-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

p-ISSN: 2325-0119 e-ISSN: 2325-0100

2014; 3(2): 33-37

doi:10.5923/j.textile.20140302.03

Process Modification of Denim Garments Dyeing with Fluorescent Dye

Muhammad Abdur Rashid 1, Md. Delwar Hossain 1, Md. Abdullahil Kafi 2, Sabina Yesmin 3

1Lecturer, Department of Textile Engineering, Dhaka University of Engineering & Technology, Gazipur-1700, Bangladesh

2Assistant Professor, Department of Textile Engineering, Dhaka University of Engineering & Technology, Gazipur-1700, Bangladesh

3Lecturer, Department of Textile engineering, People’s University of Bangladesh, Bangladesh

Correspondence to: Muhammad Abdur Rashid , Lecturer, Department of Textile Engineering, Dhaka University of Engineering & Technology, Gazipur-1700, Bangladesh.

| Email: |  |

Copyright © 2014 Scientific & Academic Publishing. All Rights Reserved.

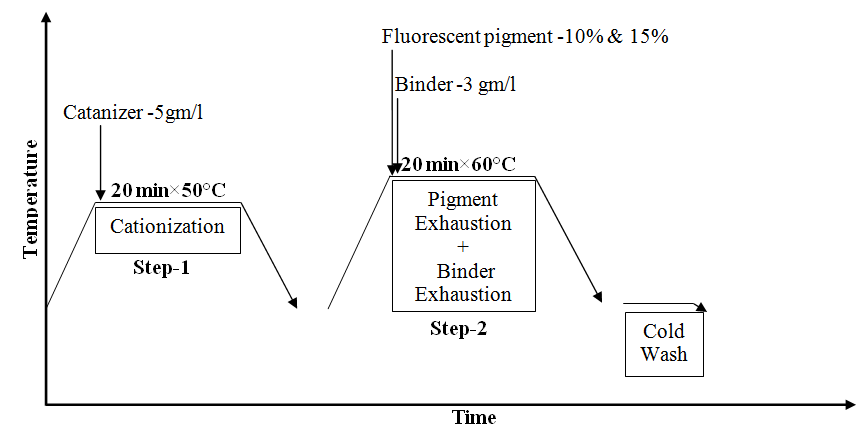

This study attempted to assess the existing process (3 steps) and modified process (2 steps) during dyeing of denim garments with fluorescent dye and compare between the effectiveness of these two processes of fluorescent dyeing in the textile industry. Here at first the grey denim samples were scoured & bleached. Then the samples were dyed in existing process i.e. through catanizing, dyeing and binding with 10% & 15% shades and dyed in modified process i.e. through catanizing and (dyeing with binding) with same shades. Then the properties of dyed samples have been studied. This study provides a set of experimental results, discussion and comparison between the two processes. Modified process shows better properties than existing process in most cases such as, CMC value is better (less than 1), k/s value, reflectance value was superior than existing process. Whiteness was as similar as existing process. Color fastness (wash, rubbing, perspiration) of the sample was improved than existing process. So the modified process will be more effectual than existing process of denim dyeing with fluorescent dyes in the textile industry.

Keywords: Fluorescent Dyestuff, Denim sample, Color fastness properties

Cite this paper: Muhammad Abdur Rashid , Md. Delwar Hossain , Md. Abdullahil Kafi , Sabina Yesmin , Process Modification of Denim Garments Dyeing with Fluorescent Dye, International Journal of Textile Science, Vol. 3 No. 2, 2014, pp. 33-37. doi: 10.5923/j.textile.20140302.03.

Article Outline

1. Introduction

- Asian countries especially Bangladesh is very suitable country in textile sector. Bangladesh is in 4th position in textile in world survey [1]. In our country mainly woven and knit samples are used in garments sector. Dyed sample or white samples are used in garments sector. Their almost all dye used in Bangladesh. Now a days the application of fluorescent dye for both woven and knitted samples are increasing day by day for its brilliance color appearance although the fastness properties are not so good. There are several very early reports of the usual fluorescent brilliance of certain dyes when applied to natural textile fiber, the most pronounced effect being obtained on silk. The greenish-yellow fluorescent and it’s orange to red halogenated derivatives (eosin) were among the dyes but there practical use was limited by inadequate fastness properties. The brilliant bluish red rhodamines were found to exhibit rather better fastness properties on textiles and they are the most important classes of fluorescent dyes for a wide range of application. The search for new fluorescent dyes for textile application gained impetus around the middle of this century from the introduction of synthetic fiber, notably polyester, nylon and acrylic. Around the same time, the development of daylight fluorescent pigment, which impart a vivid brilliance to a range of paint and printing ink providing a requirement for dyes with improved durability. Research aimed at producing new fluorescent dyes for use in the coloration of textile, coating and plastics has continued in recent years with the objectives of extending the available product shade range enhancing fluorescent intensity and improving other useful application properties such as light fastness and thermal stability. In addition several new applications have emerged which specifically exploit light emission properties of fluorescent dyes [2]. These functional applications include non-destructive flaw deletion, tunable dye lasers, solar collectors, liquid crystal displays and electroluminescent displays and the search for new dyes will appropriate properties for such uses appears to be continuing unabated. Techniques involving the use of specific fluorescent dyes are of immense importance in biological and medical research providing a useful Lolo in the search for new biologically active compounds and the potential for the development of new diagnostic methods [3]. Florescent dye is a chemical that contains a lot of property. Especially it is renowned for its special photo physical property. A lot of people are trying to implement this dye on textile field. TENCEL® (Lyocell) and other man-made cellulosic fibers using a fluorescent dye molecular probe [4]. Only TENCEL shows a significant difference between dried and never-dried fibers and it is mainly due to the structure of TENCEL. But if it is done on the other method it expects that it may bring an outstanding result. The use of hemi cyanine dyes to bring the effect that is similar to fluorescent effect [5]. The results showed that those dyed acrylic samples using hemi-cyanine dyes had obvious fluorescent effect in the spectra range 550–750 nm. But the effect that is brought by florescent is not same here. So it is possible to make an experiment by using fluorescent dye in the process reduction method that brings an effect in the spectra range 550–750 nm. An improvement in fastness to sublimation; washing and perspiration (both acidic and alkaline) were observed but there was no general improvement in light fastness compared with the parent compounds [6]. The fluorescent azo disperse dyes were applied on polyester fiber and they finally probe that it enhance various fastness property [7]. Another experiment was carried out on wool, silk and nylon with fluorescent acid azo dyes and obtained photo physical properties increased but no fastness property was noticed [8]. The maximum fluorescent reflectance would reach under acid medium dyeing (pH = 5), adding fluorescent brightener can obviously raise the reflectance [9]. At the same time other properties remain constant. So it would be very interesting if it is possible to increase other properties with the reflectance property. The experimental results show that more complete chromatogram of fluorescent acrylic yarn can be obtained with suitable proportion of mixed dyestuff in combination dyeing [10]. TF-920, a fluorescent whitening agent can further raise the fluorescence effect of acrylic yarn during one-bath process of whitening and dyeing. Thus by using this process it was possible to enhance the fluorescence effect but other property remains same. The purpose of this research is to reduce the process steps of fluorescent dyeing of denim garments without changing sample properties.

2. Materials and Methods

2.1. Materials

- The investigation has been carried out with100% cotton 3/1 twill denim sample. The yarn count was 7 s/1 carded yarn, the sample weight per unit area was 372 g/m2, EPI 68 and PPI 38 respectively. The sample was scoured and bleached by caustic soda and hydrogen per oxide in a single bath stage with the standard recipe [11]. Then the denim samples were dyed with fluorescent dye in various shade percentage.

2.2. Methods

2.2.1. Pretreatment Process

2.3. Dyeing Process

2.3.1. Existing Process

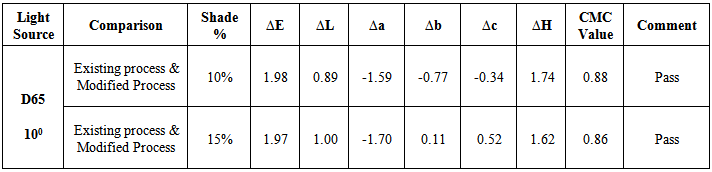

- The pretreated sample was treated with 5 gm/l catanizer (Cat MDN-96, Texodyes Company, Bangladesh) at 50°C temperature for 20 minutes in pH 8.5. Then the dye bath was prepared by 10% and 15% of fluorescent red, fluorescent yellow and fluorescent blue separately and combined in the liquor ratio 1:10. After catanizing, the sample was performed cold wash. Then the sample was added to each dye bath and dyeing was commenced 10 minutes at room temperature then raised temperature to 60°C for 20 minutes. The dyed sample was washed with cold water and treated with 3 gm/l binder for 5 minutes and finally cold wash at room temperature and then dried in oven (Figure 1).

| Figure 1. Existing Process of dyeing with Fluorescent pigment |

2.3.2. Modified Process

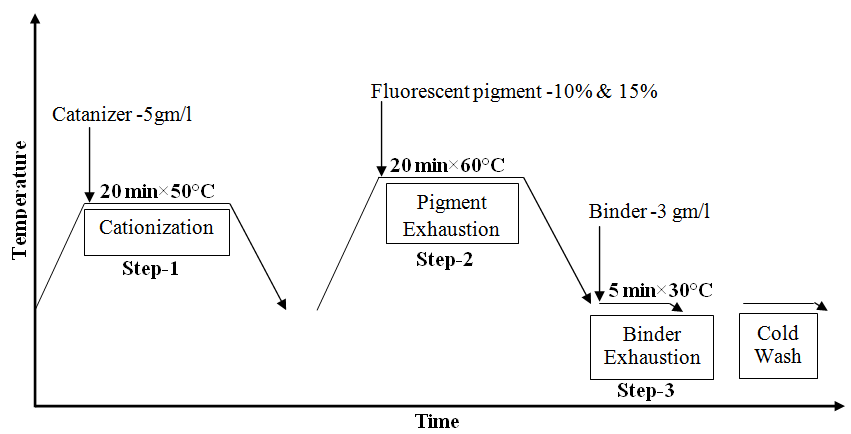

- The pretreated sample was treated with 5 gm/l catanizer (Cat MDN-96, Texodyes Company, Bangladesh) at 50°C temperature for 20 minutes in pH 8.5. Then the dye bath was prepared by 10% and 15% of fluorescent red, fluorescent yellow and fluorescent blue separately and combined in the liquor ratio 1:10. After catanizing, the sample was performed cold wash. Then the sample was added to each dye bath and dyeing was commenced 20 minutes at temperature 60°C with 3 gm/l binder. Finally the dyed sample was performed cold wash at room temperature and then dried in oven (Figure 2).

| Figure 2. Modified Process of dyeing with Fluorescent pigment |

2.3.3. Characterizing the Existing and Modified Fluorescent Dyed Denim Sample

- Treated all fluorescent dyed denim samples were conditioned in 65% RH and at 20°C for 24 hours before testing according to ASTM D1776 [13]. Shade matching was performed by data color machine. Dye yield capacity (k/s) of the sample was tested according to kubelka-munk theory by data color machine. Sample brightness test was also performed by data color machine. The values for color fastness were rated with a grey scale for color change and color staining according to AATCC test method 61 [14].

3. Result and Discussion

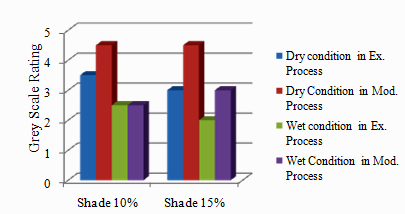

3.1. Color Fastness to Rubbing

- Colour fastness to rubbing assessment was done for both samples dyed by existing process and modified process. This test was designed to determine the degree of colour which may be transferred from the surface of a coloured sample to a specify test cloth for rubbing which could be dry and wet. The dyed sample was subjected to test fastness to rubbing. This test showed (Figure. 3) good rubbing fastness for 10% and 15% shade of modified process compared to existing process dyed of denim samples. Because the time for migration of dye was more in modified process. As a result dye fixation was better in modified process.

| Figure 3. Rubbing test result for existing and modified process |

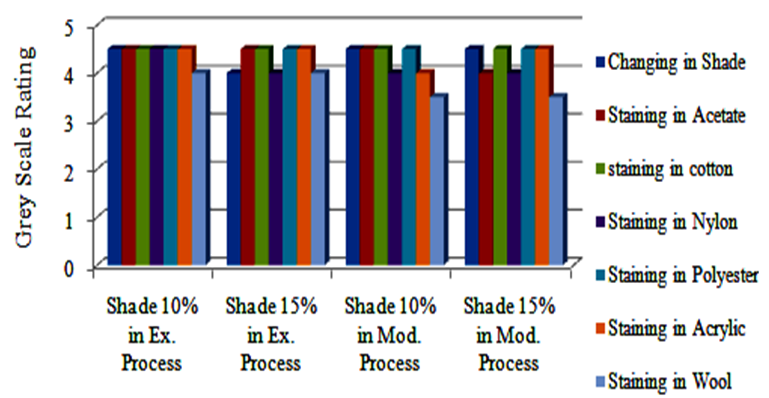

3.2. Color Fastness to Wash

- In this experiment color fastness to wash assessment was used for dyed sample both existing and modified process. The resistance of a material to change in any of its color characteristics, when subjected to washing is called color fastness to washing. In the test, change in color of the textile and also staining of color on the adjacent sample were assessed. Color fastness was usually assessed separately with respect to fading and staining. This test shows (Figure 4) good to excellent wash fastness for color changed and staining of the modified process compared to the existing process. Because the reaction of modified process has combined than the existing process.

| Figure 4. Color fastness to wash of existing and modified process |

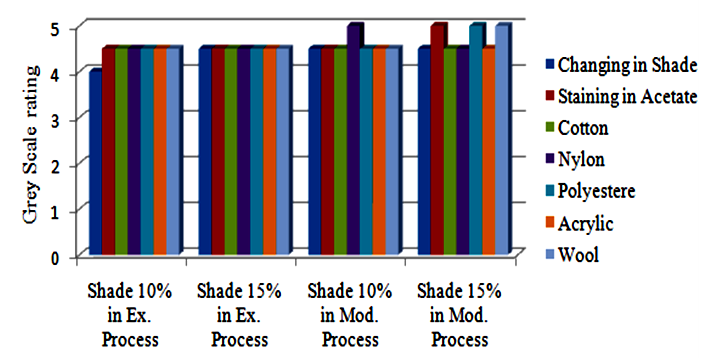

3.3. Color Fastness to Perspiration

- In this experiment color fastness to perspiration assessment was used for dyed samples both existing and modified process. The color fastness to perspiration test was carried out for two different shades as 10% and 15% for both existing and modified process. In modified process the result (Figure 5) shows better rating along with the existing process.

| Figure 5. Color fastness to perspiration of different shades |

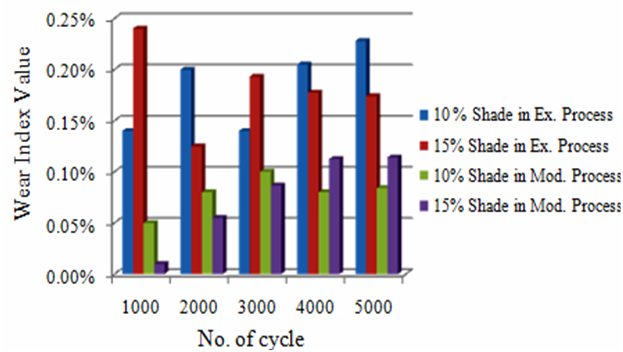

3.4. Evaluation of Wear Index

- In this experiment wear index assessment has been used for both dyed sample of existing and modified process. Abrasion of sample was done to assess the condition of sample depends upon the end use of it. The wear index of sample dyed by modified process shows (Figure.6) better result than existing process. The total number of cycle was 5000 for the test of wear index.

| Figure 6. Wear Index of existing and modified process |

|

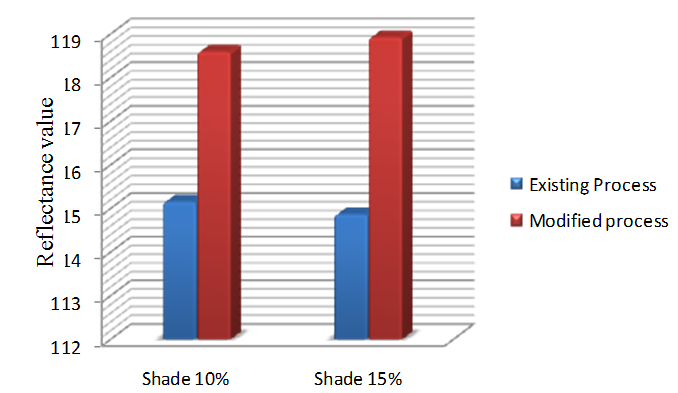

3.5. Reflectance Value

- The light reflectance value assessments were carried out for both processes. Considering the experimental results (Figure7) for reflectance, it was observed that the reflectance value was increased in modified process. So for the same shade of modified process will provide brighter shade compare to existing process.

| Figure 7. Reflectance value for different shade % in existing and modified processes |

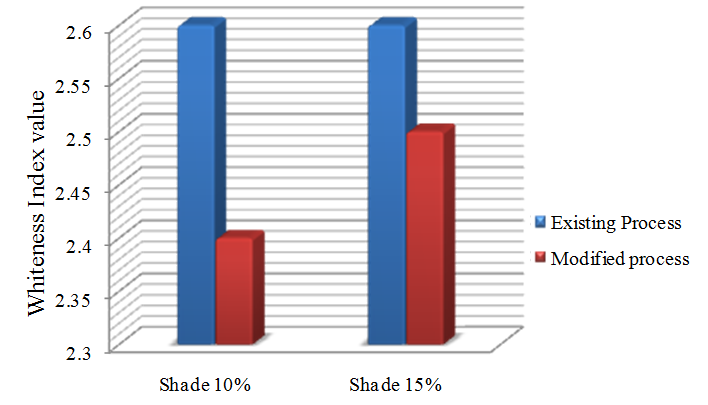

3.6. Whiteness Index

- In this project work whiteness index value assessment has been done for both samples dyed by existing process and modified process. The graphical representation of experimental result shows (Figure 8) that the whiteness index values are about more in existing process compared to modified process.

| Figure 8. Whiteness index for different shade% in existing and modified processes |

4. Conclusions

- In this research work the process optimization was done by using fluorescent dye of garments dyeing. The result shows that the fastness properties of modified process are better than the existing process. Optimization of the process parameter has been derived at which the result shows the better wear index value, color strength value (k/s) with color reflectance. It was also observed that the value of CMC less than 1 i.e. 0.88 and 0.86 of 10% and 15% shade respectively of existing and modified process.

References

| [1] | Dorpon Textiles Limited, source: EPB compiled by RDTI, [On line Available, 2013] |

| [2] | Gülümser, Tülay, Karagöz, Akçakoca Kumbasar, E. Perrin Erdem “A Research About Dyeing Of Cotton Fibers With Fluorescent Dyestuffs And Developing Light Fastness”, Tekstil Ve Konfeksiyon, 2008. |

| [3] | G. Cosa1, K.-S. Focsaneanu, J. R. N. McLean, J. P. McNamee and J. C. Scaiano, “Photophysical Properties of Fluorescent DNA-dyes Bound to Single- and Double-stranded DNA in Aqueous Buffered Solution”, Photochemistry and Photobiology, 2001, 73(6): 585–599. |

| [4] | Mohammad Abu-Rous, Ksenija Varga, Thomas Bechtold, Kurt Christian Schuster, “A new method to visualize and characterize the pore structure of TENCEL® (Lyocell) and other man-made cellulosic fibres using a fluorescent dye molecular probe” Article first published online: 23 JULY 2007. |

| [5] | Chuanxiang Qin, Ren-Cheng Tang, Bo Chen, Dawei Chen, Xiaomei Wang, Guoqiang Chen “Study on the dyeing properties of hemicyanine dyes. I. Acrylic samples, Fibers and polymers”, Springer Netherlands, Amsterdam, Netherlands, vol. 11, no. 2, pp. 193-198. |

| [6] | Robert M. Christie, Keith M. Morgan, M. Saiful Islam, “Molecular design and synthesis of N-arylsulfonated coumarin fluorescent dyes and their application to textiles” School of Textiles and Design, Scottish Borders Campus, Heriot-Watt University, Galashiels TD1 3HF, Scotland, UK. |

| [7] | Satam, Manjaree A, Raut, Rajesh K, Sekar, N, “Fluorescent azo disperse dye from 3-(1,3-benzothiazol-2-yl) naphthalen- 2-ol and comparison with 2-naphthol analogs”, Dyes and pigments, Vol. 96, No. 1, (2013), p.92-103. |

| [8] | Satam, Manjaree A, Raut, Rajesh K, Sekar, N, “Fluorescent acid azo dyes from 3-(1,3-benzothiazol-2-yl)naphthalen-2-ol and comparison with 2-naphthol analogs”, Dyes and pigments, Vol. 97, No. 1, (2013), p.32-42. |

| [9] | YANG Wen-fang, YANG Lu-jun, “Polyamide dyeing with fluorescent dye”, Tianjin Polytechnic University, Tianjin 300160, China. |

| [10] | WANG Lan, HU Liang (Key Laboratory of Advanced Textile Materials and Manufacturing Technology, Ministry of Education, Zhejiang Sci-Tech University, Hangzhou, Zhejiang 310018, China), “Combination dyeing and one-bath process of whitening and dyeing of fluorescent acrylic yarns”, Journal of Textile Research, 2008-06. |

| [11] | Panda H, “Proposed technology of textiles dyes & pigments”, National Institute of Industrial Research, Delhi-7, India, p. 247-253. |

| [12] | Trotman, E.R, M.B.E., “Dyeing and chemical technology of textile fibers”, London, Fourth edition, Charles Griffin & Company Ltd, 1970, p. 190-197. |

| [13] | Rashid, Muhammad Abdur, Md Delwar Hossain, Muhammad Mufidul Islam, and Md Nakib-Ul-Hasan. "Evaluation of Economical and Ecological Aspects of Denim Garments Dyeing with Fluorescent Dye." Journal of Materials Science and Chemical Engineering Vol. 01, No. 07, (2013), p.1-6. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML