-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2016; 5(4): 82-86

doi:10.5923/j.textile.20160504.03

Woven Fabric Coloration through Cost Effective Technology along with Adequate Quality for Turquoise Shade

Mst. Zakia Sultana1, 2, 3, Xiang Li1, 2, K. M. Faridul Hasan3, 4, Z. M. Rafid Rownak2, Md. Shamsur Rahman2, Quan Heng1

1School of Chemistry & Chemical Engineering, Wuhan Textile University, Wuhan, China

2Wuhan Textile University Graduate (Color root) workstation, Songgzi, China

3Department of Textile Engineering, Southeast University, Dhaka, Bangladesh

4School of Textile Science & Engineering, Wuhan Textile University, Wuhan, China

Correspondence to: Quan Heng, School of Chemistry & Chemical Engineering, Wuhan Textile University, Wuhan, China.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The textile market is increasing rapidly and becoming more and more competitive day by day. Customers are getting very much conscious about what they are buying and demanding more and more with respect to quality. It is creating challenge for the manufacturer to gain profit by continuing production through implementing the usual processes and they are forced to ensure various production parameters and settings in the machines for achieving much more effective, efficient and quality product as well as reducing cost. Therefore, it is very much important to know about the various dyeing processes along with gradual improvement. This research includes information that presents a detailed description of the standard & latest working procedure in wet processing. It is tried to highlight the main aspects, parameters & descriptions of important dyeing sections especially Woven dyeing section which depicts a comparison based on the information given here for getting an idea on most common dyeing processes and which are better to use in this competitive market. Then color fastness to wash, color fastness to dry & wet rub were tested. Change in K/S, lightness DE and overall color difference DE were observed & analyzed.

Keywords: Color depth, Dyeing Process, Fastness properties, Turquoise color, Cost

Cite this paper: Mst. Zakia Sultana, Xiang Li, K. M. Faridul Hasan, Z. M. Rafid Rownak, Md. Shamsur Rahman, Quan Heng, Woven Fabric Coloration through Cost Effective Technology along with Adequate Quality for Turquoise Shade, International Journal of Textile Science, Vol. 5 No. 4, 2016, pp. 82-86. doi: 10.5923/j.textile.20160504.03.

Article Outline

1. Introduction

- Dyeing is the process of applying color to fiber, yarn or fabric, usually by immersing in a dye bath. Textile materials are dyed in aqueous solutions or dispersions of dyestuffs, together with dye bath additives such as salt, alkali, acids and other auxiliary chemicals [1]. The dissolved or dispersed dyestuffs must first be absorbed on to the fiber surface and the diffuse into its interior where finally it must be fixed. Dyes are complex organic compound capable of imparting [2]. Most of them are organic compounds [3, 4].There are different types of dyes available which are used as per need. Generally Basic dyes are applied on jute, Acid dye on wool, Reactive or Vat dyes on cotton and Disperse dye on manmade fibers [5, 6]. On the other hand, there are number of dyeing processes available to carry out dyeing. They provide different color fastness and other important factors related to dyeing. Production in dyeing factories consists of various operations [7-9]. It is obvious that there is huge amount of tasks involved in each section which must be pre-planned in order to cope with the tight production schedule. Dyeing can be carried out on yarn, fabric and garments. All of them require different types of pre-treatment and after treatment for obtaining desired shade [10, 11]. It should be mentioned that, the PDTH process is actually PDC process which is used for dyeing synthetic & blend fabrics with disperse dyes. On the other hand, PDVD is similar to PD-CPS process which is used for vat dyes [12, 13].

2. Experimental

2.1. Materials

- Woven Fabric available in Beximco Textile Limited (BTL), Different dyes (Remazol turquoise blue G, Kimsoline turquoise HFGX ETC). Chemicals & Auxiliaries(Caustic soda, Soda ash, Glauber salt, Resist Salt, Urea, Heli Binder, Thermocol MP, Mordant, Acetic acid, Wetting Agent, soaping agent) used in Beximco textile industry of Bangladesh.

2.2. Methods

- Determine the comparative factors, Turquoise color selected for dyeing fabrics with different processes to achieve that color. Fabric dyed with self-shade & combination shade for each process to find out differences between self & combination shades. The fabric dyed by PDC, PD-CPS, CPB, Wet on Wet process with self & combination shade to get turquoise color. Again, dyed using soluble & pigment dyes for this shade with their respective processes. Then took the dyed samples to get data color values to get their values and used a light box with different lights to create a comparison about the color depth achieved by individual processes. After that, took the samples for testing their color fastness of wash, light & perspiration which we thought to be the most common fastness tests of all. Then took another data color value for comparing shade change before and after fastness tests. Here also found out dye & process costs along with their possible benefit & Possibility of Problem. At last of this experiment did a rating based on available experimental data & information which gives an overview on the comparative factors of different dyeing process.To carry out a dying process, it is important tov Dissolve or disperse dye in a water bath.v Feed the dye solution in the machine after suitable filteringv Transfer the dye from the liquor to the fiberv Distribute the dye homogenously on the fiberv Let the dye penetrate in the fiber structure and fix itv Wash or rinse the material to remove the dye on the surface or the unfixed dyeing liquor.There are seven dyeing processes that is used for solid dyeing on woven fabric.1. Pad Dry Cure (PDC)2. Pad Dry Thermosol (PDTH)3. Pad Dry Chemical Pad Steam (PD-CPS)4. Pad Dry Vat Develop (PDVD)5. Cold Pad Batch (CPB)6. Soluble Dyeing7. Pigment Dyeing

3. Result & Discussion

- The dyed fabric using different methods and recipes for both self & combination shade. Then tested their data color value before & after fastness tests which would give numerical value of shade change as well as there are sufficient samples to show the difference visually.The study mainly focuses on different dyeing process uses in different dyestuff and also uses a color turquois, the turquois color used for self-shade and combination shade. After completed all though process, here color measurement and color fastness testing is investigated in this study. From that study overall noble result is giving the pigment dye. However, it has the potential for up-gradation from medium to large-scale industrial production and marketing will get the availability of different process. Finding of the paper reveal that some process gave some separable good properties, so that it will lead toward better prediction and optimization of separation processes in textile industry with satisfy the obligatory demand.

3.1. Color Depth

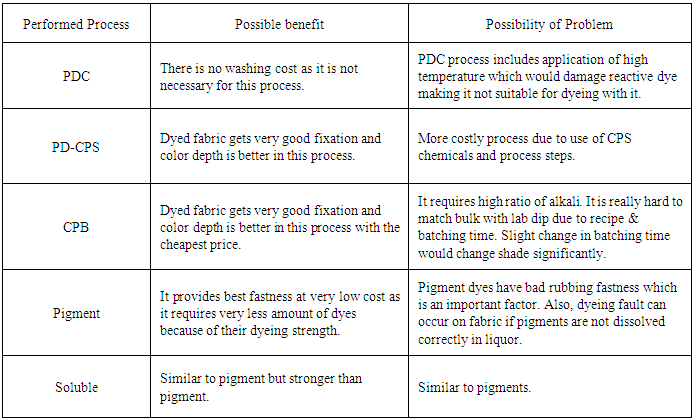

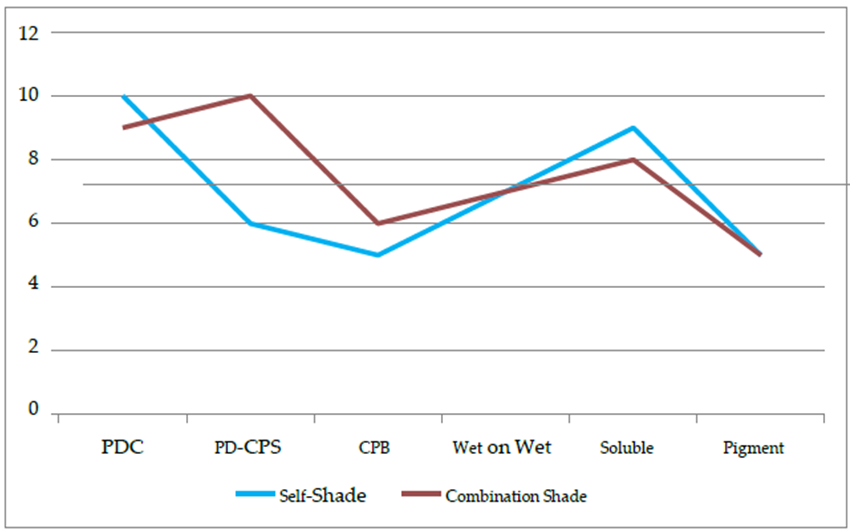

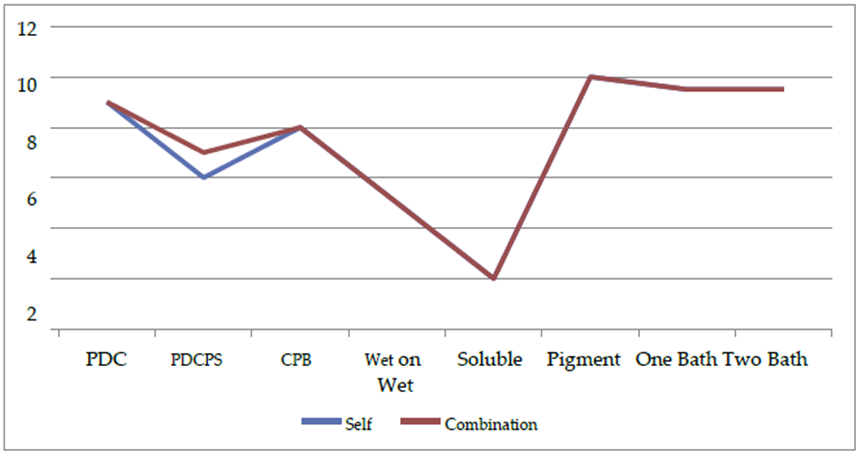

- From the figure 1 it is easy to understand that each processes have different level of color depth. Although the recipes were almost similar to get one particular shade (except for one bath & two bath, comparison is done between these two only). But for both self and combination shade, the difference of color depth achieved is visible and can be shown as below [14].

| Figure 1. Color depth comparison between Self Shade and Combination Shade |

| Figure 2. Fastness comparison between Self Shade and Combination Shade with different process |

3.2. Fastness

- Fastness is another important aspect of dyeing. If color fastness is not satisfactory, then obviously the product will lose its value. To determine color fastness, performed three tests of wash, light & perspiration to which a fabric will most frequently be in contact and probably lose its fastness.Here, both self and combination shades provided almost similar fastness properties except for PD-CPS process where combination shade gave better fastness than self-shade.Here, Pigment dye provided the best fastness after washing, perspiration and light fastness test as absolutely no change in shade occurred after the tests. Secondly, Two bath and one bath processes included dyeing with polyester- cotton blend fabric where disperse dyes were used, which gave really good fastness here too as they are not much sensitive to these fastness tests. PDC & CPB processes had pretty good fastness property, however, shade change occurred as you can see in the chart given previously. CPB process had such fastness due to use of high alkali & dozing time. PD-CPS has also moderately good fastness property due to chemical dozing and steam application rather than high temperature which would damage the dyestuffs [15]. The worst fastness property that gotten was the soluble dyed fabric. Color was almost gone from the fabric after the process which makes it the worst dyeing among all.

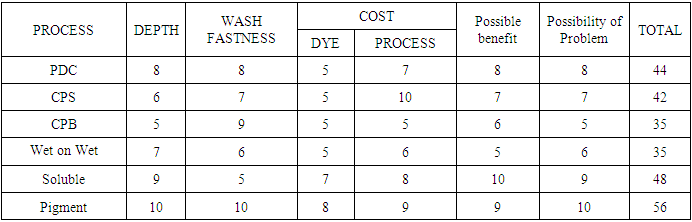

3.3. Costs

- It is hard to determine the cost of a process in woven dyeing as they did not provide sufficient information on costing. However, managed to get an idea on the cost of dyestuffs [16] which differs basically from process to process. Also, tried to determine the process cost by the number of steps, parameters, chemical dozing etc. in a process.There are basically five types of dyestuffs which are used in production floor. These are:Reactive Dye, Disperse Dye, Pigment Dye, Soluble Dye, Vat Dye.Now, above re-arrange the dyestuffs according to cost, then can say that –Dyeing with Disperse dye would cost more than that of Reactive or Pigment dyes if consider only the cost of dyestuffs?Now, if consider the number of steps, chemical application, time, temperature etc. to determine process cost, it may arrange the costly processes as -CPS is marked costliest. Because it requires two times padding & dozing of chemical as well as application of steam with sub-sequent washing processes. Pigment & Soluble dyeing are almost identical to PDC process. But, still they are costlier due to risk in shade matching and color fastness problems. Wet on Wet is much cheaper than all those processes as it only requires padding and steaming with much lesser chemicals. CPB is the cheapest process as it only requires time for dyeing with best quality after padding. However, there remains risk in shade matching for CPB.Here discussed different aspects and factors on different dyeing processes in previous sections. Based on that, to give an overview on everything and determine the most suitable process for woven dyeing, had prepared a chart where rated them in 1 to 10 based on the results achieved on different factors. The result is shown below:Pigment & Soluble dyeing is totally different process & dyes. So, it is hard to compare with other processes where reactive dyes are used for each of them. However, based on overall information, tests, results and ratings – Pigment & Soluble dyes gives us best outcome on average. Except for that, we can see that PDC & CPS process has most advantages over other processes on average which is why, these two processes are used more frequently than others even after [17] they might have some other disadvantages over them.

4. Conclusions

- The study mainly motivations on different dyeing method uses in different dyestuff and also uses a color turquois, the turquois color used for self-shade and combination shade. After completed all though process, here color measurement and color fastness testing is investigated in this study. From that study overall noble result is giving the pigment dye. However, it has the potential for up-gradation from medium to large-scale industrial production and marketing will get the availability of different process. Finding of the paper reveal that some process gave some separable good properties, so that it will lead toward better prediction and optimization of separation processes in textile industry with satisfy the obligatory demand.

|

|

ACKNOWLEDGEMENTS

- The Authors are grateful to Beximco Textiles Limited, Bangladesh for providing necessary facilities, equipment and materials to carry out the work. The Authors would like to convey thanks notation to all who directly or indirectly contributed and inspired time to time in preparing this experiment. The Authors are grateful to Prof. Quan Heng, Vice Dean Department of Chemistry and Chemical Engineering, Wuhan Textile University, China for the financial support to finish this research.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML