-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2015; 4(5): 113-117

doi:10.5923/j.textile.20150405.03

Functionalization of Polyester Fabric with UV-Protection and Antibacterial Property by Means of Atmospheric Glow Discharge

Enas M. R. El-Zairy1, Nasser N. Morgan2, 3

1Textile Printing Dyeing and Finishing Department, Faculty of Applied Arts, Helwan University, Giza, Egypt

2Physics department Faculty of Science, Al-Azhar University, Cairo, Egypt

3Center of plasma technology, Al Azhar University, Cairo, Egypt

Correspondence to: Enas M. R. El-Zairy, Textile Printing Dyeing and Finishing Department, Faculty of Applied Arts, Helwan University, Giza, Egypt.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Ultraviolet protection and bacterial inactivation of polyester fabrics by means of loading silver chloride and titanium dioxide finishing agent have been investigated. The loaded agents was activated by atmospheric pressure glow discharge generated by 15 kV, 50 Hz power supply. Different types of gases have been introduced during the discharge, including air, nitrogen and oxygen. Electrical characterization of the discharge cell has been described. The generated plasma contains a lot of free radicals, electrons, ions and UV radiations activate the polyester surface and enhance the silver - titanium dioxide incorporation onto the textile matrix. The rate of bacterial inactivation of loaded textile was tested by antibacterial activity, UV-protection measurements. It was found that the improving of UV-protecting and antibacterial properties are governed by the plasma conditions specially the discharge current and the treatment time and type of discharge gas

Keywords: Antibacterial textile, APDBD, Plasma treatment, UV protection, UV blocking

Cite this paper: Enas M. R. El-Zairy, Nasser N. Morgan, Functionalization of Polyester Fabric with UV-Protection and Antibacterial Property by Means of Atmospheric Glow Discharge, International Journal of Textile Science, Vol. 4 No. 5, 2015, pp. 113-117. doi: 10.5923/j.textile.20150405.03.

Article Outline

1. Introduction

- A plasma is a partially ionized gas includes ions, electrons, UV, and visible radiations, free radicals as well as excited neutral species. A non-thermal plasma is a type of plasma with electron temperature much higher than ion temperature. The energetic electrons can initiate reactive species in the plasma volume without excessive heat that make the plasma suited to apply for textile processing. In addition, plasma is an efficient source for generating large variety of chemically active functional groups such as oxygen functional groups: =C–O, =C=O,–O–C=O, –COH, –COOH produced on the fabric surface through the interaction between the plasma and carbon surface[1-3]. A plasma can also be regarded as an efficient sterilizing tool through generating energetic UV radiation and reactive plasma species like O, O+,O2 +,OH, H2O2, O3, ……etc those have a lethal effect on microorganisms [4-7].Atmospheric pressure glow discharge (APGD) appears as an attractive solution to realize non-thermal atmospheric pressure plasma suitable for different varieties of plasma application including surface treatment of polymers and textiles. Okazaki and others operated barrier glow discharges even at 50 Hz sinusoidal feeding voltage [7-12]. The application of silver and metal oxides particles to textile material represent the object of several studies aimed at producing finished fabrics with antibacterial properties [13, 14], nano-TiO2 for UV-blocking and self-cleaning properties [15-17] and ZnO nanoparticles for antibacterial and UV-blocking properties. It is known that the adhesion between TiO2 and polyester is not good because of the lack of chemical bonding. To improve the adhesion, surface treatments of the polyester surface may be needed for altering the chemical and physical properties of polyester. Low temperature plasma (LTP) pretreatment of polyester surface is probably the most versatile technique to improve the bondability of silver and TiO2 on polyester fibers. The surface pretreatment only modifies the outermost surface layers of the polymer without affecting the bulk properties. In the present work, atmospheric pressure glow discharge has been used to activate polyester surface to enhance the Sanitized®T27-22 silver (finishing agent based on silver chloride and Titanium dioxide) incorporation onto the textile matrix.

2. Materials and Methods

2.1. Materials

- Commercial polyester [PET] 100% plain weave fabric of (165g/m2) was used as the substrate for modification throughout this study, supplied by private sector Company in Egypt. Sanitized®T27-22 silver clariant (finishing agent based on silver chloride and Titanium dioxide Sigma- Aldtich chemic GmbH). Arkofix®NDF liq.c (low content of free formaldehyde based on modified N-methylodihydroxyethylene urea, DMDHEU, clariant). Leomin® W[nonionic wetting agent and detergent- BASF-Germany] commercial grade. All other chemicals used during this study such as citric acid were of laboratory reagent grade.

2.1.1. Characteristics of Product A (Satinized® T27-22 silver)

- – Composition: Silver chloride and titanium chloride– pH (20°C): 6.3– Ionogenicity: Non-ionogenic– Density at 20°C: 0.8–1.0 gm/cm3– Appearance: White to light grey suspension– Solubility: Mixable with water– Temp. stability: Up to 190°C– Compatibility: Compatible with other textile chemicals such as binder, fluorocarbons, softeners, and other finishing auxiliaries.– Fastness: Excellent wash, dry-cleaning, ironing, andperspiration resistance and light-fastness

2.2. Methods

2.2.1. Atmospheric Pressure Glow Discharge Set up

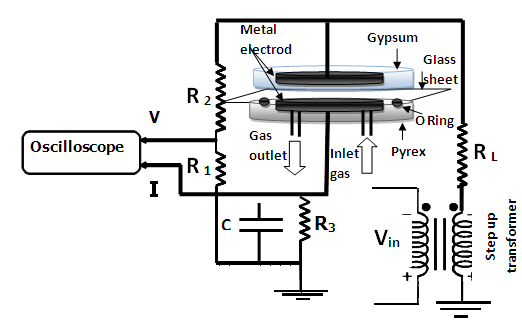

- The discharge cell shown in Fig.1 consists of two metallic circular parallel metal electrodes of 20 cm diameter, 1mm gap space, one of them is completely covered with commercial gypsum with thickness 2 mm stands on glass plate of thickness 1.5 mm that separate them from the ground electrode through an O ring lying. The ground electrode stands on Perspex sheets with inlet and out let opening for gases insertion and exhaustion. High voltage transformers (0-15kV), generates sinusoidal voltage with a frequency of 50 Hz was used for driving discharge. A limiting resistor RL was used to limit the current and protect the AC power supply. The textile sample stands on the ground electrode covered with the glass sheet through the O ring. The current and voltage wave forms has been measured using 100 MHz digital storage oscilloscope (GWinstek GDS-810S 100MHz) through potential divider (1:1000) represented by resistor R1 and R2. The current measured through 100 ohm resistance R3 connected between the ground electrode and the ground.

| Figure 1. Schematic diagram of the atmospheric glow DBD |

2.2.2. Loading of Sanitized®T27-22 Silver on Activated Textile Fabrics

- Functionalizing the original polyester textile surface was done by, non-thermal atmospheric pressure glow discharge (APGD) at different treatment time and discharge current. The treated samples was immersed in aqueous finishing formulation containing Dimethylol dihydroxy ethylene urea [DMDHEU](50g/l) as a crosslinker, [MgCl2.6H2O)]/citric acid (8/2 g/L) as a mixed catalyst, in the absence and presence of Sanitized® (20g/l) along with 2g/l nonionic wetting agent, roll squeezed to a wet-pickup of 80% , followed by drying at 80℃ for 5 min. and cured at 170℃ for 2 min, thoroughly rinsed and dried.

3. Measurements

- 3-1 UV-protection measurements UV-protection factor (UPF) was evaluated according to the Australian/New Zealand standard method, [AS/NZS] 4366-1996.3-2 Bacterial growth testing Antibacterial efficiency of functionalized fabric samples against G+ve (S. aureus) and G-ve (E.Coli) bacteria was performed using agar diffusion test according to AATCC test method 147-1988.

4. Results and Discussion

4.1. Electrical Characterization of the Discharge Cell

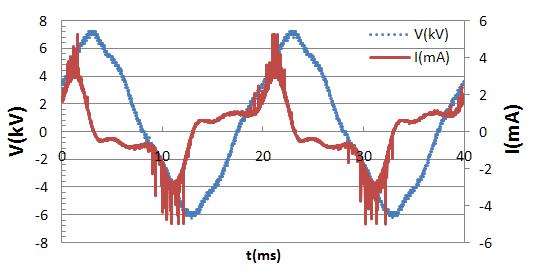

- The voltage and current waveforms for the discharge cell were measured by 100 MHz digital storage oscilloscope (GW Instek GDS-810S 100MHz) through resistor R1 and R3. Figure 2 shows the current voltage waveform for atmospheric glow discharge using at gap space nearly 1 mm with applied voltage 7 kV and discharge current 3mA with nitrogen as working gas. It is shown that the glow component is superimposed with small number of streamers. The formation of uniform glow discharge at atmospheric pressure with the existence of gypsum dielectric may be attributed to the roughness of the surface that forms a large number of sharp edges which is expected to produce a high local electric field sufficient to cause ionization in the vicinity of the edges through the discharge volume leading to a large number of streamers adds together forming continuous glow discharge. Increasing the gap space for the same dielectric will cause an increase in the density of streamers and reduction in the glow component.

| Figure 2. Current voltage waveform for the discharge cell |

4.2. UV Protection Finish

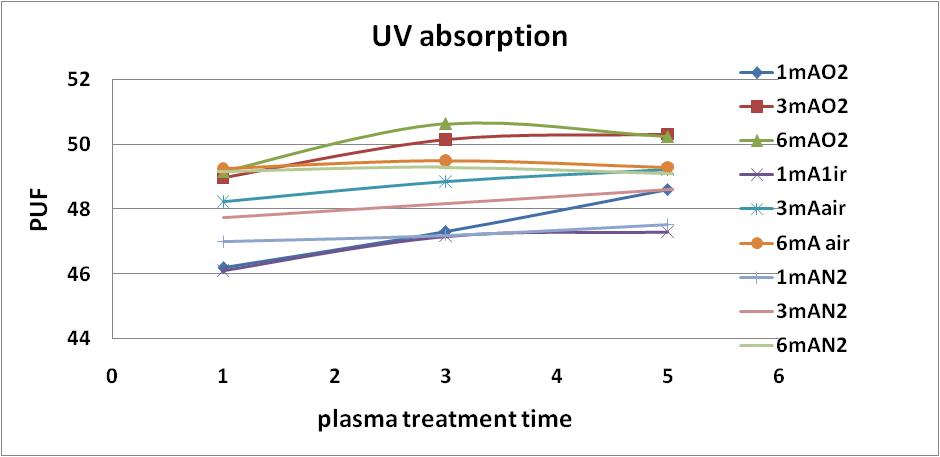

- The efficiency of UV-protection of textile material is defined by its ultraviolet protection factor (UPF). The higher the UPF value, the greater is the protection category. In recent years, ultra efforts have been devoted to improve the UV-protection function of textiles against the harmful UV-radiation [18-19]. Herein we report the feasibility of enhancing the UV-protection functionalities of polyester fabric using silver chloride and titanium dioxide, loaded on polyester fabrics activated via plasma which activates the substrate surface to increase the silver incorporation onto the fiber matrix.

4.3. Influence of UV-blocking Additive

- Figure 3 shows the UV absorption of the untreated polyester and Sanitized®-coated polyester substrate treated with atmospheric glow plasma at different discharge current 1-6 mA, at different treatment time 1-5 min as well as different working gases like oxygen, air and nitrogen plasmas. The data so obtained signifies that, there is a great difference in the UV protection properties between the plasma treated and untreated samples as shown in Figure 3. It is shown that in all types of plasmas the treatment time is not significant, one minute treatment have nearly the same effect as five minute treatment for all types of working gas. Increasing the discharge current, that is proportional to the density of electrons and consumed power in the discharge cell, shows slight increase in the UV absorption. High current ( 6 mA) is favorable for UV protection for all type of gases, since increasing the discharge current indicate a large density of electrons that enable formation of free radicals or active species that activates the fabric surface to incorporate with silver and titanium dioxide.

| Figure 3. Effect of plasma treatment on polyester fabrics via Santized® on UV-protecting properties |

4.4. Antibacterial Finish

- Microorganisms including [Bacteria, Fungi, Algae, dust mites and yeast], are so small that can not be recognized by the naked eyes, they cause various diseases and they can damage different materials, e.g. textile, food, etc. [23]. The growth of micro-organisms on textiles inflicts a range of unwanted effects not only on the textile itself but also on the wearer. These effects include the generation of unpleasant odor, stains and discoloration strength. Therefore, it is highly desirable that the growth of microbes on textiles be minimized during use and storage [24]. Accordingly, the present study is directed towards an efficient finishing formulation to add antibacterial functionality to modified polyester [PET] with plasma via an effective antibacterial finishing gent, i.e. sanitized ® T27-22 silver clariant, based on silver chloride and titanium dioxide , in the presence of DMDHEU as a crosslinker and (Mg Cl2.6H2O) / citric acid as a mixed catalyst. Silver kills bacteria by strangling them in a warm and moist environment. Highly bioactive silver ions bind with proteins inside and outside bacterial cell membranes, thus inhibiting cell respiration and reproduction.

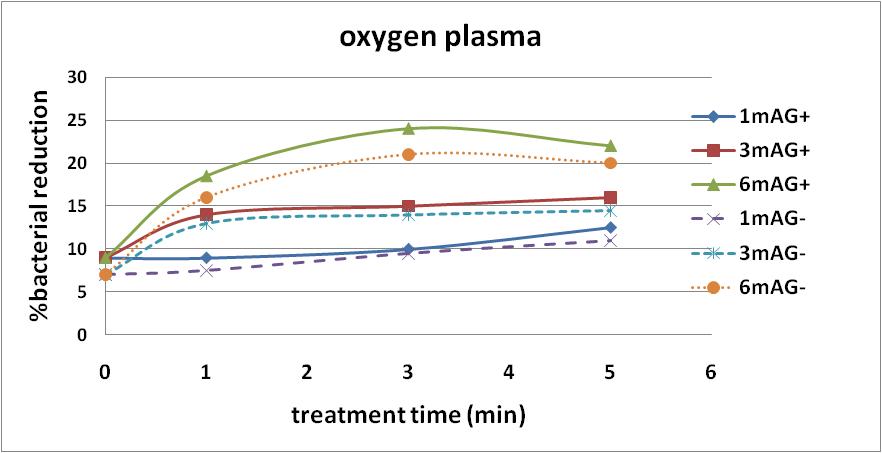

4.4.1. Antibacterial Activity

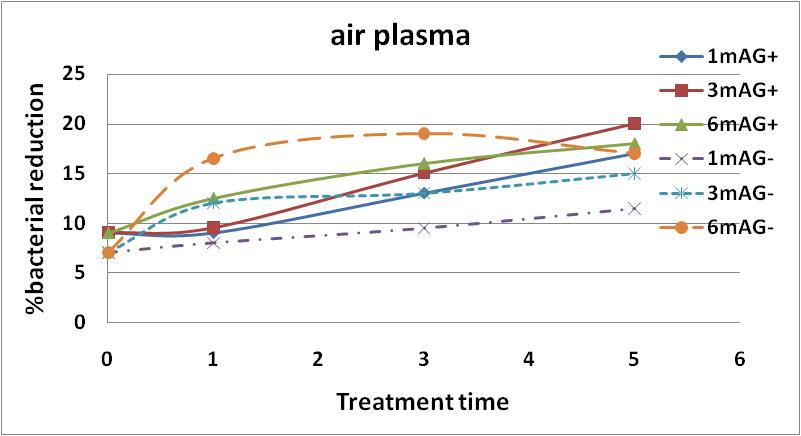

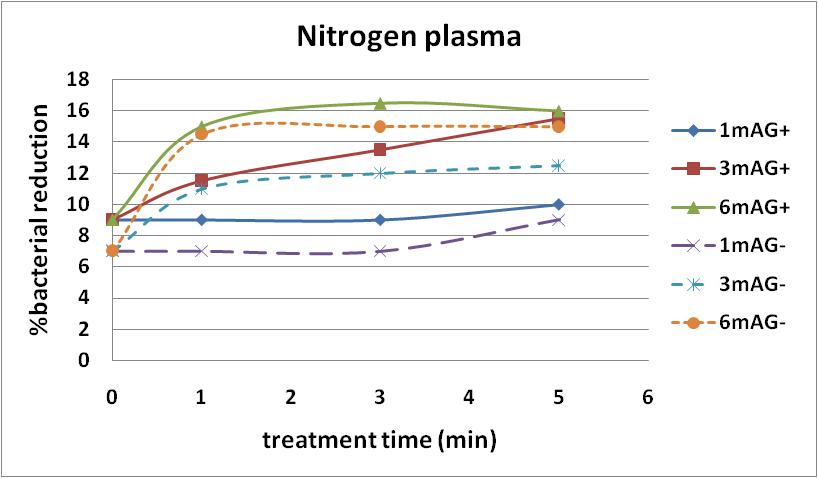

- The antibacterial properties (gram positive in solid lines & gram negative in dot lines) of the pre-modified polyester with plasma at different treatment time, discharge current and different gases post treatment with Sanitized®-finishing agent are shown in Figure 4(a,b,c).

| Figure 4(a). Bacterial reduction percentage in oxygen plasma |

| Figure 4(b). Bacterial reduction percentage in air plasma |

| Figure 4(c). Bacterial reduction percentage in nitrogen plasma |

5. Conclusions

- ● The bacterial inactivation efficiencies of combination of silver metal and titanium oxide on textile fabrics was investigated to evaluate the disinfectant action on airborne bacteria and UV blocking factor.● Atmospheric pressure glow discharge with different working gases has been used to activate polyester surface for enhancing the silver and TiO2 incorporation onto the textile matrix.● The extent improvement in the ultra violet protective factor (UPF) values may be obtained by sanitized ® coated polyester pretreated with oxygen plasma, but the nitrogen plasma pretreated substrate has the lowest UPF value.● It appears that oxygen plasma gives the most oxygenated polyester surface, which results in better adhesion onto the polyester surface. The TiO2 can be attached to the modified polyester surface through ionic attraction with the positively coated Ti4+ of TiO2.● The sanitized ®, i.e. silver and Tio2 antibacterial effect, coated polyester pretreated with oxygen plasma technique at discharge current of 6 mA for 3 minutes proved to give better antibacterial activity against G+ve than G-ve bacteria.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML