-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2016; 5(3): 49-59

doi:10.5923/j.textile.20160503.02

Effect of Sewing Work Aid in Garments Production

Sojib Raihan

Department of Textile Engineering, Southeast University, Dhaka, Bangladesh

Correspondence to: Sojib Raihan, Department of Textile Engineering, Southeast University, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Working aid is an essential part of any Garments Sewing Section. Sewing work aids adversely affect the production and product quality and also help to decrease production cost. The aim of the study was to investigate whether the presence of sewing work aid affects the production of garments and to which extent it affects the production of that garment. In this study, the manufacturing sequence of different types of bottoms, types of machines used for each process, the number of workers used in a sewing line, working hours of the garments, SMV and daily production of those related garments were enlisted and recorded as well. Those data were collected while the garments were manufactured by using work aid and also when those same garments were manufactured in the sewing line without using sewing work aids. As a result, it was concluded that garments production was hugely affected by the use of garment sewing work aid. In addition, this study also demonstrated that the quality of a garment was also affected by the presence of sewing work aid.

Keywords: Sewing Work Aid, Machine, SMV, and Production

Cite this paper: Sojib Raihan, Effect of Sewing Work Aid in Garments Production, International Journal of Textile Science, Vol. 5 No. 3, 2016, pp. 49-59. doi: 10.5923/j.textile.20160503.02.

Article Outline

1. Introduction

- The work aids that are used during sewing operations can be categorized in a number of different ways and they vary in the aspect of their overall purpose that they emphasize some otter greatly increased the speed of working in a situation where quality is already satisfactory. Others give a very little improvement in productivity but the great accuracy of sewing. In terms of their function, the commonest ones are used for guiding or folding materials for trimming threads and other components from garments and for stacking the work after sewing. In terms of their method of working some are purely mechanical, some operate Pneumatically, some are photoelectric and some are electronic, some are built into the machine such as a special monitor, some are a variation of a normal machine part such as a special presser foot, and some are a completely separate added part. Guides are used where sewing must take place in a certain position on a garment, usually a certain from a raw edge as in a conventional superimposed where a narrow item such as a lace or braid must be correctly positioned on a garment and where one garment part must be correctly placed on another such as a patch pocket on a shirt skirt or trousers. In their simplest form, they are edge guides, formatting some kind of physical barrier to the fabric being joined together [1] The extra machine parts which may attach to speed up the production and improved quality in the sewing machine are called work aid. [2]

2. Materials and Method

2.1. Materials

2.1.1. Fabric Selection

- For this experiment, 98% cotton & 2% elastic Fabric construction has been selected.

2.1.2. Garment Sewing Work Aid

- The term handling is normally used to describe those of those elements that are not sewing and it is this handling along with that dealing with garment bundling where they exist, plus various aspects of machine attention and personal needs, that make up 80 percent of the time spent working by most sewing machinists. The stacking of completed parts by one operator not takes time but may affect the next operator as well. This sewing work aid instrument very much effective for garments production. Such as Plan Guide, guide, Compensating Foot, Stitching Jig, Specialized pressure foot, Light, Folder, Compressed Air, Slack Feeder, Stacker, Latch Back Device and Thread Cutter has been used for this experiment.

2.1.3. Machines

- There are different types of machine, Such as Stitch Machine, Flat Lock Machine, Feed of the arm, Bar Tuck Machine, KANSAI Special Sewing Machine, overlock Machine has been used for this experiment.

2.1.4. Types of Equipment

- Folder, 1/4Guide, 1/16 Guide, Magnet Guide, T-Guide, piping folder and another Folder has been chosen for this experiment.

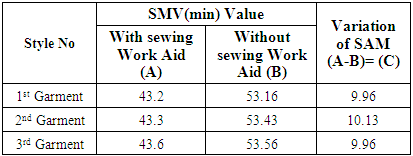

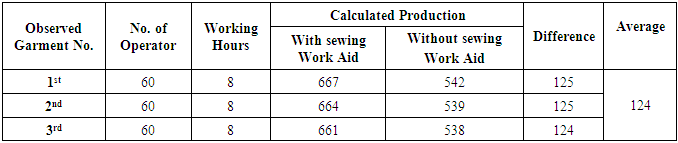

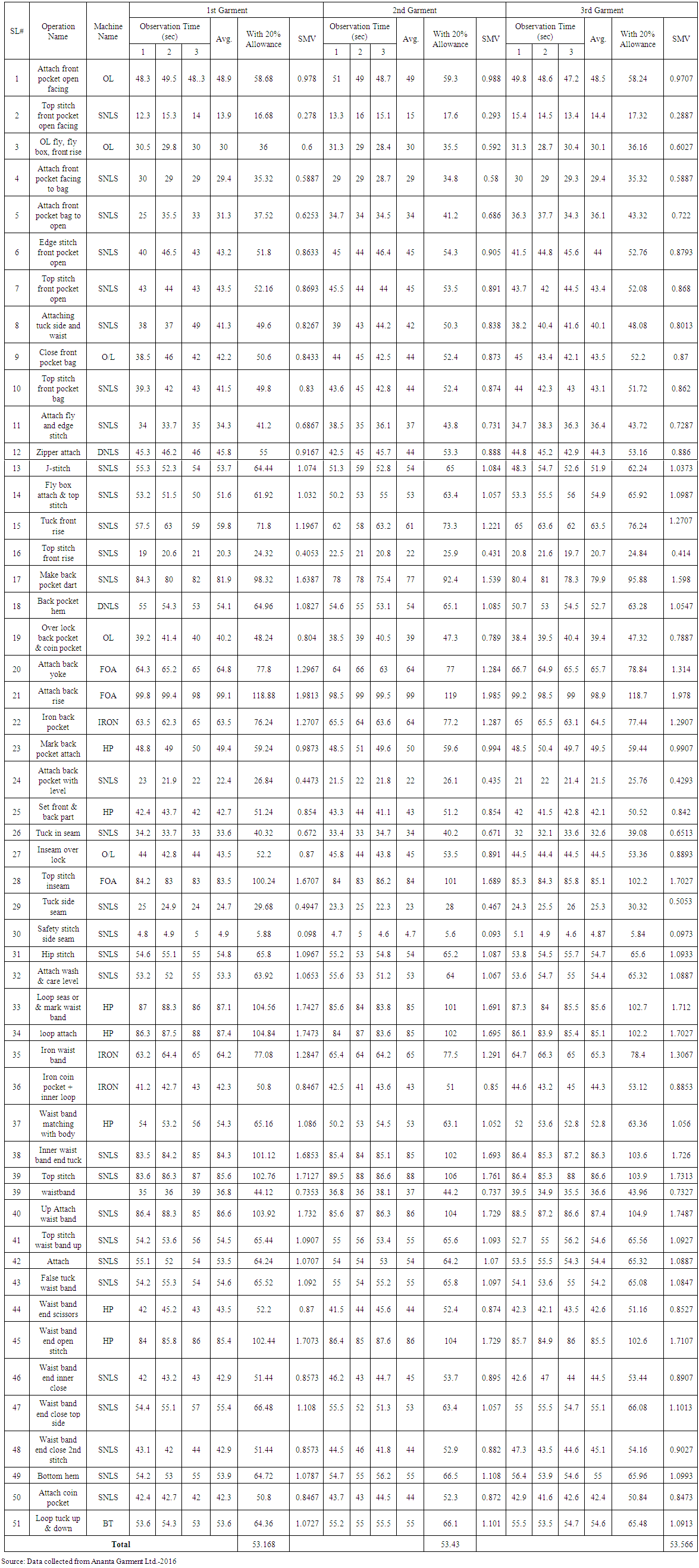

| Table 1. Experimental Garments sewing operational breakdown and SMV variation for with-sewing work Aid. Various kind of sewing work aids has been used in during garments production |

| Table 2. Experimental Garments sewing operational breakdown and SMV variation for without sewing work Aid. Any kind of sewing work aids has not been used in during garments production |

2.2. Method

2.2.1. Calculation of SAM or SMV through Time Study

- Step 1: Select one operation for which you want to calculate SAM.Step 2: Take one stopwatch. Stand by the side of the operator. Capture cycle time for that operation. (Cycle time – total time is taken to do all works needed to complete one operation, i.e. time from pick up part of the first piece to next pick up of the next piece) [3, 4]. Convert this cycle time into basic time by multiplying cycle time with operator performance rating. [Basic Time = Cycle Time X performance Rating]Step 3: Step 3: Performance rating. Now you have to rate the operator at what performance level he was doing the job seeing his movement and work speed. Suppose that operator performance rating is 80%. Suppose cycle time is 0.59 minutes. Basic time = (0.59 X 80%) = 0.472 minutes.Step 4: Standard allowed minutes (SAM) = (Basic minute + Bundle allowances + machine and personal allowances). Add bundle allowances (10%) and machine and personal allowances (20%) to basic time [4].To convert cycle time to normal or basic time needs to multiply it with operator performance rating. Now allowances for machine, fatigue and personal needs etc have been added. Machine allowance only to those elements where the machine is running, fatigue and personal needs to all elements are added. Finally, standard time for each element in seconds is found by summing up all elemental time and then seconds is converted into minutes. This is known as Standard Minute Value (SMV). [5]

3. Result and Discussion

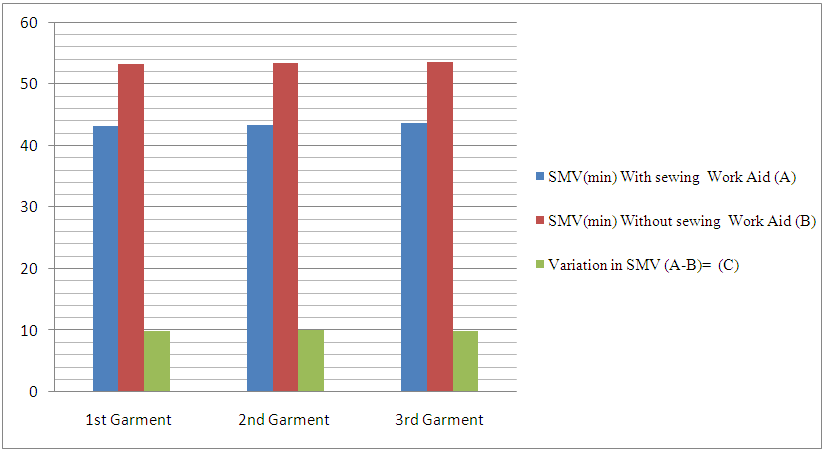

- Table 3 shows the total SMV taken for each garment to complete the process of operation.

|

| Diagram 1. Comparison of Style wise SMV variation of with and without sewing work aid |

|

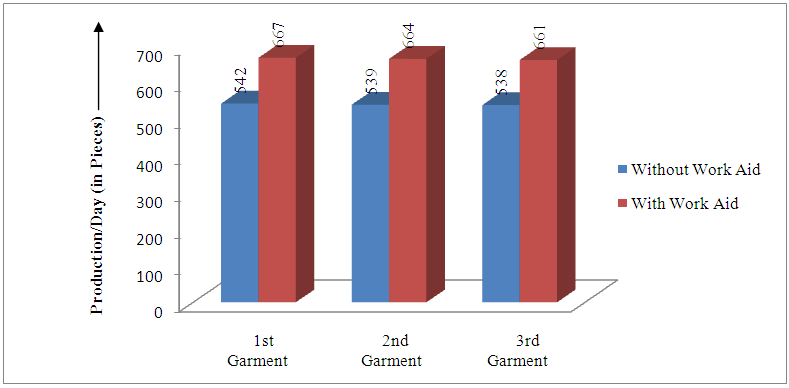

| Diagram 2. Comparison of Production Per Day with and without Work Aid |

4. Conclusions

- Working aid is an important and essential part of any Garments Industry. Working Aid is one of the most effective sewing tools. In the domestic production of garments, 50% of the time is wasted for the handling of fabric. Other 50% used for sewing. To reduce this wastage in industrial production of garments work aids required. These work aids are not only used to reduce the handling time but also used to improve the quality of the garments. The extent of process control in maintaining the processing parameters at desired level can be reduced thereby maintaining quality & increasing productivity. For this purpose, this research project will be very helpful.

ACKNOWLEDGEMENTS

- I would like to express my cordial thanks to Md. Mustafizur Rahman Manager (HR), Ananta Garment Ltd. For his kind permission, I have done the experiment successfully. I am also grateful to all shift engineers, operators for their help for successful completion of the project.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML