-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Statistics and Applications

p-ISSN: 2168-5193 e-ISSN: 2168-5215

2018; 8(1): 18-22

doi:10.5923/j.statistics.20180801.03

Optimizing Profit in Lace Baking Industry Lafia with Linear Programming Model

Titilayo Dorcas Ailobhio 1, Alhaji Ismaila Sulaiman 2, Imam Akeyede 1

1Department of Mathematics, Federal University Lafia, Nigeria

2Department of Statistics, Nasarawa State University Keffi, Nigeria

Correspondence to: Titilayo Dorcas Ailobhio , Department of Mathematics, Federal University Lafia, Nigeria.

| Email: |  |

Copyright © 2018 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Linear programming, an operations research technique is widely used in finding solutions to complex managerial decision problems. However, many firms/enterprises in Nigeria make more use of the trial-and-error method. As such, firms at the Layout have been finding it difficult in allocating scarce resources in a manner that will ensure profit maximization or cost minimization. This study was carried out to seek and arrive at the optimal solution in Lace Baking Industry Lafia, Nigeria. Data were collected as extracts from the records of the Lace restaurant and confectionaries, on six types of bread packages adopted in the firm which include Family loaf (1kg), Fancy bread(1kg), Mini loaf(150g), Banana bread(800g), Coconut bread(900g), Fruit bread(1kg). A problem of this nature was identified as a linear programming problem, formulated in mathematical terms and solved using R statistical software. The solution obtained revealed that 1550 loaves of Family loaf and 4650 loaves of Mini loaf should be produced respectively while others should be ignored since their value is zero, in order for the company to achieve a maximum monthly profit of  558000. From the analysis, it was observed that Mini loaf, followed by Family loaf contributed objectively to the profit. Hence, more of Mini loaf and Family loaf are needed to be produced and sold in order to maximize the profit.

558000. From the analysis, it was observed that Mini loaf, followed by Family loaf contributed objectively to the profit. Hence, more of Mini loaf and Family loaf are needed to be produced and sold in order to maximize the profit.

Keywords: Lace Restaurants & Confessionary (LRC), Linear Programing Model, Maximization of Profit, Simplex Method

Cite this paper: Titilayo Dorcas Ailobhio , Alhaji Ismaila Sulaiman , Imam Akeyede , Optimizing Profit in Lace Baking Industry Lafia with Linear Programming Model, International Journal of Statistics and Applications, Vol. 8 No. 1, 2018, pp. 18-22. doi: 10.5923/j.statistics.20180801.03.

Article Outline

1. Introduction

- The aim of every organization, company or firm is to make profit as that is what guarantees its continuous existence and productivity. In this modern day, manufacturing industries at all levels are faced with the challenges of producing goods (cars, machines, clothes, breads etc.) of right quality, quantity and at right time and more especially at minimum cost (minimized cost) and maximum profit for their survival and growth. Thus, this demands an increase in productive efficiency of the industry. The aim of this work is to use linear programming (LP) as a mathematical model to optimize profit of manufacturing industries such as bread bakery industries, and to employ the use of R statistical software to carry out the analysis.Bread is a baked food produced from flour that is moistened, kneaded, proofed with the addition of yeast. Bread is a convenience food made from wheat flour derived from bread wheat, the technology of which dates back to the ancient Egyptians at about 4000BC. Other raw materials for bread making apart from wheat flour include sugar, baking fat, yeast, vegetable oil, salt and water. Hard wheat flour is used for bread making because of gas produced by yeast during proofing and baking [1]. The bakery production which has been increasing steadily in the country is among the largest processed food industries in Nigeria. From the two major and common bakery industries in Nigeria bread and biscuit account for about 82% of the total bakery products. The bakery industries in Nigeria comprise organized and unorganized sectors. The organized sector consists of large, medium and small scale manufacturers who produced packaged biscuits and bread. The unorganized sector consists of small bakery units, cottage and household-type manufacturing goods and distributing their goods in the surrounding areas. (World Bank, 1995 and BFW, 2005). Bakery products are manufactured from combinations of wheat or other flours, sugar, baking powder, condensed milk, salt, jelly, dry fruits, various essences and flavoring. Different type of bakery products can be classified as dry bakery products and moist bakery products. Dry bakery products include soft biscuits, hard biscuits, cookies, crackers, fancy biscuits and cream wafer biscuits. Moist bakery products include sweet bread, milk bread, masala bread, garlic bread, fruit bread, various types of buns, cakes, pastries, muffins etc. These products are available in various sizes, shapes and forms (Indian Food Industry, 2001; Beverage and Food World, 2005) [11]. Therefore, in this study we constructed a mathematical model that provides optimal solution for production output under normal operational environment. We highlighted the peculiarities of using linear programming technique at Lace Bread Enterprises and prove that the application of the technique in determining the profit maximization in enterprise would be more profitable than otherwise and give inference on how to allocate resources to ensure optimum profit.

2. Linear Programming Technique

- Linear programming (LP) can be defined as a mathematical technique for determining the best allocation of a firm’s limited resources to achieve optimum goal. It is also a mathematical technique used in Operation Research (OR) or Management Sciences to solve specific types of problems such as allocation, transportation and assignment problems that permits a choice or choices between alternative courses of action [2].The term “linear”, as stated by [3], implies proportionality, which means that the elements in a situation are so connected that they appear as straight line when graphed. While the “programming” indicates the solution method which can be carried out by an iterative process in which a researcher advances from one solution to better solution until a final solution is reached which cannot be improved upon. This final solution is termed the optimal solution of the LP problem. This work demonstrates the pragmatic use of linear programming methods in a manufacturing company in Lafia. Linear Programming being the most prominent or technique, it is designed for models with linear objective and constraint functions. A LP model can be designed and solved to determine the best course of action as in a product mix subject to the available constraints. Generally, the objective function may be of maximization of profit (which is the focus of this project) or minimization of costs or labor hours. Moreover, the model also consists of certain structural constraints which are set of conditions that the optimal solution should justify. Examples of the structural constraints include the raw material constraints, production time constraint, and skilled labour constraints to mention a few. An optimum solution is a solution that fulfills both the constraints of the problem and the set objective to be met. [4], worked on application of linear programming for optimal use of raw materials in bakery. The result they had showed that only 962 units of small loaf, 38 units of big loaf and 0 unit of giant loaf should be produced respectively in order to make a profit of

. [5], Applied linear programming in minimization of cost of animal feed since animal feed was identified as a major factor in the overall cost of animal production in order to maximize profits. [6] Worked on the optimizing profit with the linear programming model: A focus on Golden plastic industry limited, Enugu, 2012. The result they had showed that only 2 sizes of the total 8 ‘PVC’ pipes should be produced. The intention of this paper is therefore to determine the optimum production capacity Lace Bread and confessionary Lafia, Nigeria. [9] Used linear programming technique to obtain optimal production in a production line of Coca-Cola bottling company.

. [5], Applied linear programming in minimization of cost of animal feed since animal feed was identified as a major factor in the overall cost of animal production in order to maximize profits. [6] Worked on the optimizing profit with the linear programming model: A focus on Golden plastic industry limited, Enugu, 2012. The result they had showed that only 2 sizes of the total 8 ‘PVC’ pipes should be produced. The intention of this paper is therefore to determine the optimum production capacity Lace Bread and confessionary Lafia, Nigeria. [9] Used linear programming technique to obtain optimal production in a production line of Coca-Cola bottling company.3. Methodology and Data Analysis

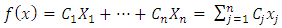

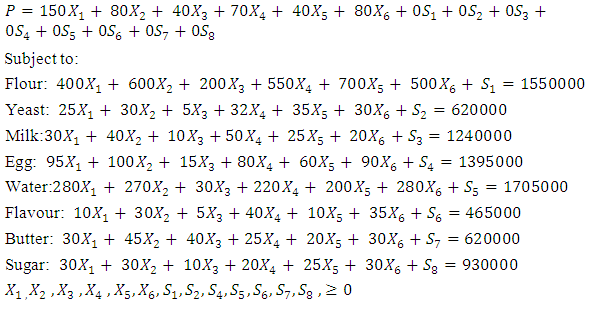

- Lace Food and Confectionaries is chosen for this study for two main reasons. First, it uses the trial-and-error method in arriving at major management decisions. Secondly, Lace Food and Confectionaries produces six different types of Bread which makes the determination of the quantity combinations of the products produced (product mix) an important and major management decision. The research is designed to cover a one month period, researchers have investigated the overall quantity combination of the six products produced by Lace Food and Confectionaries Lafia, during the research period and the allocation of resources to the various products. This has been made possible by the records kept by the Production Line Manager and the Sales Department relating to the different brands of products produced by the firm, the technical coefficients, the raw materials available and their relative prices. Researchers also had personal interview with a representative of the management.The study applied linear programming to determine a new quantity combination. The total contribution to profit of each of the products for the month using the new quantity will now be compared with the total profit contribution made by the former product mix determined by the trial-and-error method (see [8]).Linear program needs firstly to be presented in a general standard form to display all properties required of a linear programming problem. This consists of a linear objective function f(x) such that, if in general

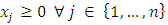

are real numbers, then the function f of real variables

are real numbers, then the function f of real variables  can be defined as:

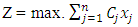

can be defined as: | (3.1) |

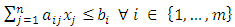

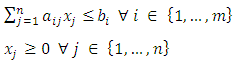

(linear constraint) and

(linear constraint) and  (non-negative constraint)Hence every linear program in the standard form can be generally presented as:

(non-negative constraint)Hence every linear program in the standard form can be generally presented as: Subject to

Subject to If

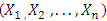

If  satisfy all the constraints of linear program, then the assignment of values to these variables are called a feasible solution of the linear program [10].

satisfy all the constraints of linear program, then the assignment of values to these variables are called a feasible solution of the linear program [10]. 4. Algorithm for Simplex Method

- i. Translate the problem into a linear programming model.ii. Setup the inequalities describing the problem in standard form iii. Convert the inequalities to equations adding slack/Surplus variables. iv. Enter the inequalities in a table for initial basic feasible solutions with all slack variables as basic variables. The table is called simplex table. v. Compute

values using

values using  where

where  is the coefficient of the slack/surplus variable (also known as basic variable) for variable j and

is the coefficient of the slack/surplus variable (also known as basic variable) for variable j and  Non-basic variable -

Non-basic variable -  column wise multiplication.vi. Determine the entering variable (key column) by choosing the one with the highest

column wise multiplication.vi. Determine the entering variable (key column) by choosing the one with the highest  . vii. Determine the key row (outgoing variable) by dividing the solution quantity values by their corresponding solution quantity values by their corresponding key column values and choosing the smallest positive quotient. viii. Identify the pivot element and compute the values of the key row by dividing all the numbers in the key row by the pivot element. Then change the product mix to the heading of the key column. ix. Compute the values of the other non-key rows x. Compute the value for the new

. vii. Determine the key row (outgoing variable) by dividing the solution quantity values by their corresponding solution quantity values by their corresponding key column values and choosing the smallest positive quotient. viii. Identify the pivot element and compute the values of the key row by dividing all the numbers in the key row by the pivot element. Then change the product mix to the heading of the key column. ix. Compute the values of the other non-key rows x. Compute the value for the new  and Z values for this solution. xi. If the column value in the

and Z values for this solution. xi. If the column value in the  row is positive, return to step (vi). If there is no positive

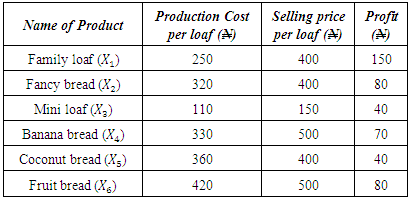

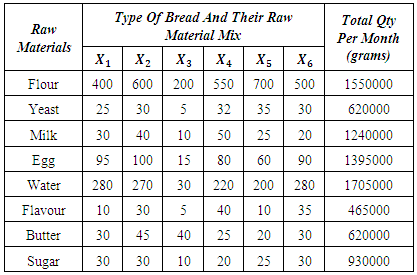

row is positive, return to step (vi). If there is no positive  , then the optimal solution has been reached. The data collected from Lace restaurant and confectionaries, Lafia on her main product line – record unit were analyzed to determine the exact type of bread that would yield maximum profit to the company. Below are the various types of bread produced by Lace Restaurants and Confectionaries.“Table 1” Presents the six different bread produced by the company, their production cost, selling price and profit. “Table 2” Present The Raw Materials used for the production of bread at Lace restaurant and confectionaries, The combinations of the quantities of these eight basic raw materials (raw material mix) for bread production per loaf (in grams), and the maximum quantity of each raw material held in stock for monthly production is also reported in the table. This information is used to determine the production cost (in terms of raw materials) per loaf of bread produced by the company. The data collected from Lace restaurant and confectionaries, Lafia on her main product line – record unit were analyzed to determine the exact type of bread that would yield maximum profit to the company.All the information provided in Tables 1 to 2 was used to form the linear programming model of the maximization type for the data as stated above.

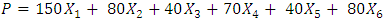

, then the optimal solution has been reached. The data collected from Lace restaurant and confectionaries, Lafia on her main product line – record unit were analyzed to determine the exact type of bread that would yield maximum profit to the company. Below are the various types of bread produced by Lace Restaurants and Confectionaries.“Table 1” Presents the six different bread produced by the company, their production cost, selling price and profit. “Table 2” Present The Raw Materials used for the production of bread at Lace restaurant and confectionaries, The combinations of the quantities of these eight basic raw materials (raw material mix) for bread production per loaf (in grams), and the maximum quantity of each raw material held in stock for monthly production is also reported in the table. This information is used to determine the production cost (in terms of raw materials) per loaf of bread produced by the company. The data collected from Lace restaurant and confectionaries, Lafia on her main product line – record unit were analyzed to determine the exact type of bread that would yield maximum profit to the company.All the information provided in Tables 1 to 2 was used to form the linear programming model of the maximization type for the data as stated above. P is the profit function that we seek to maximize, P stands for profit.

P is the profit function that we seek to maximize, P stands for profit.

|

|

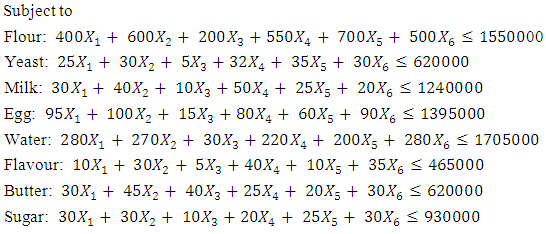

In order to represent the above LP model in canonical form, nine slack variables Si (i = 1, 2, 3, 4, 5, 6, 7, 8, 9) were introduced into the model. This changed the inequalities signs in the constraint aspect of the model to equality signs. A slack variable will account for the unused quantity of raw material (if any) it represents at end of the production. As a result, the above LP model becomes that of

In order to represent the above LP model in canonical form, nine slack variables Si (i = 1, 2, 3, 4, 5, 6, 7, 8, 9) were introduced into the model. This changed the inequalities signs in the constraint aspect of the model to equality signs. A slack variable will account for the unused quantity of raw material (if any) it represents at end of the production. As a result, the above LP model becomes that of  For the analysis, the Simplex method proposed by [7] George B. Dantzig (1947) as published in Dantzig (1963) was adopted to solve the above LP problem. The Simplex method has been found to be more efficient and convenient for computer software implementation in many instances [2] Yahya (2004). The initial tableau of the above LP model as used by Simplex algorithm an be see below, R statistical package was employed to fit the LP model using the ‘lpSolve’ library.

For the analysis, the Simplex method proposed by [7] George B. Dantzig (1947) as published in Dantzig (1963) was adopted to solve the above LP problem. The Simplex method has been found to be more efficient and convenient for computer software implementation in many instances [2] Yahya (2004). The initial tableau of the above LP model as used by Simplex algorithm an be see below, R statistical package was employed to fit the LP model using the ‘lpSolve’ library. 5. Results

- Results from the analysis carried out on the LP model using Simplex method, estimated the value of the objective function to be

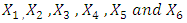

558000. The contributions of the Six decision variables

558000. The contributions of the Six decision variables  into the objective function are 1550, 0, 4650, 0, 0 and 0 respectively. This simply shows that only

into the objective function are 1550, 0, 4650, 0, 0 and 0 respectively. This simply shows that only  variables contributed meaningfully to improve the value of the objective function of the LP model.It is observed from the result’s output that the optimal solution to the linear programming model fitted here was attained at the first iteration. This simply shows the goodness of the structure of the data collected for analysis. From the results of the LP model, it is desirable for LRC Enterprise to concentrate more on

variables contributed meaningfully to improve the value of the objective function of the LP model.It is observed from the result’s output that the optimal solution to the linear programming model fitted here was attained at the first iteration. This simply shows the goodness of the structure of the data collected for analysis. From the results of the LP model, it is desirable for LRC Enterprise to concentrate more on  (Mini loaf) production. By this, total sales of about 1550 loaves of

(Mini loaf) production. By this, total sales of about 1550 loaves of  would be sold by the company per month. This would fetch the company an optimal profit of about

would be sold by the company per month. This would fetch the company an optimal profit of about  558000 per month based on the costs of raw materials and the capacity of the oven only. Hence it is expected of LRC to produce at least 50loaves of Family loaf and 150loaves of Mini loaf per day. The results of the LP model fitted to the data collected from LRC are only based on the cost of raw materials and oven capacity for bread production. Therefore, it is to note that if information on other elements of cost of production such as labour and time of process and other costs is available and incorporated into the LP model formulation and analysis, the results reported here might be remarkably different. Nonetheless, findings from this work could still serve as useful guides to the management of LRC in the formulation of production and marketing strategies for their product.

558000 per month based on the costs of raw materials and the capacity of the oven only. Hence it is expected of LRC to produce at least 50loaves of Family loaf and 150loaves of Mini loaf per day. The results of the LP model fitted to the data collected from LRC are only based on the cost of raw materials and oven capacity for bread production. Therefore, it is to note that if information on other elements of cost of production such as labour and time of process and other costs is available and incorporated into the LP model formulation and analysis, the results reported here might be remarkably different. Nonetheless, findings from this work could still serve as useful guides to the management of LRC in the formulation of production and marketing strategies for their product.6. Conclusions

- From the result, Lace Restaurant and Confectionaries should produce 1550 loaves of Family loaf and also produce 4650 loaves of Mini loaf per month, and stop presently to produce Fruit bread, Banana bread, Coconut bread and Fancy bread, because of their non-optimality to enable the company maximize profit. Other related companies should make used of the linear programming techniques in determining optimum expected profits of their products. Finally, it is also recommended that a statistical unit be created in the company so that qualified statisticians/ Mathematicians can be engaged to direct collection, compilation and subsequent storage of statistical data on the product produced/sold by the company. Because, sometimes important data are not kept, and this will affect the result of any statistical studies conducted on the data as well as invalidate the recommendations of such studies.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML