Shei Sayibu Baba1, Tuahiru Maahi2

1Department of Statistics, Faculty of Mathematical Sciences, University for Development Studies, Navrongo, Ghana

2Department of Statistics and Mathematics, School of Applied Science and Technology, Tamale Technical University, Ghana

Correspondence to: Shei Sayibu Baba, Department of Statistics, Faculty of Mathematical Sciences, University for Development Studies, Navrongo, Ghana.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

In this study, we propose a unified Cumulative Sum (CUSUM) control chart for monitoring simultaneous shifts in the parameters of the Pareto distribution. The V-mask method of constructing a CUSUM control chart was used. The characteristics of the V-mask were investigated and it was observed that the lead distance, the mask angle and the Average Run Length (ARL) of the CUSUM control chart changed considerably for a small shift in the parameters of the Pareto distribution.

Keywords:

Unified CUSUM, Run length, Lead distance, V-Mask and simultaneous

Cite this paper: Shei Sayibu Baba, Tuahiru Maahi, Unified Cumulative Sum Control Chart for Moniroring Shifts in the Parameters of the Pareto Distribution, International Journal of Statistics and Applications, Vol. 7 No. 3, 2017, pp. 170-177. doi: 10.5923/j.statistics.20170703.02.

1. Introduction

The quality of a product cannot be underestimated by both producers and consumers. Industry players therefore need a robust procedure to meet this desired quality and one of such procedures include the CUSUM control chart. The CUSUM control chart was proposed first by Page (1954) as a built up of the work done by Shewhart (1926). The Shewhart control charts are not able to detect a small to medium size shift in the process parameter. The CUSUM control chart has the tendency to detect this small to moderate size shift in the process parameter. Many researchers have studied enormously into the arena of CUSUM control charts. Notably among them include: Hawkins and Olwell (1998) stated that the CUSUM control charts are most sensitive Statistical Process Contol (SPC) to signal a persistent small step change in a process parameter. Also, Luguterah (2015) developed unified CUSUM control chart for monitoring simultaneous shifts in the parameters of the Elang-Truncated Exponential Distribution and therefore derived the parameters of the CUSUM chart proposed. Again, Naber and Bilgi (1994) developed a CUSUM control chart for the Gaussian distribution. Again, Kantam and Rao (2004) investigated the CUSUM control chart for the Log-Logistic Distribution and concluded that it was able to detect shifts on the average than the Shewhart control charts. Sasikumar and Bangusha (2014) explained the common uses of CUSUM control charts for monitoring performance overtime when the outcome is related to health science. The article provided a logical way to accumulate evidence over many patients, while adjusting for a changing mix of patients’ characteristics that significantly affected risk. Bakhodir (2004) employed CUSUM control chart in economic and finance turning point in stock price indices.Recently, Nasiru (2016) developed a one-sided CUSUM control chart for monitoring the shape parameter of the Pareto distribution.In this study, we extended the study of Nasiru (2016) and therefore develop a two-sided CUSUM control chart for monitoring shifts in the shape parameter of the Pareto distribution.

2. Pareto Distribution

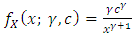

The Pareto distribution is lop-sided and a heavy-tailed distribution which was developed by the Italian economist and sociologist, Vilfredo Pareto (1848 – 1923). He worked in the field of national economy and sociology. The Pareto distribution is applied in modeling problems involving distributions of incomes or wealth and also many situations in which there will always be a shift in the equilibrium of the system.If the random variable X has a Pareto distribution, then the density function is given by; | (1) |

where  and the parameters

and the parameters  and

and  are the shape and scale parameters respectively. The corresponding cumulative distribution function is given by;

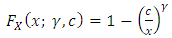

are the shape and scale parameters respectively. The corresponding cumulative distribution function is given by; | (2) |

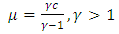

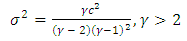

The mean and variance of the Pareto distribution are given by; | (3) |

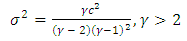

and | (4) |

respectively.

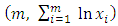

3. Sequential Probability Ratio Test

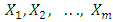

The Sequential Probability Ratio Test (SPRT) plays a significant role in the development of an acceptance sampling plan. The Wald’s (1947) SPRT is a joint, subject by subject, Likelihood Ratio Test (LRT). In this approach each subject constitutes a stage. According to Johnson (1961), the CUSUM control charts are roughly equivalent to the SPRT. The SPRT have been used extensively in the development of an acceptance sampling plan and this acceptance sampling plan is used in determining the in and out-of-control limits in CUSUM procedures.Suppose that we take a sample of m values  successively, from a population

successively, from a population  . Consider two hypotheses about

. Consider two hypotheses about  ,

,  and

and  . The ratio of the probabilities of the sample is;

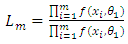

. The ratio of the probabilities of the sample is; | (5) |

We select two numbers A and B, which are related to the desired  and

and  errors. The sequential test is set up as follows;i. As long as

errors. The sequential test is set up as follows;i. As long as  we continue sampling.ii. At the first i that

we continue sampling.ii. At the first i that  we accept

we accept  .iii. At the first i that

.iii. At the first i that  we accept

we accept  .An equivalent way for computation is to use the logarithm of

.An equivalent way for computation is to use the logarithm of  . Then, the inequality becomes;

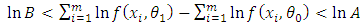

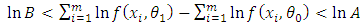

. Then, the inequality becomes; | (6) |

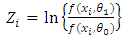

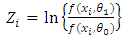

The family of test is referred to as SPRT. If  | (7) |

then the sampling terminates when | (8) |

or  | (9) |

The  are independent random variables with variance, say,

are independent random variables with variance, say,  . Obviously

. Obviously  has a variance

has a variance  . As

. As  increases the dispersion becomes greater and the probability that a value of

increases the dispersion becomes greater and the probability that a value of  will remain within the limits

will remain within the limits  and

and  tends to zero. The mean

tends to zero. The mean  tends to a normal distribution with variance

tends to a normal distribution with variance  and therefore the probability that it will fall between

and therefore the probability that it will fall between  and

and  tends to zero.If we take a sample for which

tends to zero.If we take a sample for which  lies between A and B for the first

lies between A and B for the first  trial and then

trial and then  at the

at the  trial, so we accept

trial, so we accept  (and reject

(and reject  ). By definition, the probability of getting such a sample is at least A times as large under

). By definition, the probability of getting such a sample is at least A times as large under  as against

as against  . The probability that we fail to reject

. The probability that we fail to reject  when

when  is true is

is true is  and the probability that we reject

and the probability that we reject  when

when  is true is

is true is  . Therefore

. Therefore | (10) |

Similarly, if we accept

| (11) |

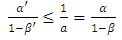

Wald (1947) showed that for all practical purposes (10) and (11) holds as equalities. Thus | (12) |

and | (13) |

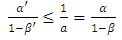

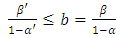

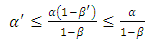

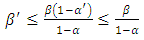

Suppose that  and

and  and that the true errors of first and second kind for the limits

and that the true errors of first and second kind for the limits  and

and  are

are  and

and  respectively. Then, from (10)

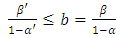

respectively. Then, from (10) | (14) |

and from (11) | (15) |

Therefore | (16) |

and | (17) |

Furthermore | (18) |

In practice  and

and  are small. From (16) and (17), the amount that

are small. From (16) and (17), the amount that  can exceed

can exceed  or

or  exceed

exceed  is negligible. In addition, from relation (18) we see that either

is negligible. In addition, from relation (18) we see that either  or

or  . Therefore the use of

. Therefore the use of  and

and  can only increase one of the errors and only by a very small amount

can only increase one of the errors and only by a very small amount

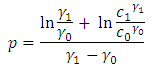

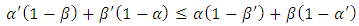

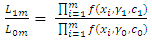

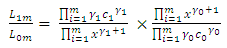

4. CUSUM Control Chart for Monitoring the Shape (γ) and Scale Parameters (c)

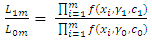

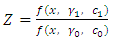

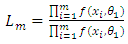

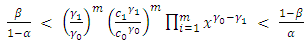

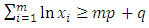

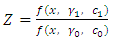

In this section a unified CUSUM chart for monitoring both the scale and shape parameters of the Pareto distribution was constructed. The likelihood ratio test of the null hypothesis which says that there is no shift in the parameters of the Pareto distribution against the alternative that there is a shift in the parameters of the Pareto distribution is given as follows: | (19) |

| (20) |

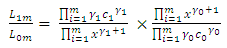

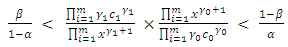

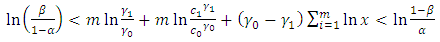

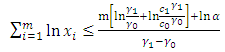

The continuation region of the SPRT that discriminates between the two hypotheses is given by | (21) |

which becomes | (22) |

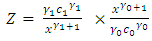

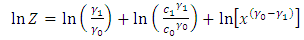

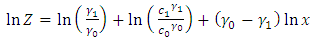

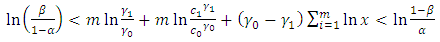

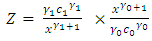

taking natural logarithm of both sides of (23) | (23) |

Bearing in mind that the mean and variance of the Pareto distribution, any shift in the parameters affects these two moments. Let  and

and  be the target values, let also

be the target values, let also  and

and  be the changed values owing to the shift in the parameters. The SPRT will be stopped by rejecting or accepting the null hypothesis or continue to sample, as

be the changed values owing to the shift in the parameters. The SPRT will be stopped by rejecting or accepting the null hypothesis or continue to sample, as  is outside or between

is outside or between  and

and  . The process stops by rejecting

. The process stops by rejecting  if

if  ; this gives a rejection line

; this gives a rejection line  and

and  . Similarly, if we make use of SPRT with the same strength to the cases

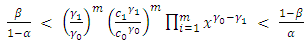

. Similarly, if we make use of SPRT with the same strength to the cases  and

and  , where

, where  , then another rejection line is determined. These two rejection lines indicates a symmetrical nature of masking. The observations in the sample enter the mask in a sequential way. Thus, the mask for the CUSUM chart for

, then another rejection line is determined. These two rejection lines indicates a symmetrical nature of masking. The observations in the sample enter the mask in a sequential way. Thus, the mask for the CUSUM chart for  is

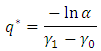

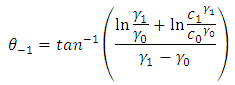

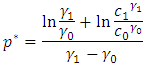

is | (24) |

This implies  | (25) |

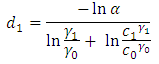

where and

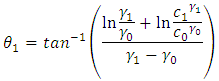

and Similarly, the rejection line, when

Similarly, the rejection line, when  , is given by

, is given by | (26) |

which can be expressed as | (27) |

where and

and Equations (26) and (28) form the regions above and below the plane

Equations (26) and (28) form the regions above and below the plane  . If m is allowed sequentially, at some stage,

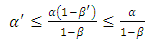

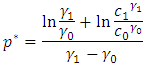

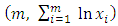

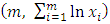

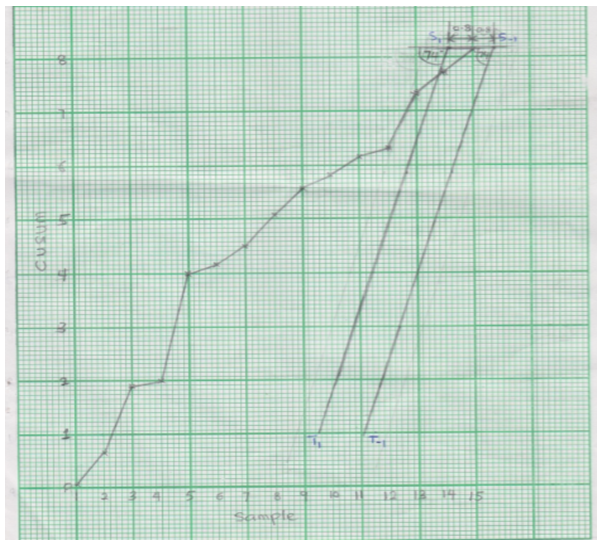

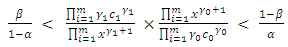

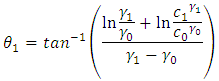

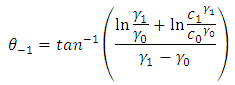

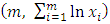

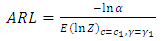

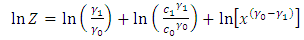

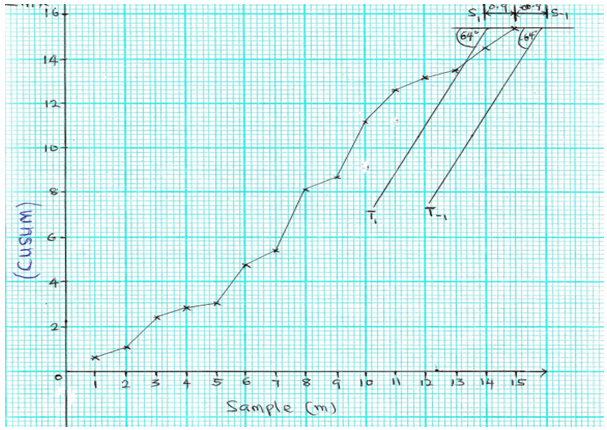

. If m is allowed sequentially, at some stage,  satisfies either (26) or (28). Until this is achieved the process continues.Using the slopes of the two lines (equations (26) and (28)), the parameters of the CUSUM chart, known as the angle of the mask and the lead distance, are obtained. From Figure 1,

satisfies either (26) or (28). Until this is achieved the process continues.Using the slopes of the two lines (equations (26) and (28)), the parameters of the CUSUM chart, known as the angle of the mask and the lead distance, are obtained. From Figure 1,  slope of the line

slope of the line  and

and  slope of the line

slope of the line  , hence

, hence  where

where  and

and  .And

.And  where

where  and

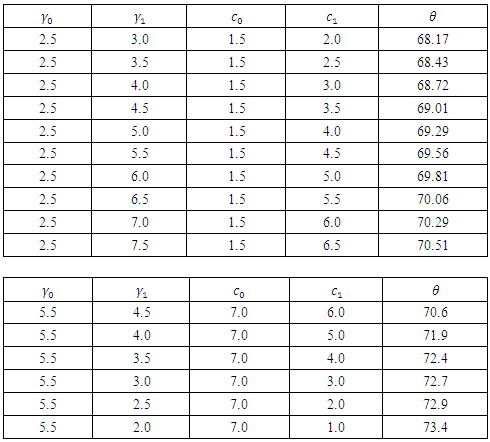

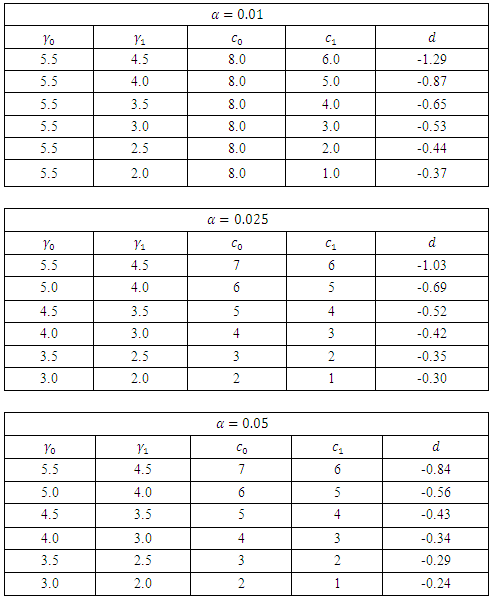

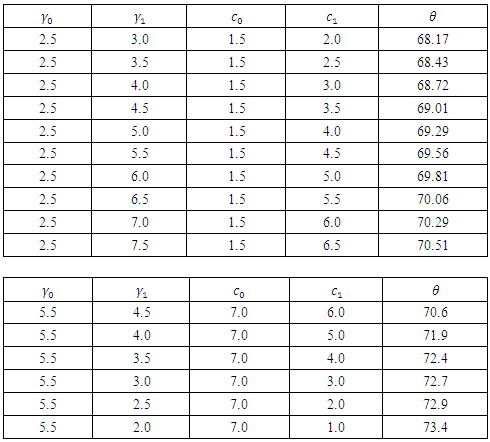

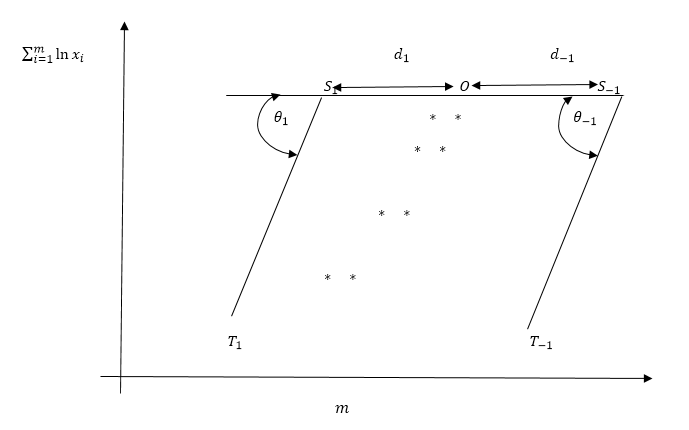

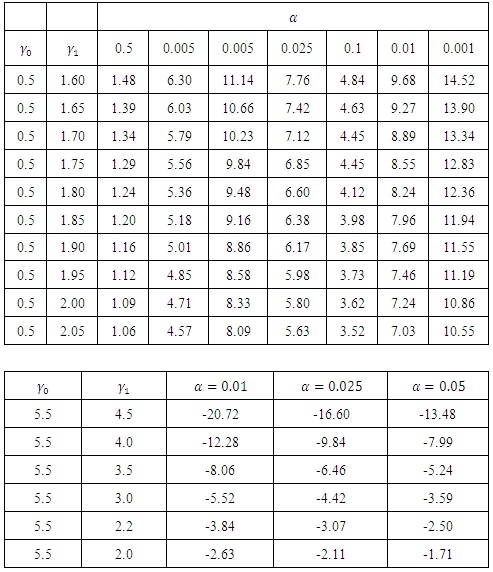

and  .Various values of the angle are shown in Table 1. It was obvious from the results that as the values of

.Various values of the angle are shown in Table 1. It was obvious from the results that as the values of  and

and  increase the value of the angle increases. Also increasing values of

increase the value of the angle increases. Also increasing values of  and

and  also increase the angle of the mask.

also increase the angle of the mask. Table 1. Values of the angle θ for controlling both γ and c

|

| |

|

When there is a negative shift in both parameters, that is where  and

and  , it can be established from the second table of Table 1 that the mask angle

, it can be established from the second table of Table 1 that the mask angle  increases as the values of

increases as the values of  and

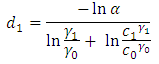

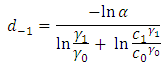

and  decreases.The lead distance

decreases.The lead distance  is given by

is given by  where

where  and

and  and the lead distance

and the lead distance  is given by

is given by where

where  and

and  .Let

.Let  be a sample from Pareto distribution, if the points

be a sample from Pareto distribution, if the points  are plotted with a suitable scale, then the ordinates of the points represent the cumulative sum of the data. Equations (26) and (28) are the effects of a shift in the population parameters

are plotted with a suitable scale, then the ordinates of the points represent the cumulative sum of the data. Equations (26) and (28) are the effects of a shift in the population parameters  and

and  . Figure 1 shows a sizable shift in the parameters if

. Figure 1 shows a sizable shift in the parameters if  falls outside the lines

falls outside the lines  and

and  . The chart is interpreted by placing the mask over the last plotted point as shown in Figure 1. If any of the points lies below

. The chart is interpreted by placing the mask over the last plotted point as shown in Figure 1. If any of the points lies below  , then it indicates a decrease in

, then it indicates a decrease in  and

and  and if any of the points falls above

and if any of the points falls above  , then it shows an increase in

, then it shows an increase in  and

and  .

. | Figure 1. V-mask for unified CUSUM control chart |

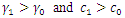

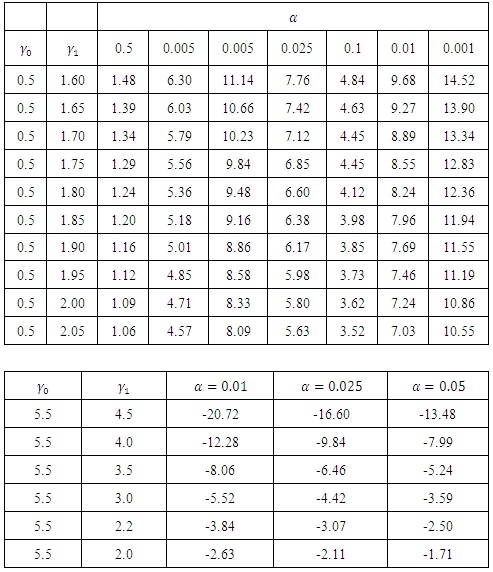

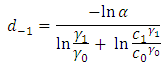

Using some hypothetical values for  and

and  , it can be determined that increasing the values of

, it can be determined that increasing the values of  and

and  , the lead distance decreases given a fixed value of

, the lead distance decreases given a fixed value of  . Again, the value of also increases with decreasing values of

. Again, the value of also increases with decreasing values of  and a given fixed value of

and a given fixed value of  and

and  . The details of the values of the lead distance are shown in Table 2.

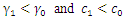

. The details of the values of the lead distance are shown in Table 2.Table 2. Values the lead distance d for controlling γ and c when

|

| |

|

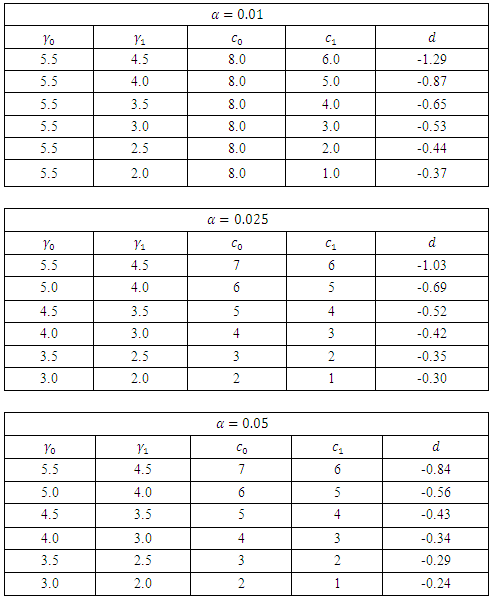

On the other hand, when there is a negative shift of the parameters, that is  and

and  , it can be established that the lead distance (d) decreases as the value of alpha

, it can be established that the lead distance (d) decreases as the value of alpha  increases and when the value of

increases and when the value of  and

and  decreases for a fixed value of

decreases for a fixed value of  , the value of the lead distance increases. The details are shown in Table 3. The values of the lead distance are negative in this case because there is a negative shift in the parameters of the distribution.

, the value of the lead distance increases. The details are shown in Table 3. The values of the lead distance are negative in this case because there is a negative shift in the parameters of the distribution.Table 3. Values the lead distance d for controlling γ and c when

|

| |

|

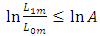

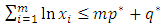

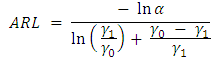

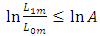

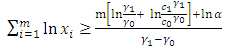

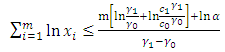

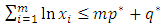

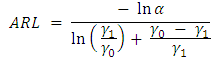

5. Average Run Length of the Unified CUSUM Control Chart

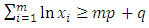

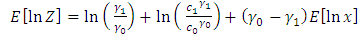

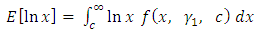

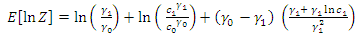

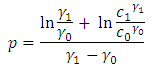

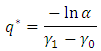

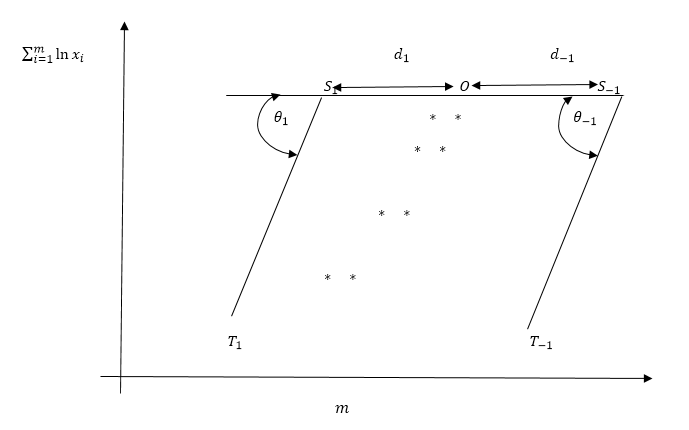

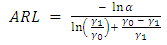

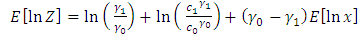

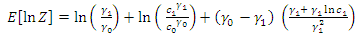

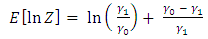

The Average Run Length of the unified CUSUM chart is the same as that of the two-sided CUSUM chart and is given by | (28) |

Proof:By definition  | (29) |

where  .using equation (1),

.using equation (1),  can be written as

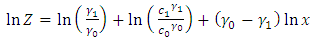

can be written as | (30) |

Taking natural logarithm of (30) | (31) |

By simplifying (31), it reduces to  | (32) |

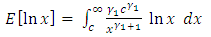

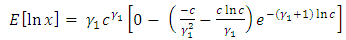

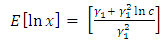

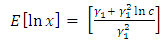

Taking expectation of (32) | (33) |

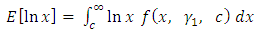

The expectation,  is obtained as follows

is obtained as follows | (34) |

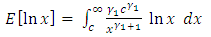

By substituting the density function for  into (34), we obtained

into (34), we obtained | (35) |

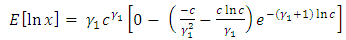

Simplifying (35), we obtained | (36) |

and finally, | (37) |

Substituting the value of  in (37) into (33) we obtain

in (37) into (33) we obtain | (38) |

Simplifying (38), we obtain | (39) |

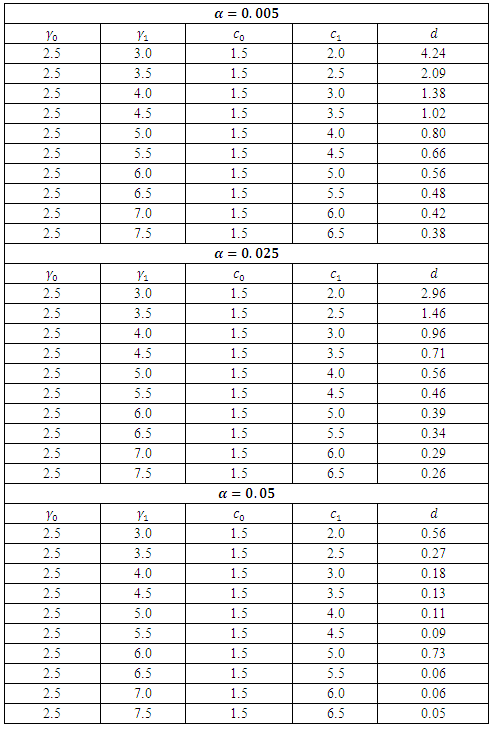

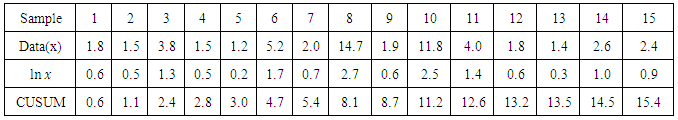

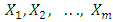

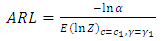

Substituting (39) into (29), the ARL formular is derived as required. Using some hypothetical values of

Using some hypothetical values of  and

and  , it can be established that as

, it can be established that as  increases in value, the ARL tends to decrease with any given value of

increases in value, the ARL tends to decrease with any given value of  . Also as the value of

. Also as the value of  decreases, the ARL also increases for fixed value of

decreases, the ARL also increases for fixed value of  as displayed in Table 4.

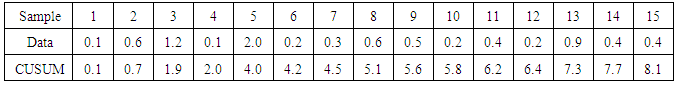

as displayed in Table 4. Table 4. Average Run Length for the parameters of the Pareto distribution

|

| |

|

Also it can be established in the second table of Table 4 that when there is a negative shift  , the ARL decreases as

, the ARL decreases as  increases and when

increases and when  decreases, the ARL also increases for any given value of

decreases, the ARL also increases for any given value of  . The negative values of the ARL obtained only indicates the negative shift in both parameters of the Pareto distribution.

. The negative values of the ARL obtained only indicates the negative shift in both parameters of the Pareto distribution.

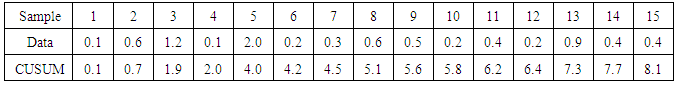

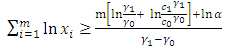

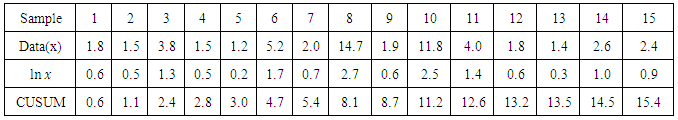

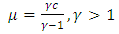

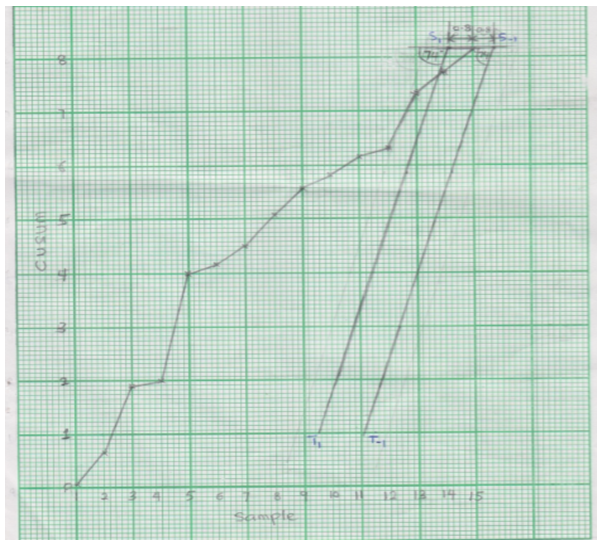

6. Practical Demonstration of the Unified CUSUM Control Chart

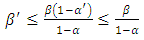

In this section, the application of the proposed CUSUM chart has been illustrated using a hypothetical data simulated from the Pareto distribution. The first ten observations were simulated with  and

and  . The last five observations were simulated with

. The last five observations were simulated with  and

and  for a simultaneous shift in both parameters. Table 5 displays the simulated data points and the corresponding cumulative sum. The parameters of the V-mask were calculated using

for a simultaneous shift in both parameters. Table 5 displays the simulated data points and the corresponding cumulative sum. The parameters of the V-mask were calculated using  ,

,  ,

,  ,

,  and

and  . The lead distance and the mask angle were obtained as 0.9 and

. The lead distance and the mask angle were obtained as 0.9 and  respectively. The sample number

respectively. The sample number  was plotted against the cumulative sum of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 2. It can be established from Figure 2, the process was out of control as observations 1 to 13 fell above line

was plotted against the cumulative sum of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 2. It can be established from Figure 2, the process was out of control as observations 1 to 13 fell above line  indicating an increase in

indicating an increase in  and

and  . On the other hand if the plotted points fall below the line

. On the other hand if the plotted points fall below the line  , means there is a negative shift in the parameters. Anytime any of the above scenarios are experience then an action should be taken in order to bring the process back to control.

, means there is a negative shift in the parameters. Anytime any of the above scenarios are experience then an action should be taken in order to bring the process back to control.Table 5. Simulated hypothetical data for the unified CUSUM

|

| |

|

| Figure 2. Unified CUSUM plot for the simulated hypothetical data |

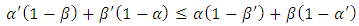

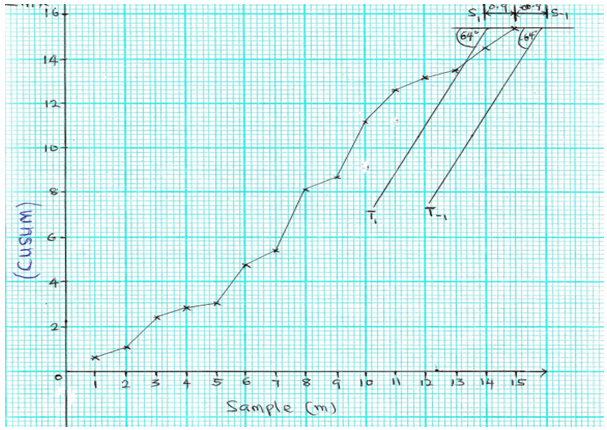

In Table 6, the first ten observations were simulated with  and

and  . The last five observations were simulated with

. The last five observations were simulated with  and

and  for a simultaneous shift in both parameters. The parameters of the V-mask were calculated using

for a simultaneous shift in both parameters. The parameters of the V-mask were calculated using  ,

,  ,

,  ,

,  and

and  . The lead distance and the mask angle were obtained as - 0.8 and

. The lead distance and the mask angle were obtained as - 0.8 and  respectively. Since distance cannot be negative, an absolute value of the distance was then used in the placing of the V-mask. The sample number was then plotted against the cumulative sum (CUSUM) of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 3. It was established from Figure 3 that the process was out of control as observations 1 to 13 fell above line

respectively. Since distance cannot be negative, an absolute value of the distance was then used in the placing of the V-mask. The sample number was then plotted against the cumulative sum (CUSUM) of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 3. It was established from Figure 3 that the process was out of control as observations 1 to 13 fell above line  indicating a shift in

indicating a shift in  and

and  . This calls for a corrective measure to be taken in order to bring the process back to control.

. This calls for a corrective measure to be taken in order to bring the process back to control.Table 6. Simulated hypothetical data for the unified CUSUM

|

| |

|

| Figure 3. Unified CUSUM plot for the simulated hypothetical data |

7. Conclusions

The results of the study showed that as the values of  and

and  increase the size of the mask angle

increase the size of the mask angle  increases. Also, increasing values of

increases. Also, increasing values of  and

and  increases the size of the mask angle

increases the size of the mask angle  . Furthermore, when there is a negative shift in both parameters, that is where

. Furthermore, when there is a negative shift in both parameters, that is where  and

and  , it can be established from the second table of Table 1 that the mask angle

, it can be established from the second table of Table 1 that the mask angle  increases as the values of

increases as the values of  and

and  decreases.With regard to the lead distance it can be determined that increasing the values of

decreases.With regard to the lead distance it can be determined that increasing the values of  and

and  , the lead distance decreases given a fixed value of

, the lead distance decreases given a fixed value of  . Again, the value of the lead distance increases with decreasing values of

. Again, the value of the lead distance increases with decreasing values of  and a fixed value of

and a fixed value of  and

and  . However, When there is a negative shift in the parameters of the distribution, that is

. However, When there is a negative shift in the parameters of the distribution, that is  and

and  , it can be established that the lead distance decreases as the value of alpha

, it can be established that the lead distance decreases as the value of alpha  increases and when the value of

increases and when the value of  and

and  decreases for a fixed value of

decreases for a fixed value of  , the value of lead distance increases. On the ARL, it was established that as

, the value of lead distance increases. On the ARL, it was established that as  increases in value, the ARL tends to decrease with any given value of

increases in value, the ARL tends to decrease with any given value of  . Also, as the value of

. Also, as the value of  decreases, the ARL also increases for a fixed value of

decreases, the ARL also increases for a fixed value of  . Again when there is a negative shift

. Again when there is a negative shift  , the ARL decreases as

, the ARL decreases as  increases and when

increases and when  decreases, the ARL also increases for any given value of

decreases, the ARL also increases for any given value of  .

.

References

| [1] | Bakhodir, E. A. (2004). Sequential Detection of U.S. Business Cycle Turning points: performances of Shiryayev-Roberts, CUSUM and EWMA procedures. Econ, papers, submitted for publication. |

| [2] | Hawkins, D. M. and Olwell D. H. (1998). Cumulative sum charts and charting for quality improvement. Springer-Verlag, New York. |

| [3] | Johnson, N. L. (1961). A simple theoretical approach to cumulative sum control charts. Journal of the American Statistics Association, 56(4): 835-40. |

| [4] | Kantam, R. R. L. and Rao, G. S. (2004). A note on point estimation of system reliability exemplified for the Log-logistic distribution. Economic Quality control. 19(2): 197-204. |

| [5] | Luguterah, A. (2015). Unified cumulative sum chart for monitoring shifts in the parameters of the Erlang-Truncated exponential distribution. Far East Journal of Theoretical Statistics, 50(1): 65-76. |

| [6] | Nabar, S. P. and Bilgi, S. (1994). Cumulative Sum Control chart for the Inverse Gaussian distribution. Journal of Indian Statistical Association. 32:9-14. |

| [7] | Nasiru, S. (2016). One-sided cumulative sum control chart for monitoring shifts in the shape parameter of Pareto distribution. Int. J. Productivity and Quality Management, 19(2): 160. |

| [8] | Page E. S. (1954). Continuous Inspection Schemes. Biometrics, 41(1): 100-115. |

| [9] | Sasikumar, R. and Bangusha, D. S. (2014). Cumulative sum charts and its Health care Applications - A systematic Review. SriLangan Journal of Applied Statistics. 15(1):47-56. |

| [10] | Shewhart, W. A. (1926). Quality Control Charts. Bell Syst. Tech. J. 5:593-602. |

| [11] | Wald, A. (1947). Sequential Analysis. |

and the parameters

and the parameters  and

and  are the shape and scale parameters respectively. The corresponding cumulative distribution function is given by;

are the shape and scale parameters respectively. The corresponding cumulative distribution function is given by;

successively, from a population

successively, from a population  . Consider two hypotheses about

. Consider two hypotheses about  ,

,  and

and  . The ratio of the probabilities of the sample is;

. The ratio of the probabilities of the sample is;

and

and  errors. The sequential test is set up as follows;i. As long as

errors. The sequential test is set up as follows;i. As long as  we continue sampling.ii. At the first i that

we continue sampling.ii. At the first i that  we accept

we accept  .iii. At the first i that

.iii. At the first i that  we accept

we accept  .An equivalent way for computation is to use the logarithm of

.An equivalent way for computation is to use the logarithm of  . Then, the inequality becomes;

. Then, the inequality becomes;

are independent random variables with variance, say,

are independent random variables with variance, say,  . Obviously

. Obviously  has a variance

has a variance  . As

. As  increases the dispersion becomes greater and the probability that a value of

increases the dispersion becomes greater and the probability that a value of  will remain within the limits

will remain within the limits  and

and  tends to zero. The mean

tends to zero. The mean  tends to a normal distribution with variance

tends to a normal distribution with variance  and therefore the probability that it will fall between

and therefore the probability that it will fall between  and

and  tends to zero.If we take a sample for which

tends to zero.If we take a sample for which  lies between A and B for the first

lies between A and B for the first  trial and then

trial and then  at the

at the  trial, so we accept

trial, so we accept  (and reject

(and reject  ). By definition, the probability of getting such a sample is at least A times as large under

). By definition, the probability of getting such a sample is at least A times as large under  as against

as against  . The probability that we fail to reject

. The probability that we fail to reject  when

when  is true is

is true is  and the probability that we reject

and the probability that we reject  when

when  is true is

is true is  . Therefore

. Therefore

and

and  and that the true errors of first and second kind for the limits

and that the true errors of first and second kind for the limits  and

and  are

are  and

and  respectively. Then, from (10)

respectively. Then, from (10)

and

and  are small. From (16) and (17), the amount that

are small. From (16) and (17), the amount that  can exceed

can exceed  or

or  exceed

exceed  is negligible. In addition, from relation (18) we see that either

is negligible. In addition, from relation (18) we see that either  or

or  . Therefore the use of

. Therefore the use of  and

and  can only increase one of the errors and only by a very small amount

can only increase one of the errors and only by a very small amount

and

and  be the target values, let also

be the target values, let also  and

and  be the changed values owing to the shift in the parameters. The SPRT will be stopped by rejecting or accepting the null hypothesis or continue to sample, as

be the changed values owing to the shift in the parameters. The SPRT will be stopped by rejecting or accepting the null hypothesis or continue to sample, as  is outside or between

is outside or between  and

and  . The process stops by rejecting

. The process stops by rejecting  if

if  ; this gives a rejection line

; this gives a rejection line  and

and  . Similarly, if we make use of SPRT with the same strength to the cases

. Similarly, if we make use of SPRT with the same strength to the cases  and

and  , where

, where  , then another rejection line is determined. These two rejection lines indicates a symmetrical nature of masking. The observations in the sample enter the mask in a sequential way. Thus, the mask for the CUSUM chart for

, then another rejection line is determined. These two rejection lines indicates a symmetrical nature of masking. The observations in the sample enter the mask in a sequential way. Thus, the mask for the CUSUM chart for  is

is

and

and Similarly, the rejection line, when

Similarly, the rejection line, when  , is given by

, is given by

and

and Equations (26) and (28) form the regions above and below the plane

Equations (26) and (28) form the regions above and below the plane  . If m is allowed sequentially, at some stage,

. If m is allowed sequentially, at some stage,  satisfies either (26) or (28). Until this is achieved the process continues.Using the slopes of the two lines (equations (26) and (28)), the parameters of the CUSUM chart, known as the angle of the mask and the lead distance, are obtained. From Figure 1,

satisfies either (26) or (28). Until this is achieved the process continues.Using the slopes of the two lines (equations (26) and (28)), the parameters of the CUSUM chart, known as the angle of the mask and the lead distance, are obtained. From Figure 1,  slope of the line

slope of the line  and

and  slope of the line

slope of the line  , hence

, hence  where

where  and

and  .And

.And  where

where  and

and  .Various values of the angle are shown in Table 1. It was obvious from the results that as the values of

.Various values of the angle are shown in Table 1. It was obvious from the results that as the values of  and

and  increase the value of the angle increases. Also increasing values of

increase the value of the angle increases. Also increasing values of  and

and  also increase the angle of the mask.

also increase the angle of the mask.  and

and  , it can be established from the second table of Table 1 that the mask angle

, it can be established from the second table of Table 1 that the mask angle  increases as the values of

increases as the values of  and

and  decreases.The lead distance

decreases.The lead distance  is given by

is given by  where

where  and

and  and the lead distance

and the lead distance  is given by

is given by where

where  and

and  .Let

.Let  be a sample from Pareto distribution, if the points

be a sample from Pareto distribution, if the points  are plotted with a suitable scale, then the ordinates of the points represent the cumulative sum of the data. Equations (26) and (28) are the effects of a shift in the population parameters

are plotted with a suitable scale, then the ordinates of the points represent the cumulative sum of the data. Equations (26) and (28) are the effects of a shift in the population parameters  and

and  . Figure 1 shows a sizable shift in the parameters if

. Figure 1 shows a sizable shift in the parameters if  falls outside the lines

falls outside the lines  and

and  . The chart is interpreted by placing the mask over the last plotted point as shown in Figure 1. If any of the points lies below

. The chart is interpreted by placing the mask over the last plotted point as shown in Figure 1. If any of the points lies below  , then it indicates a decrease in

, then it indicates a decrease in  and

and  and if any of the points falls above

and if any of the points falls above  , then it shows an increase in

, then it shows an increase in  and

and  .

.

and

and  , it can be determined that increasing the values of

, it can be determined that increasing the values of  and

and  , the lead distance decreases given a fixed value of

, the lead distance decreases given a fixed value of  . Again, the value of also increases with decreasing values of

. Again, the value of also increases with decreasing values of  and a given fixed value of

and a given fixed value of  and

and  . The details of the values of the lead distance are shown in Table 2.

. The details of the values of the lead distance are shown in Table 2. and

and  , it can be established that the lead distance (d) decreases as the value of alpha

, it can be established that the lead distance (d) decreases as the value of alpha  increases and when the value of

increases and when the value of  and

and  decreases for a fixed value of

decreases for a fixed value of  , the value of the lead distance increases. The details are shown in Table 3. The values of the lead distance are negative in this case because there is a negative shift in the parameters of the distribution.

, the value of the lead distance increases. The details are shown in Table 3. The values of the lead distance are negative in this case because there is a negative shift in the parameters of the distribution.

.using equation (1),

.using equation (1),  can be written as

can be written as

is obtained as follows

is obtained as follows

into (34), we obtained

into (34), we obtained

in (37) into (33) we obtain

in (37) into (33) we obtain

Using some hypothetical values of

Using some hypothetical values of  and

and  , it can be established that as

, it can be established that as  increases in value, the ARL tends to decrease with any given value of

increases in value, the ARL tends to decrease with any given value of  . Also as the value of

. Also as the value of  decreases, the ARL also increases for fixed value of

decreases, the ARL also increases for fixed value of  as displayed in Table 4.

as displayed in Table 4.  , the ARL decreases as

, the ARL decreases as  increases and when

increases and when  decreases, the ARL also increases for any given value of

decreases, the ARL also increases for any given value of  . The negative values of the ARL obtained only indicates the negative shift in both parameters of the Pareto distribution.

. The negative values of the ARL obtained only indicates the negative shift in both parameters of the Pareto distribution. and

and  . The last five observations were simulated with

. The last five observations were simulated with  and

and  for a simultaneous shift in both parameters. Table 5 displays the simulated data points and the corresponding cumulative sum. The parameters of the V-mask were calculated using

for a simultaneous shift in both parameters. Table 5 displays the simulated data points and the corresponding cumulative sum. The parameters of the V-mask were calculated using  ,

,  ,

,  ,

,  and

and  . The lead distance and the mask angle were obtained as 0.9 and

. The lead distance and the mask angle were obtained as 0.9 and  respectively. The sample number

respectively. The sample number  was plotted against the cumulative sum of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 2. It can be established from Figure 2, the process was out of control as observations 1 to 13 fell above line

was plotted against the cumulative sum of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 2. It can be established from Figure 2, the process was out of control as observations 1 to 13 fell above line  indicating an increase in

indicating an increase in  and

and  . On the other hand if the plotted points fall below the line

. On the other hand if the plotted points fall below the line  , means there is a negative shift in the parameters. Anytime any of the above scenarios are experience then an action should be taken in order to bring the process back to control.

, means there is a negative shift in the parameters. Anytime any of the above scenarios are experience then an action should be taken in order to bring the process back to control.

and

and  . The last five observations were simulated with

. The last five observations were simulated with  and

and  for a simultaneous shift in both parameters. The parameters of the V-mask were calculated using

for a simultaneous shift in both parameters. The parameters of the V-mask were calculated using  ,

,  ,

,  ,

,  and

and  . The lead distance and the mask angle were obtained as - 0.8 and

. The lead distance and the mask angle were obtained as - 0.8 and  respectively. Since distance cannot be negative, an absolute value of the distance was then used in the placing of the V-mask. The sample number was then plotted against the cumulative sum (CUSUM) of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 3. It was established from Figure 3 that the process was out of control as observations 1 to 13 fell above line

respectively. Since distance cannot be negative, an absolute value of the distance was then used in the placing of the V-mask. The sample number was then plotted against the cumulative sum (CUSUM) of the data. The V-mask was then placed at the last plotted point to monitor whether the process is in control or out of control as shown in Figure 3. It was established from Figure 3 that the process was out of control as observations 1 to 13 fell above line  indicating a shift in

indicating a shift in  and

and  . This calls for a corrective measure to be taken in order to bring the process back to control.

. This calls for a corrective measure to be taken in order to bring the process back to control.

and

and  increase the size of the mask angle

increase the size of the mask angle  increases. Also, increasing values of

increases. Also, increasing values of  and

and  increases the size of the mask angle

increases the size of the mask angle  . Furthermore, when there is a negative shift in both parameters, that is where

. Furthermore, when there is a negative shift in both parameters, that is where  and

and  , it can be established from the second table of Table 1 that the mask angle

, it can be established from the second table of Table 1 that the mask angle  increases as the values of

increases as the values of  and

and  decreases.With regard to the lead distance it can be determined that increasing the values of

decreases.With regard to the lead distance it can be determined that increasing the values of  and

and  , the lead distance decreases given a fixed value of

, the lead distance decreases given a fixed value of  . Again, the value of the lead distance increases with decreasing values of

. Again, the value of the lead distance increases with decreasing values of  and a fixed value of

and a fixed value of  and

and  . However, When there is a negative shift in the parameters of the distribution, that is

. However, When there is a negative shift in the parameters of the distribution, that is  and

and  , it can be established that the lead distance decreases as the value of alpha

, it can be established that the lead distance decreases as the value of alpha  increases and when the value of

increases and when the value of  and

and  decreases for a fixed value of

decreases for a fixed value of  , the value of lead distance increases. On the ARL, it was established that as

, the value of lead distance increases. On the ARL, it was established that as  increases in value, the ARL tends to decrease with any given value of

increases in value, the ARL tends to decrease with any given value of  . Also, as the value of

. Also, as the value of  decreases, the ARL also increases for a fixed value of

decreases, the ARL also increases for a fixed value of  . Again when there is a negative shift

. Again when there is a negative shift  , the ARL decreases as

, the ARL decreases as  increases and when

increases and when  decreases, the ARL also increases for any given value of

decreases, the ARL also increases for any given value of  .

. Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML