-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2016; 5(2): 36-38

doi:10.5923/j.textile.20160502.03

Comparative Analysis of Colour Strength and Colour Fastness Properties of Bamboo-Silk and Cotton-Silk Kota Doria Fabrics

Kavita Chaudhary1, Suman Pant2

1Banasthali Institute of Design, Banasthali University, Rajasthan, India

2Faculty of Home Science, Banasthali University, Rajasthan, India

Correspondence to: Kavita Chaudhary, Banasthali Institute of Design, Banasthali University, Rajasthan, India.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The colour strength and colour fastness properties of the dyed plain Kota Doria fabrics made of bamboo-silk and cotton-silk yarns have been reported. Kota Doria fabrics have been dyed with reactive dye. Colour fastness to washing, light and rubbing has been measured. K/S of bamboo-silk Kota Doria is slightly higher than cotton-silk Kota Doria. Washing, rubbing and light fastness of both the fabrics have been rated same.

Keywords: Bamboo-silk, Bamboo-cotton, Reactive dye,K/S value, Colour fastness

Cite this paper: Kavita Chaudhary, Suman Pant, Comparative Analysis of Colour Strength and Colour Fastness Properties of Bamboo-Silk and Cotton-Silk Kota Doria Fabrics, International Journal of Textile Science, Vol. 5 No. 2, 2016, pp. 36-38. doi: 10.5923/j.textile.20160502.03.

Article Outline

1. Introduction

- The economically viable product, Kota Doria in traditional and contemporary designs is still woven in the colourful state of Rajasthan (Jain and Goswami, 2010). Kota Doria is a handloom fabric which is known for its special weaving style that makes the final fabric translucent and light. It is characterized by fine checks (Bindloss and Singh, 2007). Checks are popularly known as ‘khats’. The ‘khats’ are made proficiently so that the fabric becomes transparent (Fernandez, 2010). Cotton-slik is most popular combination of Kota Doria. For value addition of Kota Doria, bamboo can be used in place of cotton considering its antimicrobial property, high breathability and thermo regulation property.Aesthetic demand of consumer is satisfied by application of colouring agents by various techniques. One of the common techniques is dyeing. Dyeing is uniform colouration of the fabric in same shade. Kota Doria is generally dyed with direct and acid dyes. In this study for value addition, reactive dye has been used for dyeing. Reactive dyes were introduced in the 1950s. Although originally developed for cellulosic fibers, new classes have been developed which react with wool, silk and nylon. Reactive dyes are very popular these days because of their versatility in application on both cellulosic and protein fibers, high brilliancy, wide range of shades and all round fastness. None of the reactive dyes has appeared in the list of banned dyes nor are they based on banned amines except few dyes. Reactive dyes are applied by simple application techniques which do not require oxidation reduction process and hence effluents caused by presence of oxidation-reduction reagents are nearly totally eliminated. Reactive dyes are fixed in the presence of small alkali and do not require any of the harmful products.The colour and colour fastness properties of reactive dyed plain 50/50 bamboo/cotton blended yarns were investigated in comparison with those of the similar fabrics made from 50/50 conventional viscose/cotton and 50/50 modal/cotton blended yarns by Gun and Tiber (2011). The bamboo/cotton fabrics showed the highest K/S and C values, but the lowest L values. The rubbing, wash and perspiration fastness results of the bamboo/cotton fabrics were found to be worse than those of the other fabrics having viscose/cotton and modal / cotton yarns. However, the highest light fastness results were obtained for the bamboo/cotton fabrics. Sheshachala et al. (2008) compared the colour fastness of fabrics made from bamboo and cotton fabrics dyed with reactive dye. The same and good wash and rubbing fastness results were obtained for both of the bamboo and cotton fabrics. Bamboo fabrics exhibited better light fastness results than cotton fabrics. In this study colour strength and fastness properties of bamboo-silk Kota Doria fabric dyed with reactive dye has been compared with that of cotton-silk Kota Doria.

2. Materials and Methods

2.1. Materials

- 100% silk yarn of 332.3 Nm, 100% bamboo yarn of 64.6 Nm and 100% cotton yarns of 53.3 Nm were used to prepare fabric. Hot brand reactive dye, C. I. Reactive Yellow 3 was used for dyeing.

2.2. Methods

2.2.1. Preparation of Fabrics

- Two types of Kota Doria fabrics were manufactured-one from combination of bamboo-silk and other from combination of cotton-silk. Each khat had 14 threads (08 bamboo/cotton and 06 silk yarns). Fabrics were made with 325 khats across the width. Fabrics of 48 inch width were prepared.

2.2.2. Dyeing with Reactive Dye

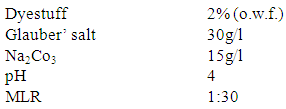

- For dyeing with reactive dye following recipe was used:

Dyeing was done in beaker dyeing machine. Dye bath pH was adjusted to 4 by adding sodium carbonate and fabric was entered. Dye solution was added in four installments and dyeing was continued for 15 minutes. 30g/l Glauber’ salt was added. Bath temperature was raised to 65°C in 30 minutes and maintained for another 30 minutes. Bath was neutralized by adding Na2CO3 and dyeing continued for another 15 minutes. Common salt was added for exhaustion, dyeing was done for another 10 minutes. Dyed samples were rinsed and dried at room temperature. (Venkataraman, 1971; Gohl and Vilensky, 2005 and; Kan and Au, 2015)

Dyeing was done in beaker dyeing machine. Dye bath pH was adjusted to 4 by adding sodium carbonate and fabric was entered. Dye solution was added in four installments and dyeing was continued for 15 minutes. 30g/l Glauber’ salt was added. Bath temperature was raised to 65°C in 30 minutes and maintained for another 30 minutes. Bath was neutralized by adding Na2CO3 and dyeing continued for another 15 minutes. Common salt was added for exhaustion, dyeing was done for another 10 minutes. Dyed samples were rinsed and dried at room temperature. (Venkataraman, 1971; Gohl and Vilensky, 2005 and; Kan and Au, 2015)2.2.3. Determination of Colour Strength

- Minolta 3600d spectrophotometer was used to measure the CIELAB coordinates (L*, a*, b*, C*) and colour strength (K/S). L* is a measure of lightness/darkness of colour of an object and range from 0 (black) to 100 (white), a* is a measure of redness (+ve a*) or greenness (-ve a*), b* is a measure of yellowness (+ve b*) or blueness (-ve b*) and C* is a measure of dullness/brightness.

2.2.4. Determination of Colour Fastness Properties

- Following colour fastness tests were performed using standard procedures-Washing fastness (ISO 105 C 10:2006), Rubbing fastness (IS: 766-1988) and Light fastness (AATCC TM 16-3).

3. Results and Discussions

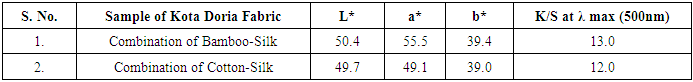

3.1. Colour Strength of Dyed Samples

- Kota doria fabrics have been dyed with reactive dye. This dye has been chosen because it can be used for dyeing of cellulosic as well as protein fiber. Result of dye ability has been expressed in terms of K/S and CIE Lab values and shown in Table 1.

|

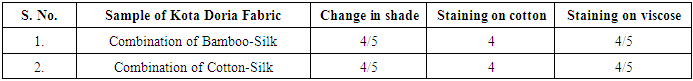

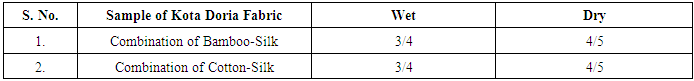

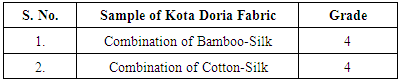

3.2. Colour Fastness Properties

- Colour fastness of dyed fabrics to various agencies during their further treatment or actual use is an important performance requirement from the viewpoint of the user or consumer.Colour fastness grades of dyed fabrics are presented in Tables 2, 3 and 4. Tables show that both the fabrics have been rated same for washing, rubbing and light fastness. Grade of change in shade is 4/5 which indicates very good colour fastness to washing. Slight staining on cotton is found whereas staining on viscose is negligible. Reactive dye forms covalent bond with -OH group of cellulose fibers. It can also form covalent bond with silk fibers. The reaction takes place between the terminal amino group of the lysine of silk and the dye in weakly alkaline pH. In a stronger alkaline pH, the dye reacts with the phenol group of the tyrosine of silk fiber. This is the reason for high wash fastness of reactive dyed fabrics.

|

|

|

4. Conclusions

- K/S value of bamboo-silk Kota Doria dyed with reactive dye was slightly higher than cotton-silk Kota Doria. This indicates higher dye absorption in bamboo-silk Kota Doria fabric. Both the fabrics exhibited same washing, rubbing and light fastness. On the basis of dyeing results it can be said that bamboo can be used as replacement for cotton in Kota Doria fabric.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML