Md. Mostafizur Rahman 1, Muhammad Abu Taher 1, Mst. Zakia Sultana 1, Ashaduzzaman 1, Md. Shipan Mia 1, Mohammad Sohel Rana 2

1School of Textile Chemistry & Chemical Engineering, Wuhan Textile University, Wuhan, China

2School of Textile Science & Engineering, Southeast University, Dhaka, Bangladesh

Correspondence to: Mohammad Sohel Rana , School of Textile Science & Engineering, Southeast University, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Finishing is used to improve the appearance, imparting functionality and enhancing durability as well as process ability of the textile products. Different processes are associated with the complete production of Coloured fabrics to get the finished fabric. Finishing processes are carried out to improve the natural properties or attractiveness of the fabric and to increase its serviceability. Every natural fiber is noted for some properties but it lacks some other properties which are essential during its end-use. The term finishing, in a broad sense, covers all the processes which the fabric undergoes after leaving the loom or the knitting machine to the stage at which it enters the market. Thus the term also includes bleaching, dyeing, mercerizing etc. but normally the term is restricted to the final stage in the sequence of treatment of Knit fabrics after bleaching and dyeing. Major processes control parameters in all machines are discussed briefly to optimizing the faults through this machine control process and some visible hindrance. Based on the overall performance it can be said that this paper gathers all the information’s related to knit-finishing factory and analyze the fault’s, causes and some ideas are suggested which can meet modern textile trends and customer demand.

Keywords:

Finishing, Dyeing, Quality, Textile, Softener

Cite this paper: Md. Mostafizur Rahman , Muhammad Abu Taher , Mst. Zakia Sultana , Ashaduzzaman , Md. Shipan Mia , Mohammad Sohel Rana , Finishing Effects on Coloured Knit Fabrics through Implementation of Effective Parameters, International Journal of Textile Science, Vol. 5 No. 5, 2016, pp. 110-118. doi: 10.5923/j.textile.20160505.03.

1. Introduction

Textile finishing, in a restricted sense, is the term used for a series of processes to which all bleached, dyed, printed and certain grey fabrics are subjected before they are put on the market. The aim of textile finishing is to render textile goods fit for their purpose or end-use [1]. This is achieved by subjecting them to various processes. Finishing can be classified according to the purposes of enhancement-organdie, lusture, crease-resistance, filling, softness, proofing (shower-proofing or water-repellency, mildew-proofing, moth-proofing, flame- proofing or flame retardancy. antistatic, soil-resistance etc.) and serviceability (dimensional stability, improved fastness to washing, improved fastness to storage, resistance to fiber slippage, improved wearing quality etc.) [2, 3].In another sense finishing processes are carried out to improve the natural properties or attractiveness of the fabric and to increase its serviceability (in that order). Every natural fiber is noted for some properties but it lacks some other properties which are essential during its end-use. Hence, the finishing processes employed will depend on the properties required in the fabric with respect to its use and its natural properties [4, 5]. The term finishing, in a broad sense, covers all the processes which the fabric undergoes after leaving the loom or the knitting machine to the stage at which it enters the market [6, 7]. Thus the term also includes bleaching, dyeing, mercerizing etc.. But normally the term is restricted to the final stage in the sequence of treatment of Knit fabrics after bleaching and dyeing [8, 9]. However, fabrics which are neither bleached nor dyed are also finished [10]. Some finishing processes such as creping of silk and rayon, mercerization of cotton or crabbing of wool are carried out as a part of the first phase of fabric treatment or even earlier, in l he form of yam [11, 12]. Hence finishing is the term usually employed for processes other than scouring, bleaching, dyeing or printing, to which the fabrics are subjected to improve their appearance, properties and serviceability. Finishing methods include chemical modifications of the materials and imparting to it dimensional stability, crease resistance and anti-shrink properties [13, 14]. The techniques of finishing depend on: chemical composition, state, weave, Nature of the fabric, physical properties of the fabric, The end-use of the material, Susceptibility to chemical modifications, Receptivity of the fabric to various finishing operations [15, 16].

2. Experimental

2.1. Materials

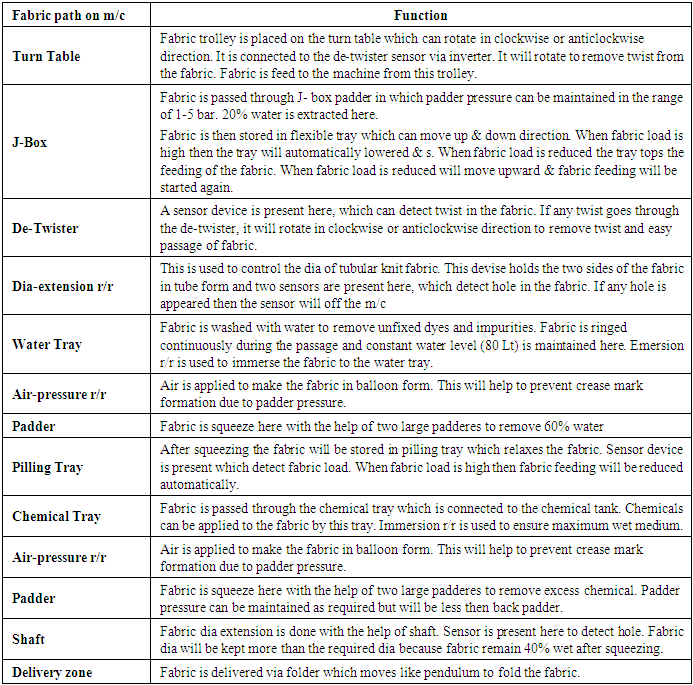

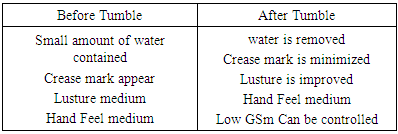

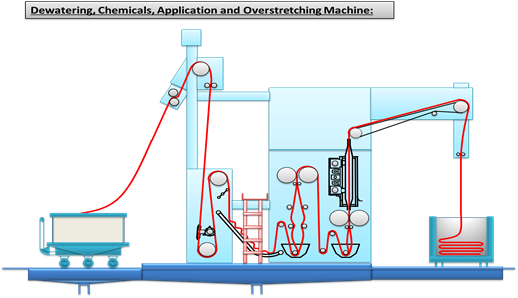

Finishing agents those are used for chemical finishing of Textiles are: Softener, Biopolishing, Enzyme, UV Protection, Anticrease, Silicon Finish etc. Mechanical finish is Shrinkage, Raising and Shearing finish and others. | Figure 1. Fabric passage on Tube squeezer m/c |

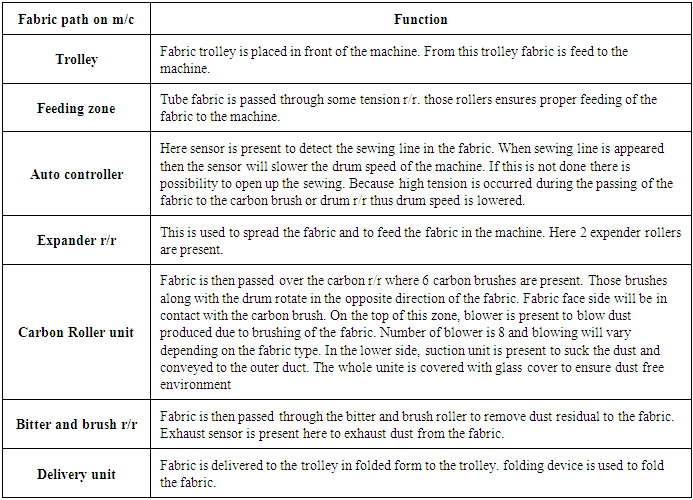

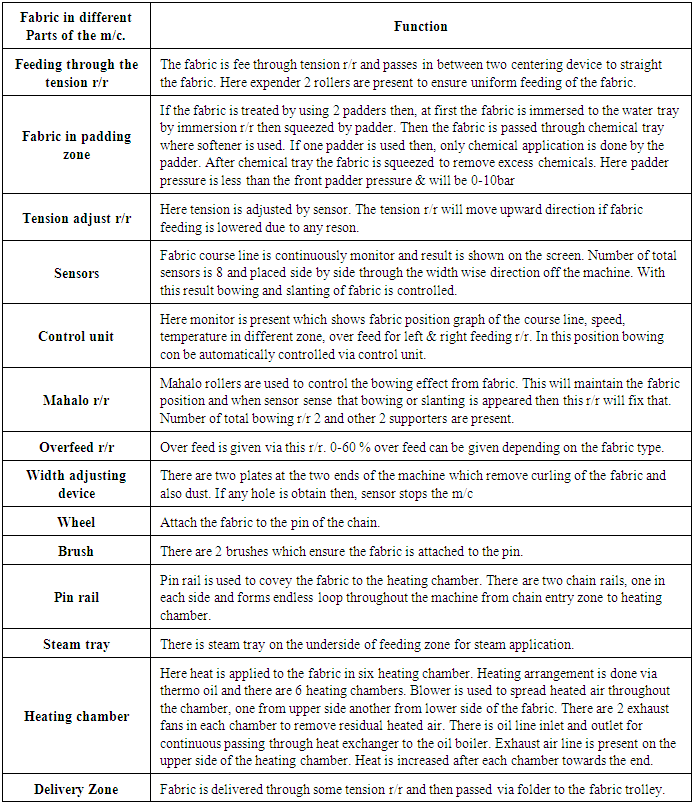

Table 1. Fabric passage & function of diff. parts of Tube squeezer

|

| |

|

2.2. Method

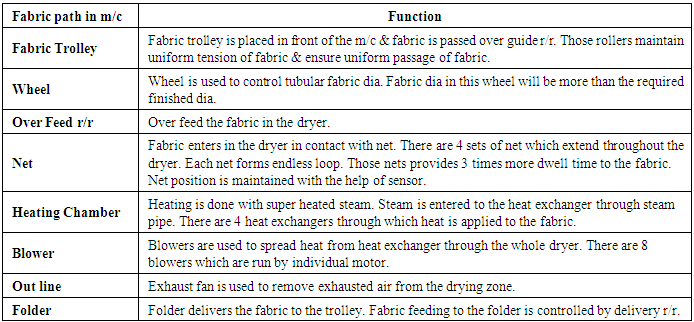

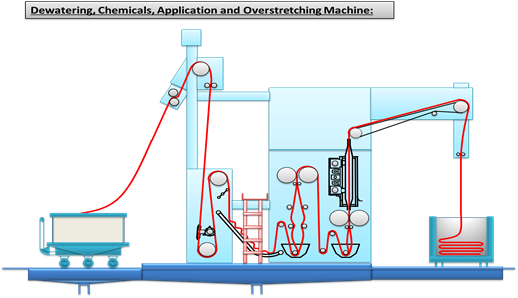

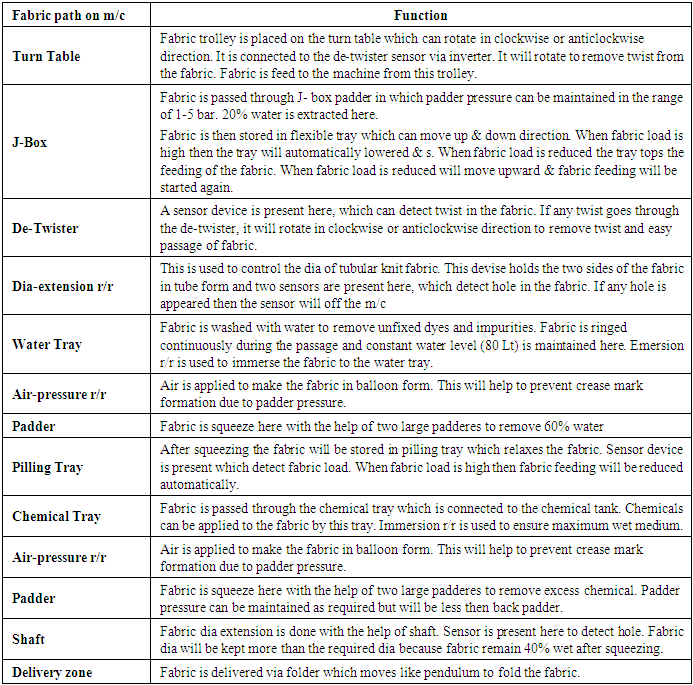

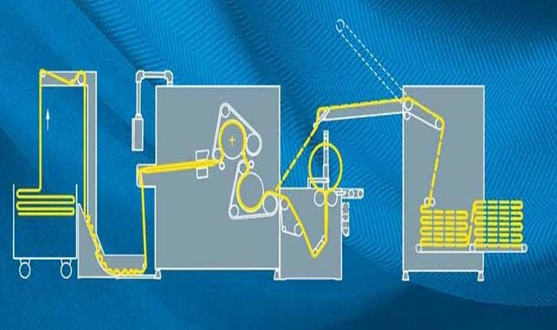

Normally finishing process is of two kinds 1. Chemical finishing and 2. Mechanical finish. By obtaining those process we get these results: Easy – care, Crease recovery, Dimensional stability, Good abrasion resistance, Improved tear strength, Good sew ability, Soft or stiff handle, Shine or lusture .After dyeing process from the dyeing machine then the fabrics arc ready for dc-watering. This is the process to remove the water from the fabric partially by squeezing But here we have to control the some important factor. Like width of the fabric, spirality of the fabric, crease mark of the fabric.Table 2. Fabric passage & function of diff. parts of Relax Dryer

|

| |

|

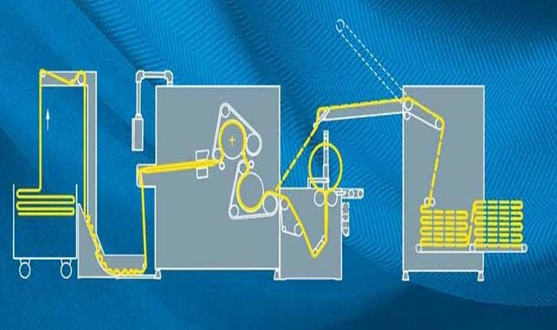

Table 3. Fabric passage & function of diff. parts of Tubular Compactor

|

| |

|

| Figure 2. Fabric passage diagram in tube compactor machine |

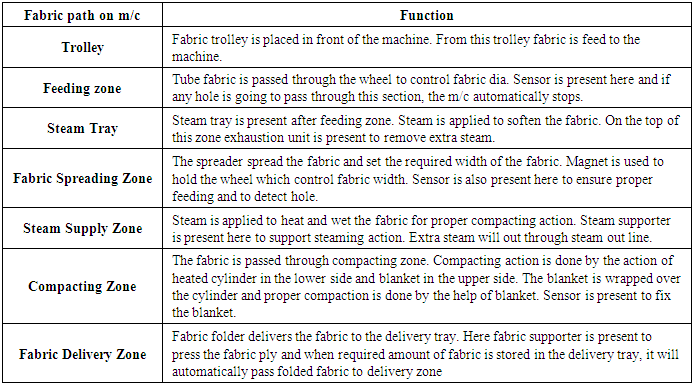

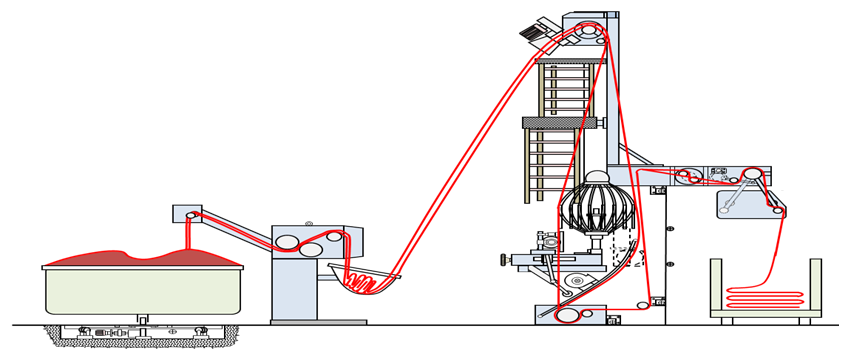

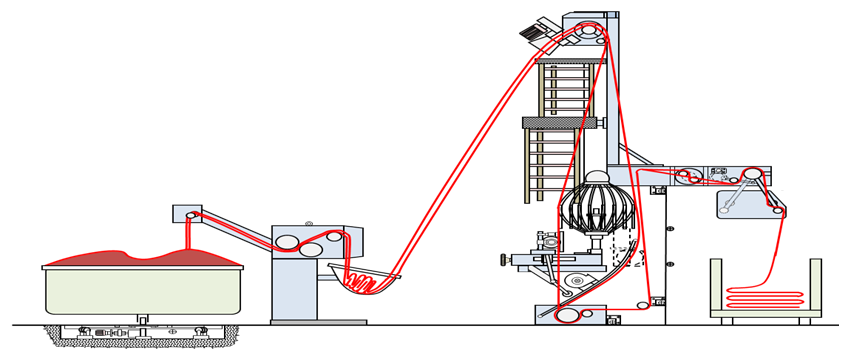

| Figure 3. Fabric passage in open squeezer m/c |

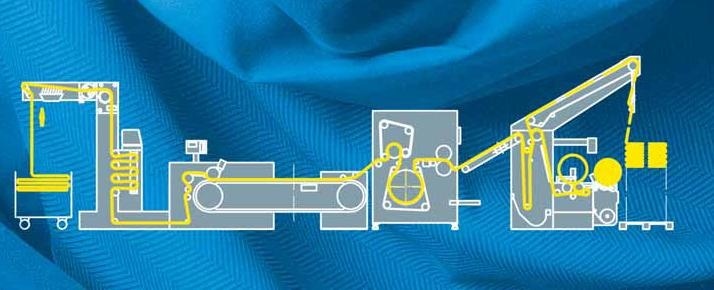

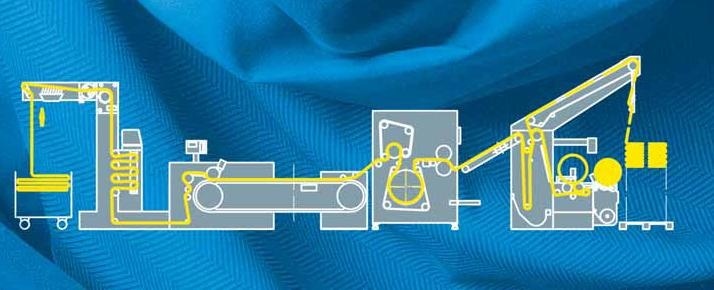

| Figure 4. Fabric passage on open compactor |

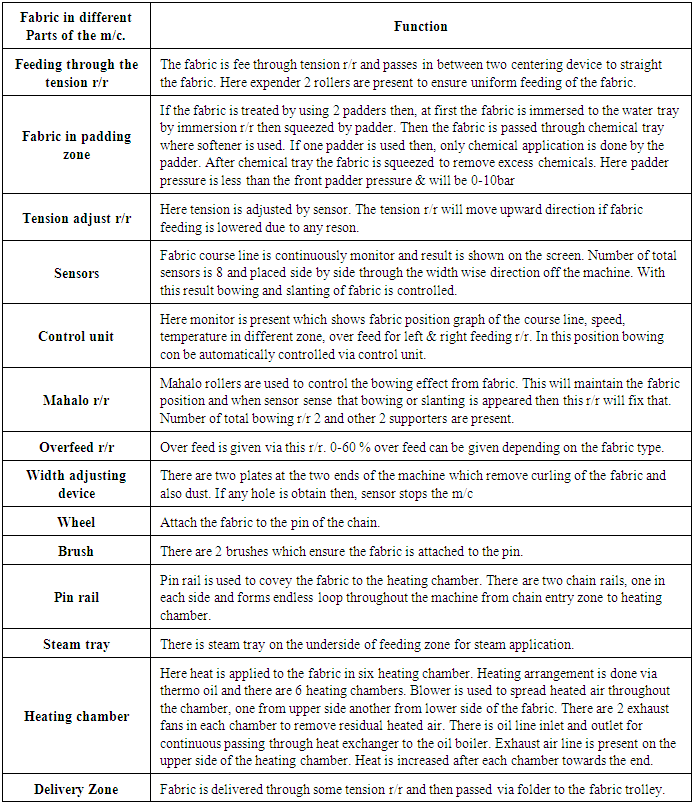

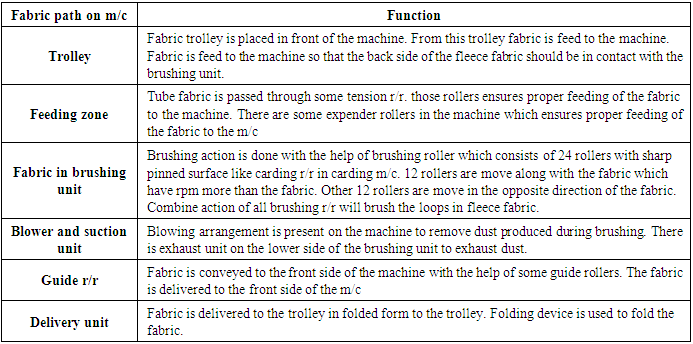

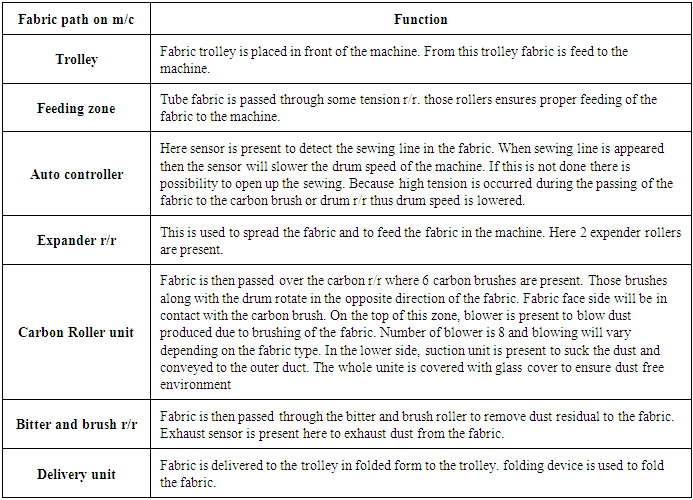

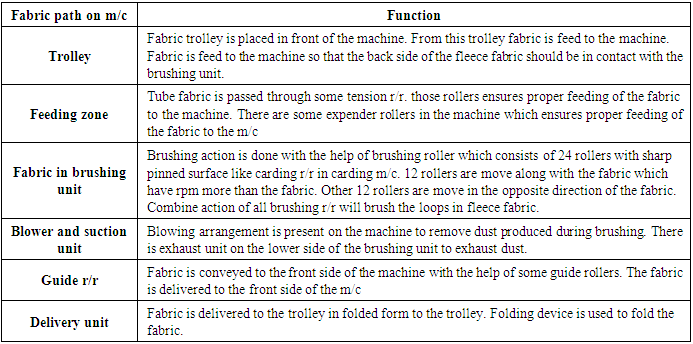

After squeezer fabric comes to dryer machine. Dryer machine is used to dry the fabric with the help of the steam. Besides drying it controls the shrinkage and prepares the fabric for the next process.Tube compactor is used to finish knit fabric in tube form. The basic functions of the Tube compactor machine is To control the GSM. (Increase & decrease), control the dia, control the shrinkage. (Increase & decrease).For open width fabric, after dyeing fabric comes in this machine for slitting and squeezing. Here fabric is cut through the dia mark and squeezing is also done.Controlling parameters of open squeezer are Speed, Padder pressure and Air Pressure. In case of light color padder pressure should be low. Otherwise shade will be lighter. If the padder is not clean, then line mark can appear in the fabric. If low gsm S/J fabric is processing, then padder pressure and speed will be maximum. If high gsm fabric is processing, then padder pressure and speed will be minimum.Open Compactor has the the basic functions of the Open compactor machine is to compact the fabric in open form &he basic functions of the Open compactor machine is to compact the fabric in open form & control the GSM. (Increase & decrease), control the dia, control the shrinkage. (Increase & decrease).Stenter machine in very important for finishing knit fabric in open form. It can be used for those functions: Apply chemical and softener, To dart set the T/C fabric, Drying of fabric, To control width, Curing of fabric, Apply pigment dyeing, control GSM, control shrinkage, decrease spirality, decrease bowing effect, Surface coating for teflon finish, Apply soil release chemical finish, Heat set for cotton/lycra fabric.Ultra soft machine is used to increase softness of fabric. This is a mechanical process of finishing.By the brushing machine back side of the fleece fabric is brushed.There are several machines are used for knit fabric finishing. Every machine is used for a particular effect.none of them are less important then each other. According to the requirement each machine has their pirticular use.Mainly finishing is necessary for all kind of fabrics both knit and woven fabrics. Now a days finishing technology is receiving a versitile improvement. One machine is not not providing only one kind of finishing like if we talk about stenter then we can see that we normally use it to dry open weidth fabrics but it also used for heat setting of knit fabrics, for application of differnt kind of chemicals for controlling dia and shrinkage etc.Table 4. Fabric passage & function of diff. parts of stenter machine

|

| |

|

Table 5. Fabric passage & function of diff. parts of Ultra soft m/c

|

| |

|

Table 6. Fabric passage & function of diff. parts of Brushing m/c

|

| |

|

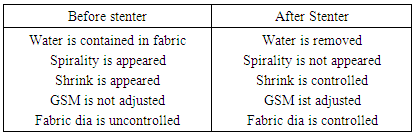

| Figure 5. Difference between fabrics before Stenter and after Stenter |

3. Results and Discussion

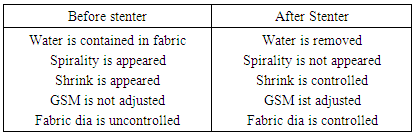

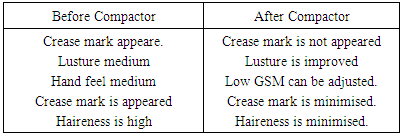

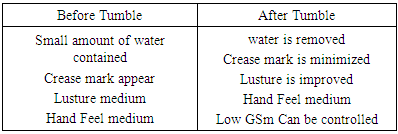

Textile finishing is a term commonly applied to different process that the textile material under go after pretreatment, dyeing or printing for final embellishment to enhance their attractiveness and sale appeal as well as for comfort. Now we will observe different sample through different finishing machine and try to test and analysis the effect. Table 7. Difference obtained before stenter and after stenter

|

| |

|

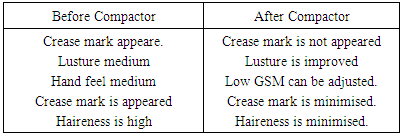

Table 8. Difference obtained before stenter and after stenter

|

| |

|

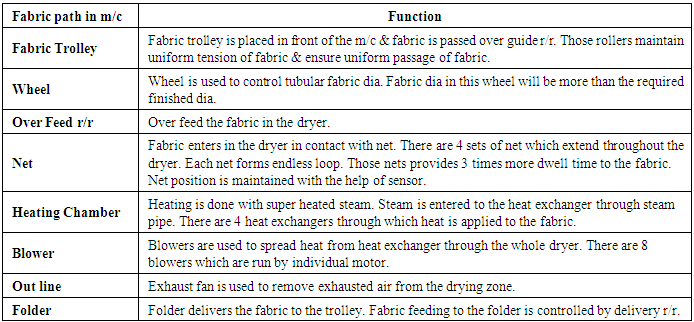

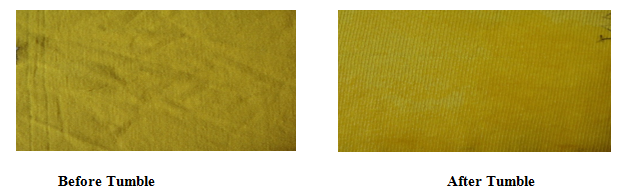

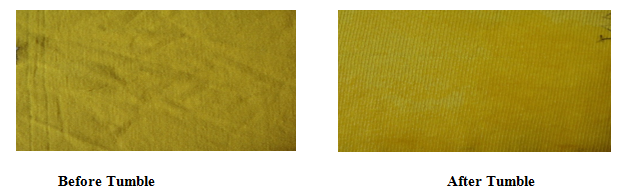

Table 9. Difference obtained before Tumble and after Tumble

|

| |

|

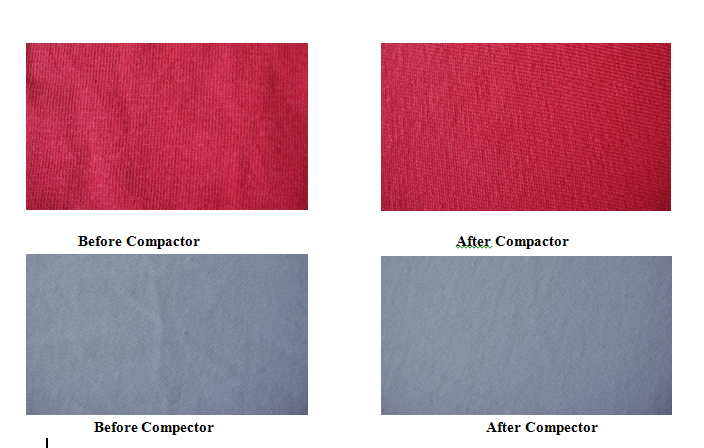

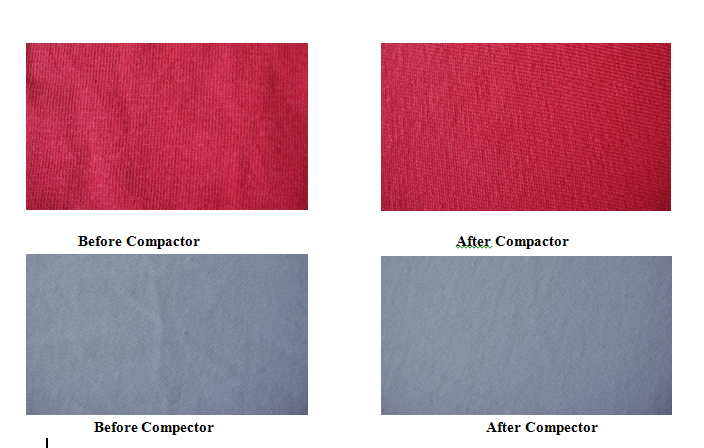

It is seen that in case of each and every finishing machine that they can not perform with their full efficiency .Every machine has some limitation for that finishing machine cannot fulfill their effect. Generally finishing machines require temperature, pressure, steam, speed, dust free environment. We found some problem on different machine which causes faulty finishing or less efficiency. Now a days some latest devices have been invented that, this can not only improve effects and but also increase the production and quality of fabric.Now we suggest using some device to improve effect, quality and production. Some faults normally found in stenter machine are in GSM control, Skewing, Bowing, Spirality, Dimensional stability. If mahalo/ plevia device is settled with stenter this problem can be minimized. This device improves quality, effect and production. And use of sensor is also necessary for ensuring the even pressure and temperature. The problem with compactor machine almost same as stenter machine. Sunforising device can solve this problem. This device can easily control of low gsm fabric. About 10 gsm can be controlled. Dimensional stability can be also controlled.In Dewatering & Squeezer Machine Softener is used. Softener is also used for shade match. Different softeners are used for different shade. When softener is used, after sometimes dust contaminated with it. Then it does not give required effect. In these case filter can be used. This is called softener recycling device. This device recycles the softener from dust. The recycled softener can be used again. It save cost and improve effects. Generally problems found in Tumble dryer are Fabric dry unevenly, Presence of crease mark, luster improvement is less.Recently a new machine is available. This is the Brio machine. It can be used instead of Tumble dryer. This machine improves the fabric quality. It also provide with those advantages: Fabric dry evenly, No crease mark, Significant luster improve, Extra care of fabric, Finishing effect creates by vibration, Ideal for decorative and sensitive fabric.For improving fabric attractiveness must have to do modification of fabric appearance by using calendaring machine and optical brightening agent. For hand feel must alter fabric handle by using Softening or Stiffening agent. and for controlling fabric dimension we use Sanforising, Compacting machine. For improving serviceability according to the demand of customer like as For Protection of fabric (Flame proofing, Water proofing), Improved performance (Water repellency, Raising), Easy care properties (Resin finish, Crease recovery). | Figure 6. Difference between fabrics before Compactor and after Compactor |

| Figure 7. Difference between fabrics before Tumbel and after Tumbel |

| Figure 8. Difference between fabrics before Brio and after Brio |

4. Conclusions

Finishing used to improve appearance, impart functionality and enhance durability as well as process ability of the textile products different processes associated with complete production of fabrics are required to get finished fabric. An effort is made to formulate all the finishing production steps. This paper also gives an idea of different processes and machineries used usually in a fast growing and mass productive knit-dyeing factory. Major processes control parameters in all machines are discussed briefly to optimizing the faults through this machine control process and some visible hindrance.Finally based on the overall performance it is concluded that the this paper tries to gather all the information related to knit-finishing factory and analysis fault’s causes and suggest some ideas which can meet modern textile trends and customer demand.In this project, different important factors are discussed on knit fabric finishing that can impact on finishing. All the reports are done by practical knowledge from different industry and finally some important factors which are obtained from knitting to dyeing and finishing. So deviations are obtained and the reason of the problem must observe to avoid in further. Because customers are always worried about the product quality. We hope this project work will be very helpful in our practical industrial life.

References

| [1] | Wang, C., et al., Toxicity evaluation of reactive dyestuffs, auxiliaries and selected effluents in textile finishing industry to luminescent bacteria Vibrio fischeri. Chemosphere, 2002. 46(2): p. 339-344. |

| [2] | Tyndall, R.M., Improving the Softness and Surface Appearance of Cotton Fabrics and Garments by Treatment with Cellulase Enzymes. Textile Chemist & Colorist, 1992. 24(6). |

| [3] | Öktem, T., Surface treatment of cotton fabrics with chitosan. Coloration Technology, 2003. 119(4): p. 241-246. |

| [4] | Schindler, W.D. and P.J. Hauser, Chemical finishing of textiles. 2004: Elsevier. |

| [5] | Ye, W., et al., Durable antibacterial finish on cotton fabric by using chitosan - based polymeric core - shell particles. Journal of Applied Polymer Science, 2006. 102(2): p. 1787-1793. |

| [6] | Hasan, K.F., Study on the Changes of GSM (Gm/m 2) of Grey Knitted Fabric from Pretreatment to Finishing. International Journal of Textile Science, 2015. 4(6): p. 119-136. |

| [7] | Hasan, K.F., et al., Role of Textile and Clothing Industries in the Growth and Development of Trade & Business Strategies of Bangladesh in the Global Economy. International Journal of Textile Science, 2016. 5(3): p. 39-48. |

| [8] | Ashaduzzaman, H.K., et al., Causes and Remedies of Batch to Batch Shade Variation in Dyeing Textile Floor. J Textile Sci Eng, 2016. 6(264): p. 2. |

| [9] | Hasan, K.F., et al., A review on Antibacterial Coloration Agent’s Activity, Implementation & Efficiency to Ensure the Ecofriendly & Green Textiles. American Journal of Polymer Science & Engineering, 2016. 4(1): p. 39-59. |

| [10] | Alpay, H.R., B. Becerir, and M. Akgun, Assessing reflectance and color differences of cotton fabrics after abrasion. Textile research journal, 2005. 75(4): p. 357-361. |

| [11] | Bajaj, P., Finishing of textile materials. Journal of Applied Polymer Science, 2002. 83(3): p. 631-659. |

| [12] | Yang, H. and C.Q. Yang, Durable flame retardant finishing of the nylon/cotton blend fabric using a hydroxyl-functional organophosphorus oligomer. Polymer Degradation and Stability, 2005. 88(3): p. 363-370. |

| [13] | Hasan, K.F., et al., Dynamic Mechanical Behavior & Analysis of the Jute-Glass Fiber Reinforced Polyester Hybrid Composites. American Journal of Applied Physics, 2016. 1(1): p. 1-12. |

| [14] | Hasan, K.F., Influence of Naturally Originated Jute on the Fabrication & Mechanical Properties of Jute/Polyester Hybrid Composite. American Journal of Polymer Science & Engineering, 2016. 4(1): p. 82-90. |

| [15] | Islam, M., et al., Improving the Fastness Properties of Cotton Fabric through the Implementation of Different Mordanting Agents Dyed with Natural Dye Extracted from Marigold. American Journal of Polymer Science & Engineering does not currently require any Article Publication Fee, 2016. 4(1). |

| [16] | Orhan, M., D. Kut, and C. Gunesoglu, Improving the antibacterial activity of cotton fabrics finished with triclosan by the use of 1, 2, 3, 4‐butanetetracarboxylic acid and citric acid. Journal of Applied Polymer Science, 2009. 111(3): p. 1344-1352. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML