K. M. Faridul Hasan1, 2, Md. Shipan Mia3, Ashaduzzaman3, Md. Mostafizur Rahman3, A. N. M. Ahmed Ullah3, Muhammad Shariat Ullah2, 4

1School of Textile Science & Engineering, Wuhan Textile University, Wuhan, China

2Department of Textile Management & Business Studies, Bangladesh University of Textiles (BUTex), Dhaka, Bangladesh

3School of Textile Chemistry & Chemical Engineering, Wuhan Textile University, Wuhan, China

4University of Dhaka

Correspondence to: K. M. Faridul Hasan, School of Textile Science & Engineering, Wuhan Textile University, Wuhan, China.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Bangladesh has emerged as a key player in RMG (Ready Made garment) sector since 1978. Textiles & Clothing account for about 85% of total export earnings of Bangladesh. Out of which 76% comes from the apparel sector which covers the major products of knit & woven shirts, blouses, trousers, skirts, shorts, sweaters, sportswear’s & many more casual & fashion items. The sector currently employs approximately 1.5 million workers, mostly females from underprivileged social classes. The pivotal factor in apparel industry is the workforce i.e. the operators, helpers, cutting masters, finishers etc. Bangladesh is endowed with abundant & cheap workforce that is easily trainable & convertible into semi-skilled & skilled workforce. Existence of such category is one of the advantages that Bangladesh will be enjoying over a considerable period in the context of international trade on clothing. To cope up with global challenge we must adopt with factors of technological advancement with proper working environment in textile & apparel sector of the country. In my report i tried to illustrate about the prospect & future of RMG sector in Bangladesh.

Keywords:

Readymade garments (RMG), Employment, GDP, Export, Global economy, Trade

Cite this paper: K. M. Faridul Hasan, Md. Shipan Mia, Ashaduzzaman, Md. Mostafizur Rahman, A. N. M. Ahmed Ullah, Muhammad Shariat Ullah, Role of Textile and Clothing Industries in the Growth and Development of Trade & Business Strategies of Bangladesh in the Global Economy, International Journal of Textile Science, Vol. 5 No. 3, 2016, pp. 39-48. doi: 10.5923/j.textile.20160503.01.

1. Introduction

This rapidly growing sector of the Bangladeshi economy offers a unique competitive edge that supports profitable expansion into new strategic markets. From spinning to weaving, from knitwear to leisurewear and high street fashions, the textiles and clothing industry is Bangladesh’s biggest export earning sector [1]. The Ready-Made Garments (RMG) industry occupies a unique position in the Bangladesh economy. It is the largest exporting industry in Bangladesh, which experienced phenomenal growth during the last 25 years. The industry plays a key role in employment generation and in the provision of income to the poor. Nearly four million workers are directly and more than twelve million inhabitants are indirectly associated with the industry. Over the past twenty five years, the number of manufacturing units has grown from 180 to over 4000 [2]. The sector has also played a significant role in the socio-economic development of the country. The quota came to an end at 2004 but it continued to show robust performance, competitive strength and, of no less importance, social commitment. RMG’s contribution to Bangladesh economy is well-known, well-appreciated and well-respected.

1.1. Objectives of the Study

The general objective of preparing this report is to fulfill the requirement of thesis Program as well as completion the MBA in Textile Program through gaining the practical job experience and view the application of theoretical knowledge in the real life. The report focuses on two parts. They are:1.1.1. Primary ObjectiveThe broad project objective is to analyze the garments sector of Bangladesh and relate the knowledge with the practical experience.1.1.2. Secondary ObjectiveIn order to reach the broad objective, some specific objectives are identified.1. To know the different aspect of garments industry, its prospects and problems.2. To show some statistics of RMG industry.3. To analyze the statistical data related to RMG industry.

1.2. Limitations of the Study

○ In many cases, up to date information was not published.○ In some cases, access to relevant papers and documents were strictly prohibited.○ In some other cases, access was denied to procedural matters conducted directly by the top management in the operations of foreign exchange business.

2. Literature Review

2.1. Overview of Bangladesh Ready Made Garments Industry

Agriculture has been the backbone of economy and chief source of income for the people of Bangladesh, the country made of villages. Government wants to decrease poverty by getting highest productivity from agriculture and achieve self-reliance in food production. Apart from agriculture, the country is much concerned about the growth of export division. Bangladesh have accelerated and changed her exports substantially from time to time [2]. After Bangladesh came into being, jute and tea were the most export-oriented industries. But with the continual perils of flood, failing jute fiber prices and a considerable decline in world demand, the role of the jute sector to the country’s economy has deteriorated (Spin anger, 1986). The RMG industry is the only multi-billion-dollar manufacturing and export industry in Bangladesh. Whereas the industry contributed only 0.001 per cent to the country’s total export earnings in 1976, its share increased to about 76 per cent of those earnings in 2005 & still now. Bangladesh exported garments worth the equivalent of $6.9 billion in 2005, which was about 2.5 per cent of the global total value ($276 billion) of garment exports. The country’s RMG industry grew by more than 15 per cent per annum on average during the last 15 years as shown in table-1. The foreign exchange earnings and employment generation of the RMG sector have been increasing at double-digit rates from year to year [2, 3]. Some important issues related to the RMG industry of Bangladesh are noted in table-1.Table 1. Important issues related to the Bangladesh ready-made garment industry

|

| |

|

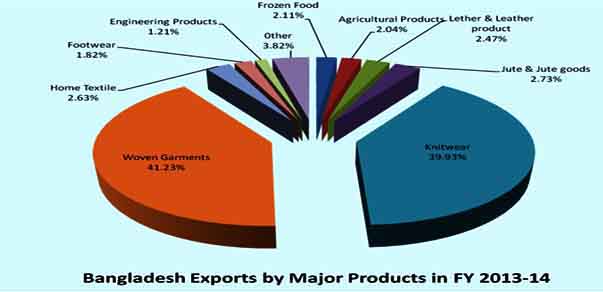

Currently, there are more than 4,000 RMG firms in Bangladesh. More than 95 per cent of those firms are locally owned with the exception of a few foreign firms located in export processing zones (Gonzales, 20014). Shirts, T-shirts and trousers are the main woven products and undergarments, socks, stockings, T-shirts, sweaters and other casual and soft garments are the main knit products. Woven garment products still dominate the garment export earnings of the country. The share of knit garment products has been increasing since the early 1990s; such products currently account for more than 40 per cent of the country’s total RMG export earnings (BGMEA website). Although various types of garments are manufactured in the country, only a few categories, such as shirts, T-shirts, trousers, jackets and sweaters, constitute the major production-share (BGMEA website; and Nath, 2001) [1, 4]. Economies of scale for large-scale production and export-quota holdings in the corresponding categories are the principal reasons for such a narrow product concentration.

2.2. Size of the Garments Industry of Bangladesh

The garment industry is by far the country’s most important manufacturer, earning around $5 billion annually and accounting for about two thirds of all exports. Bangladesh has near about more than 4,000 garment factories with up to 10 million livelihoods dependent on it directly or indirectly as shown in table-2.Table 2. Size of Bangladesh Textile Industry

|

| |

|

3. Methodology

3.1. Sources of Data

Data regarding the completion of this report are collected from both primary and secondary sources.3.1.1. Primary SourceThrough direct conversation with the respective officers of the Textile companies.3.1.2. Secondary Sources1. Various data source like BKMEA, BGMEA, Bangladesh bank, Export Promotion Bureau, BTMC etc.2. Internet browsing through website searching.3. Annual report of the various organizations such as BKMEA, BGMEA, Bangladesh bank, Export Promotion Bureau, BTMC etc.4. Different published material Such as books and articles.

3.2. Analysis of Data

For analyzing the collected data different statistical tools are used.For showing the trend of export, contribution of export to GDP, time series analysis has been used.For determining the significance of RMG export and Total export simple regression analysis has been used.For measuring the significance of profit and commission simple regression analysis has been used.

4. Analysis & Findings of RMG Sector in Bangladesh

4.1. Major Market of RMG Industry

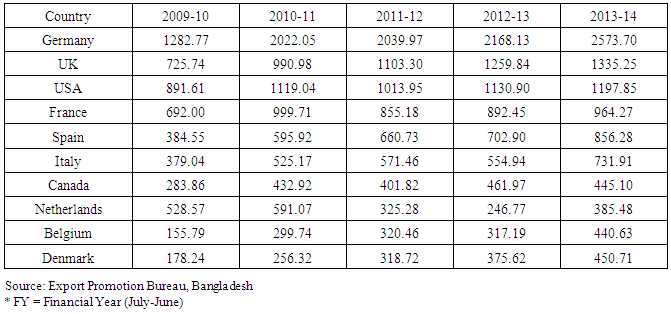

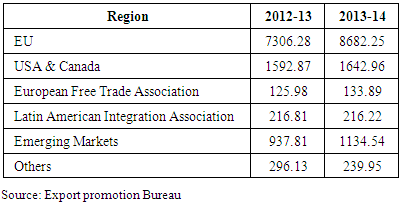

The RMG industry of Bangladesh fully depends on the export. The major importer of RMG products are USA and Europe. But there is other country that has a contribution to the total RMG export. The following table contains the list of major importer of our RMG products.

4.2. Contribution to Economy

The Ready-Made Garments (RMG) industry contributes to the Bangladesh economy in a distinctive manner. The last 20 years witnessed unparalleled growth in this sector, which is also the largest exporting industry in Bangladesh. It has attained a high profile in terms of foreign exchange earnings, exports, industrialization and contribution to GDP within a short span of time. The Bangladesh RMG industry, with its woven and knit sub-components, is a pre-dominantly export oriented sector, with 95 per cent of the woven and 90 per cent of the knit exports being directed to foreign markets. The cumulative foreign currency earnings by the sector, since 1978, when first export was registered, is estimated at 70.56 billion US dollars [5].

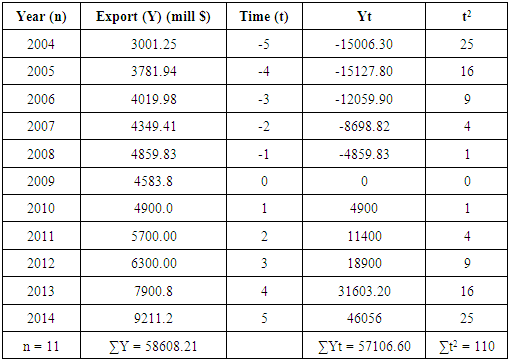

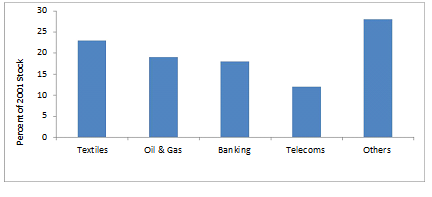

4.3. RMG Industry Contribution to Different Sector

Growth of RMG sector has spawned a whole new set of linkage industries and facilitated expansion of many service sector activities. The RMG industry not only propelled the growth of spinning, weaving, dyeing and finishing industries, production of accessories and spare parts, but also rendered large externalities by contributing to other economic activities in such areas as banking, insurance, real estate, packaging, hotels and tourism, recycling, consumer goods utility services and transportation. RMG sector has overwhelmingly high backward linkage with textile sector providing fabrics, yarn and other ancillaries. It has important backward linkage with utilities such as electricity, gas, and machinery and spare parts supplying [6].Banking and InsuranceGrowth of the RMG sector and the related activities has contributed a lot to the robust growth of the financial sector in Bangladesh. A World Bank survey revealed that almost all firms (98%) are the clients of the commercial banks for working capital and procurement of machines and equipment (57%). All firms have their machines and plants insured and, additionally, 87% of importers of input and 15% of the RMG exporters get their imports/exports insured.Shipping and LogisticsThe RMG sector has contributed to the shipping business in Bangladesh and stimulated setting up of several container yards, expansion of port facilities to handle large container carrying trains, increase of cargo handling and storage facilities. RMG manufacturers also extensively use services of Clearing & Forwarding Agents for the purpose of customs clearance of inputs and finished goods. It is estimated that port usage fees earned from the RMG sector account for more than 40% of the income of the port authority.Contribution to Government ExchequerThe RMG sector contributes to the government exchequer both directly and indirectly. In FY 2007 the sector paid 10.13 million dollars as stamp and postage, license renewal fee etc. The sector also paid USD 12.61 million to the government as direct taxes in FY 2014.Engineering SectorThe RMG industry paid 28.55 million dollars to the engineering sector which included payments to repairing and maintenance service industry (USD 8.29 million), electrical engineering (USD 9.21 million), transport vehicle maintenance service ( USD 5.53 Million), and machine tools service (USD 5.52 Million). | Figure 1. Bangladesh Exports by Major Products in FY 2013-14 |

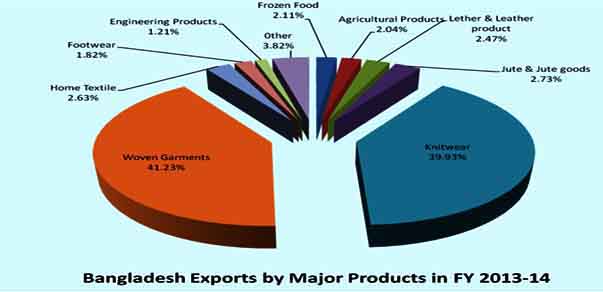

Table 3. Comparative Export Performance of Bangladeshi Knit Production Major Importing Countries (Figures in Million US $)

|

| |

|

| Figure 2. Some pictures of Spinning, Knitting, Dyeing and Garments production floor of Bangladesh |

Utility ServicesPayment of Electricity bill by the RMG industry is estimated to be 29.47 million dollars in FY2002. Utility payments for gas, WASA etc. amounted to an additional 7.37 million dollars, in 2014. It’s about 49 million dollar in 2014.Information and Communication TechnologyThe RMG sector also plays a catalytic role in the growth of the country’s ICT sector. The services consumed by the RMG industry generated revenue for the ICT sector. Payments for ICT services which include communication, hardware and software services are estimated at 19.34 million dollars in FY 2014.Emerging Consumer MarketThe 2.2 million workers in the industry have created a large demand for consumer goods. A regular source of earning increases the basic consumption needs such as improved diet, better healthcare, improvements in family utensils and housing conditions etc. The sector has created an increasing demand for consumption of low cost commodities, cosmetics items, dresses, footwear, fast food and other products. A whole industry has been created to service this growing demand and created employment opportunities for hundreds of thousands of people.

4.4. Social Impacts of the RMG Sector

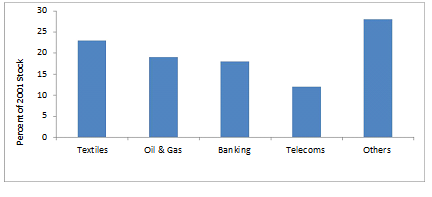

Women EmpowermentIt is well recognized that women’s participation in income generation activities lends them a better status within the family and provides them with considerable freedom. A job ensures equitable access to household resources (nutrition) and larger investment on female human capital (health and education). Employment opportunities draw attention to women’s needs for public facilities such as transportation, communication, safety etc. and create a demand for policy response in these areas. It also has created a demand for education and health. As the income by the female member reduces dependency on male income it reduces their vulnerability. It also reduces the possibility of domestic violence against women. Expansion of women’s employment has contributed positively to the improvement of the savings behavior of the poor people since women tend to be better savers.  | Figure 3. Distribution of FDI in Bangladesh by Activities |

The same survey further showed that female workers were spending their earnings on their marriage, thus taking a big burden off their families. The independent earnings also allow these women to have a greater share in household decision making. Evidently, wage work at the garment industry has empowered women and improved their status [3].Child LaborIn recent years, international debate on child labor has intensified. The elimination of child labor is also among the core labor standards in the ILO Convention. The Harkin Bill placed at the US Senate entitled “The Child Labor Deterrence Act of 1993” which called for the elimination of child labor in the export oriented manufacturing and mining industries. As a consequence many garment industries had to retrench child workers from their factories. In many countries these retrenched children ended up in more strenuous and less-remunerative jobs, or worst, turned to begging in the street. The Bangladesh RMG sector set a unique example through collective efforts which eventually led to the development of a safety-net program for the child labors. The BGMEA/ILO/ UNICEF Child Labor Project in the garment industry of Bangladesh, funded by the US Development of Labor was the first of a series of child labor programs executed by the International Program on the Elimination of Child Labor of the ILO [3, 4].

4.5. Condition of Workers of RMG Sector

According to BGMEA about 3 million people are employed in the RMG sector (around 80% are female). Growing apprehension is the already deprived garment workers may face further retrenchment which may worsen the existing poor working and living standard of the workers.A “decent employment” means rising productivity and real wages by ensuring rights to work, employment, social protection, freedom of association and social dialogue in an integrated approach. The concept of decent work has significant gender implications in Bangladesh RMG sector since women constitute a vast majority of the labor force, and women and the worst victims of violations of decent work conditions.Women workers are particularly deprived of their special legal rights (e. g. maternity benefits) and remain more exposed to exploitation within their particular spheres of work. The female workers tend to be underpaid and exposed to physical assault by both fellow colleagues and employers.The national labor movements are continuously demanding for National Minimum Wage. The minimum wages rule for the garment sector, endorsed in 2006. The minimum wage is Taka 1650, which is now more than 5000 taka.The exhaustive and prolonged work schedule of RMG industries sometimes causes occupational disease among the workers, which ultimately impacts negatively on their productivity.Though export-oriented apparel industry is the lifeblood of Bangladesh’s foreign exchange earnings, the basic rights, welfare issues of garment workers are severely neglected [3].

4.6. Some Tragedies of RMG Sector

“It is heartbreaking that year after year women and men are killed while making clothes for stores in our communities,” said Ineke Zeldenrust of the Clean Clothes Campaign International Secretariat, an international network that for years has highlighted the safety risks plaguing the Bangladesh garment industry.The spate of tragedies began on Thursday, February 23, 2006 when a fire, possibly caused by an electrical short circuit, destroyed the four-story KTS Textile Industries in Bangladesh’s port city of Chittagong. Initial reports stated that 54 were killed and at least 60 were injured, however other sources peg the death toll at several hundred in what local garment workers rights’ advocates are calling the worst tragedy in the history of the Bangladesh garment industry. Over 1,000 workers were reportedly in the factory at the time of the 7 p.m. fire. Meanwhile, authorities have apparently sealed off three other factories connected to this facility (Vintex Fashion, Cardinal Fashion and Arena Fashion) citing unplanned construction and inadequate safety measures as life-threatening for their more than 6,000 workers. There is also some problems & accidents happened at different times in Bangladesh like as Rana plaza & Tajrin tragedy.

4.7. Steps needed to be taken to Minimize the Risk

A real and effective national consensus should be the prime concern to get prepared for post MFA Bangladesh needs to prepare a time bound national action plan to minimize the potential risks. It needs to priorities its immediate actions from a number of possible solutions.As most of the labor laws have become old and not time befitting, government should formulate a National Policy on Ready Made Garments to establish a development trajectory for the sector to survive, in a quota-free world.The growth of RMG sector was facilitated by the supply of low cost labor and since the female workers could easily learn the sewing techniques, the management took very limited or no effort for any further development of its workers. The apprehension regarding the post-MFA also discouraged the employers to arrange further training programs for their work force. However this not only limited workers skill, but also contributed to loss of production through loss of production time, low labor productivity, re-working, quality inconsistence, materials wastage, etc.Improved working conditions can help to increase productivity level. Investment in human resources, e.g. training, betterment of working conditions, maintenance of proper safety and health measures, protection from physical and psychological harassment, freedom of association and rights to collective bargaining at factory/enterprise level etc will certainly improve the productivity of the workers.Rights and welfare of the employees working in the subcontracting garments factories of the multinational companies should be ensured under corporate social responsibility.

4.8. Possible Way to Face the Upcoming Challenges for RMG Sector in Bangladesh

To face the upcoming challenges in RMG sector, the country should take the following measures:1. Formulation of a national policy on RMB industry and workers for post MFA period.2. Unconditional and quick implementation of core labor standards and labor laws at workplace of all RMGs.3. Establishing a compulsory social safety net package for RMG workers.4. Exploration of new market for RMG to protect the industry and the workers and take maximum advantage of free excess to Canadian, Australian and other markers.5. Capacity building training and re-training activity for employers and workers in RMG sector to develop productivity and efficiency level.6. Develop backward linkage industries for RMG.7. Export and product diversification.8. Building alliances with likeminded neighbors and competitors within the LDCs.9. Continuous training program to sensitize the workers about their rights and 10. Interest should be undertaken in cooperation with and financial assistance from the fraternal organizational abroad.

4.9. Prospects of the RMG Industry

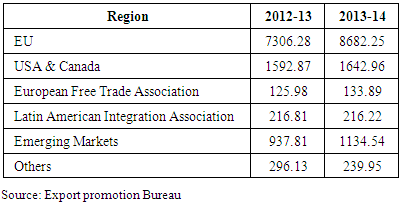

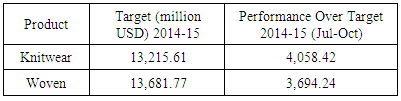

Despite many difficulties faced by the RMG industry over the past years, it continued to show its robust performance and competitive strength. The resilience and bold trend in this MFA phase-out period partly reflects the imposition of ‘safeguard quotas’ by US and similar restrictions by EU administration on China up to 2008, which has been the largest supplier of textiles and apparel to USA as shown in table-3. Other factors like price competitiveness, enhanced GSP facility, market and product diversification, cheap labor, increased backward integration, high level of investment, and government support are among the key factors that helped the country to continue the momentum in export earnings in the apparel sector. Some of these elements are reviewed below.Table 4. Region wise Export Performance FY 2012-13 & 2013-14

|

| |

|

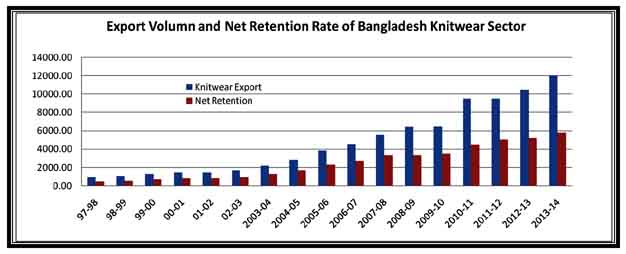

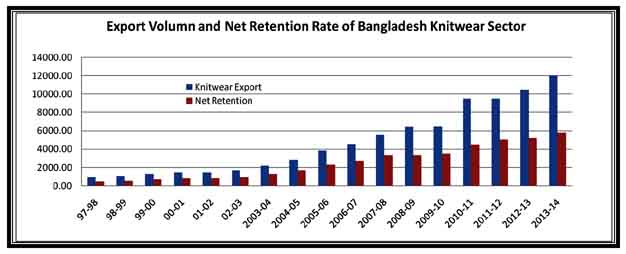

Product DiversificationThe growth pattern of RMG exports can be categorized into two distinct phases. During the initial phase it was the woven category, which contributed the most. Second phase is the emergence of knitwear products that powered the recent double digit (year-on-year) growth starting in FY04.In the globalize economy and ever-changing fashion world, product diversification is the key to continuous business success. Starting with a few items, the entrepreneurs of the RMG sector have also been able to diversify the product base ranging from ordinary shirts, T-shirts, trousers, shorts, pajamas, ladies and children’s wear to sophisticated high value items like quality suits, branded jeans, jackets, sweaters, embroidered wear etc. It is clear that value addition accrues mostly in the design items, and the sooner local entrepreneurs can catch on to this trend the brighter be the RMG future.Backward IntegrationRMG industry in Bangladesh has already proved itself to be a resilient industry and can be a catalyst for further industrialization in the country. However, this vital industry still depends heavily on imported fabrics. After the liberalization of the quota regime some of the major textile suppliers Thailand, India, China, Hong Kong, Indonesia and Taiwan increased their own RMG exports.If Bangladesh wants to enjoy increased market access created by the global open market economy it has no alternative but to produce textile items competitively at home through the establishment of backward linkage with the RMG industry. To some extent the industry has foreseen the need and has embarked on its own capacity building. The trend of back-to-back import has been declining over the years implying a rising contribution of domestic value addition (Figure 2). This is an optimistic indication that a well equipped and modern backward linkage industry may well prove cost effective and thus helping Bangladesh to meet the challenges in the post-MFA era.Flow of InvestmentIt is plausible that domestic entrepreneurs alone may not be able to develop the textile industry by establishing modern mills with adequate capacity to meet the growing RMG demand. It is important to have significant flow of investment both in terms of finance and technology. The investment outlook in this sector is encouraging, although the uncertainties before the MFA phase-out period caused a sluggish investment scenario. In part the momentum in the post-MFA phase-out period is indicative of the efforts underway towards capacity building through backward integration. This is evident in the pace of lending to the RMG sector and in the rising import share of RMG related machinery. However further progress would be necessary to improve and sustain competitiveness on a global scale.Labor ProductivityThe productive efficiency of labor is more important determinant for gaining comparative advantage than the physical abundance of labor. In Bangladesh, the garment workers are mostly women with little education and training. The employment of an uneven number of unskilled labors by the garment factories results in low productivity and comparatively more expensive apparels. Bangladesh labor productivity is known to be lower when compared with that of Sri Lanka, South Korea and Hong Kong SAR. Bangladesh must look for ways to improve the productivity of its labor force if it wants to compete regionally if not globally.Cheap Labor ForceThe strength of a firm depends on its specific comparative advantages, which its competitors do not possess. To date the local industry has flourished in spite of the challenges cited above (e.g., lead time, infrastructure, and bureaucratic red tape) on the back of cheap female labor. The wages paid to RMG workers in Bangladesh are the lowest even by the South Asian regional standard. Figure 4 illustrates the comparative average hourly wages in apparel industry of selected developed and developing countries.Research and TrainingThe country has no dedicated research institute related to the apparel sector. RMG is highly fashion oriented and constant market research is necessary to become successful in the business. At present whatever design work is done in the country, these are mostly carried out with foreign workers and experts. BGMEA has already established an institute which offers bachelor’s degree in fashion designing and BKMEA is planning on setting up a research and training institute. These and related initiatives need encouragement possibly intermediated by donor-assisted technology and knowledge transfer. A facilitating public sector role can be very relevant here [2, 4 and 5]. | Figure 4. Export Volume & net retention of Bangladesh Knit wear sector |

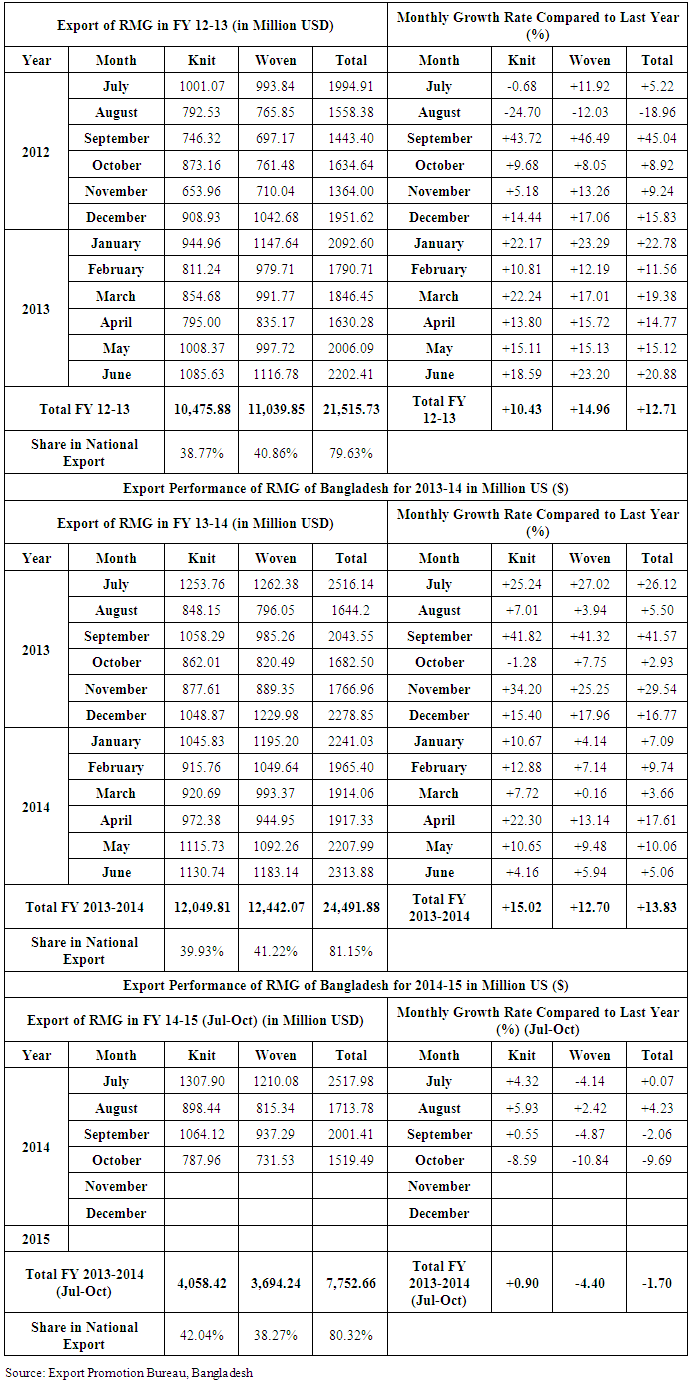

Table 5. Export Performance of RMG of Bangladesh for 2012-13 in Million US ($)

|

| |

|

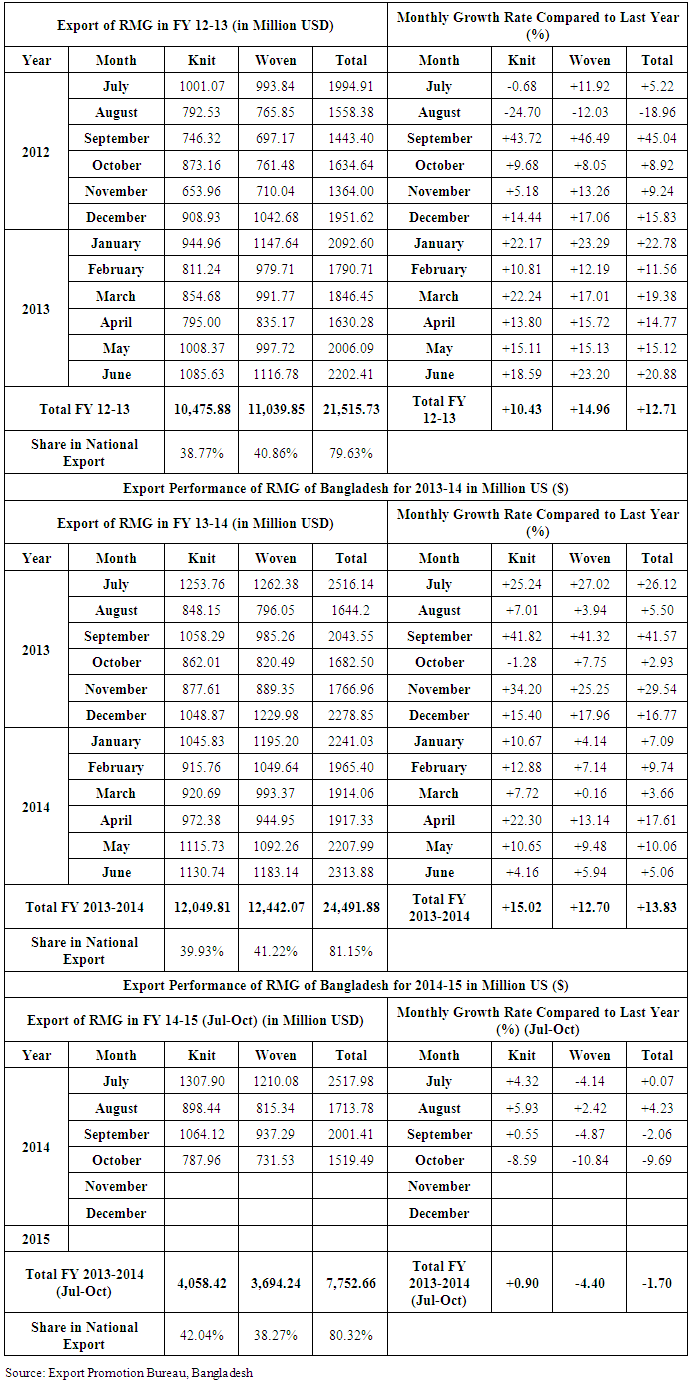

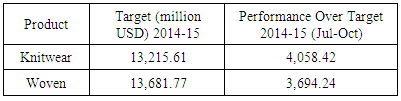

4.10. Ready Made Garments Sector of Bangladesh & Its Statistics

Export Performance of RMG of Bangladesh for 2012-13, 2013-14 & 2014-15 in Million US ($)Export of RMG product from Bangladesh to different countries of the world is as shown in table-6.Table 6. Export Performance of RMG over Government's Strategic Target for 2013-14

|

| |

|

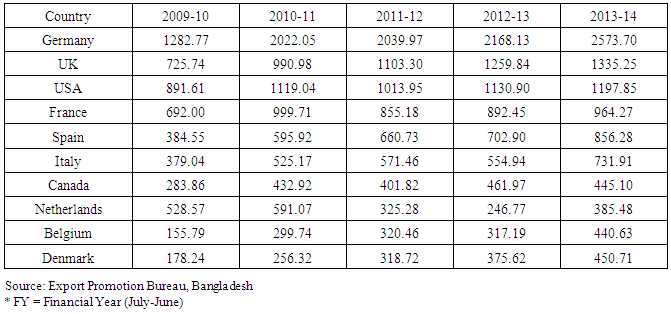

4.11. Statistical Analysis on RMG Sector

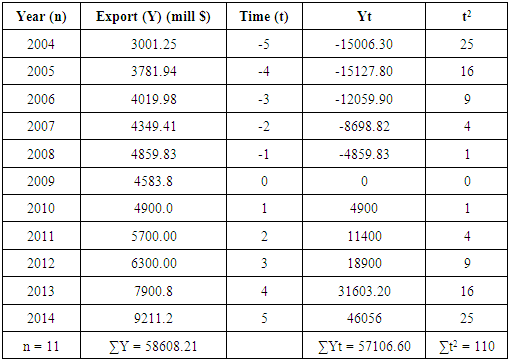

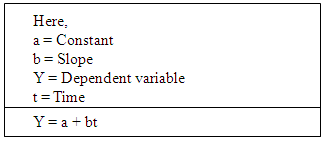

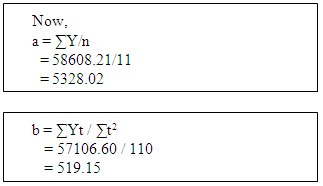

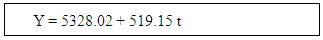

This chapter reveals the statistical analysis on the RMG Sector for last ten years, its growth and the significance of RMG export to total export and the significance of RMG export growth to GDP growth. For analyzing the performance of RMG industry of Bangladesh some statistical tools has been used.4.11.1. Time Series AnalysisHere, the trend of RMG Export has been revealed through indirect method of time series analysis by using eleven years data. The model of Time series analysis is RMG Export TrendExport is an influential tool for foreign exchange business. Any decrease in export can cause a huge decrease in foreign exchange income as well as profit. The trend of export business for last five years is presented here.

RMG Export TrendExport is an influential tool for foreign exchange business. Any decrease in export can cause a huge decrease in foreign exchange income as well as profit. The trend of export business for last five years is presented here. So the equation for Export Business is,

So the equation for Export Business is, Here, Y = RMG Export of Bangladesh

Here, Y = RMG Export of BangladeshTable 7. Calculation for RMG Export trend

|

| |

|

4.12. Regression Analysis

In this age of globalization the demand for RMG products is increasing day by day. This increasing trend in export sector helps to build the economy of Bangladesh. For showing the significance of RMG export to total export and the significance of RMG export growth to GDP growth simple regression analysis has been done. Software SPSS 15.0 is used to do this statistical analysis.The outputs that are got by using SPSS 15.0 software are enclosed in the appendix and interpretations of those are presented below sequentially. Simple regression between RMG Export & GDPHere, RMG export is considered as independent variable and GDP is considered as dependent variable. The model will be as follows.i. Regression equationFrom the simple regression analysis the following equation is formed by considering GDP as dependent variable (denoted as Y) and RMG export (denoted as X) as independent variable. The equation is:Y = 24404.01 + 4.877 XThis equation indicates if RMG export of Bangladesh increases for US$1 million, GDP will be increased by US$ 4.877 million.ii. Mean and standard deviationThe mean of GDP is US$38737.29 million, which indicates the average GDP per year of Bangladesh is US$ 38737.29 million. And the standard deviation is US$ 13042.27 million. So, the variability of GDP is US$ 3196.15million.Mean of RMG export is US$ 2939.20 million. That means the average amount of RMG export per year is US$ 2939.20 million. And the standard deviation is US$ 2622.43 million. So, the variability of RMG export is US$ 2622.43 million.iii. Correlation MatrixThe correlation between Total export and RMG export is 0.981 & significance level (1-tailed) is .000. Here, the significant level is bellow .05. So, there is a significant relationship between GDP and RMG export.iv. Co-efficient of multiple determinations & Co-efficient of multiple correlationsHere, r2 = 0.961. r2 stands for Co-efficient of multiple determination. The result indicates that RMG export explains 96.1% of the variation in the GDP. So, this variable is very influential as it can explain more than 50%. Again, r = 0.981, r stands for Co-efficient of multiple correlation. The result shows that there exists a high degree of positive relationship between GDP and RMG export.

4.13. Strength, Weakness, Opportunity & Threat of Garments Sector of Bangladesh at a Glance

Strength1. Considerable Qualified/keen to learn workforce available at low labor charges.2. Energy at low price.3. Easily accessible infrastructure like sea road, railroad, river and air communication.4. FDI is legally permitted.5. Moderately open Economy, particularly in the Export Promotion Zones.6. Improved GSP advantages under Regional Cumulative.7. Bangladesh is a member of Multilateral Investment Guarantee Agency (MIGA) under which protection and safety measures are available.8. Excellent Tele-communications network of E-mail, Internet, Fax, ISD & Cellular services.Weakness1. Lack of marketing tactics.2. Absence of easily on-hand middle management.3. A small number of manufacturing methods.4. Lack of training organizations for industrial workers, supervisors and managers.5. M/c advancement is necessary. The machinery required to assess add on a garment or increase competence are missing in most industries.6. Speed money culture.7. Subject to natural calamities.Opportunity1. EU is willing to establish industry in a big way as an option to china particularly for knits, including sweaters.2. Bangladesh is included in the Least Developed Countries with which US is committed to enhance export trade.3. If skilled technicians are available to instruct, prearranged garment is an option because labor and energy cost are inexpensive.4. Foundation garments for Ladies for the FDI promise is significant because both, the technicians and highly developed machinery are essential for better competence and output.ThreatThe exporters have to prepare themselves to harvest the advantages offered by the opportunities.

5. Conclusions

RMG is the highest contributor in terms of both gross and net export earnings. Comparing with other items in Bangladesh, the contribution of RMG in national export earnings is more than 76%. This has resulted because of the backward linkage industry that has grown over time which helped the sector to have the higher value addition and therefore a much higher net retention rate. In addition to, relaxation of Rules of Origin (RoO) has accelerated the export growth.Readymade garments industry is the manufacturing sector of Bangladesh from which most of the foreign currency is earned. There’s a large number of population are engaged in this sector for their employment purpose. So for the economy of Bangladesh RMG role of sector is extremely important.

References

| [1] | Bhattacharya, D, Rahman, M., Raihan, A (2002), “Contribution of the RMG Sector to the Bangladesh Economy”, CPD Occasional Paper Series 50. |

| [2] | Haider, M.A (2007), “Competitiveness of the Bangladesh Ready-made Garment Industry in Major International Markets”, Asia-Pacific Trade and Investment Review, Vol. 3, No.1. |

| [3] | Adeyanju, F.B. “The Effects of Unconscious Ideologies about Women on Sustainable Development” Society for International Development Publication. |

| [4] | Nehal, A., Hossain, S. (2006), “Future Prospects of Bangladesh’s Ready-Made Garments Industry and the Supportive Policy Regime”, Policy Note Series: PN 0702, Policy Analysis Uni (PAU), Bangladesh Bank. |

| [5] | Rashid, A. (2006), “Rise of Ready Made Garments industry in Bangladesh: Entrepreneurial ingenuity or public policy”, Workshop on Governance and Development, World Bank, Dhaka. |

| [6] | General Economics Division, Government of the Peoples Republic of Bangladesh, Perspective Plan of Bangladesh (2010-2021). |

RMG Export TrendExport is an influential tool for foreign exchange business. Any decrease in export can cause a huge decrease in foreign exchange income as well as profit. The trend of export business for last five years is presented here.

RMG Export TrendExport is an influential tool for foreign exchange business. Any decrease in export can cause a huge decrease in foreign exchange income as well as profit. The trend of export business for last five years is presented here. So the equation for Export Business is,

So the equation for Export Business is, Here, Y = RMG Export of Bangladesh

Here, Y = RMG Export of Bangladesh Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML