Einas Ibrahim Ali Mousa

Shagra University, Afif, KSA

Correspondence to: Einas Ibrahim Ali Mousa, Shagra University, Afif, KSA.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

Plastic bags waste cases the environment problem, recycle plastic bags products in to handy textile product give a way to the contribute of protect environment, and enables the production of new handmade textiles from raw materials available. in this work Low density polyethylene bags waste (LDPE) cut to strips then woven by manually method in to handicrafts products, these products introduced to 50 person to know their opinion about the products, then the scale (questioner) was applied after having checked its psychometric properties to collect information, descriptive analytical method was used and descriptive analytical method was used, and The results of the study concluded that the feasibility of using waste plastic bags in handmade textile products.

Keywords:

Plastic bags waste, Recycle plastic bags, Handmade textile

Cite this paper: Einas Ibrahim Ali Mousa, Recycle Plastic Bags Waste into Handmade Textile Products, International Journal of Textile Science, Vol. 5 No. 2, 2016, pp. 31-35. doi: 10.5923/j.textile.20160502.02.

1. Introduction

Find the Solutions to reduce plastic waste is an important process to protect the environment and reduce pollution, where the risk of solid waste is the biggest problems facing the world, plastic waste in continuous increase of 5 million tons in 1950 to 100 million tons in the year 2000 (William et al., 2000), In 2012 Hoornweg and Bhada-Tata estimated in their book “What a waste” that the world cities generate about 1.3 billion tons of solid waste per year and the amount of waste would increase to 2.2 billion tones by 2025 (Hoornweget. Bhada, 2012). Some plastic products become waste after a short time of purchase such as plastic bags, Many of its non- friend to environmental and could still rest on the environment for hundreds of years, and also plastic has lightweight and resists water absorption which means it can float in the air and the water and travels long distances. Effect of Plastic on the environment vary depend on the type and method of manufacturing plastic and chemical items additives for add color or desired properties some of these items has the risk effect on the environment and on human health. With cultural and technological development, modern industry produce products from plastic easy to use like plastic bags that help us move or save our things. It has become an important part of our daily lives from the home kitchen is unimaginable without it, and the end of the shopping process is complete without back and in our hands several plastic bags loaded with our purchases., Which makes great problem on the environment and to human life. One of the most effective ways to reduce waste, reuse the product more than once time, this helps reduce the energy used to produce and the raw materials and production costs in addition to maintaining the environment, also recycling in to new products good to environment, it is method to give long life to raw material before incinerate or burial and reduce amount of new material which needed to produce same product. To contribute to a cleaner environment by recycle plastic, the researcher use the recycled for one type of plastic is the low density polyethylene which used in producing not degradable LDPE bags, these bags become waste after short time of use, and they become important in our daily lives, and because of their low weight the air and water can be transported long distances which cause additional pollution, if incinerated or buried also non-friend to environment, the researcher recycled these LDPE bags to handy textile products as The books-holder, The mobile - holder and handy bag, been selected for this type of product to simplify the method and cost of production to promote the idea of reusing waste bags.

2. Objectives of the Study

The study aim to achieve the following:1- Contributing to protect environment by recycle plastic bags.2- Utilization of carries bags waste in to handy textiles.3- Development anew forms of handy textiles.4- Propose available and cheap raw materials for the handy textile.

3. Review of Related Literature

3.1. Types of Plastic

There are about 50 2 different groups of plastics (21), with hundreds of different varieties. Types of recyclable plastic are sorted cleaned and thus make recycling easier, The American society of plastics industry developed a standard making coder to help consumer identify and sort the main types of plastic, these types and their most common uses are: PET: Polythene teraphthalate – drink bottles and oven ready meal trays.HDPE: high density polyethylene bottles for milk and washing up liquids.PVC: Polyvinyl chloride – food trays, cling film, for squash, mineral water and shampoo.LDPE: low density polyethylene – carrier bags and bin liners.PP: Polypropylene – margarine tubs, microwaveable meal trays.PS: Polystyrene – Yoghurt pots, foam meat or fish trays, hamburger boxes and egg cartons, viding cups, plastic cutlery, protective packaging for electronic goods and toys.Other:-any other plastic that do not fall in to above categories such as melamine, which often used in plastic plates and plastic cups plastic (Manas and Roy, 2006).

3.2. Polyethylene

(-CH2- CH2-)n Polyethylene is the most widely used thermoplastic material and is composed of ethylene. The two main types are low-density polyethylene LDPE and high-density polyethylene (HDPE) (Manas and Roy, 2006).

3.3. Low Density Polyethylene (LDPE)

Its properties include toughness, flexibility, resistance to chemicals and weather, and low water absorption. It is easily processed by most methods and has a low cost. It is also resistant to organic solvents at room temperature, 59% of LDPE is mainly used as film which use for product packaging, medical and hygiene shrink, shower curtains, unbreakable bottles, bowls, lids, gaskets, toys, packaging films, toys, carrier bags, high-frequency electrical insulation, chemical tank linings and heavy duty sacks, while extrusion coating (17%), injection moulding (6%), wire and cable (4%), adhesives and sealants (4%), sheets (2%), blow moulding (1%), and miscellaneous, including pipe, conduit, and rotomoulding (7%) (S.S DARA and Nagar, 1993).

3.4. LDPE Carry Bags

Plastic bags are made from ethylene, a gas that is produced as a by-product of oil gas and coal production. Ethylene is made into polymers. This substance is used by plastic manufacturers to produce a range of items, including LDPE carry bags (Gogte 2009).Use of polythene bags for packaging is increasing day by day. Polythene bags are widely used in daily life with every household using it for varied purposes of packaging and storage. They are considered to be more convenient for packing products.There is ever increasing demand for the polythene bags in the market. Now a days, all shop keepers and sellers of any products are using polythene bags for packing purpose.

3.5. Recycle

Is the process of recovering scrap or waste and reprocessing the material into useful products, sometimes completely different from their original state for instance.

3.6. The Hand Bag

The handbag is a bag to carry the different things of light weight for the purpose of the simple movements or in the shopping, and it carry by hand.

3.7. The Books-holder

It is a boxy shape open from the top and front, use for keeping books.

3.8. The Mobile-holder

It is like small handbag, use for keeping mobile by hang on the neck.

4. Materials and Methods

4.1. Sample Materials

LDPE bags with different thickness and different colors (green, white, red, violet, blue).

4.2. Sample Preparation

The LPET waste carry bags collected from supermarkets, sorted out, cleaned by water and soap and dried by moving air then cut to Strips to use as handy textile yarns.

4.3. Equipment and Tools

Square frame handloom - A Questionnaire.

4.3.1. A Questionnaire

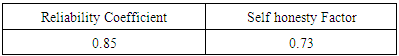

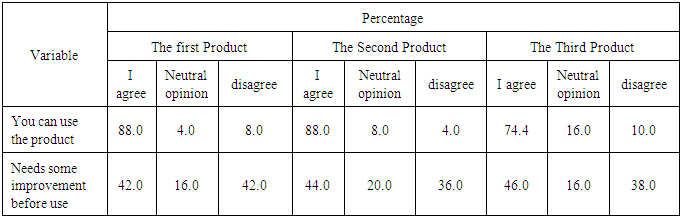

To achieve stability and validity of the questionnaire, split half method (Spearman and Brown correlation coefficient) was used.Table 1. Validity and Reliability of the Questionnaire

|

| |

|

4.3.2. The Questionnaire Asks

A - the plastic bags waste Suitably for use in the product ? B - Do the product is beautiful? C - Are you accept to use the product?D - is the product contribute to environment protection ?

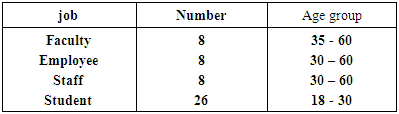

4.3.3. The Responders

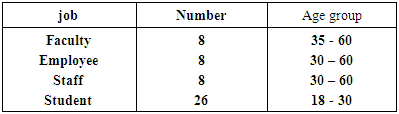

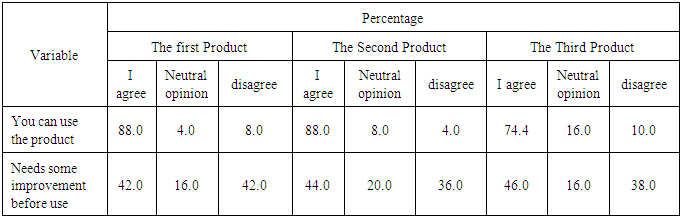

The samples which consist from 50 people randomly selected from employees of the shaqra university - Faculty of education, Afif as the Table 2.Table 2. The responders description

|

| |

|

4.4. Methods

4.4.1. The First Product (figure 1)

The hand bag, LDPE bag cut to strips, each strips 2.5 cm width then each three strips twist together to produce yarns has different colors (violet, yellow, white, blue), Then woven the waste plastic bags yarns in handloom to produce five separate pieces of 1/1 plain fabric, then for produce the hand bag, five parts of the fabrics sewing together by using the same yarn which produced from waste bags to produce front and back and the sides and the base of the hand bag, and then using polyester fabric as the lining. And for produce hands of the hand bag, three strips of plastics waste bags was braid together. | Figure 1. The first Product (Hand Bag) |

4.4.2. The Second Product (figure 2)

The books-holder, produced by cut cartoon to the books- holder form, then cut the thick plastic bags which have the blue, violet and pink color, by Using the textile design depends on the extend of the weft, the strips which produced from plastic bags waste been glued on carton taking color format to produce books - holder which decorated by the use of waste plastic as flowers. | Figure 2. The Second Product (Books Box) |

4.4.3. The Third Product (figure 3)

The mobile-holder, Produced by twisting three green strips of waste plastic bags, the width of the strip is 2 cm to product yarn formation of waste plastic bags, then woven these yarns on handloom using textile design 3/3, then used industrial plastic strips as a hand of mobile - holder.  | Figure 3. The Third Product (Mobile Bag) |

4.4.4. Data Collected and Analysis

To assess the feasibility of using waste plastic bags in the first and second and third products the questionnaire was distributed to 50 people randomly selected from employees of the shaqra university - Faculty of education, Afif, which consist from a faculty, staff, employees and students to answer on questionnaire, then “SPSS” program was used to manipulate the data statistically, frequency and percentage was used for the answers.

5. Results and Discussion

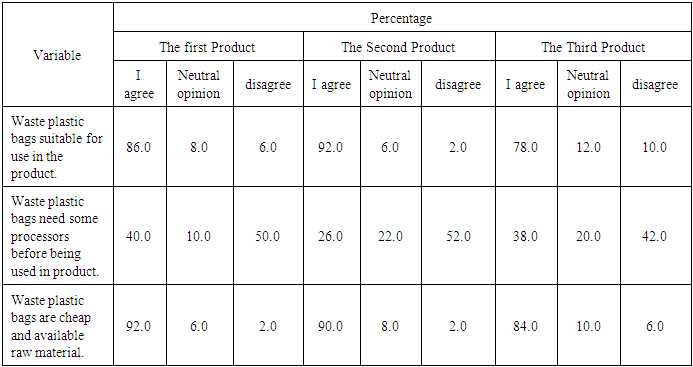

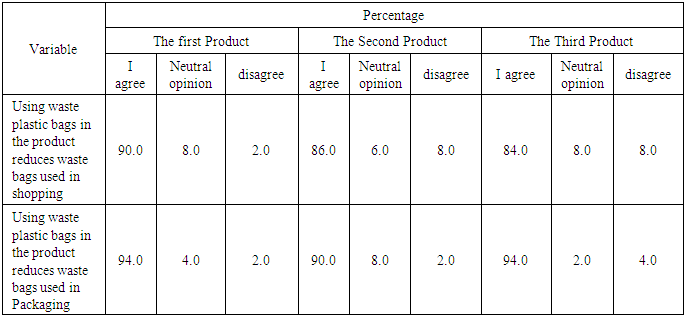

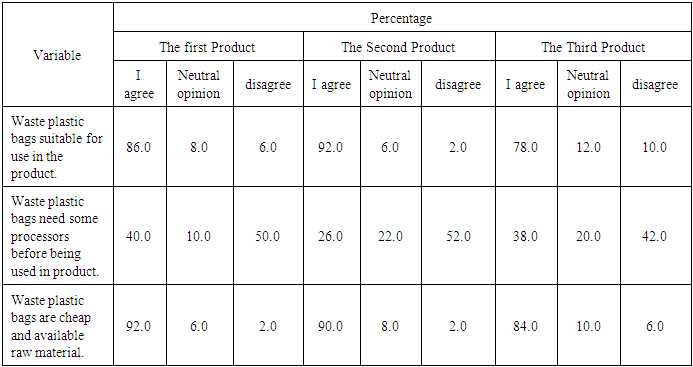

Table 2 shows that 86% of the sample survey agree on the suitability of waste plastic bags as raw material for use in the first product (figure 1), And 92% agree their suitability for use in second product (figure 2), while 78% on their suitability for use in the third product (figure 3), From the above table it is clear that the great majority agree on waste plastic bags are cheap and available raw materials for use in handy textile products in the pictures above. Opinion varies on whether should do some processors to the plastic bags waste before use in previous products, so that 40%, 26% and 38% sample survey saw that should be do some processors to the raw material prior to use in the product first, second and third respectively, while 50%, 52% and 42% of sample survey saw that waste plastic bags suitable for use as the product without do any process to the first and second and third product respectively. To Evaluate the acceptability of using the plastic bags waste in handy textile products from aesthetically by evaluate of general shape, texture and shine then the results were as in table 3. 76% to 88% and 74% sample survey agree on the beauty of the form while not agree 6% and 2% and 10% to the shape beauty of the first and second and third product respectively, 74%, 84% and 66% agree to the suitability of the texture of the first and second and third product respectively, and also 62% and 78% and 68% agree to the suitability of the shine of the first and second and third product.Table 3. Suitability of Plastic Bags Waste for Use in the Products

|

| |

|

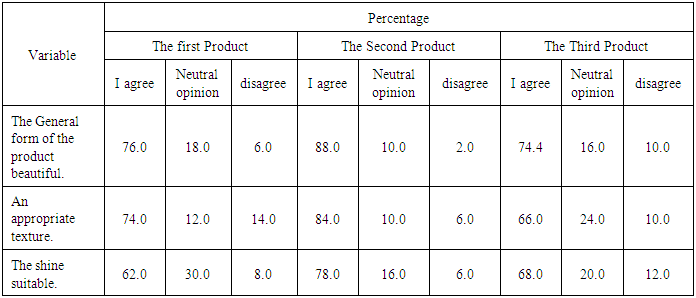

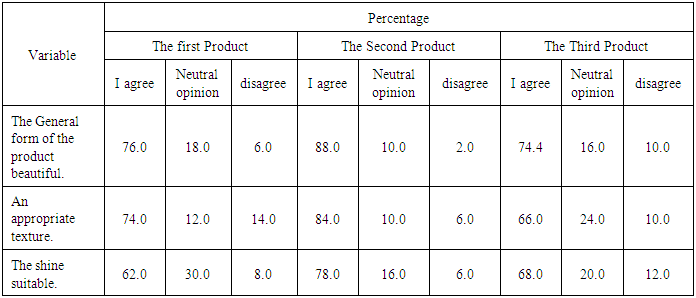

From the Results of Table 3 was observed accept aesthetically to products that have been produced using waste plastic bags. From Table 4 see that 88% agreed to the possibility of using the first and second product, while 74% agree on the possibility of using the third product, and from the above table it is also clear that some equality (42%, 44%, 46%) Among those who felt that the first and second and third product respectively needs some improvements before the uses.Table 4. Aesthetic of the Products

|

| |

|

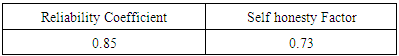

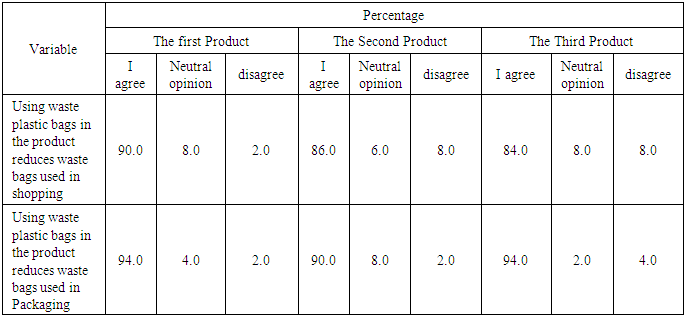

Table 5 shows that those who believe that the use of waste plastic bags to handmade textile production as it is in first, second and third help to reduce waste bags used in shopping as well as used in packaging. Table 5. Acceptance of Products Use

|

| |

|

Table 6. Contribution to Environmental Protection

|

| |

|

6. Conclusions

In this study found that the recycle of plastic bags waste into handy textile in the first product which is a hand bag and the second product which is the books holder and third product which is the mobile holder, found acceptance as raw material used in manual textile products and the material are also cheap and available to work. The results of the study found that aesthetic in the general form for the first and second and third products also the texture and shine is acceptable. And also found that there is a high acceptance for use manual products from waste plastic bags. The results also indicated that there were some views that indicate a further improvement by using these products while others use their present and finds that it does not need to be improved before they wish to use. The study concluded depending on the results that the recycling of waste plastic bags which used for packaging and marketing to manual textile products reduce the amount of plastic waste and give long to the period of using plastic bags before turning to waste, which contributed in environmental protection in addition to the features as raw material for hand textiles and aesthetic features.

References

| [1] | Hoornweg, Daniel, Bhada-Tata, Perinaz. 2012. What a Waste: A Global Review of Solid Waste Management. Urban development series; knowledge papers no.15. World Bank, Washington, DC.©WorldBank.https://openknowledge.worldbank.org/handle/10986/17388 License: CC BY 3.0 IGO. |

| [2] | Vasile, Cornelia, Pascu, Mihaela. (2016) Practical Guide to Polyethylene. Rapra Technology Limited, Shawbury, Shrewsbury, Shropshire, SY4 4NR, UK. |

| [3] | S.S DARA – S.chand and company LTD, Ram Nagar. (1993). A Text book of environmental chemistry and pollution control, New Delhi. |

| [4] | J.Anquetil, (1990). Global Programme for the Development of Handicrafts in the Repuplic of Yemen, Report prepared for the Government of the Republic o f Yemen by the United Nations Educational, Scientific and Cultural Organization (Unesco). United Nations Educational, Scientific and Cultural Organization Paris. |

| [5] | European Environment Agency. (2013). Managing Municipal Solid Waste: A review of achievement in 32 European countries. 1-40. |

| [6] | The Bower Reuse & Repaire Center. (Accessed: March 12, 2014). The History of The Bower. Retrieved from: http://www.bower.org.au/index.php/about/history.html. |

| [7] | Hessah M. Al-Moosa1, Dr. Abdulrahman A. Al-Hammad, Hussain A. Al-Salamin. (2015). Assessment of Household Recycling Behavior in Saudi Arabia Case Study of Saudi Aramco Camp Residences. international Journal of Education and Research, Vol. 3 No. 3 March 2015. |

| [8] | Alexandra, Andreea Rusu. (2011). Traditional textile art between sustainability and economic growth. Review of Applied Socio-Economic Research (Issue 2/ 2011) pag 160. |

| [9] | Willaim F Martin, John M Lippitt and Paul J Webb. (2000). Hazardous waste Hand Book. Third Edition,Butterworth-Heinemann, August 15, 2000.2,http://ecosafepak.comau/page003.html. |

| [10] | P. Surya Kumar. (2015). Handloom Industry in India: A Study. International Journal of Multidisciplinary Research and Development 2015; 2(1): 24-29. |

| [11] | Agrawal, K C. (2001). Environmental pollution cause, Effects and Controls. M.Sc. Ph.D. NIDHI Publishers, India. |

| [12] | Education Project. (2006). Museum of Solid Waste. |

| [13] | Jagulerhr, Marve Human, Tyler, E Gass and William, J Seevers. (2001). Handbook of Complex Environmental Remediation Problems. Hill Hand Books, McGraw-Hill Professional, 1 st Edition, November 14. |

| [14] | Manas, Chanda. and SolilK, Roy. (2006). Plastics Technology Hand Book. Fourth Edition, Taylor & Francis Group. |

| [15] | Willaim, F Martin, John, M Lippitt, and Paul, J Webb. (2000). Hazardous waste Hand Book. Third Edition, Butterworth - Heinemann, August 15, 2000.2, http://ecosafepak.com. au/page003.html. |

| [16] | Gogte, Mangal. (2009) Are Plastic Grocery Bags Sacking the Environment? International Journal for Quality research UDK - 504.5:675.5 Short Scientific Paper (1.03). |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML