Ichetaonye S. I1, Ichetaonye D. N1, Tenebe O. G2, Dim J. C2, Yibowei M. E3

1Department of Polymer and Textile Technology, Yaba College of Technology, Yaba, Lagos

2Department of Polymer and Textile Engineering, Federal University of Technology, Owerri

3Department of Materials and Metallurgical Engineering, University of Lagos, Akoka, Lagos

Correspondence to: Ichetaonye S. I, Department of Polymer and Textile Technology, Yaba College of Technology, Yaba, Lagos.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The comparative study of the influence of stitch length and fabric structure on the pilling, crease recovery and drape properties of 100% cotton, 50/50 and 67/33% polyester/cotton fabrics in interlock and single pique structures were studied. It was found that drape and fabric pilling increased with increase in stitch length and polyester content. The single pique fabric shows an improved performance for pilling, crease recovery and drape compared with interlock fabric.

Keywords:

Stitch, Interlock, Pique, Crease, Cotton, Polyester, Drape

Cite this paper: Ichetaonye S. I, Ichetaonye D. N, Tenebe O. G, Dim J. C, Yibowei M. E, The Effect of Yarn Composition and Stitch Length on Interlock Fabrics, International Journal of Textile Science, Vol. 2 No. 4, 2013, pp. 113-120. doi: 10.5923/j.textile.20130204.05.

1. Introduction

The frequent changes in fashion and requirements of the modern way of life, both at home or at work have presented the textile industry with the task of developing fabrics with better and improved washing performance characteristics such as ease of laundering, improved washing shrinkage, better pilling and other aesthetic properties. Expecting one type of fibre to provide all these qualities would be asking too much.The introduction of synthetic fibres opened a new field and made available properties not found in natural fibres[1]. The most important of these properties were high levels of crease recovery, strength and abrasion resistance as well as easy wash and dry procedures. Like the natural fibres, the synthetic fibres could not provide all the desirable textile properties. In fact they brought along with them their own problems such as harsh handle, static build-up, hydrophobic properties and discomfort in wear[2]. In order to obtain the require fabric performance the next stage is the development of blend fabrics where fibres are blended together in an attempt to capture the best properties of both fibres and to reduce their worst features. Many blends were attempted out of the desired properties and they soon began to find increasing market acceptance.For over eighteen years, the weaving sector of the textile industry has dominated the production of cotton / polyester blend fabrics, particularly in shirting materials on which some work has already been carried out. Perhaps, given a similar attention, some knitted cotton / polyester fabrics of certain composition, structures and tightness factors could be developed to compete in the areas of men’s shirting, women’s dress materials, T-shirts and sports wear[3][4].This research is therefore an attempt to study the interaction of yarn composition, fabric structure and tightness factor on knitted fabric properties such as pilling, crease recovery, drape, elastic recovery and washing relaxation shrinkage.

2. Experimental

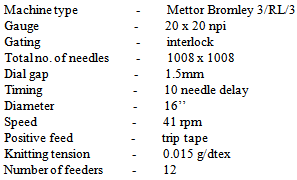

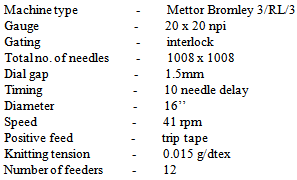

2.1. Machine and Knitting Details

2.2. Testing of Yarns

2.2.1. Composition

The analyses of the blends compositions were carried out by immersing a known weight of the dry fibre blend and stirring in 75% sulphuric acid for 20 minutes at room temperature, to dissolve out the cotton component. The polyester residue was then rinsed, bone dried, weighed and its proportion worked out.

2.2.2. Linear Density

The linear densities of the yarns were determined by reeling off a 100 meter hank of each yarn type on an automatic wrap reel. The hanks were dried and then weighed. Their appropriate regains were added and the weights in grams multiplied by 10 to obtain the linear densities in Tex. Three samples taken from three different cones of each yarn type were tested and the mean of the results taken.

2.2.3. Twist Test

Yarn twist analysis was based on 25 tests per yarn type using a 25cm (10’’) length of yarn and the twist-untwist method. The mean of the 25 tests for each yarn type was taken.

2.3. Tests for Fabrics

2.3.1. Relaxation and Conditioning

The knitted fabrics were laid flat for several days on the benches of the test laboratory of RH 65 ± 2% at 20 ± 2℃ to attain a dry – relaxed state before being subjecting to the various tests. This precautionary measure had to be taken because the state of relaxation of a fabric affects its properties.

2.3.2. Pilling

The pilling test for each fabric was carried out in ICI Pill Box. Four 5’’x 5’’ samples of each stitch length (2 in course direction, 2 in wale direction) were sewn and fitted round four rubber tubes. The cut ends were sealed with sellotape to prevent them from fraying and specimens pilled in the box which rotates at 60 rev/min for 5 hours.

2.3.3. Crease Recovery

Twelve rectangular specimen measuring 2 x 4 cm (six specimens with their short sides parallel to the wales and six with their short sides parallel to the course) were tested for each fabric on the Shirley crease recovery apparatus. The rectangular specimen was folded into halves and maintained in that state for three minutes under a load of 800 g/cm and between glass plates. The load was then removed and the sample transferred to the instrument with forceps. The grip was then rotated (keeping the free arm of the specimen hanging vertically) for three minutes and the crease angle read off.

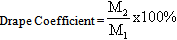

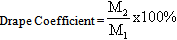

2.3.4. Drape

Two test specimens were cut out for each fabric using template B (30cm diameter) and the test carried out on the CUSICK DRAPE TESTER. Each test consists of draping the specimen with its face uppermost followed by alternative draping with its underside uppermost. This was repeated three times giving a total of six measurements on each specimen. The drawn shadow outline on the paper ring was cut out with scissors and the inner part of the ring weighed to the nearest 0.01g. The drape coefficient for each fabric was then calculated as follows: Where M1 is the total mass of the paper ring andM2 is the mass of the shaded area of the paper ring.

Where M1 is the total mass of the paper ring andM2 is the mass of the shaded area of the paper ring.

3. Results

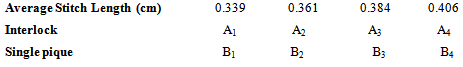

3.1. Fabric Code Numbers

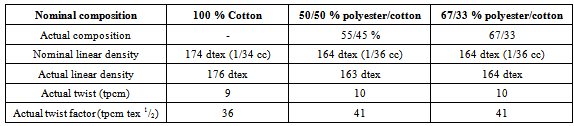

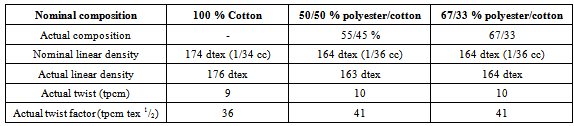

Table A. Yarn details

|

| |

|

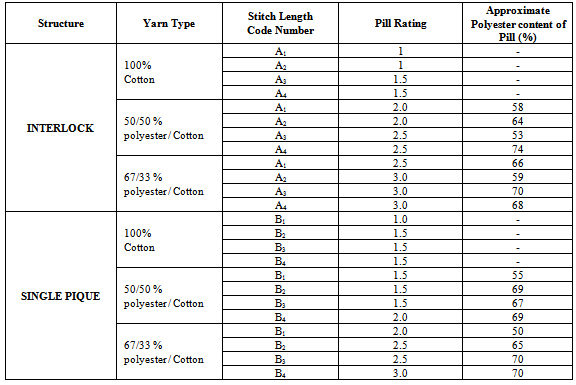

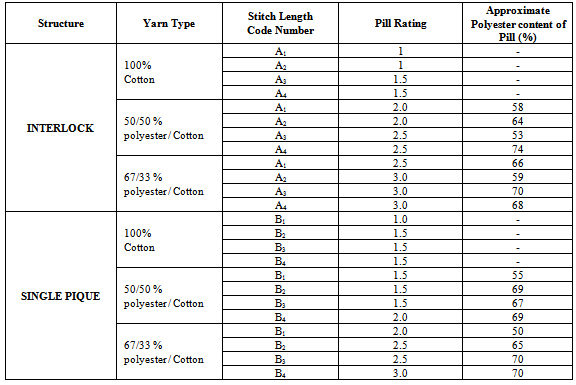

Table 1. Effect of Yarn Composition, Stitch Length and Fabric Structure on Pilling

|

| |

|

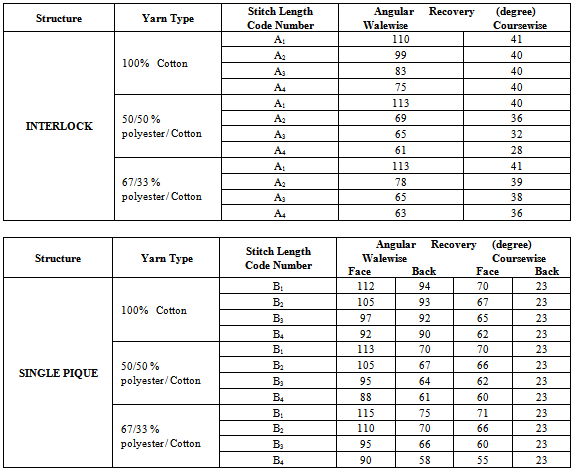

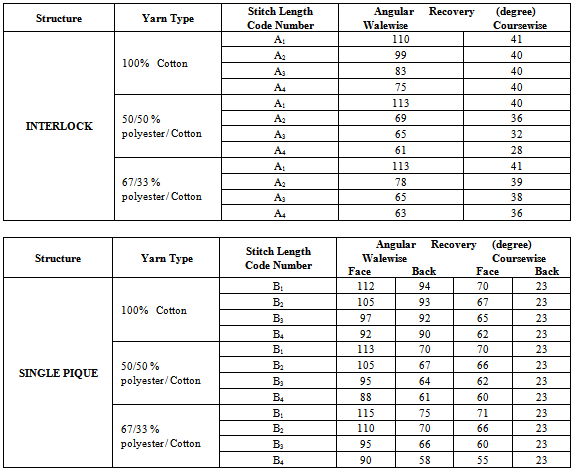

Table 2. Influence of Yarn Composition and Stitch Length on Crease Recovery

|

| |

|

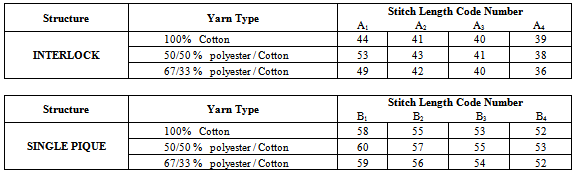

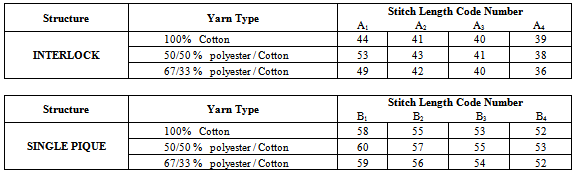

Table 3. Relationship between Yarn Composition, Stitch Length, Structure and Drape

|

| |

|

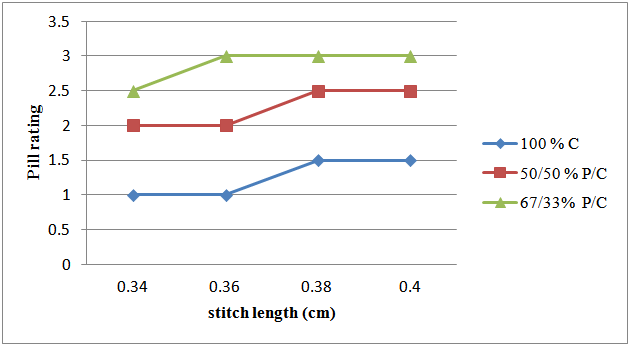

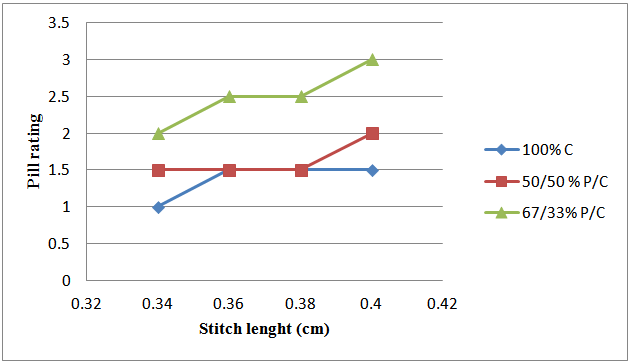

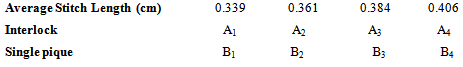

Graph 1INTERLOCK | Figure 1. The Dependence of Pilling on Stitch length |

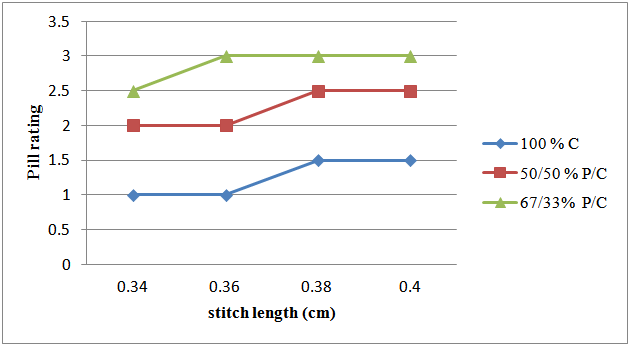

SINGLE PIQUE | Figure 2. The Dependence of Pilling on Stitch length |

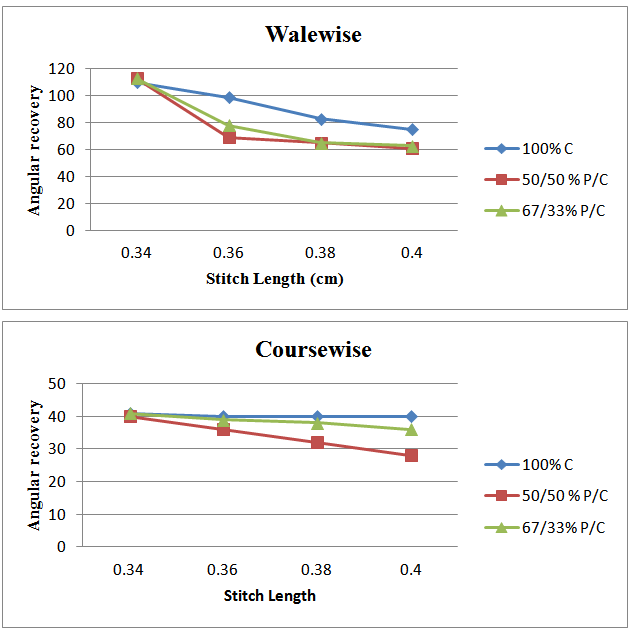

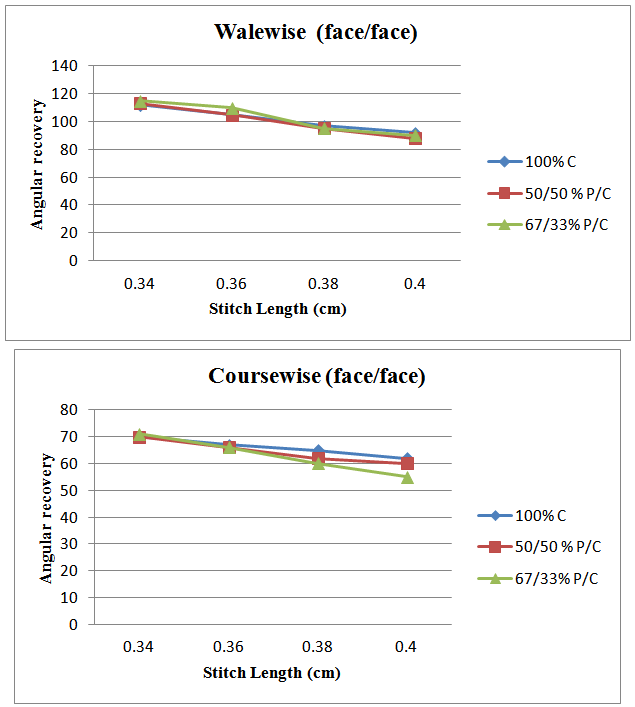

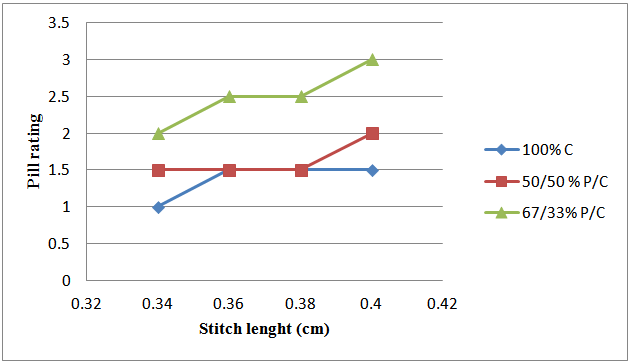

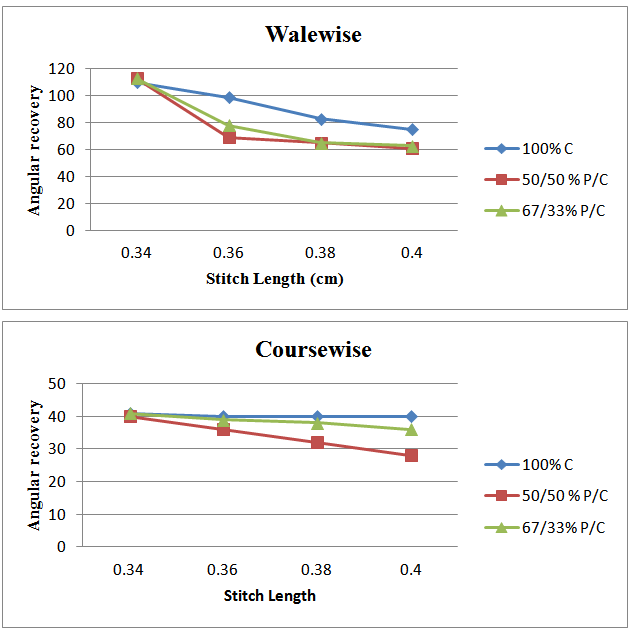

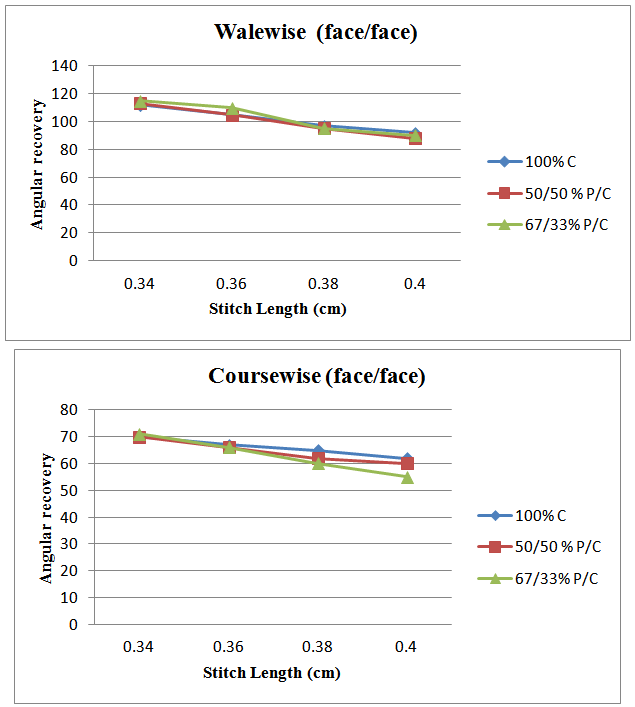

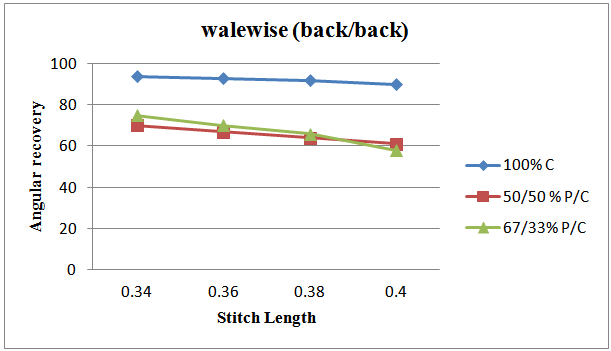

Graph 2INTERLOCK | Figure 3. The Effect of Yarn Composition and Stitch Length on Crease Recovery |

SINGLE PIQUE | Figure 4. The Effect of Yarn Composition and Stitch Length on Crease Recovery |

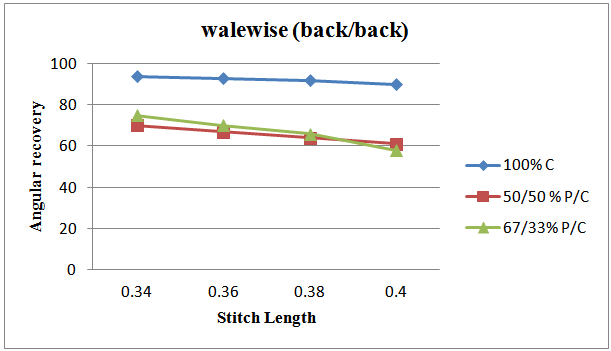

| Figure 5. The Effect of Yarn Composition and Stitch Length on Crease Recovery |

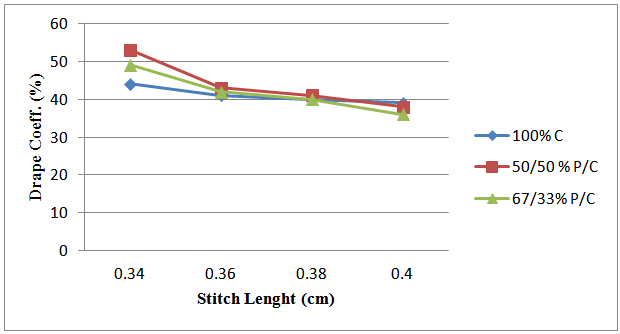

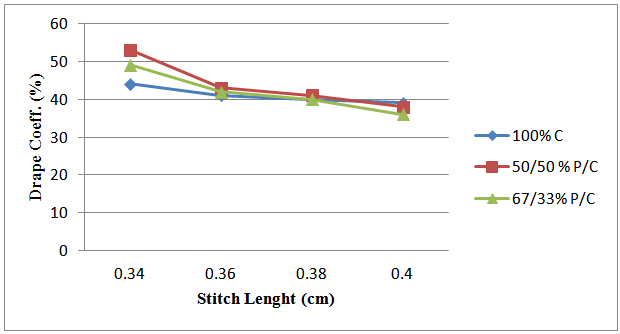

Graph 3INTERLOCK | Figure 6. The Relationship between Yarn Composition, Stitch Length and Drape |

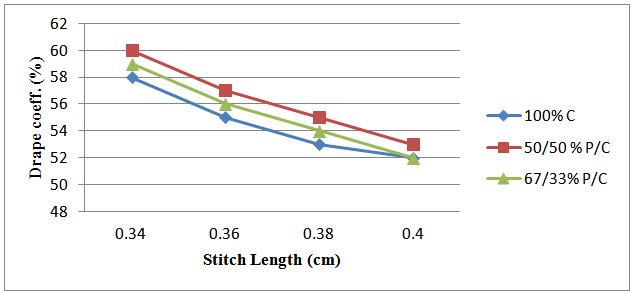

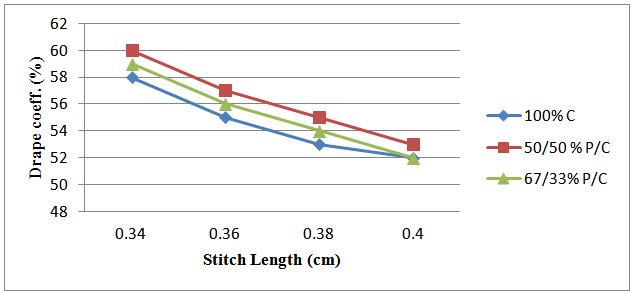

SINGLE PIQUE | Figure 7. The Relationship between Yarn Composition, Stitch Length and Drape |

4. Discussion

The 100% cotton fabrics in both interlock and single pique produced the least pills, their worst grade being 1.5 which is still an acceptable level of pilling. This level of result persisted in the single pique fabrics up to stitch length B3 of 50/50% polyester/cotton (Table 1). The introduction of polyester into the structure produced a dramatic increase in pilling particularly with interlock due to the high tensile strength of the synthetic fibres which enables them to anchor the pills to the main body of the fabric[8]. Microscopic examinations of the pills produced by the blended fabrics revealed that majority of the fibres in the pills were polyester. However, cotton fibres due to their convolutions have relatively higher coefficient of friction and are much more difficult to pull out of their yarns than polyester fibres whose higher flexural rigidity and lower coefficient of friction make them easier to pull out of their yarns onto fabric surface especially when in a blend with cotton. The higher the percentage of polyester in the blend, the greater the imbalance and the higher the tendency of the fabric to form pills[5][6].Furthermore, cellulosic materials crease badly and blends containing cellulosic fibres should be expected to crease to some extent. It has been claimed that synthetic materials resist creasing which implies that they resist deformation and are therefore rigid but a product which has the ability to recover from deformation as well as possessing some degree of crease resistance is what is required[7][10]. The fibre arrangement in the yarn and knitted structure all affect the crease resistance and recovery power of a fabric since the yarns used were spun on the same system and have roughly the same twist faster. The crease recovery results obtained here were due to mainly yarn type (composition), fabric tightness factor and structure. More so, the drape coefficient is dependent on its shear stiffness as well as the blending stiffness and weight (mass per unit area) of the fabric[9]. 100% cotton produced the least drape coefficient (DC) in both structures. The highest D.C results were produced by 50/50 polyester/cotton. 67/33% polyester/cotton results fell in between. This order is in accordance with the linear densities of the yarns and weight per unit area of the fabric (i.e. from Table A, 100% cotton – 176 dtex, 50/50% polyester/cotton – 163 dtex, 67/33% polyester/cotton – 164dtex). Based on stitch length, the results clearly show that an increase in stitch length produces a decrease in D.C. In other words, loosely knitted structure will tend to drape better than tightly knitted ones[11]. This follows since a loose fabric is more susceptible to deformation than a tight one. The relative position of graph nos. 3 (fig. 6 and 7) in relation to the D.C axis, indicate that interlock fabrics draped better (lower D.C) than single pique. This was obviously due to the tuck stitches in single pique which tends to stiffen the fabric and therefore increase the forces of deformation needed to drape it[13].

5. Conclusions

Pilling1. Pilling increased as polyester content of the blends increased and the majority of the fibres in the pills were polyester.2. As stitch length was increased pilling increased rapidly initially and less rapidly later.3. Interlock in general pilled more than single pique of similar tightness factor in the loose end of the tightness range.Crease Recovery1. The contribution to creasing of the polyester component of 50/50 and 67/33 polyester / cotton blends may not be as great as it has been commercially claimed.2. Tightly knitted constructions tend to recover better from wrinkles than loose ones of the same type.3. Tucking tends to improve fabric crease recovery.4. Knitted structures tend to recover better when creased along wale than course.Drape1. Interlock and single pique fabrics drape better as their polyester content increases.2. Loose interlock and single pique fabrics drape better than tight ones.3. Single pique fabrics are stiffer than interlock of the same tightness factor.

References

| [1] | D.L. Mundun. ‘‘The Geometry and Dimensional Properties of Plain Knit Fabrics,’’ Journal of the Textile Institute, vol. 50, p. 448. |

| [2] | N.J. Abbott. ‘‘The Relationship between fabric Structure and Ease of Care Performance of cotton Fabrics,’’ Textile Research Journal, 1964, vol. 34, p. 1049. |

| [3] | R. Tattersall. ‘‘Polyester Cotton Blend Fabrics,’’ Shirley Institute Publication, 1977, S26. |

| [4] | Z.M. Sudnik. ‘‘Effect of Weave and Composition on Dry Wrinkling of Woven Nylon 6.6 Shirting Fabrics,’’ Journal of the Textile Institute, vol. 57, p. 148. |

| [5] | T.S. Nutting and G.A. Leaf, ‘‘A Generalised Geometry of Weft-Knitted Fabrics,’’ Journal of the Textile Institute, 1964, vol. 55, p. 45. |

| [6] | J.W. Hearle, P. Grosberg, and S. Backer, ‘‘Structural Mechanism of Fibres and Yarns and Fabrics’’ vol. 1, p. 403. |

| [7] | J.W. Hearle, ‘‘Thermodynamics Relations among Stresses, Deformation and Moisture Absorption,’’ Textile Research Journal, 1957, vol. 27, p. 940. |

| [8] | P.V. Mehta, and K.B. Satish, ‘‘Managing Quality in the Apparel Industry,’’ New Delhi: National Institute of Fashion Technology and New Age International Publishers, 1998, P.110 ISBN 978-81-224-1166-9. |

| [9] | G.E. Cusick, ‘‘The Dependence of Fabric Drape on Bending and Shear Stiffness,’’ Journal of the Textile Institute, 1965, vol. 56, p. 596. |

| [10] | G. Susich, and S. Backer, ‘‘Tensile Recovery Behaviour of Textile Fibres,’’ Textile Research Journal, vol. 21, p. 482. |

| [11] | G.E. Cusick, ‘‘Objective Measurement of Fabric Drape: Practical Experience in the Laboratory,’’ Textile Institute and Industry, 1972, vol. 10, p. 14. |

| [12] | N. Richard, ‘‘Pilling of Plain-and Rib-Knit Wool Fabric,’’ Journal of the Textile Institute, 1962, vol. 53, p. 357. |

| [13] | C.C. Chu, M.M. Platt, and W.J. Hamburger, ‘‘An investigation of the Factors Affecting Drape-ability of Fabrics,’’ Textile Research Journal, 1960, vol. 30, p. 66. |

Where M1 is the total mass of the paper ring andM2 is the mass of the shaded area of the paper ring.

Where M1 is the total mass of the paper ring andM2 is the mass of the shaded area of the paper ring.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML