-

Paper Information

- Next Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

International Journal of Statistics and Applications

p-ISSN: 2168-5193 e-ISSN: 2168-5215

2015; 5(1): 21-30

doi:10.5923/j.statistics.20150501.04

Selecting the Right Central Composite Design

1Department of Statistics, University of Ilorin, Ilorin, Nigeria

2Department of Computer Science, Renaissance University Ugbawka, Enugu, Nigeria

Correspondence to: J. C. Nwanya, Department of Computer Science, Renaissance University Ugbawka, Enugu, Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Comparative studies of five varieties of Central Composite design (SCCD, RCCD, OCCD, Slope-R, FCC) in Response Surface Methodology (RSM) were evaluated using the D, A, G and IV-optimality criteria. The fraction of design space plot of these designs was also displayed. The basis of variation in these designs is distance of the axial points from the center of the design. These axial portions of these designs were also replicated. The results show that replicating the star points tends to reduce the D and G-optimality criteria of the CCDs (SCCD, RCCD, OCCD, Slope-R, and FCC) in all the factors that were considered while it is not so for A-optimality criterion. In IV-optimality, the CCDs are relatively the same both when the center points and axial portion are increased. The FDS plots indicates that the CCDs maintain relatively low and stable SPV when the star points are replicated with increased center points.

Keywords: SCCD, RCCD, OCCD, Slope-R, FCC, FDS, CCDs, SPV

Cite this paper: B. A. Oyejola, J. C. Nwanya, Selecting the Right Central Composite Design, International Journal of Statistics and Applications, Vol. 5 No. 1, 2015, pp. 21-30. doi: 10.5923/j.statistics.20150501.04.

Article Outline

1. Introduction

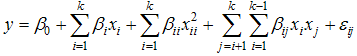

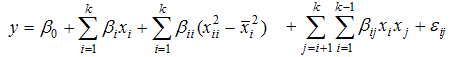

- Experiments are performed by researchers in every fields of inquiry so as to study and model the effects of several design variables on the responses of interest. The foundation for response surface methodology (RSM) was laid by [5]. Response surface methodology consists of statistical and mathematical techniques for empirical model building and model exploitation. It seeks to relate a response or output variable to the levels of a number of predictors or input variables that affect it. The form of such a relationship is usually unknown, but can be approximated by a low-order polynomial such as the second-order response surface model

| (1) |

1.1. Central Composite Design

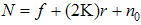

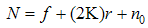

- The central composite design (CCD) is a design widely used for estimating second order response surfaces. It is perhaps the most popular class of second order designs. Since introduced by [5], the CCD has been studied and used by many researchers. It consists of 2k full or 2k-1 half replicate (k is the number of independent variables) factorial points (±1,±1, …,±1); 2k axial or star points of the form (±α, 0,…, 0), (0,±α,… , 0),and a center point (0,0,…,0). In this work, full factorial points will be used for factors k = 3 and 4 while half replicate factorial points will be for factors k = 5 and 6. The axial points will be replicated one and two times while the center points will be replicated one and three times. The center points provide information about the existence of curvature in the the addition of axial points allow for efficient estimation of the pure quadratic terms. The choice of the number of center runs provides flexibility to get a better estimate of the pure error and better power for test. Moreover, the choice of the number of center runs affects the distribution of the scaled prediction variance. The factorial points allow estimation of the first-order and interaction terms. Let N denote the total number of experimental runs in the CCD,

. Here f is the number of factorial points, 2k is the axial points which is replicated r times and n0 the center points. The choice of axial distance α is based on the region of interest. Choosing the appropriate values of α specifies the type of CCD. To be able to make use of these varieties, the researcher must first understand the differences between these varieties in terms of the experimental region of interest and region operability, [17]. The region of operability for the CCDs considered in this paper is the spherical region except FCC which is employed if the primary region of interest is cuboidal.

. Here f is the number of factorial points, 2k is the axial points which is replicated r times and n0 the center points. The choice of axial distance α is based on the region of interest. Choosing the appropriate values of α specifies the type of CCD. To be able to make use of these varieties, the researcher must first understand the differences between these varieties in terms of the experimental region of interest and region operability, [17]. The region of operability for the CCDs considered in this paper is the spherical region except FCC which is employed if the primary region of interest is cuboidal.1.1.1. Spherical Central Composite Design (SCCD)

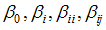

- Setting α =

, makes the CCD a spherical CCD. In spherical CCDs, all design points occur on the same geometric sphere. Spherical CCDs are not exactly rotatable, but they are near-rotatable.

, makes the CCD a spherical CCD. In spherical CCDs, all design points occur on the same geometric sphere. Spherical CCDs are not exactly rotatable, but they are near-rotatable.1.1.2. Rotatable Central Composite Designs (RCCD)

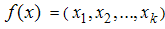

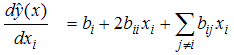

- In RSM, rotatability is considered as one of the desired properties of the second order designs. The concept of rotatability was first introduced by [4], in the rotatable design the variance of the predicted response ŷ(x) depends on the location of the point

that is, it is a function only of distance from the point

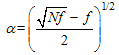

that is, it is a function only of distance from the point  to the center of the design. By definition, a design is rotatable if is constant at all the points that are equidistant from the center of the design. Setting

to the center of the design. By definition, a design is rotatable if is constant at all the points that are equidistant from the center of the design. Setting  makes CCD rotatable. Where ƒ is the factorial points

makes CCD rotatable. Where ƒ is the factorial points1.1.3. Orthogonal Central Composite Design (OCCD)

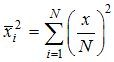

- A 2k factorial design and the fractional factorial 2k-1 design in which the main effects are not aliased with other main effects are orthogonal designs. Consider a second order model with pure quadratic terms corrected for their means.

| (2) |

. Let

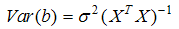

. Let  denote the least square estimators of

denote the least square estimators of  respectively. In the CCD, all the covariances between estimated regression coefficient except

respectively. In the CCD, all the covariances between estimated regression coefficient except  are zero. But if the inverse of the information matrix

are zero. But if the inverse of the information matrix  is a diagonal matrix, then

is a diagonal matrix, then  also becomes zero. This property is called orthogonality. The condition for making a CCD orthogonal is by Setting

also becomes zero. This property is called orthogonality. The condition for making a CCD orthogonal is by Setting  see [13]. Where

see [13]. Where ,

,  . The orthogonal CCD provides ease in computations and uncorrelated estimates of the response model coefficients.

. The orthogonal CCD provides ease in computations and uncorrelated estimates of the response model coefficients.1.1.4. Slope Rotatable Central Composite Design (Slope-R)

- Suppose that estimation of the first derivative of η(x) with respect to each of the independent variables. For the second order model,

| (3) |

| (4) |

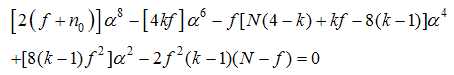

be constant on circles (k=2), spheres (k=3), or hyperspheres (k≥4) centered at the design origin. Estimates of the derivative over axial directions would then be equally reliable for all points x equidistant from the design origin. They referred to this property as slope rotatability, and showed that the condition for a CCD to be a slope –rotatable is as follows

be constant on circles (k=2), spheres (k=3), or hyperspheres (k≥4) centered at the design origin. Estimates of the derivative over axial directions would then be equally reliable for all points x equidistant from the design origin. They referred to this property as slope rotatability, and showed that the condition for a CCD to be a slope –rotatable is as follows | (5) |

for slope-rotatable central composite design are evaluated. See [20].

for slope-rotatable central composite design are evaluated. See [20].1.1.5. Face Center Cube (FCC)

- Setting α = 1 makes the CCD, a Face-centered CCD and also a three level design. The axial and the factorial points of face-centre CCD fall onto the surface of the cube. The face-centered cube CCD does not require center points because of the existence of (

)-1. But center points are included for testing for lack of fit.

)-1. But center points are included for testing for lack of fit.1.2. Optimality Criteria

- Optimal designs are experimental designs that are generated based on a particular optimality criterion and are generally optimal only for a specific statistical model. Optimal design methods use a single criterion in order to construct designs for RSM; this is especially relevant when fitting second order models. [12] detailed the theory behind optimum designs.An optimality criterion is a criterion which summarizes how good a design is, and it is maximized or minimized by an optimal design. Design optimality is often called the alphabetical optimality criteria because they are named by some of the letters of the alphabet.

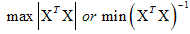

1.2.1. D-optimality

- When considered historically, D-optimality by [18] was the first alphabetical optimality criterion developed. It is the most well studied problem which is seen in the literature by [12], [15], [1], [16] and [10]. It is also still among the most popular because of its simple computation, and many available algorithms.The D-optimality focuses on the estimation of model parameters through good attributes of the moment matrix which is defined as

, where

, where  is the information matrix and N, the total number of runs, is used as a penalty for the larger design. D-optimality seeks to maximize the determinant of the information matrix

is the information matrix and N, the total number of runs, is used as a penalty for the larger design. D-optimality seeks to maximize the determinant of the information matrix  or equivalently seeks to minimize the inverse of the information matrix. That is

or equivalently seeks to minimize the inverse of the information matrix. That is  . The D-efficiency

. The D-efficiency where p is the number of model parameters.

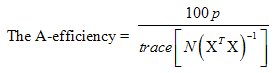

where p is the number of model parameters. 1.2.2. A-optimality

- This criterion introduced by [6] seeks to minimize the trace of the inverse of the information matrix (X’X). This criterion results in minimizing the average variance of the estimates of the regression coefficients. Unlike D-optimality, it does not make use of covariance among coefficients.

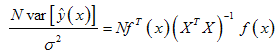

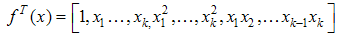

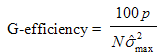

1.2.3. G-optimality

- This criterion is concern with prediction variance. It may be that the aim of the practitioner is to have good prediction at a particular location in the design space. To attain this, [4] defined a variance function, i.e., the scaled prediction variance (SPV). The SPV is defined as

| (6) |

is the vector of coordinates of point in the region of interest expanded to model form. That is

is the vector of coordinates of point in the region of interest expanded to model form. That is , N is the total sample size penalizing the larger designs, X is the design matrix and

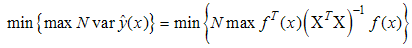

, N is the total sample size penalizing the larger designs, X is the design matrix and  is the process variance which is assumed to be 1. The SPV provides a measure of the precision of the estimated response at any point in the design space. A G-optimal design is one that minimizes the maximum SPV over the experimental design region. Symbolically, it is written as

is the process variance which is assumed to be 1. The SPV provides a measure of the precision of the estimated response at any point in the design space. A G-optimal design is one that minimizes the maximum SPV over the experimental design region. Symbolically, it is written as  | (7) |

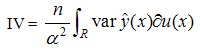

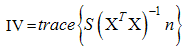

1.2.4. IV-optimality

- IV-optimality, also called I-optimality and V-optimality in the literature, is based on properties of the scaled prediction variance. Instead of finding maximum prediction variance in the region of interest, it makes use of the average of prediction variance (throughout the region of interest). Hence this gives a measure of the overall distribution of prediction variance. A design is said to be IV-optimal if it minimizes the normalized average integrated prediction variance.

| (8) |

| (9) |

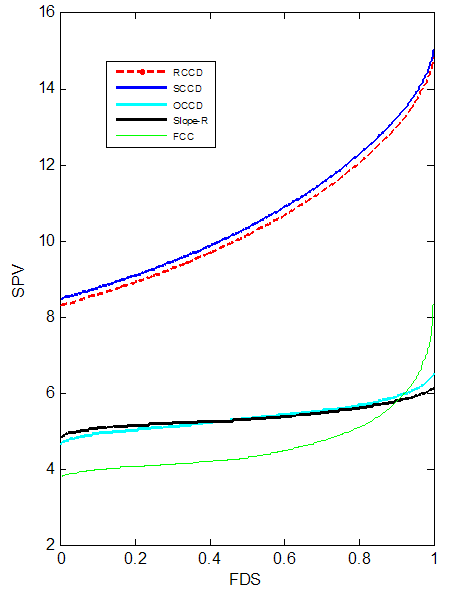

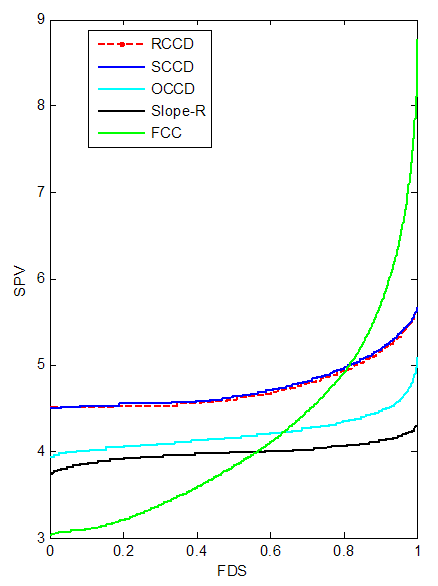

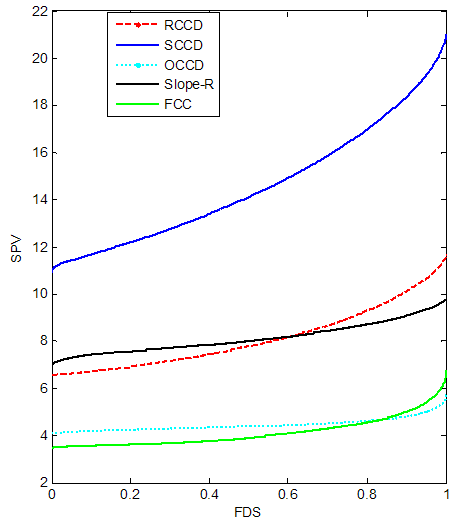

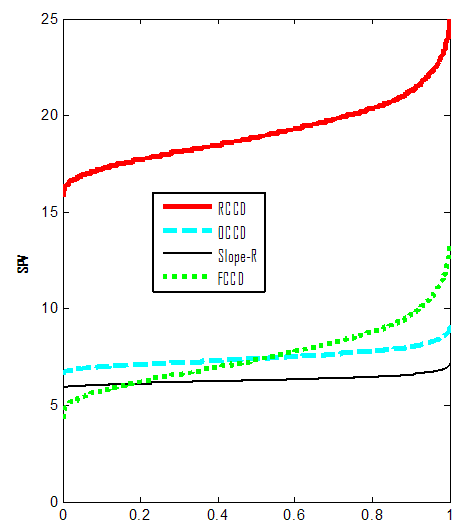

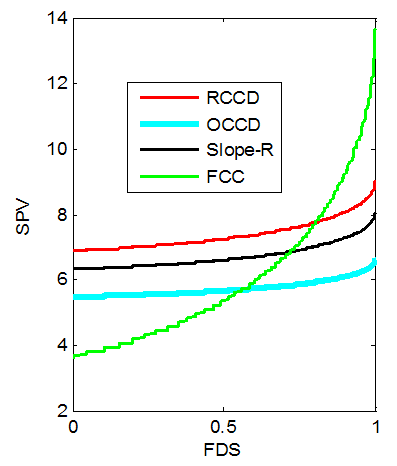

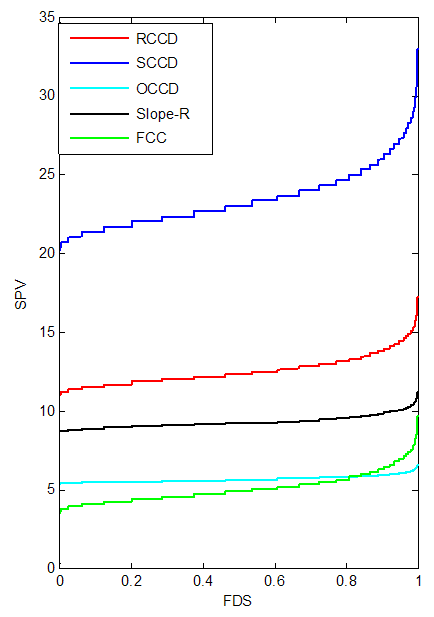

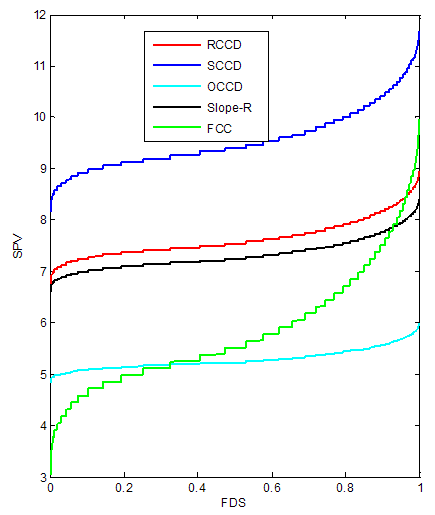

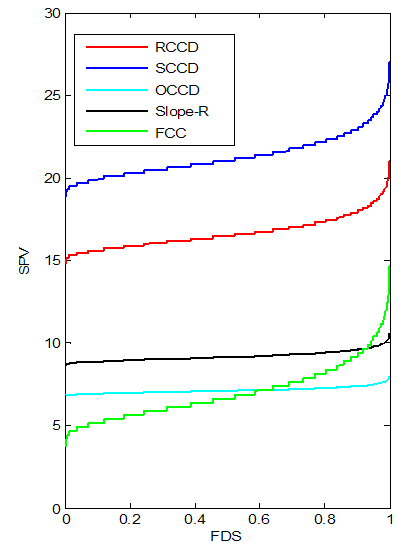

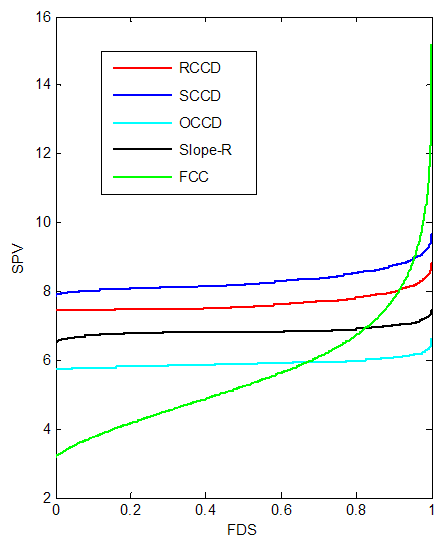

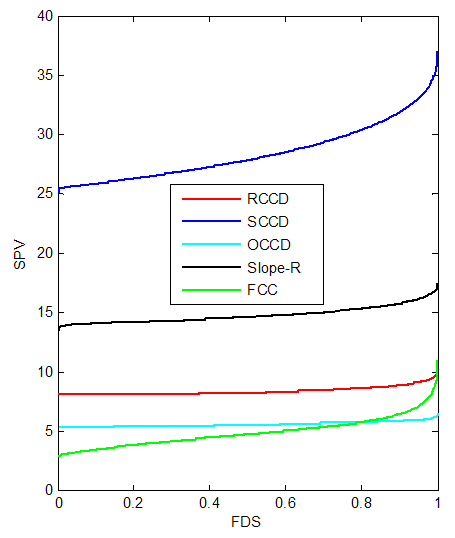

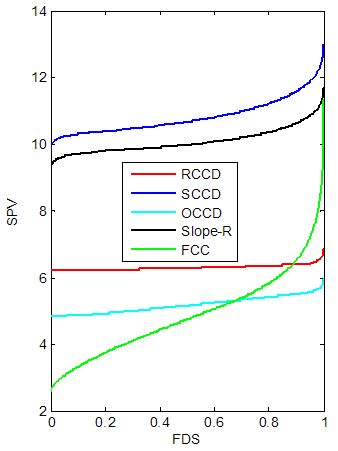

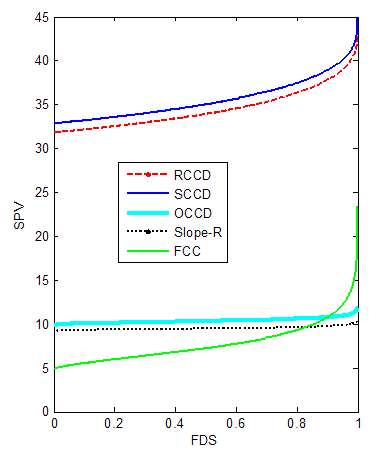

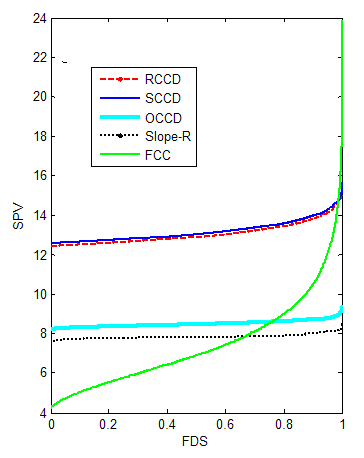

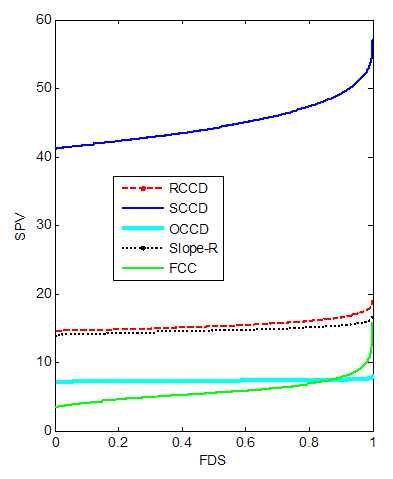

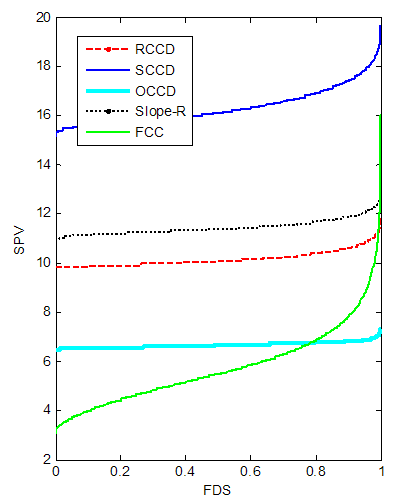

1.3. Fractions of Design Space (FDS) Plots

- Single-number criteria such as D, A and G-efficiency or IV criterion do not completely reflect the prediction variance characteristics of the design in question. However, a design that is superior by one optimality criterion may perform poorly when evaluated by another optimality criterion. According to [2], by condensing the properties of a design to a single value, much information is lost as regards the design’s potential performance. FDS plot introduced by [9], as alternative to single-value criteria, overcome this shortfall by displaying the characteristics of the prediction variance throughout the entire design space. The plot also displays characteristics of scaled prediction variance (SPV) throughout a multidimensional region on a single two- dimensional graph, this time with a single curve. The FDS plot shows the fraction of the design space at or below any SPV value. It is constructed by sampling a large number of values, say n, from throughout the design space and obtaining all of the corresponding SPV values which are then ordered and plotted against the quantiles (1/n, 2/n …). The x-axis gives the quantiles of the design space ranging from 0 to 1, while the y-axis shows the SPV values.

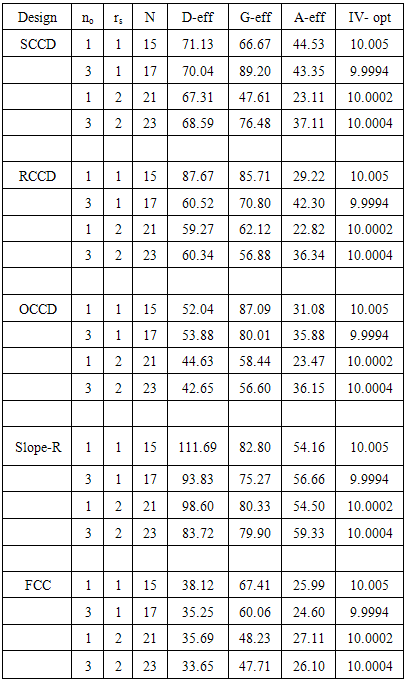

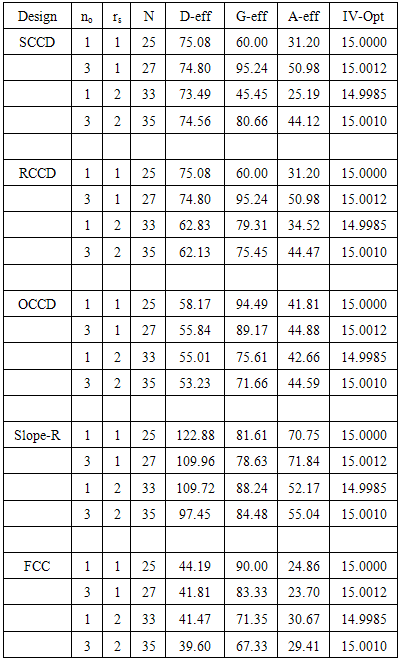

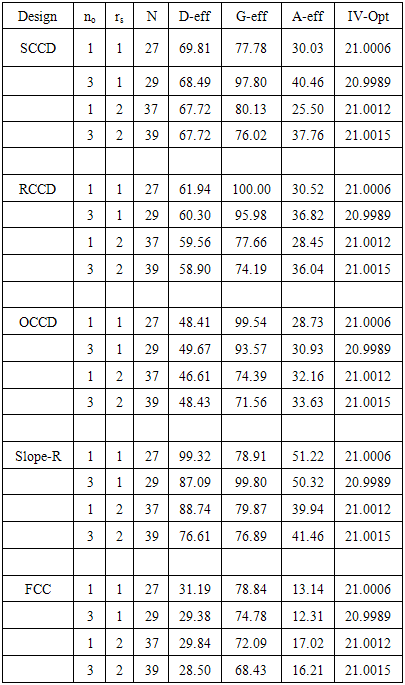

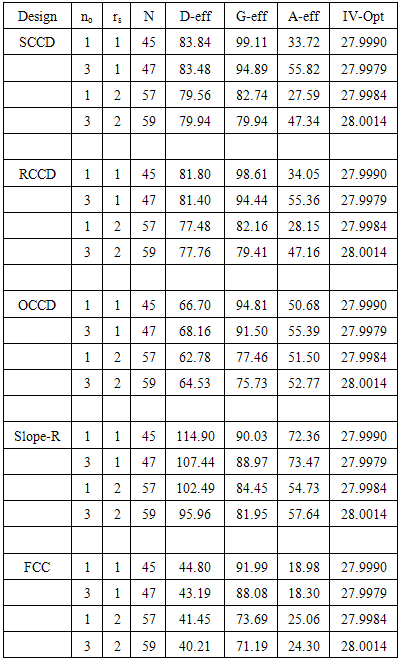

2. Design Comparison

- In this section, the D, A, G and IV optimality criteria for the full second order model comparisons of the 5 varieties of CCD (RCCD, SCCD, OCCD, FCC, and Slope-R) for factors k = 3, 4, 5 and 6 are summarized in tables 1, 2, 3 and 4 respectively. For the optimality criteria; larger values imply a better design (on a per point basis). Let rs indicate the replication of star points of the design and N the number of design runs.

2.1. Three-Factor Design

- Table 1 shows that replicating the star points or axial portion (increasing rs) tends to reduce the D and G-optimality criteria for the CCDs (RCCD, SCCD, Slope-R, OCCD and FCC). In A-optimality criterion, replicating the star points tends to reduce the SCCD, RCCD and OCCD but in vice versa for Slope-R and FCC. Increasing the center points tends to reduce the D- optimality criterion of SCCD, RCCD, FCC and Slope-R except the OCCD. But if the star points are replicated, increasing the center points tend to increase the D-optimality criterion of the CCDs. In G-optimality criterion, increasing the center points tends to reduce the performance of the RCCD, OCCD, FCC, and Slope-R except SCCD.

|

| Figure 1. FDS Plot of CCD for k =3 with 1 center point |

| Figure 2. FDS Plot of CCD for k =3 with 3 center points |

| Figure 3. FDS Plot of CCD with replicated axial |

2.2. Four-Factor Design

- Table 2 shows that replicating the star points or axial portion (increasing rs) tends to reduce the D and G- optimality criteria for the CCDs. But for A-optimality criterion, SCCD, RCCD and Slope-R tends to reduce with an increase in axial portion but in vice versa for OCCD and FCC.

|

| Figure 5. FDS Plot of CCD for k =4 with 1 center point |

| Figure 6. FDS Plot of CCD for k = 4 with 3 center points |

| Figure 7. FDS Plot of CCD with replicated axial portion for k = 4 with 1 center point |

| Figure 8. FDS Plot of CCD with replicated axial portion for k = 4 with 3 center points |

2.3. Five-Factor Design

- Table 3 shows that replicating the axial portion tends to reduce the D and G- optimality criteria for the CCDs. Also for A-optimality criterion, replicating the axial portion tends to reduce the performance of RCCD, SCCD and Slope-R but in vice versa with OCCD and FCC.

|

| Figure 9. FDS Plot of CCD for k =5 with 1 center point |

| Figure 10. FDS Plot of CCD for k =5 with 3 center points |

| Figure 11. FDS Plot of CCD with replicated axial portion for k = 5 with 1 center point |

| Figure 12. FDS Plot of CCD with replicated axial portion for k = 5 with 3 center points |

2.4. Six-Factor Design

- Table 4 shows that replicating the star points tend to reduce the D and G-optimality criteria for the CCDs. Also replicating the star points tend to reduce the A-optimality criterion for the CCDs except the FCC.

|

| Figure 13. FDS Plot of CCD for k =6 with 1 center point |

| Figure 14. FDS Plot of CCD for k =6 with 3 center points |

| Figure 15. FDS Plot of CCD with replicated axial portion for k = 6 with 1 center point |

| Figure 16. FDS Plot of CCD with replicated axial portion for k = 6 with 3 center points |

3. Conclusions

- Replicating the star points tends to reduce the D and G-optimality criteria for the CCDs. Slope-R performs better than all the designs when D and A –optimality criteria are employed for all the factors considered. OCCD is a better design when G-optimality criterion is employed especially when the star points are not replicated for factors k = 3 and 4. But when the star points are replicated, Slope-R is a better design when G-optimality is employed for factors k = 3 and 4. For factor k = 5, RCCD is a better design when G-optimality is employed and SCCD a better design when G-optimality criterion is employed for factor k = 6. The FDS plots indicates that the CCDs maintain relatively low and stable SPV when the star points are replicated with increased center points. In all the factors considered, the OCCD maintained a better, low and stable SPV when the star points are replicated. The Slope-R has a better low and stable SPV at factor k = 6 when the star points are not replicated.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML