Jannika Bailey1, Alfredo Esteves1, Noelia Quiroga2, Emilia Raimondo2

1INAHE-Instituto de Ambiente, Hábitat y Energía - CCT CONICET Mendoza, Mendoza, Argentina

2Facultad de Ciencias Agrarias, Universidad Nacional de Cuyo, Mendoza, Argentina

Correspondence to: Jannika Bailey, INAHE-Instituto de Ambiente, Hábitat y Energía - CCT CONICET Mendoza, Mendoza, Argentina.

| Email: |  |

Copyright © 2019 The Author(s). Published by Scientific & Academic Publishing.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Abstract

On mountainous areas, fuel for cooking, such as propane or firewood, has to be transported. A heat retention box (HRB) is an energy-efficient cooking device by completing the cooking process while reducing energy consumption and preserving all of the food’s organoleptic properties. In this article we present the design of a cylindrical-shaped HRB (C-HRB), its construction and thermal evaluation. In addition, we have compared its thermal performance and its cost to the parallelepiped heat retention box (P-HRB), traditionally used in rural and urban areas of Mendoza, Argentina. Results show that the P-HRB keeps the food only 3.3°C warmer than the C-HRB after 1 hour. This period is an average cooking time for most meals. Furthermore, the cost is similar to the P-HRB, and it is moredurable during transport. This box is easily portable by mule, the pack animal most commonly used to transport goods and equipment in mountainous regions worldwide.

Keywords:

Heat Retention Box, Low Cost Fireless Cooker, Mountainous Areas

Cite this paper: Jannika Bailey, Alfredo Esteves, Noelia Quiroga, Emilia Raimondo, Efficient Cooking for Montainous Areas: Development, Assembly and Thermal Behavior of Cylindrical Heat Retention Box, Science and Technology, Vol. 9 No. 1, 2019, pp. 12-17. doi: 10.5923/j.scit.20190901.03.

1. Introduction

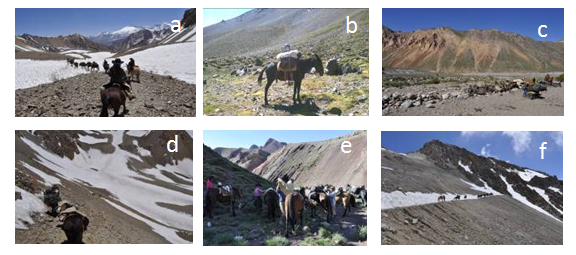

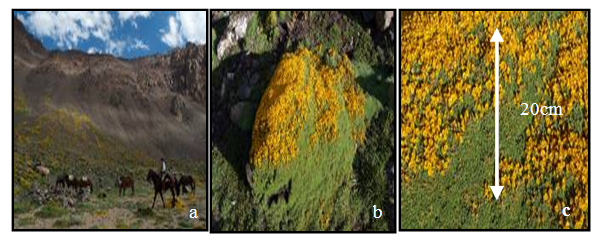

In mountainous areas equipment is normally carried by pack mule in pack saddles cinched with rope. Every year in Argentina and Chile, adventure tourists retrace General San Martin’s epic Andes crossing. During the South American wars of independence, San Martin crossed into Chile at the “Los Patos” pass, in San Juan province, and returned to Argentina via the “Los Piuquenes” pass, in Mendoza province. The number of people visiting Aconcagua National Park is increasing each year the most popular excursions are treks to Confluencia Camp (3300 masl), Plaza Francia (4000 masl), Plaza de Mulas (4300 masl) and summiting Mt. Aconcagua (6962 masl). To make the summit, trekkers remain 14 days in the park, while for the shorter treks, their stay is between 2 and 7 days. For both the Aconcagua treks and the Andes crossing, fuel, consisting of either liquefied gas or firewood, must be transported for cooking. Pack mules are used because they are surefooted on steep slopes, strong, and they are resistant to disease, adverse weather conditions and a lack of food. During the Andes Crossing, biomass found in the area serves as fuel. In the Paso Piuquenes area, the root of a plant called “Yareta” (Azorella compacta) is commonly used for firewood. In its combustion the emitted heat is high, but the embers are very few and to maintain the heat for cooking or warmth or boiling water, the fire consumes a large quantity of roots. This species takes 100-150 years to grow and develop a useful biomass [1] because of its slow growth rate with a radial growth rate of 1.70 cm over 14 months [2]. Since 1980, the destruction of this plant has increased dramatically, which has contributed significantly to the desertification process. In Fig. 1, we show in detail an example of the Yareta species in its high mountain habitat. | Figure 1. (a) Extention of Yareta at “Real de la Yareta” camp, Andes Crossing (b) (c) Yareta (Azorella compacta) |

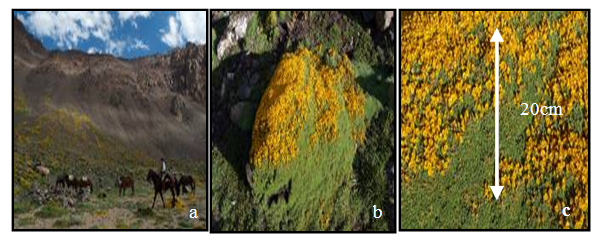

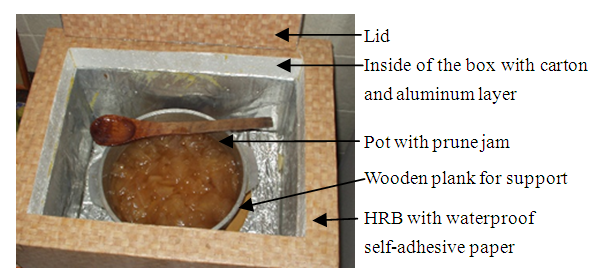

In order to test the performance of the HRB, it was used during an Andes crossing via Paso Piuquenes. The starting point was the Manzano Histórico, Tunuyán, Mendoza. Cooked meals had to be provided for all who were involved in the trip. Daily cooking, either on an open fire or stove, requires a long period of time for most meals, especially those that involve legumes, grains, hard vegetables and meats. Most meals on these trips consist of rice, pasta, soups, stews, polenta, risotto, couscous, corn and meats. The amount of energy required to cook could be reduced by 50-70%, depending on the initial source of heat (gas, firewood or solar oven), if heat retention boxes were used [3].The HRB is based on the principle of energy conservation, acting as a barrier that stops heat transfer by conduction (using an insulating thermic material) and radiation (it has a radiant barrier to stop the transmission of infrared energy). Therefore the box is constructed with the goal of maintaining the heat in the pot and preventing excessive heat transfer to the coldest object (in this case, the outside environment).The advantages of using HRB are [4-6]:The cooking process is carried out with significantly less external heat loss compared to traditional methods that use a pot in direct contact with the outside air.The box can be used in a domestic kitchen and in combination with traditional methods, thus making its incorporation into traditional cooking easier.It is not affected by daily weather conditions.Cooking times are similar to that of ovens or stoves.It is possible to combine several heat sources in the box, and this reduces cooking times and increases energy efficiency.It is not necessary to check on what one is cooking or stir constantly because food does not burn or stick to the pot.Food that can be cooked in a HRB is varied: stews, pasta, vegetables, legumes, meats and many others. In general terms, suitable foods are those that contain some liquid (water, milk, sauce, broth).It is possible in HRB with appropriate size, to cook large amounts of food. For example in community kitchens where 20 to 40-liter pots are often used.It is very cheap to make.It can easily be built in community workshops where the future user contributes with the workforce.Other low energy consumption cooking methods exist, such as placing a previously boiled pot of food into a hole in the ground, covering it with hay and dirt and cooking with the heat retained in the process. The insulating effect of the hay means that the food cools very slowly. Sawdust, feathers, rags, wool or paper towels are also suitable insulators [7].Not many articles have been written on heat retention boxes. In India, a study carried out by Vandana Kaushik [8] studied the box’s efficiency for cooking rice, India’s staple food. Results showed that the box (made with sheets of compressed hay 20 x 20 cm and 10 cm thick) could not only cook the food but also keep it hot within a safe temperature range, for a period of 6 hours.McCarton [9] invented a stored heat cooking utensil that consists of an outer container, a cooking vessel, a heat storage element, a lid for enclosing the outer container and cooking vessel. All these elements are metal and therefore are very heavy.At the World Solar Cooking and Food Processing Conference, Milano 1999 [10], a small mention of the HRB was made, recommending its use in combination with solar ovens.A method involving the combination of thermization (58–63°C for 30s) and low-cost evaporative cooling has been shown to be effective and has been successfully tested by Kisaalita [11] in different districts of Uganda.In national research, Saravia proposes the use of a solar oven made of concentrators, mobile solid accumulators and a heat retention box designed to make cooking easier. This system was designed for cooking large quantities of food, such as for boarding schools or community kitchens in energetically isolated areas. The box, used to heat a 20-liter pot, was 32 cm in height and diameter with 5 cm thick fiberglass insulation [4].In a paper published by Esteves [12], the effectiveness of cooking a reduced amount of food, for a family for instance, was proven. In Mercado and Esteves [5], they suggested introducing HRBs in school dining halls. Several trials were carried out to examine the cost of cooking large amounts of food and a design for a box with a capacity for 20-40 kg of food was presented. Their time and temperature experimental trials allowed them to optimize the system and evaluate the cost saving element of the fuel used.This current study references the model published by Esteves because it uses the same materials, this time aimed at cooking for a small group of people [12]. Fig. 2 shows interior of HRB as it is traditionally built by the research team of INAHE-CONICET. Fig. 3 shows the exterior of HRB. | Figure 2. P-HRB and its parts |

| Figure 3. P-HRB with painted cardboard on the outside |

This box has proven its efficacy within the research community, as well as with participants at workshops (future users). In constructing their boxes, they have even tested giving them different finishes (brightly adhesive paper, papier-mâché, cardboard, and various handles or knobs). The assembly method has been the one described by Mercado [13]. Fig. 4 shows the boxes built in a workshop in the rural area of central-western Argentina. | Figure 4. P- HRB built in a workshop |

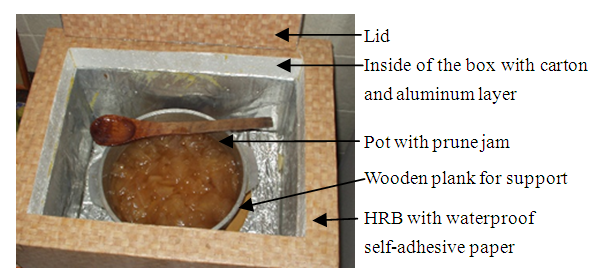

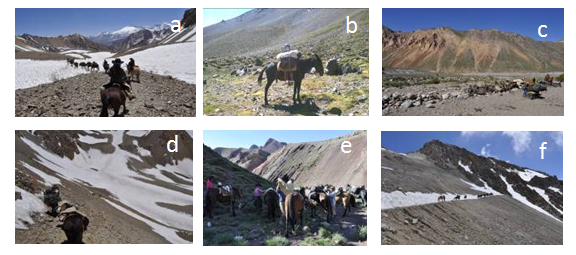

The HRB that we made specifically for the Andes Crossing had a round base and capacity for a 5-liter pot. Although different materials can be used [12], we chose expanded polystyrene (EPS) sheets, the assembly method being the one indicated by Serrano (personal communication). The materials chosen had to be sturdy, without adding too much weight. Fig. 5 shows the box being transported by mule during the Andes Crossing. | Figure 5. Transport of cylindrical HRB from Real de la Yareta to Real de la Cruz, in the Andes Crossing by “Paso Piuquenes” |

Fig. 6 shows the different situations in which the HRB was transported and strapped to the pack saddles on the mules. The load had to be prepared several hours before departure in plastic boxes, with each item wrapped in newspaper. | Figure 6. (a) Transport of load from Portillo Argentino to Real de la Cruz (b) Mule and its load at Real de la Yareta (c) Preparation of the load at Real de la Cruz (d) Mules and horses going down from Portillo Argentino (e) Preparation of load at Real del Gauchito (f) Horses going up Portillo Argentino |

The HRB box had to be placed in a round plastic bin or wrapped in blankets to protect it from dirt and any marks that cinching the mule might cause. Because the box had to be loaded and unloaded from the mule many times, its design, based on practicality and safety, was fundamental in preventing damage.Although the box could theoretically be reinforced on the outside with a metal sheet or wooden slats to avoid damage, this would also increase its weight (and subsequently the weight of the mule’s load—a crucial factor). In this article we will describe the construction of a cylindrical HRB and its thermic and economic evaluation. The box has been adapted for easy transport by mule and reinforced to prevent the saddle straps altering its shape.

2. Methodology

2.1. Making the Heat Retention Box

2.1.1. Parallelepiped HRB (P-HRB)

Materials needed to make a P-HRB:6 sheets of 30 x 40 x 5 cm thick expanded polystyrene (EPS).Aluminum foil (240 cm long x 30 cm wide to cover all 6 inner sides).Corrugated cardboard (240 cm long x 30 cm wide to cover all 6 inner sides).Glue for EPS (toluene-free). Enough to stick down all sides of the EPS sheets, cardboard and aluminum.Handle or knob for the lidSelf-adhesive or contact paper or another kind of material to finish the outside.The HRB (Fig. 7) used by the research team at INAHE (Instituto de Ambiente, Hábitat y Energía) has given very good results, but because of its size, 50 cm long and 30 cm high, it is difficult to transport to isolated places that are only accessible by mule or horse. | Figure 7. HRB used by the research group with cardboard on the outside (b) and contact paper (a) (b) |

2.1.2. Cylindrical HRB

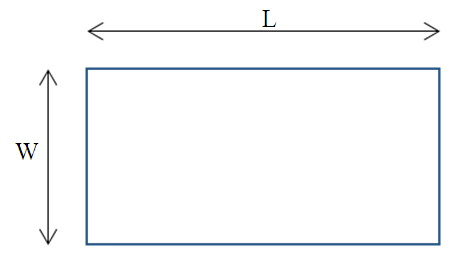

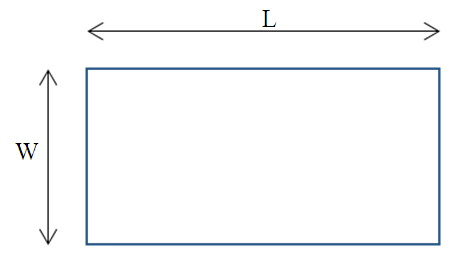

Taking into account that the size of the P-HRB was its main drawback, a cylindrical one was devised. The C-HRB is constructed from an expanded polystyrene sheet, as shown in Fig. 8. The measurements of the sheet (L: length and W: width) are obtained using the diameter and height of the pot, according to Eq. (1)-(2). Note that it is possible to make a cylindrical thermal box for any size of pot.  | Figure 8. Expanded polystyrene sheet measures: length (L) and width (W) |

| (1) |

Where:Ep = Gap in cylindrical box to easily insert the pot (cm), usually 4 cm.Ea = Thickness of Expanded polystyrene (cm), usually 5 cm | (2) |

Where:Ea = Thickness of top and bottom of expanded polystyrene (cm), usually 5 cm.The cover and bottom of the cylindrical HRB must have the measurement indicated in Eq. (3). | (3) |

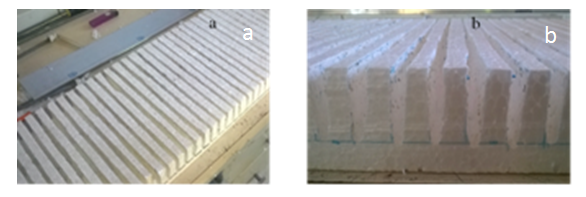

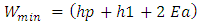

Where:Ep = Gap in cylindrical box to easily insert the pot (cm), usually 4 cm.R Note that Eq. (1) (2) give minimum L and W, this is just for that pot. However we could consider a higher value to use with other larger pots.In this case, the materials and its measures are:1 sheet of EPS-140 cm x 30 cm and 5 cm thick.2 discs of EPS – 32 cm diameter.Aluminum foil 200 cm x 30 cm (to cover the inner part of the cylinder and the 2 discs).Corrugated cardboard 200 cm x 30 cm (to cover the inner part of the cylinder and the 2 discs).Enough polyurethane foam to fill in the gaps (approx. 1 x 750 ml spray).Glue for EPS (toluene-free). Enough to stick down all sides of the EPS sheets, cardboard and aluminum).Handle or knob for the lid.Self-adhesive or contact paper, or another kind of material to finish the outside.There are no cylindrical-shaped EPS containers on the market suitable for this device, so the cylinder was made from a rectangular sheet measuring 140 cm x 30 cm x 5 cm. By making notches in the EPS every couple of centimeters, the sheet can then be bent to form the cylinder. The cylinder has a 41 cm outer diameter and a 31 cm inner diameter.The notches are made with a 2"x 1/8" metal rod heated with a blowtorch. The rod produces notches 3.5 cm deep, leaving 1.5 cm without intervening, creating a pattern of clefts as shown in Fig. 9. Then the sheet can be formed into a cylinder (Fig. 10) whose inner diameter is slightly larger than the pot. | Figure 9. (a) Rectangular EPS sheet 1.4 m long x 0.3 m width showing the notches made by melting the EPS (b) View of the melted 1 cm wide notches |

| Figure 10. Decreased water temperature inside the pot when the pot is placed inside the P-HRB and C- HRB in a 12h period |

Once the cylinder is formed, all gaps must be filled with polyurethane foam, which gives the box more rigidity, as well as improves its insulation. Interestingly, the outer surface of the box is 0.67 m2, which is considerably less than the surface of the P-HRB, which is 0.84 m2.

2.2. Handling and Usage

As described in Mercado and Esteves [5], the box is very simple to use. Food in the pot must be heated to the boiling point on a regular stove. Then the pot is left to rest for 5-10 minutes and placed in the HRB to finish cooking. The flame under the pot on the stove should be just enough to reach the boiling point; once it is reached, cooking should continue in the HRB.The pot should be placed inside the HRB on top of a wooden board or on small strips of wood (approx. 10 x 1 cm) to avoid overheating and damaging the EPS. The time that the pot is in the box is directly proportional to the energy saved in liquefied gas or firewood. Cooking time in the box varies according to the food being cooked, and ranges from 20 minutes to 5 hours. The amount of food placed in the pot is also a factor [3].Most vegetables, pasta, and rice only need to be cooked until boiling point is reached. With legumes it is preferable to soak them in water for 8 hours prior to cooking and boil them for 15 minutes before putting them in the HRB. However, if they have not been allowed to soak, they may need to be boiled for a longer period.

3. Results

3.1. Thermal Performance Evaluation

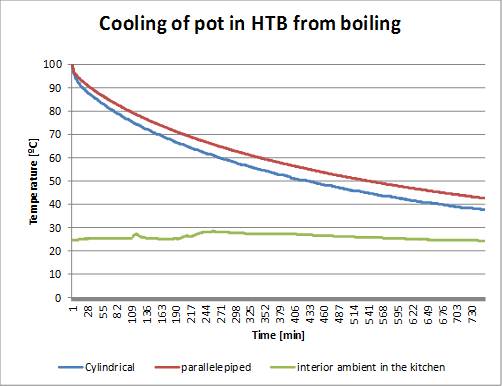

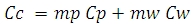

Tests were carried out to measure the time the P-HRB takes to cool down as compared to the cylindrical HRB. The same pot filled with 2 liters of water was used for both HRBs.In both cases, the drop in temperature was measured over a 12 hour period. The temperatures of the water contained in each pot and of the outside environment was measured every minute. Temperatures were recorded with a HOBO data logger with type T thermocouple. The water and the pot were weighed with a electronic scale (Systel bumer, max 30 kg, min 0.1 kg, Argentina).In order to take into account the effect of the pot, the material and its weight have been taken into account. According to Eq. (4), the calorific capacity value of the pot with respect to the calorific capacity of the water could be said to be negligible. | (4) |

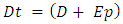

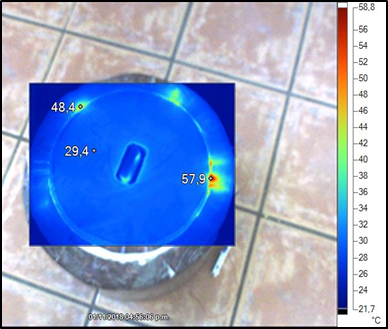

The material of the pot is aluminum, has a mass of 0.48 kg; Cp = 0.88 kJ/kg.°C and the water has a mass of 2 kg and Cw=4.186 kJ/kg.°C. The total calorific capacity value is 8.794 kJ/°C, in which the pot is only 0.422 kJ/°C (only 4.8%).Fig. 11 shows the differences in temperature of the water in the pot in both boxes over a 12 hour period. The pot in the P-HRB cools more slowly. | Figure 11. Decreased water temperature inside the pot when the pot is placed inside the P-HRB and C-HRB in a 3h period |

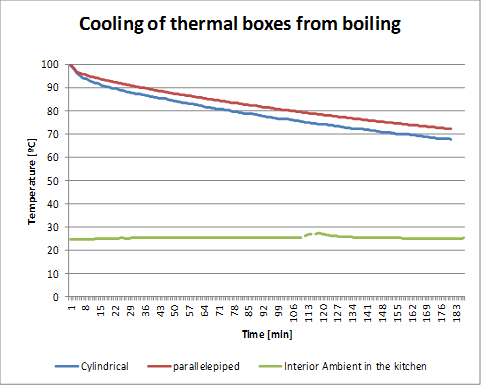

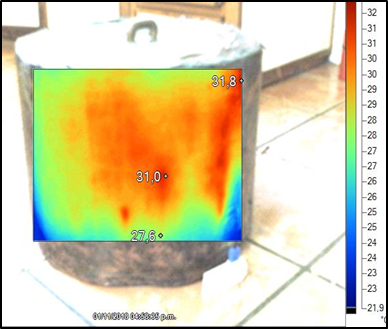

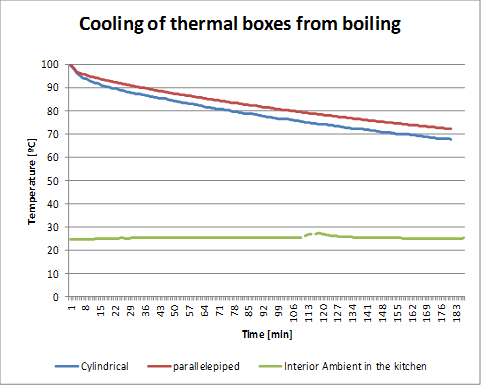

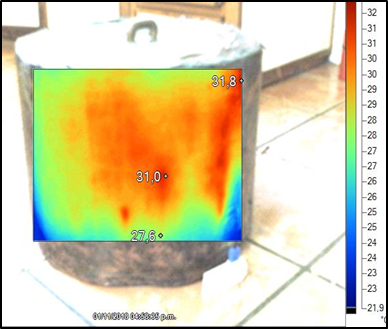

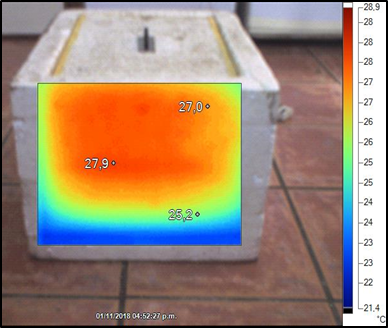

Fig. 12 shows in more detail how the temperature decreased in both pots over a 3 hour period. Clearly, the drop is slower in the parallelepiped HRB, with a difference of 3.3°C. It is worth pointing out that this 1 hour time period is the average cooking time for most foods, with the exception of more time consuming preparations such as roulade or jam, and that the temperatures remained above 80°C for both HRBs. | Figure 12. Wall thermography of cylindrical HRB |

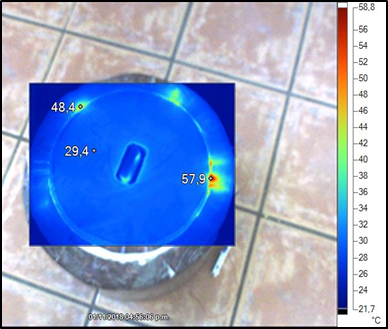

| Figure 13. Top thermography of cylindrical HRB |

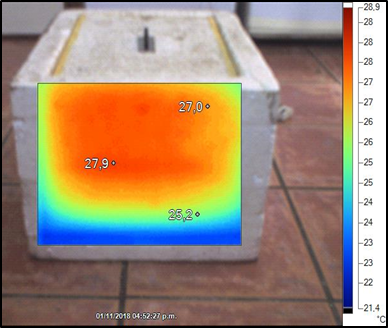

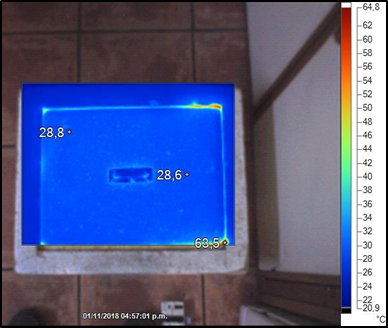

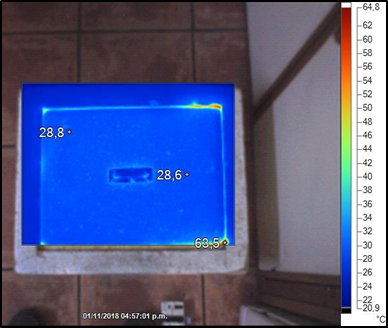

Fig. 12 and 13 show the wall and top thermographs respectively of the C-HRB. The heterogeneity derived from the method of making the thermal box is observed, and produces higher heat losses than P-HRB, whose thermographs are indicated in the Fig. 14 and 15. | Figure 14. Wall thermography of parallelepiped HRB |

| Figure 15. Top thermography of parallelepiped HRB |

4. Conclusions

The cylindrical heat-retention box (C-HRB) presents a slightly better thermal performance than the P-HRB, moreover its shape makes it portable and able to accommodate 5-liter pots.The design is easy to replicate without prior knowledge, and because fewer materials are required in its construction this translates into a smaller, lighter box and less heat loss. The outer surface of the cylindrical HRB is 0.67 m2, which is considerably less than the surface of the parallelepiped HRB, that is, 0.84 m2.The use of polyurethane foam adds rigidity to the box, unlike boxes made of EPS without covering and reinforcement on the outside.This box was used on the Andes crossing, carried by mule and cinched with ropes to a pack saddle. The box did not lose its shape or split. This was despite the fact that during the ride it was subjected to rough handling and had to be tightly secured due to the moderate to strong winds that are frequent during this type of mountain crossing. A variety of meals were cooked in the box during the trip, including pasta, stews, soups, and polenta. Use of the C-HRB resulted in a significant fuel savings, and it showed good thermal performance when cooking in low outdoor temperatures.

ACKNOWLEDGEMENTS

To the National Department of the Environment and Sustainable Development and CONICET for subsidizing part of the research work. To Fernando Buenanueva that assisted in the construction of the C-HRB.

References

| [1] | C. Muñoz Pizarro, 1973, Chile: Plantas en extinción (Chile: plants in extinction), ed. Editorial Universitaria, in Muñoz M. y Serra M.T., 2006. Estado de Conservación de las Plantas de Chile. MNHN-CONAMA. |

| [2] | C. Kleier, P.W. Rundel, Microsite requirements, population structure and growth of the cushion plant Azorella compacta in the tropical Chilean Andes, Austral Ecology 29 (2004) 461–470. |

| [3] | A. Esteves, C. Ganem, M. V. Mercado, Energy Conservation and Solar Energy Use for Cooking -Impact of Its Massive Adoption in the Arid Zone of Argentina, International Journal of Architecture, Engineering and Construction 3 (1) (2014) 44-56. |

| [4] | L.R. Saravia, C. Cadena, H. Suárez, C. Fernández, El uso de la “Caja Caliente” en los procesos de cocción solar y las alternativas para su calentamiento (Use of HRB in cooking processes and alternatives for heating). Avances en Energía Renovable y Medio Ambiente 3 (2) (1999). https://0x9.me/I0zvg. |

| [5] | M. V. Mercado, A. Esteves, Caja caliente para comedores comunitarios y/o escuelas rurales (HRB for community kitchens and/or rural schools), Avances en Energía Renovable y Medio Ambiente 8 (2) (2004) 55-60. |

| [6] | V. N. Quiroga, R. Ruiz Huidobro, E. Stocco, Transferencia de tecnología de cocción energéticamente eficiente. Caso del Carrizal y Ugarteche, Luján de Cuyo - Mendoza Mujeres rurales innovadoras (transfer of energy efficient technology. Case of Carrizal and Ugarteche, Luján de Cuyo-Mendoza. Innovative rural women), en: XXXI Reunión de la Asociación Argentina de Energía Renovable, Mendoza, Argentina, 2008. |

| [7] | Solar Cooking. 2016. Retained Heat Cooking. http://solarcooking.org/heat-retention/ret-heat.htm. (accessed 04/08/2018). |

| [8] | V. Kaushik, Designing Fireless Cooker of Indigenous Insulation Material for Better Heat Retention, Journal of human ecology (Delhi, India), 30 (2) (2010) 99-104. DOI: 10.1080/09709274.2010.11906278. |

| [9] | D. J. McCarton, V. T. Minto, Stored heat cooking utensil. USA Patent 4258695, 1981. |

| [10] | D. Seifer. 1999. Offprint Proceedings International Conference World solar cooking and food processing -Strategies and Financing Varese, World Solar Academy, Milano Proposals for a Global Solar Cooker Programme. |

| [11] | W. S. Kisaalita, A. Katimbo, E. Sempiira, D. Mugisa, EvaKuula. 2018. Saves Ugandan smallholder farmers’ evening milk. Sustainable Energy Technologies and Assessments, (29) 155-163. DOI: 10.1016/j.seta.2018.08.002. |

| [12] | Esteves A. 2005. Caja Caliente para completar la cocción de alimentos. (HRB for complete foods). https://www.mendoza.conicet.gov.ar/portal//inahe/upload/caja-termica-para-completar-cocciones.pdf (accessed 10/02/2019). |

| [13] | Mercado M. V. 2018. Secuencia de armado de Caja Térmica. (HRB-sequence to make it). https://www.mendoza.conicet.gov.ar/portal//inahe/upload/secuencia-de-armado-de-caja-termica.pdf (accessed 10/02/2019). |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML