-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

2012; 1(3): 5-9

doi: 10.5923/j.textile.20120103.01

Aesthetic Finishes for Home Textile Materials

D. Vasanth Kumar, N. Boopathi, N. Karthick, P. Ramesh

Department of Fashion Technology, Angel College of Engineering and Technology, Tiruppur, 641 665, India

Correspondence to: D. Vasanth Kumar, Department of Fashion Technology, Angel College of Engineering and Technology, Tiruppur, 641 665, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

Fragrance finishing of textile materials has been greatly expanded and used in recent years. Fragrance finishing can be done effectively using exhaust method than any other methods. If the fabric is treated with fragrance agents which exhibits higher durability of functionality is estimated. Fragrance finishing can be done by means of lavender aroma with non-ionic binder. This paper examines the effects of fragrance finished aloe-vera and cotton fabrics. Finally both the fragranced finished fabrics were made into wall hangings and the ambiance of the room was evaluated by comparing various factors. In this investigation, factors such as fabric performance, durability of the fragrance and laundering properties of the treated fabrics were investigated. The fragrance finished fabrics can be used in home textile applications such as wall hangings, table covers, carpets and sofa covers.

Keywords: Fragrance Finishes, Cotton Fabric, Aloe-Vera Fabric, Lavender

Article Outline

1. Introduction

- Fragrance finishing of textiles is one of the processes which enhance the value of the product by adding various odours to it. The world marketplace is constantly changing and so the demand of consumers is also increased. Everyone desires for continuous change .i.e. something different and unique. This increase in demand, as well as tremendous competition in the market, opens up opportunities for value addition to all forms of textile materials[1]. The effective change has to be implemented in the market. By this extensive analysis, fragrance finishing is considered as emerging area and which has tumble-down the textile industry with lively value added finish by incorporating different fragrances into fabrics, leading to the production of fragranced fabrics[2].The uses of fragrance finished textile materials were diverse. By taking lavender odour as excellent for wall hangings, the odour of lavender was treated with cotton and aloe-vera fabrics. This proved a good way to meet important emotional and emotional needs, as well as those of a pure and sensorial nature[3, 4]. Interior textiles such as sheets, quilt-covers, curtains, carpets and bed gowns are suitable for the attachment of lavender, rose and sandal fragrances, which are good for fatigue and eliminate tiredness.

2. Materials

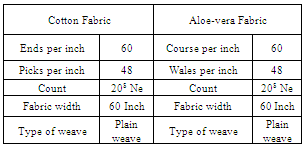

- Normally cotton fabrics can be used for fragrancenominated for fragrance finishing and the evaluation of various factors were completed. Subsequently both the fibres were plant fibres, grown organically and the materials are free from chemical substances. Thus 100% cotton and aloe-vera fabric is taken as the raw material for this fragrance finishing process.

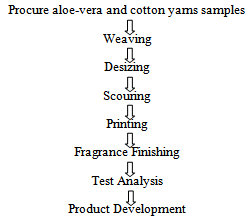

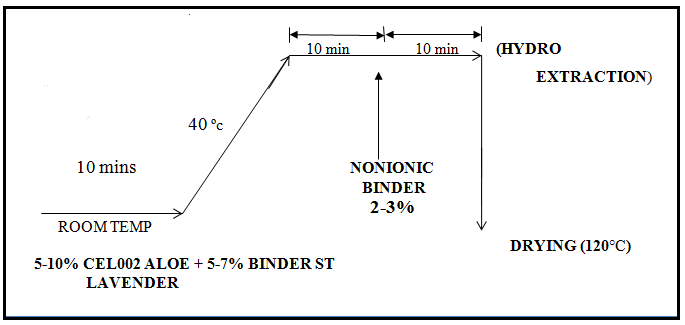

2.1. Process for Fragrance Finishing

|

2.2. Weaving

- In the weaving process, the fabric is woven by plain weave with 60 ends per inch (EPI), 48 Picks per inch (PPI) and the yarn count used is 20s Ne (100 % cotton and aloe-vera yarn).

2.3. Desizing

- Both the cotton and aloe-vera fabrics are treated with desizing process for removing starch size. The fabric is padded with malt extract enzyme (3-5%) at 60°C by using 1:20 material to liquor ratio with pH 6-7. Finally the material is washed, squeezed and dried.

|

2.4. Scouring

- After desizing the fabrics are treated with scouring process for remove the natural and added impurities present in fabric such as natural oils, wax, pectins, proteins, mineral matters, dirt etc. The fabric is treated with NaOH (2-3gm/l) and (2-3gm/l) non-ionic surfactant at 100°C for two hours by using 1: 20 material to liquor ratio with 12 pH. Finally the material is washed, squeezed and dried to get better absorbency.

2.5. Printing

- The fabrics are printed with pigment colours by using direct style roller printing machine. And the fabrics were dried at 100°C, cured at 150°C for 4 to 5 minutes. Finally the fabrics are washed with 2% non-ionic surfactant and dried.

3. Methodology

3.1. Fragrance Finishing

- Fragrance finishing is the process of imparting aroma in any textile substrate. This is done by exhaust method which means, fragrance agents is applied on both the cotton and aloe-vera fabrics with the help of binder. Lavender fragrance was taken as a flavour for this process.

|

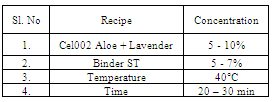

3.2. Preparation of Recipe

- The lavender fragrance agents with binder ST were formed by mixture solution containing alcohol and distilled water with ratio (1:3). The solution was emulsified with a high-speed mixer at a speed of about 10,000 rpm for 5 minutes. The emulsified system was transferred into a flask. The alcoholic fragrance solution was added into the emulsified solutions over 30 minutes, and stirred at a temperature of 40°C for 2 hours.

3.2. Finishing Process

- Fragrance finishing was given to the fabric by exhaustion method with 5-7% binder ST which is used as cross-linking agent. The fabrics were kept immersed in the solution containing lavender fragrance, (ML ratio – 1: 10) for 20-30 minutes at 40ºC in water bath. After finishing, the fabrics were removed, squeezed and dried at 100ºC in the oven for 5 minutes and then cured at 120 ºC for 2 minutes

| Figure 1. Fragrance Finishing Process |

4. Results and Discussions

- Tests and analysis are done to check the efficiency of the process that has been carried out. It helps in evaluating the success rate of any innovation. The testing process is done by carried out for 20 cycles in both fabrics to enable accurate evaluation of the study. The following tests were carried out to analyze the effectiveness of the fragrance finish and compared by the fastness properties of the fabric.

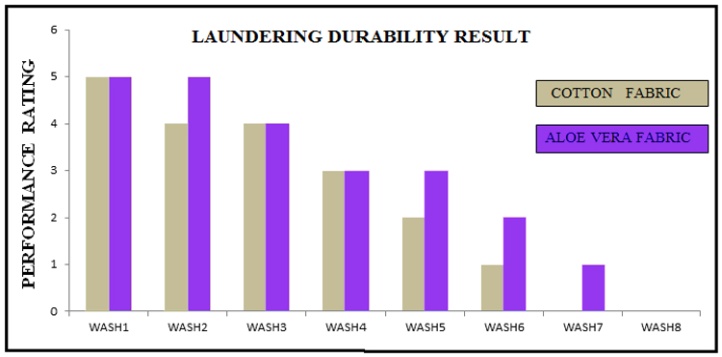

4.1. Laundering Durability Results

- Laundering durability was tested according to standard ISO 105-C06: 1987 using a detergent solution for 35 minutes at 40°C. Samples were rinsed with abundant water and air dried.

| Graph No.1. A Graphical Representation on Laundering Durability Results, Ratings: 5 - Excellent, 4 - Very Good, 3 - Good, 2 - Poor, 1 - Very Poor, 0 - No Fragrance |

4.1.1. Interpretation

- When comparing the laundering durability results of cotton and aloe-vera fabrics after 20 cycles, the aloe-vera fabric has better effect of fragrance upto 5 washes and the cotton fabric has better effect of fragrance upto 4 washes only. From the interpretation, it justifies that fragrance finished aloe-vera fabric has better laundering durability.

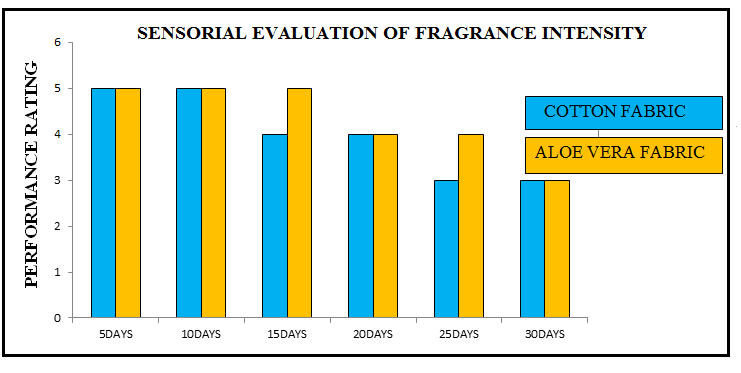

4.2. Sensorial Evaluation of Fragrance Intensity

- Treated fabrics were tested for the presence of fragrance before and after a wash cycle. Judges would use a finger nail to scratch the specimen and then smell the swatch. The rating required was a ‘5’, ‘4’, ‘3’, ‘2’, ‘1’, ‘0’ about fragrance intensity, correcting ‘5’ to maximum intensity and ‘0’ to non-detectable fragrance.

4.2.1. Interpretation

- When comparing the sensorial effect of fragrance intensity of both cotton and aloe-vera fabric, the aloe-vera fabric express common until 25days and the cotton fabric express common until 20 days. From the interpretation, it justifies that fragrance finished aloe-vera fabric has better sensorial effect of fragrance intensity.

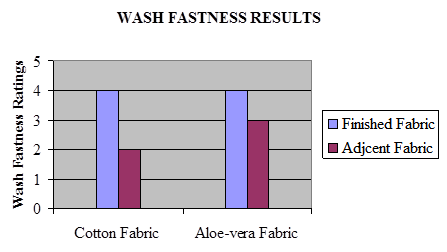

4.3. Washing Fastness Results

- The washing fastness test was based on AATCC 61-2A. A specimen of textile in contact with pieces of specified adjacent fabrics is mechanically agitated in detergent solution, rinsed and dried. The change in colour of the specimen and the staining of the adjacent fabrics are assessed with the standard grey scale.

| Graph No.3. A Graphical Representation of Washing Fastness, Ratings: 5 - Excellent, 4 - Very Good, 3 - Good, 2 - Poor, 1 - Very Poor, 0 - Poor |

4.3.1. Interpretation

- When comparing the washing fastness results of cotton and aloe-vera fabric, both fabric exhibits equal but adjacent fabrics staining rating is better for aloe-vera fabric than cotton. From the interpretation, it justifies that fragrance finished aloe-vera fabric has better adjacent fabrics staining rating than cotton fabric.

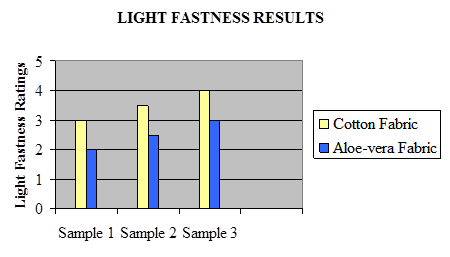

4.4. Light Fastness Results

- A specimen of the textile is exposed to the light from a xenon arc lamp of correlated colour temperature 5500°C to 6500°C. The fastness is assessed by comparing the fading of the specimen with that of the standards.

| Graph No.4. A Graphical Representation of Light Fastness, Ratings: 5 - Excellent, 4 - Very Good, 3 - Good, 2 - Poor, 1 - Very Poor, 0 - Poor |

4.4.1. Interpretation

- When comparing the light fastness rating of cotton and aloe-vera fabric, cotton fabric exhibits lighting fastness rating ranges from 3-4 and aloe-vera fabric exhibits 2-3. From the interpretation, it justifies that fragrance finished cotton fabric has slightly better light fastness rating than aloe-vera fabric.

4.5. Wick ability Results

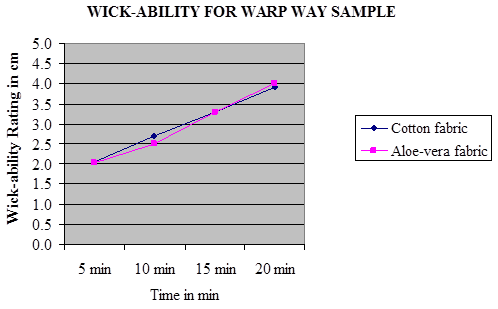

| Graph No.5. A Graphical Representation of wick-ability for warp way sample |

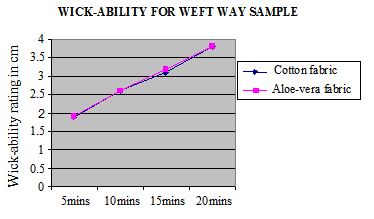

| Graph No.6. A Graphical Representation of wick-ability for weft way sample |

4.5.1. Interpretation

- When comparing the wick-ability results of cotton and aloe-vera fabric, both the fabrics have small variations in rating but the effect of wick-ability were good. From the interpretation, it justifies that wick-ability were good in both fabrics.

5. Conclusions

- Fragrance finish is the process by which textile materials are treated with the pleasant odours which yields better beneficial effects. The pleasant smells can be created by the essential oils have pharmacological effects like antibacterial, antifungal, antiviral, etc. and mood elevating effects. The fragrance of lavender proves good way to meet important psychological and emotional needs, as well as those of a purely physical and sensorial nature.Thus by comparing the laundering durability results, it justifies that fragrance finished aloe-vera fabric has better laundering durability. Comparing the sensorial effect of fragrance intensity, it justifies that fragrance finished aloe-vera fabric has better sensorial effect of fragrance intensity. Then based on the washing fastness results, it justifies that fragrance finished aloe-vera fabric has better adjacent fabrics staining rating than cotton fabric. Comparing the light fastness rating, it justifies that fragrance finished cotton fabric has slightly better light fastness rating than aloe-vera fabric. Based on the wick-ability results, it justifies that wick-ability were good for both fabrics.Finally based on the overall performance it is concluded that the fragrance finished aloe-vera fabric is better than cotton fabric for wall hanging (curtain) and in all home textile applications.

6. Product Development

- The finished fabric (both aloe-vera and cotton) has been developed into curtain (wall hangings) for home textiles applications. In other areas, household textiles such as sofa, covers, various product covers, table covers and floor mats as well as apparel items such as gloves, socks and ties may also be treated with fragrance and deodorizing finishes. The carpets can be finished with fragrances of different kinds and can be widely used in home textiles as well as in automotive textiles.

ACKNOWLEDGEMENTS

- We take great pleasure in expressing our heartfelt thanks to Management, Principal, Dean and Faculty members for extending their generous support.We express our sincere thanks to M/s. Resil Chemicals- Tirupur (Tamil Nadu), India for supporting us with sample chemicals which was a greater contribution for this work.We express our gratitude to M/s. Washtech, Tirupur (Tamil Nadu), India for their valuable support extended towards for finishing of the fabrics.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML