-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2014; 3(4): 70-75

doi:10.5923/j.textile.20140304.03

Effect of Gauge Variation of Circular Knitting Machine on Physical and Mechanical Properties of Cotton Knitted Fabrics

Faisal Abedin1, K. M. Maniruzzaman2, Ahmad Saquib Sina3, Elias Khalil4

1Department of Textile Engineering, BGMEA University of Fashion and Technology, Dhaka, Bangladesh

2Department of Knitting Production, Square Fashions Limited, Mymensingh, Bangladesh

3Department of Wet Processing, National Institute of Textile Engineering and Research (NITER), Dhaka, Bangladesh

4Department of Textile Engineering, World University of Bangladesh, Dhaka, Bangladesh

Correspondence to: Elias Khalil, Department of Textile Engineering, World University of Bangladesh, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

This paper deals with the results of an investigation of various gauges of circular knitting machines with a view to producing same single jersey fabric with different parameters. All parameters including machine diameter, stitch length, yarn count, yarn lot, yarn tension etc. but gauges are used for this work is different. Even dyeing has been done at the same time on the same machine by stitching one with other, finishing parameters and processes are also same and done at same time as well to minimize the effects of other variable which can be responsible for changing the physical and mechanical properties like finished width of the fabric, finished GSM (Grams per Square Meter), shrinkage, spirality, bursting strength etc. This is done for finding only the effects which actually affects the fabric properties. Finally the findings or results are as expected with some variations with the results that are thought theoretically.

Keywords: Circular Knitting, Machine Gauge, GSM, Shrinkage, Spirality, Physical and Mechanical Properties

Cite this paper: Faisal Abedin, K. M. Maniruzzaman, Ahmad Saquib Sina, Elias Khalil, Effect of Gauge Variation of Circular Knitting Machine on Physical and Mechanical Properties of Cotton Knitted Fabrics, International Journal of Textile Science, Vol. 3 No. 4, 2014, pp. 70-75. doi: 10.5923/j.textile.20140304.03.

Article Outline

1. Introduction

- Knitting is a technique for producing a two-dimensional fabric made from a one-dimensional yarn or thread [1]. It is the method of creating fabric by transforming continuous strands of yarn into series of interloping loops, each row of such loops hanging from the one immediately preceding it [2]. The basic element of a knit fabric structure is the loop intermeshed with the loops adjacent to it on both sides and above and below it. Knitted fabrics are divided into two main groups, weft and warp knitted fabrics [3]. Weft knitted fabrics can be produced in circular or flat knitting machine. The primary knitting elements are needle, cam and sinker. With the variation of the elements different characteristics of fabrics can be produced. The rising demands on knitted garments all over the world motivate the researchers to research about the various knitted fabrics, their production processes, developing new structures. Knitting machine comprise a needle holder that supports a plurality of needles, which are arranged side by side and can be actuated with an alternating motion along their axis with respect to the needle holder in order to form knitting. Single cylinder circular knitting machines are generally provided, at the upper end of the needle cylinder, with an annular element, which is fixed integrally around the upper end of the needle cylinder and is provided with radial cuts, inside each of which a sinker is arranged, and this radial cuts are angularly offset around the needle cylinder axis with respect to the needle sliding channels so that each sinker is located between two contiguous needles [4]. In the circular knitting machine with a great number of knitting needles, when the number of needle increases, the distance between the needles or sinkers have to be shrunk [5]. This investigation is done for scrutinizing the consequences due to change the gauge of the knitting machine. Gauge is a very important factor in terms of circular knitting machine which denotes the density of the needles in cylinder or dial of a circular knitting machine [6]. Typically no. of needles per unit length of cylinder or dial is called gauge. Most of the time, the number of needles per inch is used in terms of gauge [7]. Literally it is thought that the finished width of the fabric with all the same parameters except the gauge will be higher for higher gauge. But what the reason against this phenomenon is described with the practical results. The consequences of various gauges for various fabrics especially for different GSM or fineness of the fabrics can be gained by this research. Machine gauge is the number of needles in an inch which has a great influence in the fabric structure. Not all the yarn counts can be used in same gauge of machine. Usually yarn needs to be fine with the increase of machine gauge. Knitting machines come in various gauges to accommodate the wide range of yarn available today. According to gauge of the machine the patterns of stitches in a fabric is changed. Same thickness of yarn will produce different stitch length due to variation of gauge. And again GSM will change if the same yarn is used by different gauge. Generally for hand spun and bulkier weight yarns or heavy worsted weight lower needle gauge is practiced. Mid gauge is used for sport weight to light worsted yarns. Standard gauge is used for sock weight, fingering weight, baby weight yarns. Fine gauges are used for lace weight to fingering weight yarns [8]. No. of needles per inch present in a needle bed of a knitting machine is called machine gauge for that knitting machine. Selection of machine gauge depends upon the following: yarn count, fibre type, and yarn twist, yarn finished [9].

2. Materials and Methods

2.1. Materials

2.1.1. Yarn Selection

- As the experiment has done only for identifying the consequences of the change in circular knitting machine gauge so all the others parameters were kept constant. For this experiment 30 Ne 100% cotton grey yarn has been selected.

2.1.2. Knitting Machine

- Knitting Machines (Mayer & Cie, Germany) with same diameter of cylinder but different gauges have been chosen. Four single jersey circular knitting machines of each 30 inches diameter having 20 gauge, 22 gauge, 24 gauge and 28 gauge have used for knitting single jersey fabric. Stitch length used for this experiment was 2.65 mm.

2.2. Methods

2.2.1. Batching

- Batching is an operation which is done after knitting before dyeing or wet processing. As the four fabrics have undergone through the same dyeing operation or wet processing, the four fabrics have joined in the same batch by stitching the ends of the fabric. But all the four fabrics were identified by cutting no cut to three cuts which had done to identify the different fabrics separately.

2.2.2. Dyeing

- All the four fabrics have been dyed with same average color in a same machine at the same time. Dyeing process was carried out at 60°C on PH 9-1.2 with M: L Ratio 1:10 for 60 minutes.

2.2.3. Finishing

- Finishing has a strong impact on fabric properties. The finishing operation had done in several steps. Firstly Slitting had done immediately after the dyeing to make the tube fabric open by cutting the fabric through a preset needle line. Secondly Drying was carried out by monforts dryer which had been used to dry the wet fabric for the further smooth operation. Silicone softener (60g/l) was used at 30% overfeed at 130°C. At last stentering and compacting operation had done.

2.2.4. Relaxation

- Knitted fabrics are very much prone to extend and shrink. So proper relaxation before any kind of test is very much essential, especially for dimensional properties. The fabrics had been kept at standard atmosphere of 27°C and 65% Relative Humidity for 24 hours at Physical Lab.

2.2.5. Determination of Fabric Width

- After relaxation & conditioning, the width of the fabric was measured by measuring tape, for different gauge samples [10].

2.2.6. Determination of Fabric Weight (GSM)

- After relaxation & conditioning of knit fabric samples, GSM of samples were tested by taking test samples with the help of GSM cutter & weighting balance (electronic) [11].

2.2.7. Determination of Spirality

- First cut a sample of (50cm×50cm) with the scissors. Then by the over lock sewing m/c the 4 ends of the cut fabric were sewn. After sewing, again by a scale mark (35cm×35cm) on the fabric & then sample washed with a standard soap solution (1g/l). After washing the sample was tumble dried at 65°C± 15°C for 60 minutes. Then after cooling the sample tested with the shrinkage tester scale also the spirality was tested. Shrinkage was tested length wise & width wise along the mark of (35cm×35cm). And spirality was tested along sewing line alignment. (Distortion of the formation of loops) [12]

2.2.8. Determination of Bursting Strength

- Bursting strength of samples was measured by an automatic bursting strength tester. Samples are gradually set on the diaphragm, the automatic bursting strength tester, measures time, distortion, pressure & the flow rate to burst the fabric. For different samples we recovered there parameters. [13]

2.2.9. Determination of Pilling Resistance

- For this test, each specimen was prepared at (125mm×125mm) by cutting from the fabric. A seam allowance of 12mm was marked on the back of each square. The samples were then folded face to face & a seam was sewn on the marked line. Each specimen was turned inside out & 6mm cut off each end of it thus removing any sewing distortion. The fabric tabs made were then mounted on rubber tubes. So that the length of table showing at each end is the same. Each of the loose end is taped with PVC tape so that 6mm of the rubber tube left exposed. All the specimens were then placed in 3 pilling boxes. All the specimens were then placed in 3 pilling boxes. The samples were then tumbled together in a cork – lined box. We had used 2000 cycles of revaluations for the test. [14]

2.2.10. Determination of Fabric Shrinkage

- Shrinkage is an inherent property of knit fabrics which can’t be prohibited, but for better quality, it must be controlled in a systematic way. After tumble drying & cooling of the fabric, shrinkage of this samples are in widthwise. It was calculated from the difference in fabric length before and after washed garment according to AATCC test methods 135 and 150 [15].

3. Results and Discussion

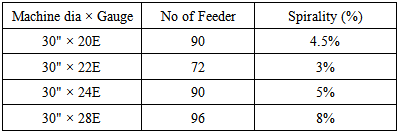

3.1. Effect on Fabric Width

- Actually grey width of the fabrics is not acknowledged at all because it varies at a wide range due to various factors of the knitting machine including fabric take-up tension, take-up mechanism (using take-up roller or box storage) etc. But after finishing the width of the fabric is considering as the working width of the fabric.The width of the fabric is formed by the wale of knitted fabric and one wale is formed one needle. That means the greater the number needle greater the width of the fabric. It is very normal unit equation, if a 30 diameter and 24 gauge machines produce a single jersey fabric of finished width 150cm from 30Ne yarn with 2.60mm stitch length then if all the other parameter remains constant and same single jersey fabric is produced in a 30 diameter and 28 gauge machine then the width of the finished fabric can be determined with a simple equation, 24 gauge produce 150 cm, so 28 gauge produce ((150×28)/24) cm = 175cm, Here in a 30 diameter 24 gauge machine has = 3.1416×30×24 = 2262 pieces needle. So this machine produce 2262 wale in the fabric and 30 diameter and 28 gauge machine has = 3.1416×30×28 = 2638 pieces needles. So this machine produces a fabric which has 2638 wale in its full width. The ratio between width of the fabric of 28 and 24 gauge machine is = 175/150 = 1.166667 and the ratio between the ratio between the number of wale of 28 and 24 gauge machine is = 2638/2262 = 1.1662246. The both ratio are almost same. So the width of the fabric largely depends on the machine gauge. If the experimented results are observed and compared with the above calculation, the following results can be obtained. Here all the other results are compared with the 30 diameter and 24 gauge machines results in the figure 1.

| Figure 1. Effect on fabric width on variation of machine gauge |

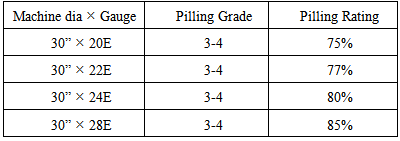

3.2. Effect on Fabric Weight (GSM)

- From the following figure 2, it is seen that the greater the compactness of the wale of the fabric, the greater the GSM of the fabric is found. As in the higher gauge the compactness of the fabric is greater so the GSM rises from the 20 gauge to the 28 gauge machine gradually.

| Figure 2. Effect on fabric weight on variation of machine gauge |

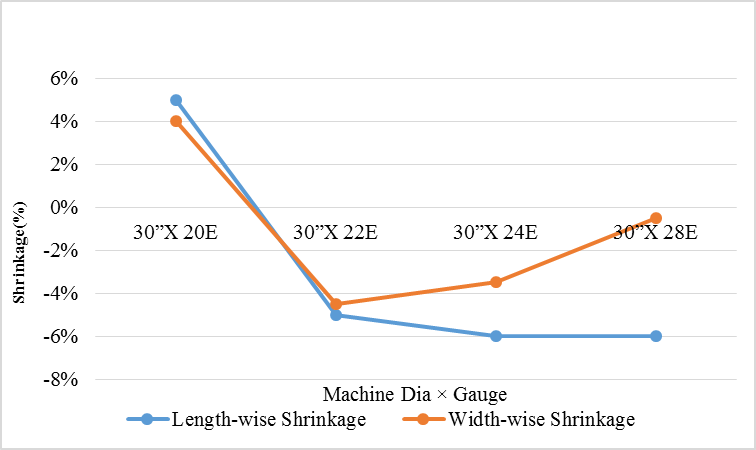

3.3. Effect on Fabric Shrinkage

- From figure 3 it is seen that Gauge affects the shrinkage of the fabric actually on the width-wise as gauge only change the fabric on width-wise.

| Figure 3. Effect on fabric shrinkage on variation of machine gauge |

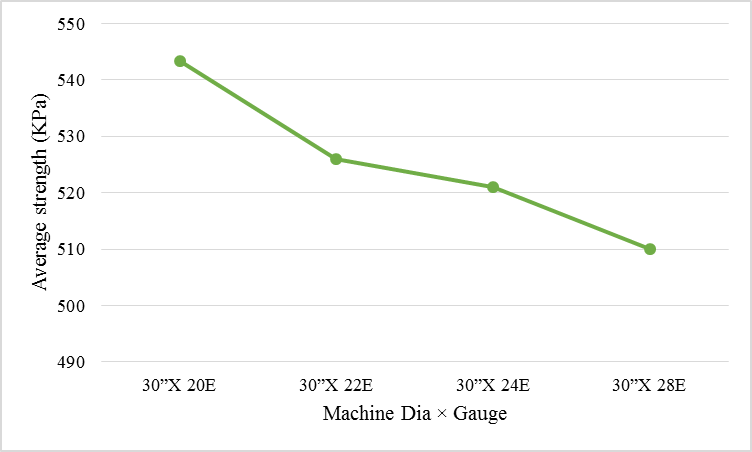

3.4. Effect on Fabric Bursting Strength

- From figure 4 it is seen that the more the gauge of the machine, the less the strength of the fabric is observed. The reason behind this is the option of relaxation for the low gauge machine fabric higher than the higher gauge knitting machine. So for more strength the lower gauge is prescribed for the same fabric.

| Figure 4. Effect on fabric strength on variation of machine gauge |

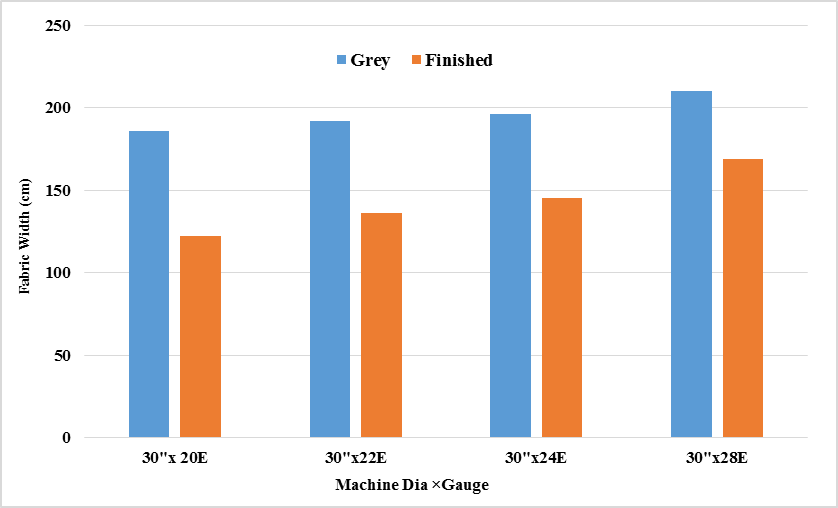

3.5. Effect on Fabric Spirality

- From the table 1 it is seen that spirality of knit fabric varies with the change of machine gauge. As the machine gauge increases, spirality also increases. Here number of feeder plays an important role as lower the value of it, lower the value of spirality in spite of increasing machine gauge.

|

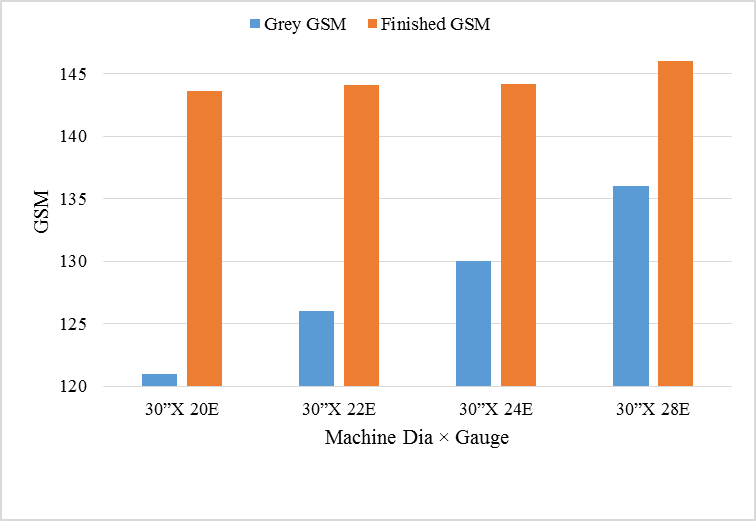

3.6. Effect on Fabric Pilling Formation

- From Table 2 the lower the gauge, the greater the looseness of the fabric and the distance between the wale is sometime more than the greater gauge fabric. So the fabric surface becomes rough which gives a poor result at pilling test.

|

4. Conclusions

- The Gauge of the knitting machine plays a vital role in most of the physical properties of the knitted fabrics. As about 80% of the garments production cost depends on the fabric cost. So to minimize the wastage of the fabric it is very important to know about the effect of gauge on the knitted fabric. Without the knowledge of the gauge effect on the knitted fabric there is huge probability of wastage in cutting section. Also it is responsible for the others properties of the knitted fabric like the shrinkage, spirality, strength etc. So before commencing the bulk production in knitting, the gauge of the knitting machine should be selected carefully by analysing the requirement of the fabric. For this purpose, this research project will be very helpful.

ACKNOWLEDGEMENTS

- We would like to express our cordial thanks to Engr. Mofizur Rahman, Assistant General Manager, Fabric Processing, SQUARE Fashions Ltd. For his kind permission we have done the experiment successfully. We are also grateful to all shift engineers, operators for their help for successful completion of the project.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML