-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2015; 4(2): 36-41

doi:10.5923/j.textile.20150402.02

Mango Bark Mordant for Dyeing Cotton with Natural Dye: Fully Eco-Friendly Natural Dyeing

Lodrick Makokha Wangatia, Kidist Tadesse, Senelisile Moyo

Ethiopian Institute of Textile and Technology (EiTEX), Bahir Dar University, Ethiopia

Correspondence to: Lodrick Makokha Wangatia, Ethiopian Institute of Textile and Technology (EiTEX), Bahir Dar University, Ethiopia.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Use of metal salts mordants in naturally dyed textile products make them not fully environmental friendly. We have investigated mango bark extract possibility of being used as a mordant. The natural dye used was extracted from bitter leaves and pre or post mordanted with mango bark extract, the amount of dye in the sample after dyeing and after washing was tested using CIELAB equipment, UV-Vis absorption spectroscopy and wash fastness test. Comparing the mango bark mordanted sample with control samples which included; un-mordanted sample and samples mordanted with copper II sulphate, significant mordanting effect was confirmed which was even better than the conventional mordant used. Further investigation revealed that post mordanting with mango extract gives better wash fastness performance than pre-mordanting. This study forms an important basis on which many more natural materials can be developed to be used as mordants when dyeing not only cotton but other textile products made from other fibers.

Keywords: Natural dye, Natural mordant, Fastness property, Eco-Dyeing, Cotton

Cite this paper: Lodrick Makokha Wangatia, Kidist Tadesse, Senelisile Moyo, Mango Bark Mordant for Dyeing Cotton with Natural Dye: Fully Eco-Friendly Natural Dyeing, International Journal of Textile Science, Vol. 4 No. 2, 2015, pp. 36-41. doi: 10.5923/j.textile.20150402.02.

Article Outline

1. Introduction

- The use of non-allergic, non-toxic and eco-friendly natural dyes on textiles have become a matter of significant importance due to the increased environmental awareness in order to avoid some hazardous synthetic dyes [1, 2]. Natural dyes are considered to be eco-friendly as these are obtained from renewable resources as compared to synthetic dyes which are derived from non-renewable petroleum resources [3]. Most of the natural dyes have no substantivity for the fiber and mordants must be used. Mordants are usually derived from metallic salts, the commonly used metal salts include alum, chrome, stannous chloride, copper sulphate and ferrous sulphate [4-7]. These chemicals act as mordant by fixing themselves on the fiber and also combines with the dyestuff. Therefore, mordants form a link between the fiber and the dye, which allows certain dyes with no or little affinity for the fiber to be fixed [8, 9]. However, the use of metallic mordants during natural dyeing often puts a question mark on the eco-friendliness of natural dyes. Only a small amount of these metal salts gets fixed onto the textiles and the rest is discharged as effluent which leads to the contamination of land and water resources. Furthermore, the presence of some of these metal salts in the finished goods exposes the wearer to some harm.Much study has already been dedicated to developing mordanting agents which are non toxic and eco-friendly. Some of the approaches which have been explored include use of metal salts which are considered to be ecologically safe like alum and iron sulphates, use of natural oil product as mordants has also been reported [10]. Tannins and other natural extracts from plants have also been investigated for mordanting natural dyes [11-13]. In this work we investigate the possibility of dyeing cotton fabric using two natural dye extracts. One dye extract is supposed to act as a mordant while the other acts as the main coloring material. To achieve this objective, we have extracted green dye from Bitter leave (vernonia amygdalina) and used it as the main natural dye. Vernonia amygdalina plant is member of the Asteraceae family, is a tropical shrub, 1-3m in height with petiole leaf of about 6mm in diameter, and elliptic in shape. The leaves are dark green colored with a characteristic odor and a bitter taste. This plant occurs naturally along rivers and lakes, in forest margins, woodland and grassland, up to 2000 m altitude. It often occurs in disturbed localities such as abandoned farmland, and can be found growing spontaneously in secondary forest making its readily available for use. Extracts from the bark of the Mango tree (Mangifera indica) with a yellowish color has been used as a mordant. After dyeing the amount of color in the fabric and amount of color extracted from the solution were evaluated for both freshly dyed and washed samples to establish the mordanting effect of the mango tree using CIELAB equipment and UV-Vis spectroscopy.

2. Experimental

2.1. Materials and Equipments

- Dried and crushed powder of bitter leaves and mango bark, acetone, copper II sulphate (synthetic mordant), bleached cotton fabric cut into several 5g pieces to be used for dyeing in different conditions. The dyeing results were compared using CIELAB equipment and UV-Vis spectroscopy. Machines used for dyeing, washing, padding were all from Mesdan Lab company.

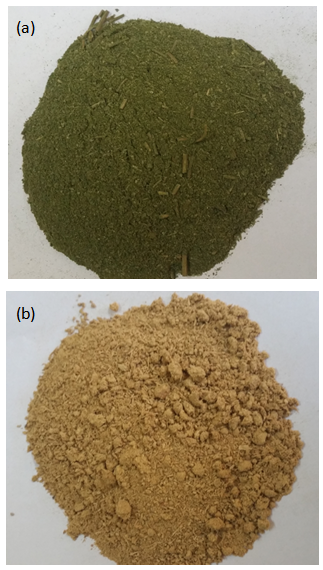

2.2. Extraction of Dye from Bitter Leave and Mango Bark Powder

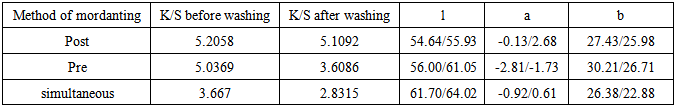

- The bitter leaves were collected from the trees, dried and crushed into powder, the mango barks were also separately dried and crushed into powder as shown in Figure 1. The extraction of the two dyes was done separately since they were to be used for different functions. 30 g of powder bitter leaves were extracted using 100 ml of acetone (an organic solvent which gave higher yield than water) at 50℃ for 1 hour. After extraction, acetone was evaporated leaving behind the dye concentrate which was diluted with water to form 100ml solution to be used for dyeing without further dilution. For mango bark, 15 g of the powder was extracted using 200 ml of water at 90℃ for 1 hour. The extract was directly used without any dilution.

| Figure 1. Dried and crushed powder of a). Bitter leaves and b). Mango bark |

2.3. Pre-Mordanting

- Two pieces of fabric samples were pre-mordanted one with mango extract and the other with copper II sulphate. For mango bark, the extract was used while for copper II sulphate 2g/l concentration was used. Both the two samples were placed in 50 ml of respective mordant solution and heated at 60℃ for 1 hour. The fabric were then padded to remove excess water and dried in open air.

2.4. Dyeing Using Bitter Leaves

- A total of 5 samples prepared as follows: the two fabrics samples previously pre-mordanted and three fabric samples only bleached but not mordanted were all dyed separately using the same conditions. Each fabric was placed in similar 100 ml bitter leave dye solution and dyed at 80℃ for 2 hours. After dyeing the samples were padded and dried.

2.5. Post Mordanting

- Two of the un-mordanted dyed samples were post mordanted using mango and copper II sulphate following the same procedure as pre-mordanting. The last piece remained as the control sample.

2.6. Washing

- The dyed samples were tested for wash fastness according to the conditions of ISO 105 standard test method.

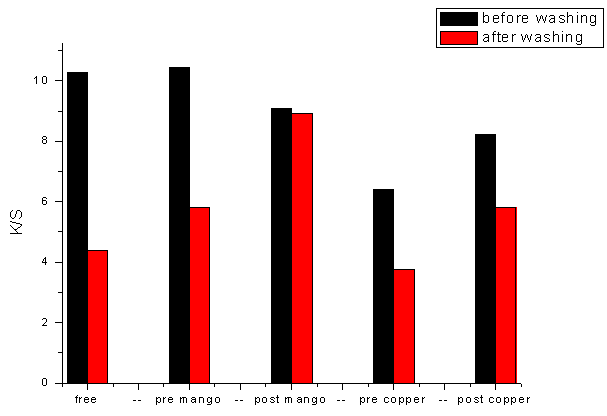

3. Results and Discussions

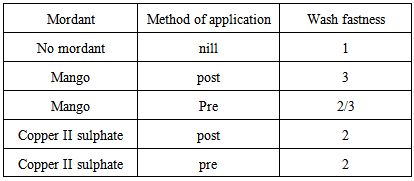

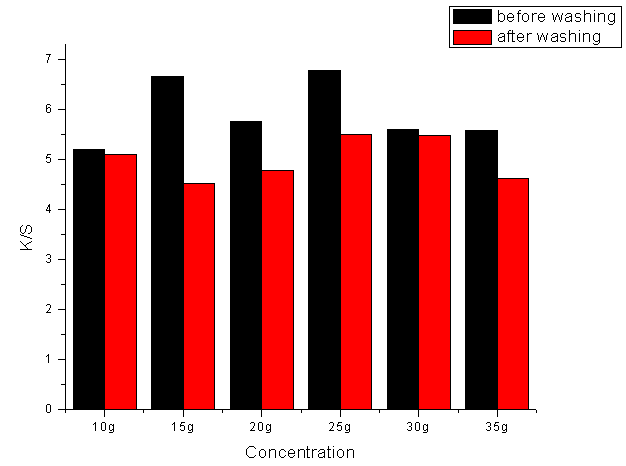

- To investigate the effect of mordanting from mango extract, bleached cotton fabrics were dyed using bitter leaves dye and mango extract as a mordant and compared with those dyed with similar dye but mordanted using conventional mordant in this case copper II sulphate under similar dyeing conditions. The effect was measured using CIELAB equipment to establish the K/S values after dyeing and after washing, results obtained are as represented in Figure 2.

| Figure 2. K/S values of dyed and washed samples mordanted differently |

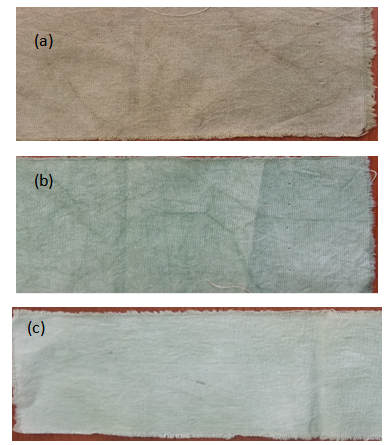

| Figure 3. Dyed and washed samples a). post mordanted with mango, b). pre mordanted with mango and c). No mordant added |

|

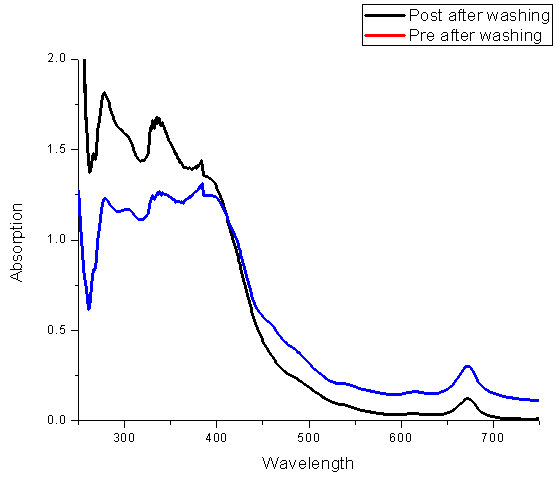

| Figure 4. UV-Vis absorption spectra of water collected after washing from samples differently mordanted |

| Figure 5. Effect of varying the concentration of mango mordant on K/S value during post mordanting |

|

4. Conclusions

- For naturally dyed fabric to be referred as fully eco- friendly products their processing must eliminate the use of metal salts for mordanting. In this study we have successfully investigated the possibility of using extract from mango bark as a mordant to dye natural dye (bitter leaves). Using the same dyeing conditions we have shown that mango extract even can mordant bitter leave dye better than the conventional metal salt under similar conditions; in this case copper II sulphate was used to compare. Further investigation revealed that post mordanting with mango extract gives better wash fastness performance than pre-mordanting. This was purported by the deeper color shade visually observed on the post mordanted dyed sample as compared to pre-mordanted. However there was more dye color in waste water collected after washing from post mordanted sample than pre-mordanted an effect attributed to contribution of unused mango extract during post mordanting. This study forms an important basis on which many more natural materials can be developed to be used as mordants when dyeing not only cotton but other textile products made from other fibers.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML