-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Science and Technology

p-ISSN: 2163-2669 e-ISSN: 2163-2677

2023; 13(2): 17-21

doi:10.5923/j.scit.20231302.01

Received: Jan. 18, 2022; Accepted: Feb. 22, 2022; Published: Mar. 17, 2023

Filamentous Bacterial Bulking, Causes, Control and Misconceptions in the Aeration Tank of the SWTP

Ghulam Mustafa, Paul Chappell, Allan Bate, Kendrick Ha

Opal Quality Section, Opal Paper & Recycling Mill, Sydney, Australia

Correspondence to: Ghulam Mustafa, Opal Quality Section, Opal Paper & Recycling Mill, Sydney, Australia.

| Email: |  |

Copyright © 2023 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Filamentous growth in the aeration tank of the Secondary Water Treatment Plant (SWTP) can easily be detected by calculating the Sludge Volume Index 30 (SVI30). Once detected, an application of 12.5% sodium hypochlorite @ 15 L/hour effectively reduced 71% of filamentous bulking after 12 days. It was recommended not to use sodium hypochlorite for more than 10-12 days because it will kill microorganisms present in the aeration tank of the SWTP. However, sometimes filamentous bulking is not the cause due to the increased SVI30, and the increased value of SVI30 can be misleading due to the processes of nitrification and denitrification in the aeration tank and the clarifiers. It was concluded after the 33 days trial that despite the fact SVI30 was high, no filamentous bacterial growth was seen under the compound microscope. High values of nitrate (29 ppm) were found in the aeration tank and clarifiers causing solids to float on the surface due to nitrification and denitrification. Nitrogen (N2) gas pushed and assisted the solids to float up on the surface of the clarifier. At this stage, SVI30 of 136 mL/g was observed. It was found due to the denitrification and nitrification processes in the aeration tank. Reduced airflow through the air blowers helped to decrease the nitrification process in the aeration tank of the SWTP. Almost no literature is available on the miss conception that increased SVI30 is always due to filamentous bulking.

Keywords: Aerobic sludge, Aeration tank, Filamentous bulking, Sludge volume index30, Nitrification

Cite this paper: Ghulam Mustafa, Paul Chappell, Allan Bate, Kendrick Ha, Filamentous Bacterial Bulking, Causes, Control and Misconceptions in the Aeration Tank of the SWTP, Science and Technology, Vol. 13 No. 2, 2023, pp. 17-21. doi: 10.5923/j.scit.20231302.01.

Article Outline

1. Introduction

- The excessive growth of filamentous bacteria present in the aeration tank of the Secondary Water Treatment Plant (SWTP) causes filamentous bulking and inhibits the sludge separation from the activated sludge [1] & [2].Filamentous bulking in the aeration tank may be caused by excessive fat, oil, and grease coming through the paper mill water. The presence of abundant filamentous bacteria can reduce flock settling [3]. Normally the additional discharge of sugar into the aeration tank could lead to rapid filamentous growth but with long-lasting effects [4]. Despite extensive research devoted to this topic, the prevention of filamentous bulking and foaming is challenging [5]. Gas bubbles may also be found trapped under the filamentous bacterial bulking mat and enhanced its floating. The activated sludge process is controlled by aerobic organisms using dissolved oxygen in the aeration tank of the SWTP. However, sludge bulking occurs due to the growth of filamentous bacteria when solids suspend and float out of the disposal or effluent water [6]. However, chlorine is one of the most popular methods used to control filamentous bulking in the aeration tank [7]. Filamentous bulking and foaming are the most common settling problems experienced in activated sludge (AS) in wastewater treatment plants (WWTPs) [8]. The quality of the final effluent is poor during episodes of bulking and foaming, which is an environmental, human health, and economic burden [8].Filamentous growth in the aeration tank of the Secondary Water Treatment Plant (SWTP) can easily be detected by calculating the Sludge Volume Index 30 (SVI30). SVI30 index depends on the two values such as the 30-minute settleability test result and the activated sludge Mixed Liquor Suspended Solids (MLSS) test result. The SVI30 values where the filamentous bulking begins to vary from treatment plant to plant [9]. Filamentous growth causes major disruption and does not allow solids to settle down at the base of the clarifiers, thus causing the supernatant solution to be more turbid. Therefore, due to filamentous bacterial bulking, suspended solids-laden wastewater is a costly disposal option. A relative scarcity of available literature convinced us to research this topic. Therefore, the increased SVI30 due to the filamentous bulking may not be true all the time and sometimes is misleading. Instead, it may be due to the denitrification process in the aeration tank. Therefore, this study aimed to investigate whether the increased SVI30 was due to the filamentous bulking only or due to any other reason such as N2 gas produced as a result of denitrification, which pushed the solids up to float on the surface of the clarifier.

2. Material and Methods

- MLSS (Mixed Liquor Suspended Solids) samples were collected from the aeration tank in a 1.0 L plastic container provided with a lid. MLSS was measured using Imhoff cone method [10] & [11]. SVI30 was measured using the Imhoff Cone method [12]. Calcium was analyzed using the EDTA titration method [13]. HACH [14] vials TNT 836 for Nitrate-N and TNT 832 for NH3-N were used to analyze using the Spectrophotometer DR 3900. Photos were taken using the compound microscope in the Wet Chemistry Lab. All the analysis was carried out in the Wet Chemistry Laboratory of Opal Paper & Recycling Mill.

3. Results and Discussion

3.1. Filamentous Bulking

- Currently, the upper limit of SVI30 for Opal’s SWTP is 120 mL/g. The Sludge Volume Index (SVI30) of the aeration tank is measured twice a week. However, if the SVI30 values are higher than 120 mL/g, it is monitored daily until the rectification of troubleshooting. If we find the values of SVI30 are consistently higher than 120 mL/g for at least 3 days, then a microscopic analysis is conducted in Opal’s Wet Chemistry Laboratory to ascertain the stage of the filamentous bacterial growth using the subjective scoring system [15]. After three days, filamentous growth reduction treatment is applied upon filamentous growth confirmation. For this purpose, 12.5% sodium hypochlorite @ 15 L/hour was found effective to overcome the excessive filamentous bulking in the aeration tank without killing the microbial population. Filamentous bulking at the start of sodium hypochlorite dosing is shown in figure 1, and the reduction of filamentous growth after one week of treatment application is shown in figure 2. It was 203 mL/g at the start and reduced to 59 mL/g at the end of hypo treatment. Figure 3 shows the effectiveness of hypochlorite treatment after 12 days with the reduction of sludge volume index to 59 mL/g. It is suggested to apply this dose through the sludge recirculation line and not directly into the aeration tank to avoid excessive disruption to the microbes. The application of sodium hypochlorite may prolong up to 2 weeks or more depending on the phase of the filamentous bulking in the aeration tank.

| Figure 1. Filamentous bacterial growth in the MLSS sample under the compound microscope at the start of sodium hypochlorite treatment |

| Figure 2. Filamentous bacterial growth in the aeration tank after one week of treatment |

| Figure 3. Scanty filamentous bacterial growth in the aeration tank after 10 days of treatment. SVI 30 reduced to 59 from 203 mL/g |

| Figure 4. Muddy surface of Opal's SWTP Clarifier due to the filamentous bulking @ 203 mL/g SVI30 |

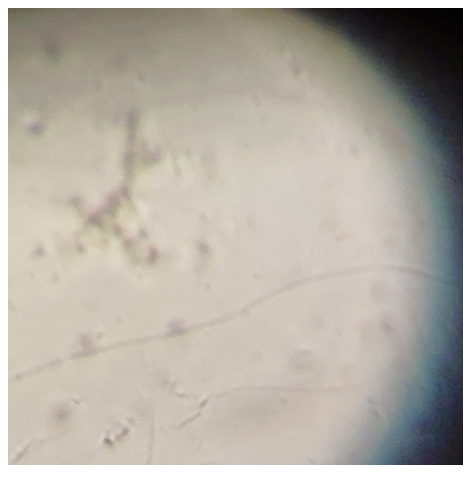

3.2. Misconceptions

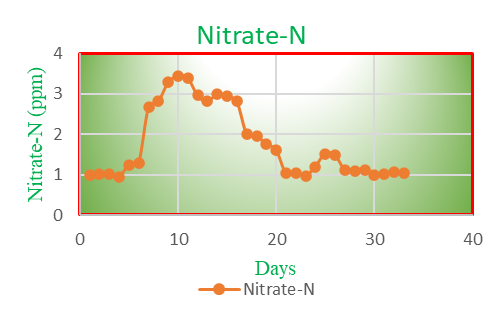

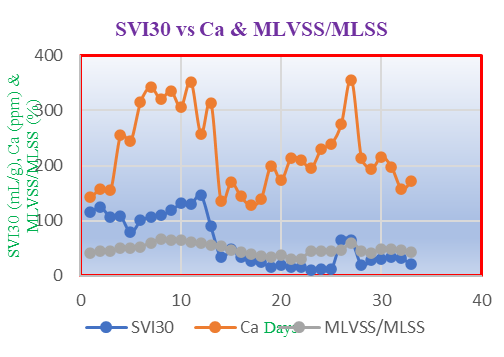

- Increased SVI30 may not be the reason for filamentous growth in the aeration tank of the SWTP. It could be due to the nitrification and denitrification processes, which caused total suspended solids to float on the surface of the clarifier because of denitrification. If the SVI30 value does not decrease after the 10 days of 12.5% sodium hypochlorite dose @ 15 L/hour. The problem could be due to the processes of nitrification and denitrification in the clarifier as well as in the aeration tank. Under such conditions, nitrification values exceeded 3.28 ppm. It is important to note that no literature is available on the increased SVI30 in the aeration tank due to the high levels of nitrate-N and denitrification. Ammonia-N was found between 28.3 to 29.5 ppm in the aeration tank and the high concentration of ammonia-N combined with the O2 blown in the aeration tank through the air blowers triggered the nitrification process as shown in figure 5. Furthermore, in the clarifiers and decanter, O2 is liberated from the NO3-N leaving behind N2 gas only. This N2 gas pushed the solids up in the clarifiers. Therefore, solids were found floating on the surface of the clarifier. To mitigate the nitrification in the aeration tank, reduce the airflow for not more than 24 hours. Reduction of airflow for an extended period caused odour or unpleasant smell around the SWTP and the clarifier, thus causing an environmental problem for the community. However, reduced airflow in the aeration tank may cause the death of microorganisms. Calcium (Ca) concentration in the treated effluent or the disposal water during the nitrification period in the aeration tank was found higher than normal. It is important to note that during the period of high SVI30, Ca concentration in the disposal water was high (352 ppm) but had no filamentous growth issues, despite the fact SVI30 was 130-147 mL/g as shown in figure 6.

| Figure 5. Nitrate -N levels during 33 days in the aeration tank |

| Figure 6. SVI30 vs Calcium and MLVSS/MLSS during the 33 days |

| Figure 7. No filamentous bulking @ 147 mL/g SVI30 |

4. Conclusions

- The growth of filamentous bacteria in the aeration tank can be controlled by the application of 12.5% sodium hypochlorite @ 15 L/hour.High Total Suspended Solids (TSS) in the clarifier supernatant solution can be reduced quickly to save money paid to Sydney Water due to the high TSS load in the disposal wastewater.It is a cost-effective method and a quick solution for the filamentous growth problem in the aeration tank of the SWTP. Do not overdose sodium hypochlorite for more than 10-12 days.Increased SVI30 may be due to the high rate of nitrification and denitrification in the aeration tank if it sustains after the hypochlorite treatment for more than 10-12 days.Reduce the airflow in the aeration tank to stop the nitrification but not for more than 24 hrs.

ACKNOWLEDGEMENTS

- This work is carried out in the Wet Chemistry Laboratory, Opal Paper and Recycling Mill, Sydney, Australia. The author is thankful to Opal Paper and Recycling Mill for the supply of the necessary resources and equipment required to conduct this research work.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML