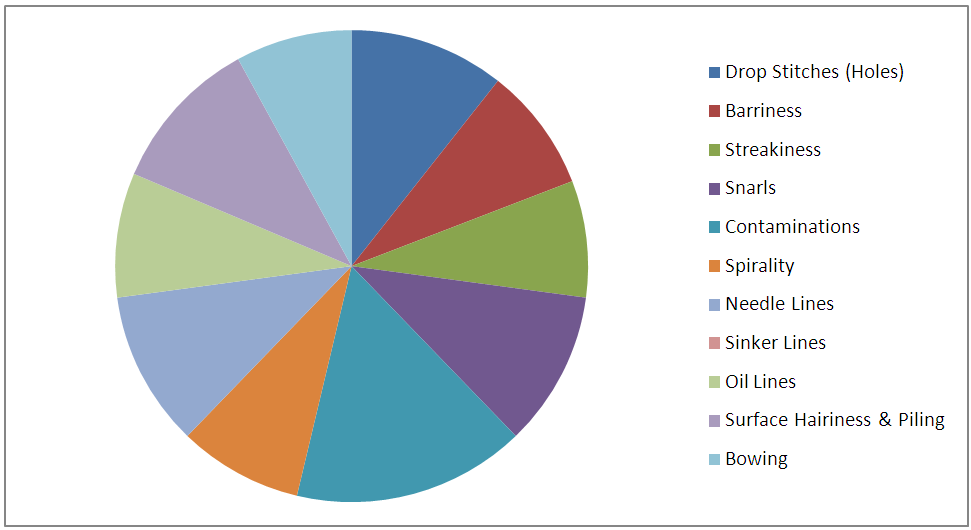

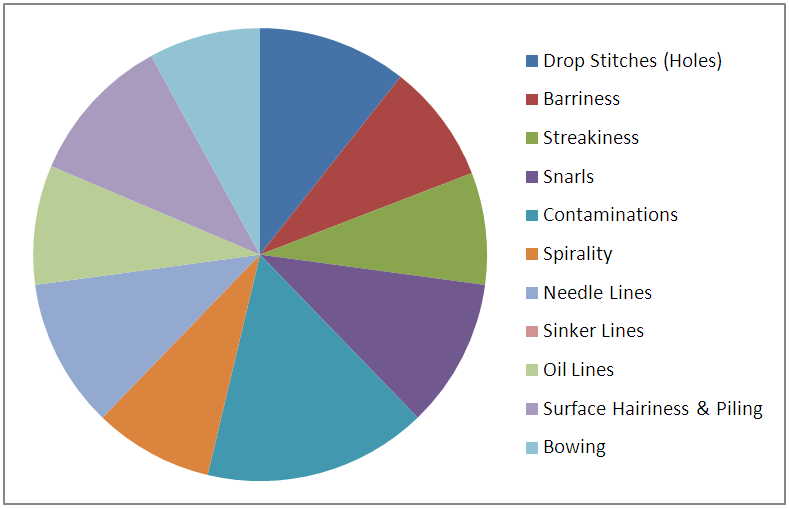

3.2.1. Percentage of Knitting Faults in Rib Fabric

| Figure 7. Percentage of dyeing faults in rib fabric |

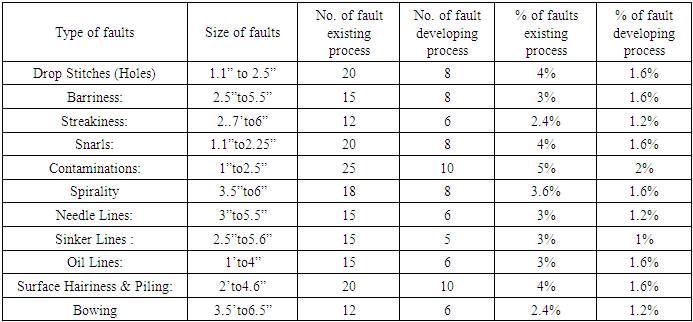

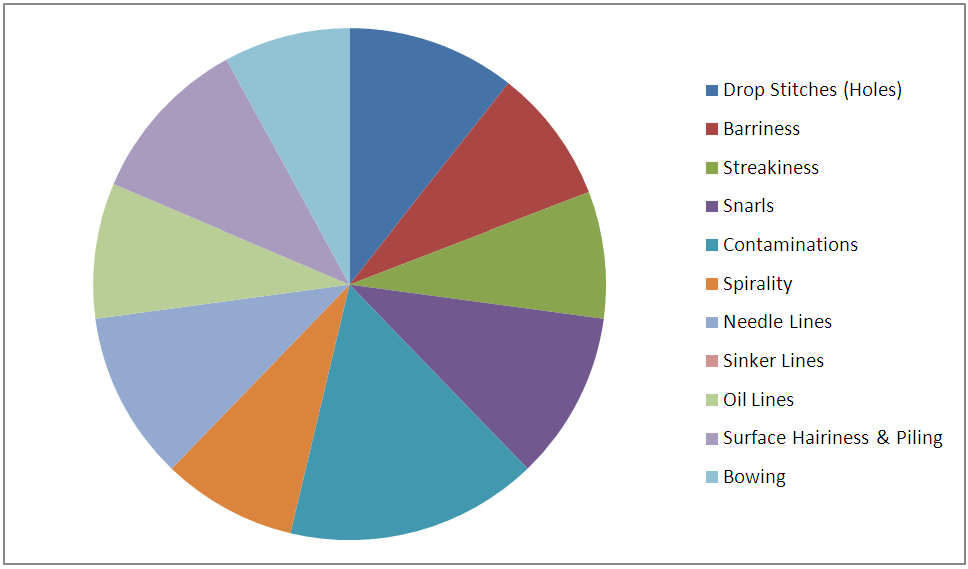

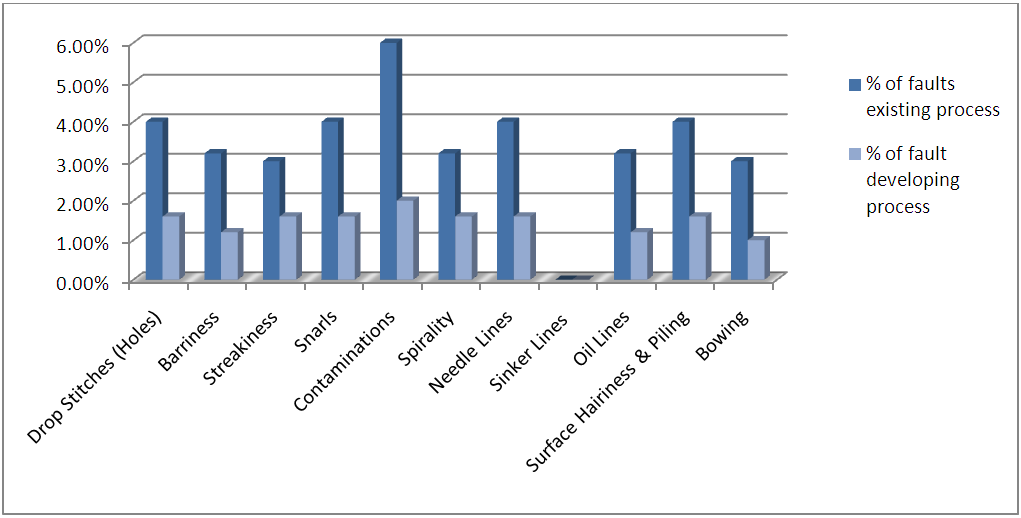

3.3. For Interlock Fabric: (500 Meter)

Table 3. Fault of interlock fabric (500 meter)

|

| |

|

Calculation:% of fault in existing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 20,So the no. of fault in 100 meter fabric is = (20x100)/500 = 4%The rest fault percentage is calculated in the same way.% of fault in developing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 5 So the no. of fault in 100 meter fabric is = (5x100)/500 = 1.6%The rest fault percentage is calculated in the same way. | Figure 8. Major knitting fault of rib fabric |

3.3.1. Percentage of Knitting Faults in Interlock Fabric

| Figure 9. Percentage of dyeing faults in interlock fabric |

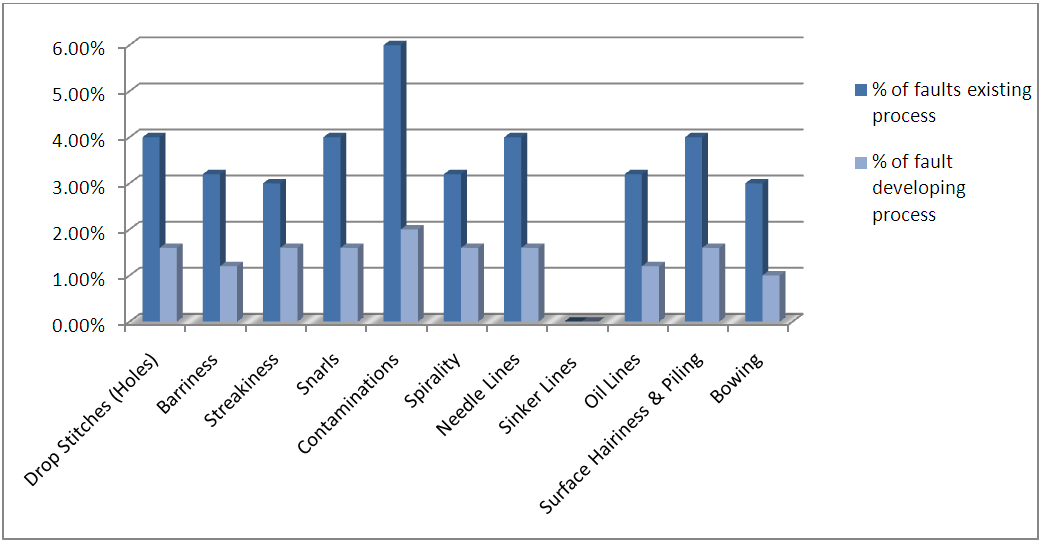

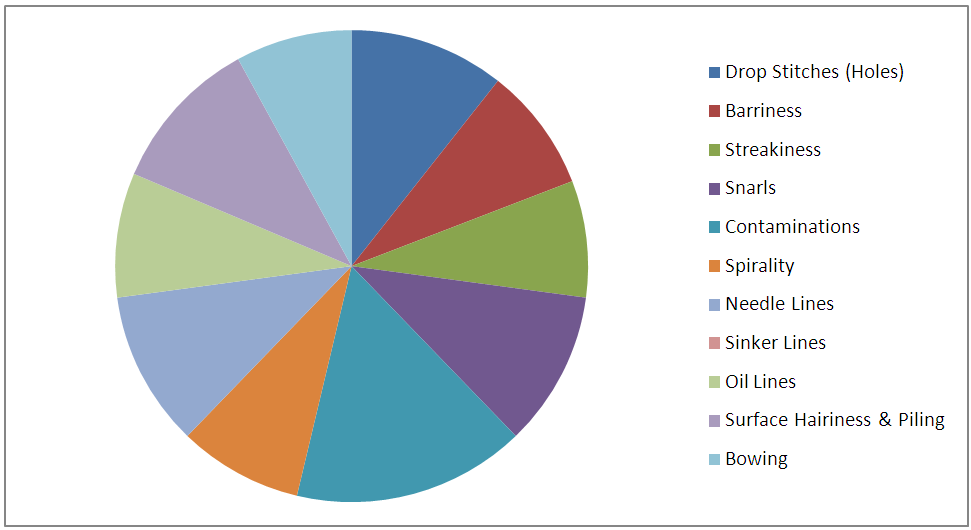

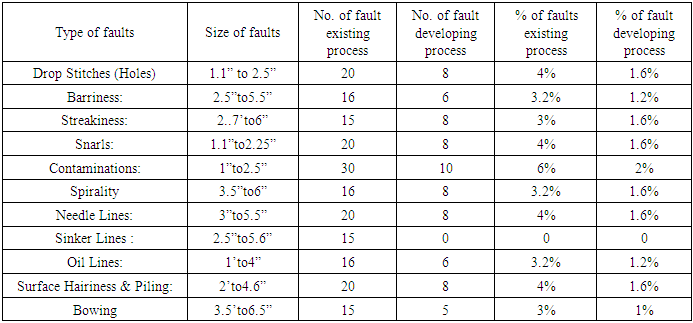

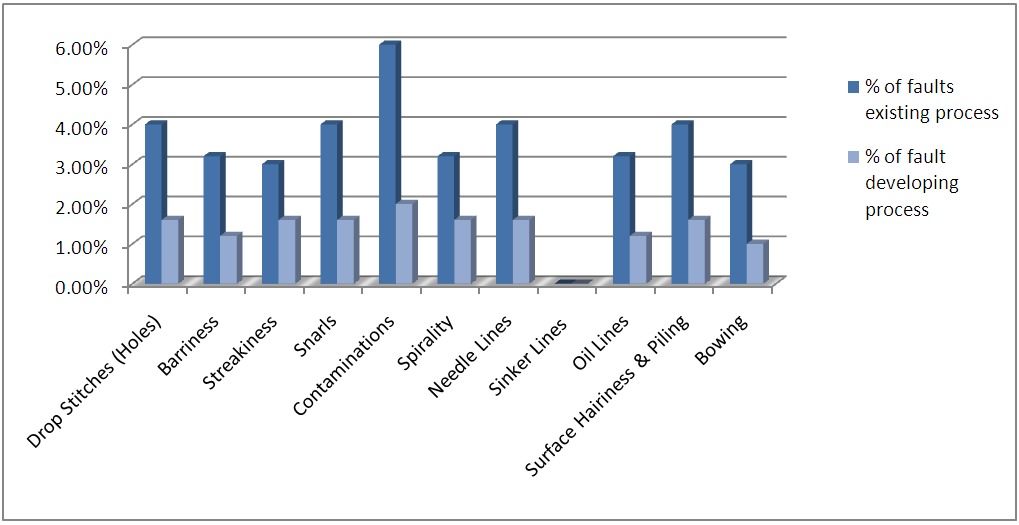

3.4. For Lacoste Fabric: (500 Meter)

Table 4. Fault of lacoste fabric (500 meter)

|

| |

|

| Figure 10. Major knitting fault of lacoste fabric |

Calculation:% of fault in existing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 25,So the no. of fault in 100 meter fabric is = (20x100)/500 = 5%The rest fault percentage is calculated in the same way.% of fault in developing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 5 So the no. of fault in 100 meter fabric is = (5x100)/500 = 1%The rest fault percentage is calculated in the same way.

3.4.1. Percentage of Knitting Faults in Lacoste Fabric

| Figure 11. Percentage of dyeing faults in lacsote fabric |

3.5. For Pique Fabric: (500 Meter)

Table 5. Fault of pique fabric (500 meter)

|

| |

|

Calculation:% of fault in existing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 20,So the no. of fault in 100 meter fabric is = (20x100)/500 = 4%The rest fault percentage is calculated in the same way.% of fault in developing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 8So the no. of fault in 100 meter fabric is = (8x100)/500 = 1.6%The rest fault percentage is calculated in the same way. | Figure 12. Major knitting fault of pique fabric |

3.5.1. Percentage of Knitting Faults in Pique Fabric

| Figure 13. Percentage of dyeing faults in pique fabric |

3.6. For Fleece Fabric: (500 Meter)

Table 6. Fault of fleece fabric (500 meter)

|

| |

|

| Figure 14. Major knitting fault of fleece fabric |

Calculation:% of fault in existing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 20,So the no. of fault in 100 meter fabric is = (20x100)/500 = 4%The rest fault percentage is calculated in the same way.% of fault in developing process:Drop Stitches (Holes):Number of Fault in 500 meter fabric is 8So the no. of fault in 100 meter fabric is = (8x100)/500 = 1.6%The rest fault percentage is calculated in the same way.

3.6.1. Percentage of Knitting Faults in Fleece Fabric

| Figure 15. Percentage of dyeing faults in fleece fabric |

4. Findings and Suggestions

Many faults are coming from yarn and knitting but we have to ensure that from where the fault is coming and causes/remedies will also be according to the source. According to this figure, 50% of the fault causes represents 80% of the recorded faults. This means that faults linked unsettled fabric, holes and dropped stitches have to be repaired in priority to improve significantly fabric quality. [8]. Morphological analysis: A system has been developed knitted fabric parameters using image analysis techniques. This technique can be used to evaluate courses per unit length, wales per unit length, fabric cover and weight per unit area [9].

5. Conclusions

Faults found in knitted fabric mainly originated from three separate aspects e.g. (i) Faults due to yarn, (ii) faults occur during knitting and (iii) faults occur due to environment. In order to ensure quality of knitted fabric one must ensure coordination of all the three aspects mentioned above. We believe that our work will help the people working in the knitting industry to identify the source of detected faults & proposes specific solutions for these faults causes. So knitters can take necessary remedial steps to overcome the faults. Some knitting faults are remain till the fabric is finished but this type of fault easily remove by dyeing condition. This report is able to give a deep concept about knit faults, causes and their remedies.

References

| [1] | Mouritz, A., et al., Review of applications for advanced three-dimensional fibre textile composites. Composites Part A: applied science and manufacturing, 1999. 30(12): p. 1445-1461. |

| [2] | Kader, G. and M.N. Rana, Study on Quality Issues in Circular Weft Knitting. 2013, Daffodil International University. |

| [3] | Gebru, K., Identifying defect causes of weft greige knitted fabric: the Case. 2014, Citeseer. |

| [4] | Asefa, L., Measuring National Quality Cost in Ethiopian Import Export Products. 2013, aau. |

| [5] | Spencer, D. J., Knitting technology: a comprehensive handbook and practical guide. Vol. 16. 2001: CRC Press. |

| [6] | Johnson-Laird, P.N., The computer and the mind: An introduction to cognitive science. 1988: Harvard University Press. |

| [7] | Kalayu, G., Identifying defect causes of weft greige knitted fabric: the Case of MAA-Garment & Textiles Factory. 2014, Mekelle University. |

| [8] | Jardine, A.K., D. Lin, and D. Banjevic, A review on machinery diagnostics and prognostics implementing condition-based maintenance. Mechanical systems and signal processing, 2006. 20(7): p. 1483-1510. |

| [9] | Abou-Ana, M., et al., Assessing structural changes in knits during processing. Textile research journal, 2003. 73(6): p. 535-540. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML