-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Textile Science

2012; 1(1): 1-6

doi: 10.5923/j.textile.20120101.01

New Azo Heterocyclic Disperse Dyes with Thiophene Moiety for Dyeing Polyester Fibers

Mohamed E. Khalifa 1, 2, Mohamed A. Metwally 3, Ehab Abdel-latif 3, Fathy A. Amer 3

1Department of Chemistry, Faculty of Science, Taif University, Taif 21974, Saudi Arabia

2Department of Chemical Engineering, Higher Institute for Engineering and Technology, New Damietta, Egypt

3Department of Chemistry, Faculty of Science,University of Mansoura, Mansoura, Egypt

Correspondence to: Mohamed A. Metwally , Department of Chemistry, Faculty of Science,University of Mansoura, Mansoura, Egypt.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

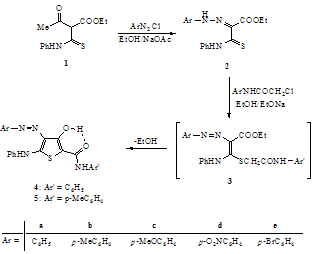

Heterocyclization of the highly versatile ethyl 2-arylhydrazono-2-phenylthiocarbamoyl acetate derivatives 2 with 2-chloro-N-aryl-acetamide reagents in the presence of sodium ethoxide furnished the corresponding 4-arylazo -3-hydroxythiophene dyes 4 and 5. These dyes were applied as disperse dyes for dyeing polyester fibers and their characteristics and fastness properties have been measured.

Keywords: Thiophene, 2-chloro-N-arylacetamide, diazonium salt, azo disperse dyes, polyester fibers, fastness properties

Cite this paper: Mohamed E. Khalifa , Mohamed A. Metwally , Ehab Abdel-latif , Fathy A. Amer , "New Azo Heterocyclic Disperse Dyes with Thiophene Moiety for Dyeing Polyester Fibers", International Journal of Textile Science, Vol. 1 No. 1, 2012, pp. 1-6. doi: 10.5923/j.textile.20120101.01.

Article Outline

1. Introduction

- A wider variety of thiophenes, prepared directly by the Gewald synthesis or after subsequent dramatization[1,2], was used to produce a range of yellow-red to green dyes [3,4]. An important commercial aspect of certain dyes is their sensitivity towards alkali, which can destroy the chromophore, allowing discharging or clearing without the need for reducing agents[5,6]. Not only does this property confer better fastness in tests employing alkaline washing liquors, but it also permits removal of any disperse dye cross-staining the cellulosic component of polyester- cotton/viscose blends with mild alkali, improving wet fastness, brightness and productivity[7]. Disperse dyes of azo benzo[b] thiophene derivatives had generally good colouration and fastness properties on polyester[8]. On the other hand, organic dyes containing thiophene[9] and alkyl substituted thiophene moiety were synthesized highly efficient dye-sensitized solar cell[10] which could be used in several applications using molecular engineering techniques[11]. Also in the area of electrooptical applications, azodyes containing thiophene moiety were used in development of materials for quadratic nonlinear optics, due to their large β value owing to lower resonance energy, therefore increasing the electron transmission between donor and acceptor groups[12].

2. Results and Discussion

2.1. Synthesis and Spectral Characteristics of 4-arylazo-3-hyd roxythiophene Dyes 4 and 5

- Treatment of ethyl α-pheny- lthiocarbamoylacetoacetate 1[13] with the appropriate aromatic diazonium salt in ethanol containing sodium acetate effected acetyl group cleavage (Japp-Klingmann reaction) with the formation of the corresponding thiocarbamoyl intermediates 2[14]. The versatile ethyl 2- arylhydrazono- 2-phenylthiocarbamoyl acetate derivatives 2 underwent heterocyclization with 2- chloro-N-aryl-acetamide reagents, namely chloro-N-phenyl- acetamide and chloro- N-(p-tolyl) -acetamide, in the presence of sodium ethoxide to furnish the corresponding 4-arylazo-3-hydroxythiophene dyes 4 and 5. The formation of thiophene derivatives 4 and 5 from the reaction of 2 with appropriate alkylating agent such as chloroacetamide derivatives seems to follow the sequence outlined in scheme 1

| Scheme 1. Synthesis of 5-anilino-4-arylazo-3-hydroxythiophene dyes 4 and 5. |

2.2. Absorption Spectral Characteristics

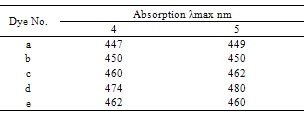

- The visible absorption data for the synthesized dyes were measured in chloroform and are listed in table 1.

|

2.3. Analysis of Dyeing Performance from Aqueous Dispersions

- This work describes the application of the synthesized compounds as new disperse dyes for dyeing polyester fibers where a range of bright color shades has been obtained as the visual color shades varied from yellow, golden yellow, orange, green, reddish brown to brown. Generally, variation in color of these dyes results from the alternation in the diazonium and coupling components. The performance is further examined by means of the following techniques:

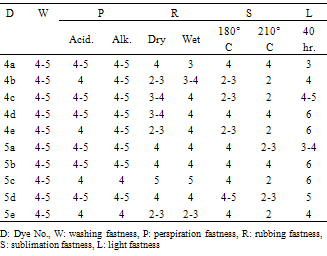

2.3.1. Color Fastness Evaluation

- The synthesized disperse dyes under investigation were applied to polyester fibers at 2% shade by high temperature- pressure technique (130℃), where they produced generally deep and bright hues, ranging from yellow to reddish brown. The dyes on polyester fibers were evaluated in terms of their fastness properties as shown in table 2.

|

|

|

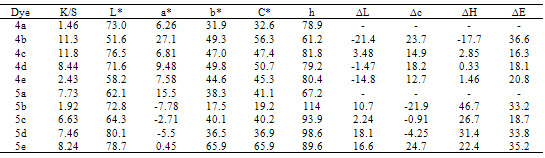

2.3.2. Color Difference Measurements

- The color parameters of the dyed polyester fibers were measured using the GretagMacbeth CE 7000a spectrophotometer and showed in table 3. The assessment of color-dyed fibers was made in terms of tristimulus colorimetry. The following CIELAB coordinates are measured, lightness (L*), chroma (C*), hue angle from 0º to 360º (h), (a*) value represents the degree of redness (positive) and greenness (negative) and (b*) represents the degree of yellowness (positive) and blueness (negative). A reflectance spectrophotometer (GretagMacbeth CE 7000a) was used for the colorimetric measurements on the dyed samples. K/S value given by the reflectance spectrometer is directly correlated with the dye concentration on the dye substrate according to the Kubelka–Munk equation: K/S = (1-R)2/2R, where K = absorbance coefficient, S = scattering coefficient, R = reflectance ratio.

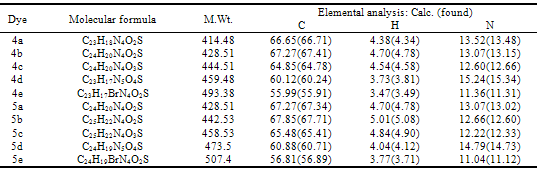

2.4. Characterization Data of Prepared Azo Dyes 4 and 5

- Microanalysis of the elements: carbon, hydrogen and nitrogen for the prepared azo dyes 4 and 5 were shown in table 4.

3. Conclusions

- A set of 10 disperse dyes 4 and 5 were synthesized by azo coupling. All of them were investigated for their dyeing characteristics on polyester fibers and showed good affinity to polyester fibers. These results are in line with the previously reported by Műller[15] on the effect of substituent in the dye structure and hue. The electronic absorption spectra give bright hues from yellow to brown on polyester fibers. The dyed fibers exhibit very good to excellent washing, perspiration and sublimation fastness properties with little variation in the good to excellent rubbing fastness. The remarkable degree of levelness and brightness after washing is indicative of good penetration and the excellent affinity of these dyes for polyester fiber. This in combination with the ease of preparation makes them particularly valuable.

4. Experimental

4.1. Materials and Instrumentation

- Microanalysis of the elements: carbon, hydrogen and nitrogen were determined at Microanalytical Laboratories, Faculty of Science, Mansoura, and . All melting points are in degree centigrade and are uncorrected. Infrared spectra were recorded on a Perkin Elmer 14 spectrophotometer using potassium bromide Waffer technique. 1H NMR spectra were measured on a Bruker WP 300 in CDCl3, DMSO or CF3COOD as solvent, using TMS as an internal standard. Mass spectra were recorded on a Finnigan MAT 212 instrument. The substrate used for dyeing (100% polyester fiber) was kindly provided by Misr Beida Dyers Company, , , a product of Misr For Synthetic Fibers Company, . All applications, fastness properties and color measurements of the dyes were studied in Laboratories and Reasearch sector in Misr Beida Dyers Company, . The colorimetric measurements for the dyed polyester fibers were carried out using a reflectance spectrophotometer (GretagMacbeth CE 7000a). Fastness to washing was carried out using the automatic launder Rotadyer (sponsored by the British Standard Institute – Society of Dyers and Colourists, fastness to perspiration was assessed according to the test sponsored by the (BSS), fastness to rubbing was carried out according to the standard method of testing (BSS) using Crockmeter of Electric Hungarian FD-17 type, fastness to sublimation was carried out using the Electric Japanese Thermotester T-10 type and fastness to light was carried out using the “Weather-o-meter” (Atlas Electric Devices Co. USA), AATCC standard test method.

4.2. Dyestuff Synthesis

- Compounds 1 and 2 were prepared according to Ref. [13,14]. Their analytical data agreed with the published work. Synthesis of 5-anilino-4-arylazo-3-hydroxythiophene dyes 4 and 5To a solution of 2 (0.005 mol) in ethanolic sodium ethoxide (prepared by dissolving 0.23 gm sodium metal in 30 ml absolute ethanol), the appropriate chloroacetamide derivatives (0.005 mol) was added. The reaction mixture was heated under reflux for 2 h. The reaction mixture was poured into cold water, neutralized with dilute HCl, and the solid product that formed was filtered off and recrystallized from ethanol or DMF-ethanol (1: 2) mixture to afford the corresponding thiophene dyes 4 and 5.4-(2-phenyldiazenyl)-3-hydroxy-N-phenyl-5-(phenylamino)thiophene-2-carboxamide (4a, C23H18N4O2S)Yield 40%; brown; M.p.: >265℃; IR (ν/cm-1): 3214, 3147 (NH and OH) and 1636 cm-1 (CO).4-(2-p-tolyldiazenyl)-3-hydroxy-N-phenyl-5-(phenylamino)thiophene-2-carboxamide (4b, C24H20N4O2S )Yield 80%; brown; M.p.: 238℃; IR (ν/cm-1): 3237, 3163 (NH and OH) and 1649 cm-1 (CO); 1H NMR (CDCl3/ CF3COOD): δ/ppm = 2.4 (s, 3H, CH3), 7.1-7.8 (m, 14H, Ar-H).4-(2-(4-methoxyphenyl)diazenyl)-3-hydroxy-N-phenyl-5-(phenylamino)thiophene-2-carboxamide (4c, C24H20N4O3S)Yield 82%; brown; M.p.: 160℃; IR (ν/cm-1): 3245, 3194 (NH and OH) and 1653 cm-1 (CO); 1H NMR (CDCl3/ CF3COOD): δ/ppm = 3.8 (s, 3H, CH3), 6.9-7.7 (m, 14H, Ar-H). 4-(2-(4-nitrophenyl)diazenyl)-3-hydroxy-N-phenyl-5-(phenylamino)thiophene-2-carboxamide (4d, C23H17N5O4S)Yield 23%; brown; M.p.: 175℃; IR (ν/cm-1): 3264, 3182 (NH and OH) and 1661 cm-1 (CO); EI- MS: m/z (%) = 459 (M+, 71). 4-(2-(4-bromophenyl)diazenyl)-3-hydroxy-N-phenyl-5-(phenylamino)thiophene-2-carboxamide (4e, C23H17BrN4O2S)Yield 30%; brown; M.p.: 135℃; IR (ν/cm-1): 3257, 3273 (NH and OH) and 1658 cm-1 (CO).4-(2-phenyldiazenyl)-3-hydroxy-5-(phenylamino)-N-p-tolylthiophene-2-carboxamide (5a, C24H20N4O2S)Yield 40%; brown; M.p.: >265℃; IR (ν/cm-1): 3222, 3151 (NH and OH) and 1661 cm-1 (CO).4-(2-p-tolyldiazenyl)-3-hydroxy-5-(phenylamino)-N-p-tolylthiophene-2-carboxamide (5b, C25H22N4O2S)Yield 82%; yellow; M.p.: 193℃; IR (ν/cm-1): 3255, 3167 (NH and OH) and 1664 cm-1 (CO); 1H NMR (DMSO): δ/ppm = 2.35 (s, 3H, CH3), 2.40 (s, 3H, CH3), 7.00-7.60 (m, 14H, Ar-H and CONH), 10.2 (s, 1H, NH), 11.1 (s, 1H, OH).4-(2-(4-methoxyphenyl)diazenyl)-3-hydroxy-5-(phenylamino)-N-p-tolylthiophene-2-carboxamide (5c, C25H22N4O3S)Yield 50%; orange; M.p.: 192℃; IR (ν/cm-1): 3248, 3158 (NH and OH) and 1662 cm-1 (CO); 1H NMR (DMSO): δ/ppm = 2.4 (s, 3H, CH3), 3.8 (s, 3H, CH3), 6.8-7.6 (m, 14H, Ar-H and CONH), 10.4 (s, 1H, NH), 11.2 (s, 1H, OH).4-(2-(4-nitrophenyl)diazenyl)-3-hydroxy-5-(phenylamino)-N-p-tolylthiophene-2-carboxamide (5d, C24H19N5O4S)Yield 27%; brown; M.p.: 153℃; IR (ν/cm-1): 3282, 3177 (NH and OH) and 1666 cm-1 (CO); EI- MS: m/z (%) = 473 (M+, 100).4-(2-(4-bromophenyl)diazenyl)-3-hydroxy-5-(phenylamino)-N-p-tolylthiophene-2-carboxamide (5e, C24H19BrN4O2S)Yield 32%; brown; M.p.: >265℃; IR (ν/cm-1): 3266, 3163 (NH and OH) and 1660 cm-1 (CO).

4.3. Dyeing and Fastness Determinations

4.3.1. Preparation of Dye Dispersion

- The required amount of the dye (2% shade) was dissolved in acetone and added dropwise with stirring to a solution of Setamol WS (0.5–1.5), an anionic dispersing agent of BASF (sodium salt of a condensation product of naphthalene sulfonic acid and formaldehyde).The dye was precipitated in a fine dispersion ready for use in dyeing after evaporation of the solvent by warming.

4.3.2. Dyeing Procedure

- The dye bath (1:20, good to dye liquor ratio) in a sealed stainless steel dye pots of 250 ml capacity in “Galvanin- Marino VI-Italy” dyeing machine. Additional dispersing agent (0.5-1.0 g/l) was added and the pH of the bath adjusted to 5.5 using glacial acetic acid. Dyeing carried out by raising the dye bath temperature from 20 to 130℃ at a rate of 3℃ /min and holding at this temperature for 60 min before rapidly cooling to 50℃ at 9.9℃/min. The dyed fibers was then rinsed with cold water, reduction-cleared using sodium hydroxide (2 g/l) and sodium hydrosulphite (1 g/l) and soaped with 2% nonionic detergent and ammonia (pH 8.5) at 50℃ for 30 minutes to improve washing fastness.

4.3.3. Color Fastness

4.3.3.1. Fastness to Washing

- A specimen of dyed polyester sample was stitched between two pieces of undyed cotton and polyester fabrics (10 cm 4 cm), all approximately of equal weight and then washed at 50℃. The staining on the white adjacent fabrics was assessed according to the international Grey scale [16,17], where 1 = poor, 2 = fair, 3 = moderate, 4 = good, 5 = excellent.

4.3.3.2. Fastness to Acid and Alkaline Perspiration

- The AATCC standard test method 15 –1960 was used. The acid solution (pH = 3.5) contained sodium chloride (10 g/l), lactic acid U.S.P 85% (1g/l), disodium orthophosphate anhydrous (1 g/l) and histidine monohydrochloride (0.25 g/l). The alkaline solution contained sodium chloride (10 g/l), ammonium carbonate (4 g/l), disodium orthophosphate anhydrous (1 g/l) and histidine monohydrochloride (0.25 g/l).A composite specimen was made from the dyed sample as a layer between undyed cotton and polyester fabrics as the same weight as the dyed sample, composite specimen was immersed in the perspiration solution for 30 minutes with occasional agitation and squeezing to insure complete wetting, then stitched between the plastic in such a way that the dyed sample will be in a vertical position when placed in the oven.The loaded sample was kept in an oven at 37℃ for 6–8 hours, so that fibers were dried by conventional means. The change in color of the dyed material and staining on the undyed adjacent fabrics was assessed according to the international Grey scale.

4.3.3.3. Fastness to Rubbing

- The dyed polyester fiber was placed on the base of crockmeter, so that it rested flat on the abrasive cloth with its long dimension in the direction of rubbing. A square of white testing cloth was mount over the end of the finger which protects downward on the dry specimen sliding back and forth twenty times by making ten complete turns of the crank at the rate of one turn per second. For wet rubbing test, the testing squares were thoroughly wet in distilled water and squeezed between filter papers through hand wringer under standard conditions. The rest of the procedure is the same as the dry crocking test. The staining on the white cloth was assessed according to the international Grey scale.

4.3.3.4. Fastness to Sublimation

- The fastness to sublimation was assessed according to ISO/R 10S/IV – Part 2. The dyed polyester fiber was stitched between two pieces of white polyester and cotton fabrics, all of equal length. The samples were treated at 185℃ and 210℃ for 30 seconds. After conditioning the sample for 16 hours, the change in color of the dyed sample and the staining of white ones were assessed according to the Grey scale.

4.3.3.5. Fastness to Light

- The tested samples and standard blue scales were exposed to the “Weather-o-meter” (Atlas Electric Devices Co. USA)[16,17]. The exposure of both was discontinued at one of the time indicated in AATCC standard of 5, 10, 20, 40, 80, 160, 320 and 640 hours, at which it shows just appreciable fading. In the present work the dyed fabrics were exposed to light for 40 hours, after which the fibers were allowed to lie in the dark at room temperature for about two hours in order to cool-off and regain normal moisture from air. The samples were viewed in the daylight fluorescent lamp.The changes in color were assessed according to the following scale ratings; (1-poor, 3-moderate, 5-good, and 8- very good) standard of AATCC.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML