-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Science and Technology

p-ISSN: 2163-2669 e-ISSN: 2163-2677

2017; 7(1): 4-24

doi:10.5923/j.scit.20170701.02

A Reviev on Advances in Rapid Prototype 3D Printing of Multi-Functional Applications

V. K. Srivastava

Department of Mechanical Engineering, Indian Institute of Technology (BHU), Varanasi, India

Correspondence to: V. K. Srivastava, Department of Mechanical Engineering, Indian Institute of Technology (BHU), Varanasi, India.

| Email: |  |

Copyright © 2017 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

The present paper is providing overview information in rapid prototype manufacturing process of 3D printing for multifunctional applications. To make precise and useful products, 3D printers are attractive method over 2D printers because of multiple types of material within a single build-up cycle. This technology allows the printing of multiple colors. The multi-functional material printers work for a single family of a materials like polymers, for instance and are largely used for prototyping applications. Various factors mostly generated to materials themselves, which make further improvement in prototype printing. Mostly processes are built-up around an ideal material that responds to a narrow range of temperature inputs or light frequency. Using heat or light, printers often liquefy or solidify substances to manipulate the material into specific forms.

Keywords: 3D printing, Multifunctional materials, Fused deposition modelling, Nanomaterials, Biomaterials

Cite this paper: V. K. Srivastava, A Reviev on Advances in Rapid Prototype 3D Printing of Multi-Functional Applications, Science and Technology, Vol. 7 No. 1, 2017, pp. 4-24. doi: 10.5923/j.scit.20170701.02.

Article Outline

1. Introduction

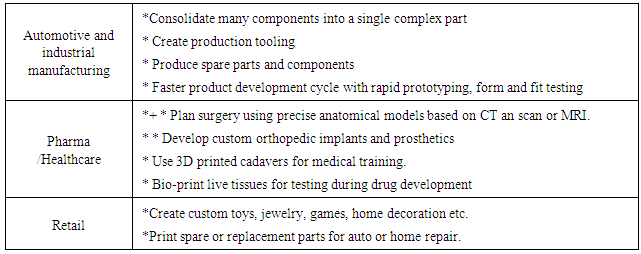

- Basically, 3D printing technology has been developed by Silicon Valley start-up, Carbon3D Inc., enables objects to rise from a liquid media continuously rather than being built layer by layer as they have been for the last several years, representing a fundamentally new approach to 3D printing [1]. 3D is also known as rapid manufacturing or rapid prototyping printing process, which has ability to make efficient use of raw materials and produce minimal waste while reaching satisfactory geometric accuracy [2-3]. Using this method, a design in the form of a computerized 3D solid model can be directly transformed to a finished product without the use of additional fixtures and cutting tools. These open the possibility of producing parts with complex geometry which are difficult to obtain using material removal processes. In addition, 3D printing is ability to construct complex geometries means that many previously separated parts can be consolidated into a single object [4]. The 3D software digital slice model is utilized for final model into hundreds or thousands of horizontal layers. When the sliced file is uploaded in a 3D printer, the object can be obtained layer by layer. The 3D printer reads every slice or 2D image and creates the object, blending each layer without visible of any sign of the layers, with as a result the three dimensional object. The 3D printing is applicable for different sectors as mentioned in Table-1. Generally, many different printing technologies are material dependents.

|

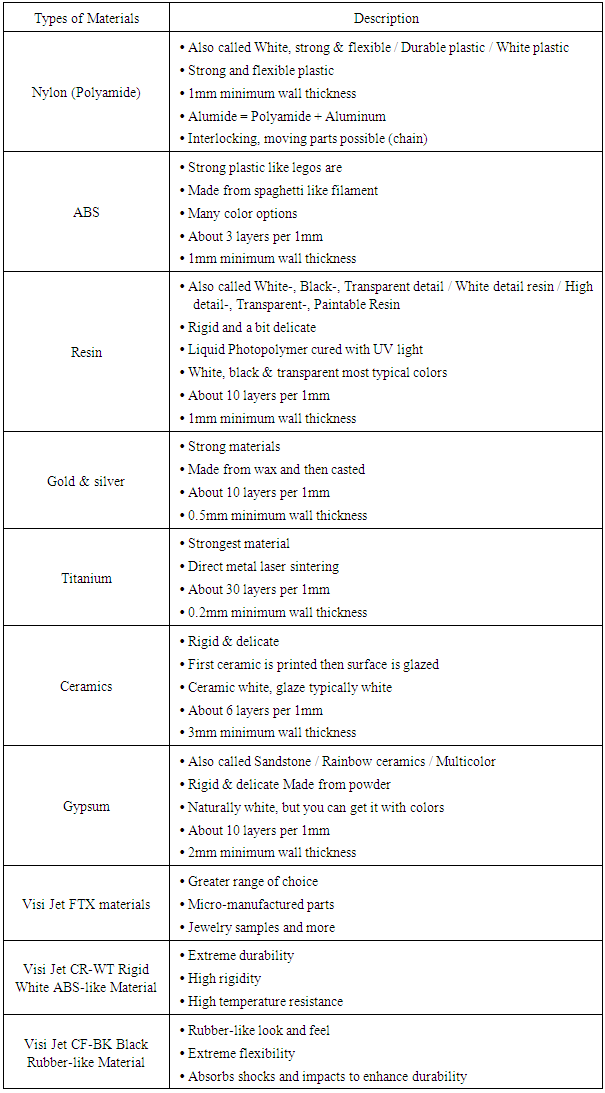

2. 3D Printing Materials

- 3D printing has emerged as a leading manufacturing technology all over the world. The development of new method does not affect only quality of the end product but it also opens new markets and influences on the price of used materials. The success of 3D printing is depended on fine-tuning materials to the needs of each application. This fine-tuning process is involved on the type and the quality, strength and costs of materials. There are many materials that can select when it comes to 3D printing. However it’s often tough to decide on the right one. The various materials can be adopted for 3D printing based on the needs of market. The types of materials are listed in Table-2 [5]. There are many materials that can be used for 3D printing depending on their application. The thermoplastics materials ABS and PLA are soft and moldable when heated and return to a solid after cooling. This process can be repeated several times and their ability to melt again to processed further. However, there are many thermoplastics in which very few of them are currently used for 3D Printing. The best 3D printing materials, which has to pass three different tests; initial extrusion into Plastic Filament, second extrusion and trace-binding during the 3D Printing process, then finally end use application. The ABS and PLA is the best materials if before use or when stored long term, they are sealed off from the atmosphere to prevent the absorption of moisture from the air. This does not mean plastic will be ruined by a week of sitting on a bench in the shop, but long term exposure to a humid environment can have affects the printing process and to the quality of finished parts. Varieties of ABS, PC and high performance materials are available in the market likes ABS Plus, ABSi, ABS-M30, ABS-30i, ABS-ESD7, ASA, PC, Pc-ABS, PC-ISO, PPSF/PPSU, ULTEM1010, ULTEM9085 and nylon12 [6].

|

3. Manufacturing Process of 3D Printings

- The American Society for Testing and Materials group ASTM-F42 have developed a set of standard method that classify the additive manufacturing (AM) processes into seven categories according to Standard Terminology for Additive Manufacturing Technologies.

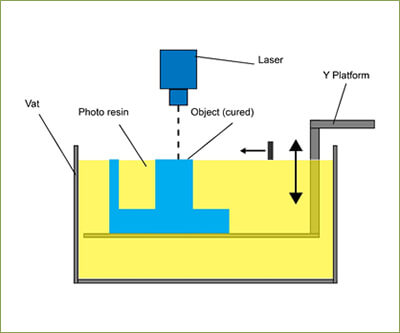

3.1. Vat Photo Polymerization

- 3D printer is based on the Vat Photo polymerization method in which container filled with photopolymer resin and then hardened with UV light source as shown in Fig.1.

| Figure 1. Photo Vat Polymerization method [6] |

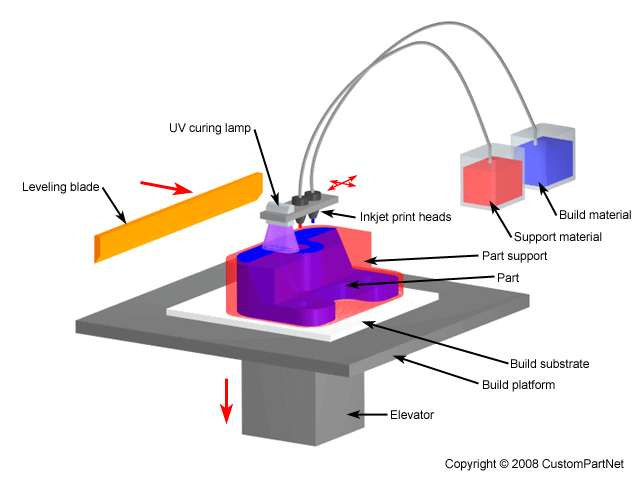

3.2. Material Jetting

- In this process, material is applied in droplets through a small nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform making a 3D object and then hardened by UV light. Then, we can see presentation of Stratasys’ Objet 500 Connex 3D printers that use their proprietary Triple-Jetting technology and can clearly identify (Fig.2) the print heads and UV light [7].

| Figure 2. Material Jetting schematics. Image source [7] |

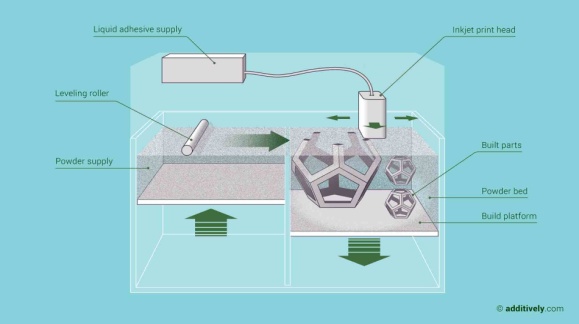

3.3. Binder Jetting

- Two materials (likes powder base material and a liquid binder) are used in the binder jetting method at a time. The powder is spread in the build chamber in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the shape of a programmed 3D object as shown In Fig.3.

| Figure 3. Binder jetting 3D printing technology overview. Image source [7] |

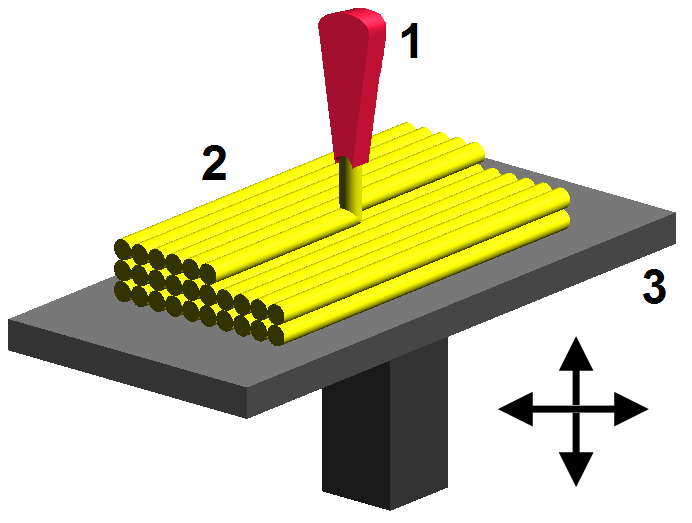

3.4. Material Extrusion

- The Fused deposition modeling (FDM) method is commonly used in 3D process. The FDM technology is working by the use of plastic filament or metal wire in unwound from a coil and supplying material to an extrusion nozzle, which can turn the flow of material on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a computer-aided manufacturing (CAM) software package. The details are mentioned in Fig.4. The object is produced by extruding melted material to form layers as the slowly material hardens after extrusion from the nozzle. This technology is commonly used with two plastic filament material types: ABS (Acrylonitrile Butadiene Styrene) and PLA (Polylactic acid) but many other materials are available ranging in properties from wood filed, conductive, flexible etc. FDM was invented by Scott Crump in the late 80’s and was commercialized in 1990 [8]. Stepper motors or servo motors are typically employed to move the extrusion head. The mechanism used is often an X-Y-Z rectilinear design, although other mechanical designs such as deltabot have been employed. Although as a printing technology FDM is very flexible, and it is capable of dealing with small overhangs by the support from lower layers. The software that comes with this technology automatically generates support structures if required. The machine dispenses two materials, one for the model and one for a disposable support structure. The term fused deposition modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

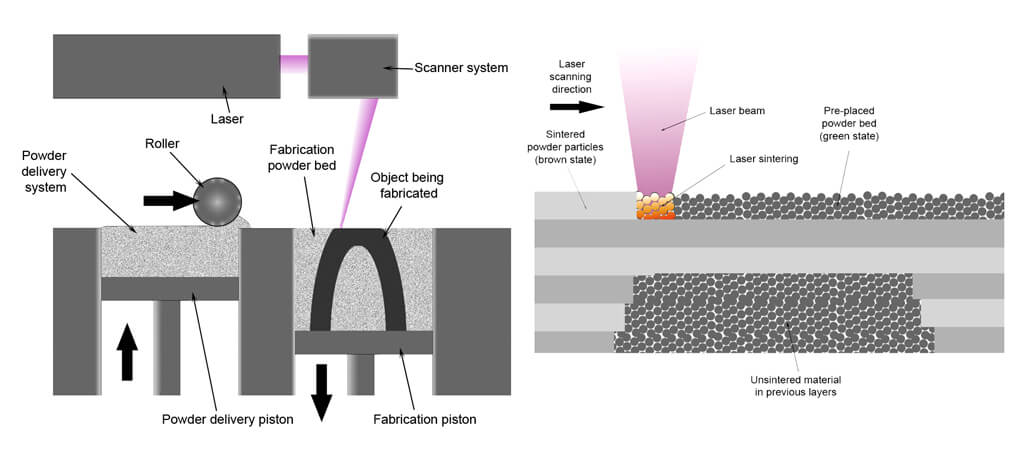

3.5. Powder Bed Fusion

- The most commonly used technology in the 3D processes is Selective laser sintering (SLS) and it is also known powder bed fusion method. An SLS printer is used for powdered material as the substrate for printing new objects. This technology uses a high power laser to fuse small particles of plastic, metal, ceramic or glass powders into a mass that has the desired three dimensional shapes. The laser source fuses the powdered material by scanning the layers generated by the 3D modeling program on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness.Then a new layer of material is applied on top and the process is repeated until the object is completed. All untouched powder remains as it is and becomes a support structure for the object. The schematic picture is given in Fig. 4. Therefore there is no need for any support structure which is an advantage over SLS and SLA [9, 10].

3.6. Sheet Lamination

- Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape as can be seen in Fig.5. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades [9].

| Figure 5. SLS system schematic. Image source [11] |

3.7. Thermal Inkjet Printing

- Inkjet printing is a “noncontact” method that uses thermal, electromagnetic, or piezoelectric technology to deposit tiny droplets of “ink” (actual ink or other materials) onto a substrate according to digital instructions. In thermal inkjet printing (TIJ), droplet deposition is usually done by using heat or mechanical compression to eject the ink drops. In TIJ printers, heating the print head creates small air bubbles that collapse, creating pressure pulses that eject ink drops from nozzles in volumes as small as 10 to 150 picoliters. Droplet size can be varied by adjusting the applied temperature gradient, pulse frequency, and ink viscosity. TIJ printers are particularly promising for use in tissue engineering and regenerative medicine. Because of their digital precision, control, versatility, and benign effect on mammalian cells, this technology is already being applied to print simple 2D and 3D tissues and organs (also known as bioprinting). TIJ printers may also prove ideal for other sophisticated uses, such as drug delivery and gene transfection during tissue construction [11].

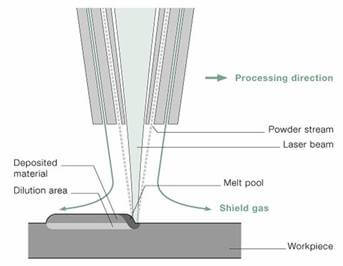

3.8. Directed Energy Deposition

- This process is used in the high-tech metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object as shown in Fig.6 [12].

| Figure 6. Direct Energy Deposition with metal powder and laser melting [12] |

4. Development of 3D Printing Materials

4.1. Metal Particles Filled ABS Material

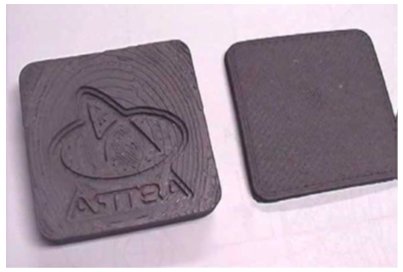

- A new metal/polymer composite material is successfully produced and tested for direct rapid tooling application using the FDM rapid prototyping process. Characterization of this new material displays desirable mechanical properties, offering fabrication of flexible feed stock filaments for producing functional parts and tooling directly on the FDM system [13]. These properties can help to establish the upper limits for the process ability of filament of composites in terms of the particle size and the volume fraction of filler content. In the initial stages of FDM processing, there are a few problems related to filament size variation, over filling with material, clogging of the nozzle and delamination of a few layers due to presence of plasticizer. However, these problems can overcome by making more uniform filaments, regulating the amount of plasticizer, and selecting appropriate values of slice thickness, road width, fill patterns and nozzle diameter. In the initial trials, the build time of a part built with this new composite is almost twice of the time taken in building the same part with the P301 nylon material used in the FDM machine as shown in Figure 7. Also, the tool used in additive manufacturing (AM) to rapidly create three-dimensional models is a fully developed technique and capable of fabricating multifunctional devices.

| Figure 7. A complex shaped injection moulding insert produced on FDM [13] |

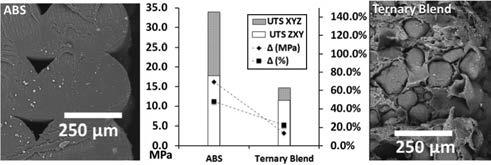

| Figure 8. The rheological differences of the ternary blend as compared to ABS obscure the print rasters leading to a decrease in build orientation-caused mechanical property anisotropy [14] |

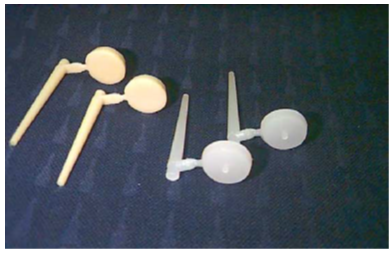

| Figure 9. ABS (left two) and LDPE (right two) parts produced on injection moulding machine using FDM made inserts [21] |

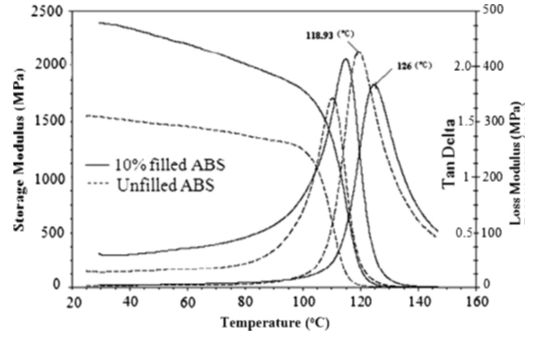

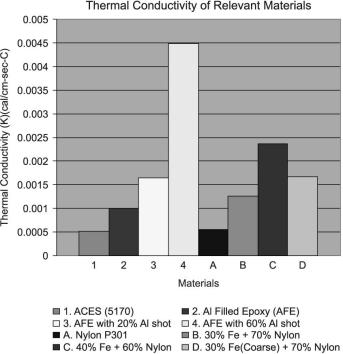

| Figure 10. Comparison of dynamic mechanical properties of virgin ABS and 10% iron-powder filled ABS [22] |

| Figure 11. Thermal conductivity values for various materials [23] |

4.2. Fibre/Nano Filled ABS Material

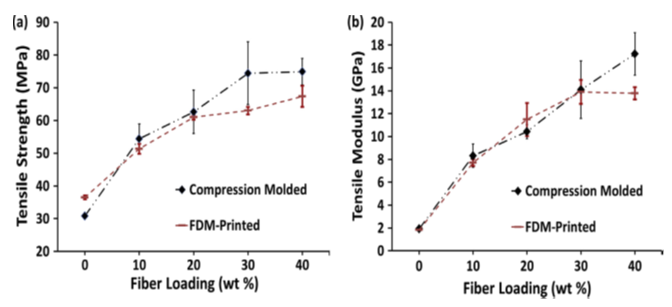

- Most of the material likes, metal, ceramic and carbon nanomaterials are frequently used into AM technologies such as stereo lithography, laser sintering, fused filament fabrication, and three-dimensional printing. The addition of nanomaterials into the printing media for additive manufacturing affects significantly the properties of the final parts. Therefore, it is limitation of nanomaterials in the area of 3D printing by AM method [25]. However, the ability to ceramic materials in 3D printing is critical for structural, functional, and biomedical applications. The best approach is direct ink writing (DIW), in which 3D structures are built layer by layer through the deposition of colloidal or polymer based inks [26]. This method allows one to design and rapidly fabricate ceramic materials in complex 3D shapes without the need for expensive approach.Whereas, the small amount of short glass fibre (4 mm in length) reinforced ABS composite is also significantly improves the strength of an ABS filament at the expense of reduced flexibility and handle ability during FDM process [27]. Short carbon fiber (3.2 mm in length) reinforced ABS resin feedstock at different fiber loadings is prepared, and these feedstock materials are used to successfully fabricate composite specimens by both the FDM printing and compression molding (CM) processes. The comparison between tensile strength and elastic modulus of ABS-CF composites by CM and FDM processes are shown in Fig.12.

| Figure 12. Effect of fiber content and preparation process on (a) tensile strength, and (b) modulus, of ABS/CF composites [28] |

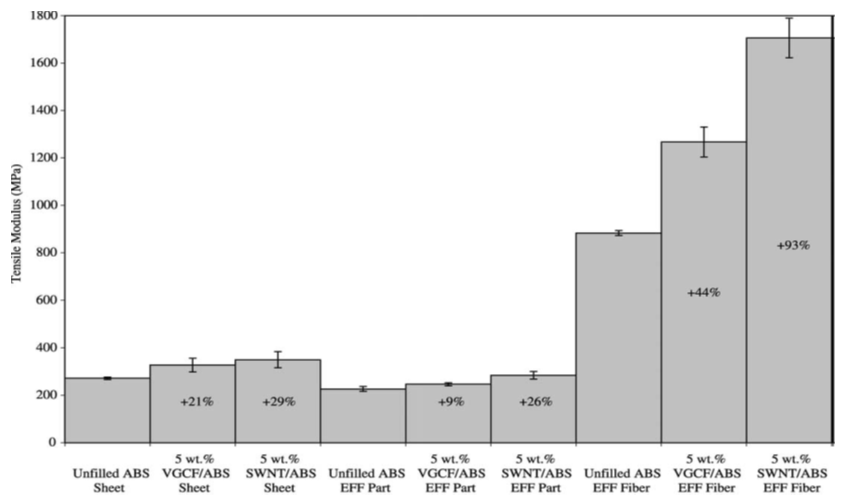

| Figure 13. Variation of tensile modulus versus modifies composites [31] |

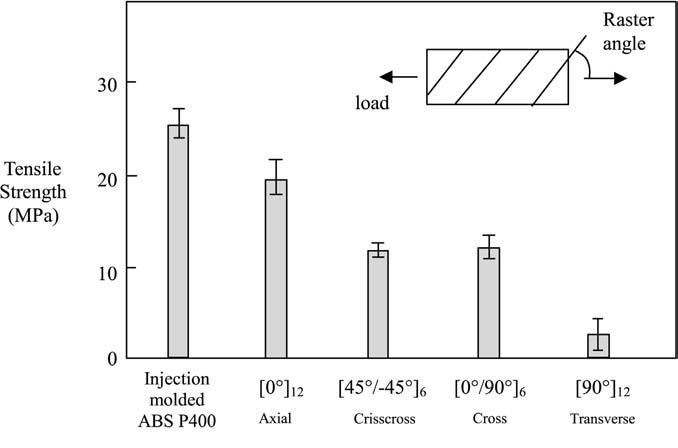

| Figure 14. Tensile strength of specimens with various raster (zero air gap) compared with injection molded ABS P400 [36] |

4.3. Effect of Variation in Deposition on FDM

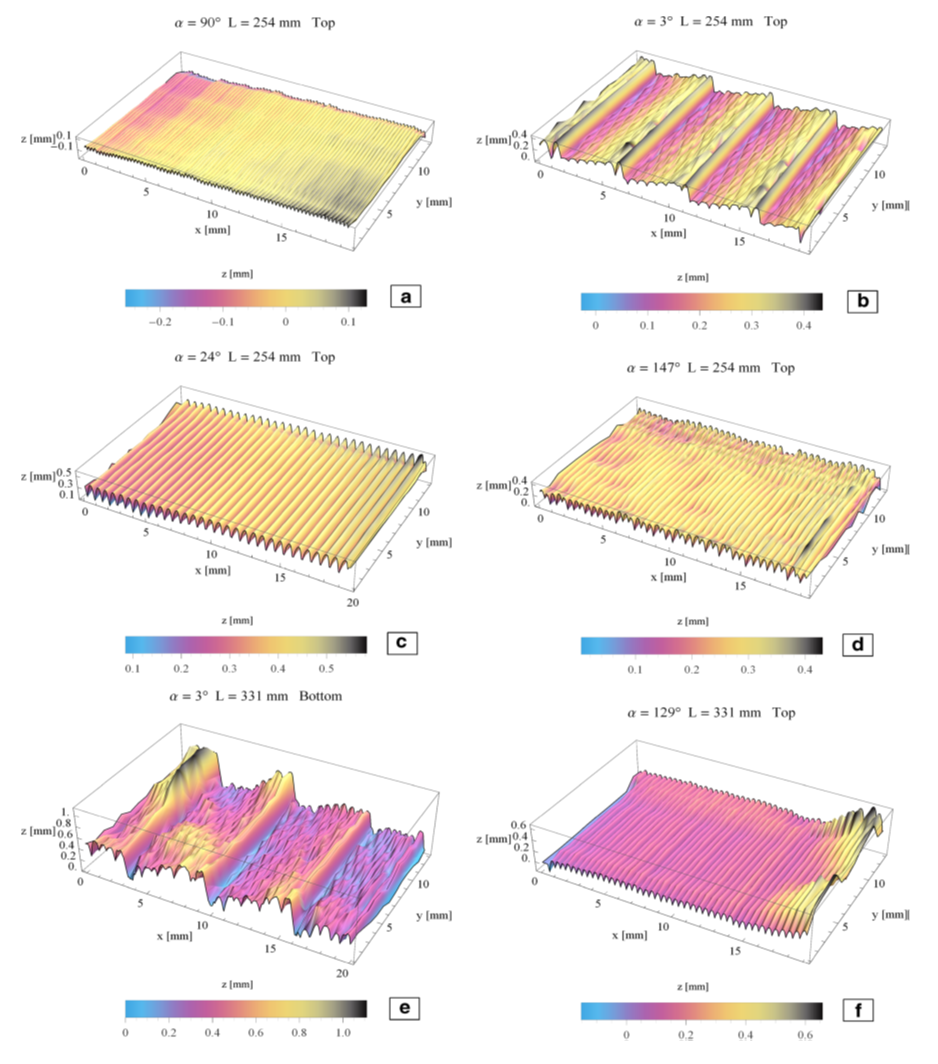

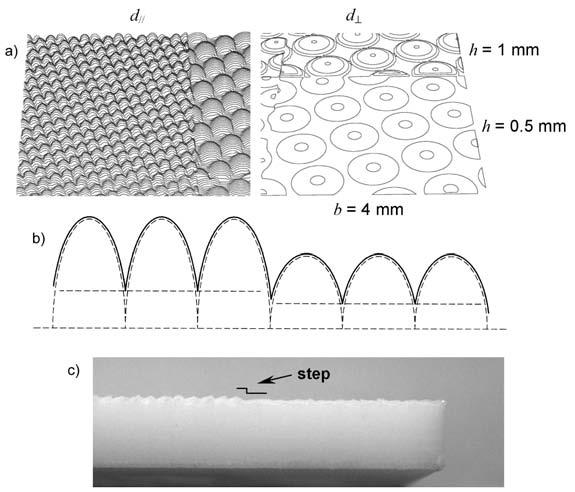

- FDM models are able to develop the layer thickness, deposition angle and roughness. The quantitative analysis regards the bench marking studies which compare the FDM and other AM technologies. It originates from a geometrical model of the filament which takes into account the radius and the spacing of the profile section. The model shows that the dimensional deviation is pair to zero for the vertical walls, as demonstrated in a preliminary experimentation and it increases for deposition angles less and greater than 90°. The validation has been performed by a specimen designed for the purpose in order to investigate 60 different deposition angles in the range 0–180° as shown in Fig.15 [37].

| Figure 15. Three dimensional maps of specimen surface of different deposition angle and layers [37] |

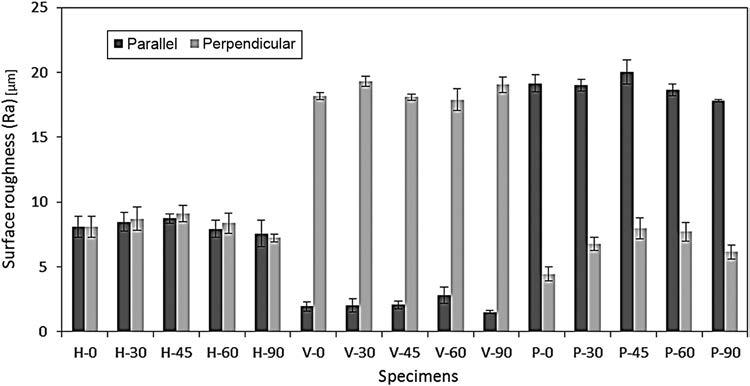

| Figure 16. Showing roughness in parallel and perpendicular direction [39] |

| Figure 17. Resolution limits: (a) spacing of layer contours; (b), (c) feature sinking [44] |

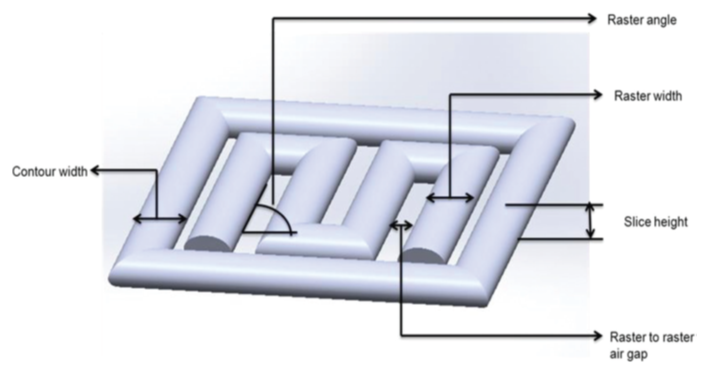

| Figure 18. FDM building parameters [50] |

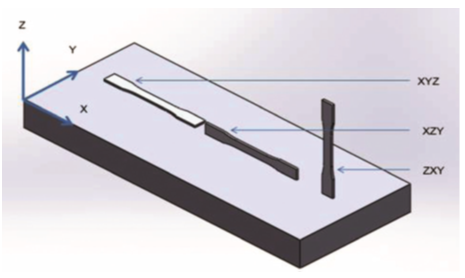

| Figure 19. Build orientations used for the fabrication of ASTM D638 type I specimens [51] |

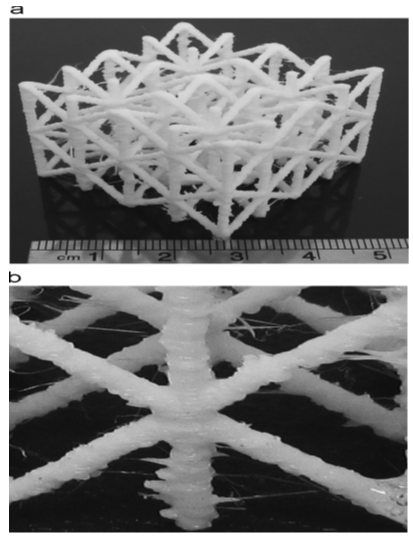

| Figure 20. (a) APLA cellular lattice structure fabricated by FDM (b) a close view of CLS's struts and joints [51] |

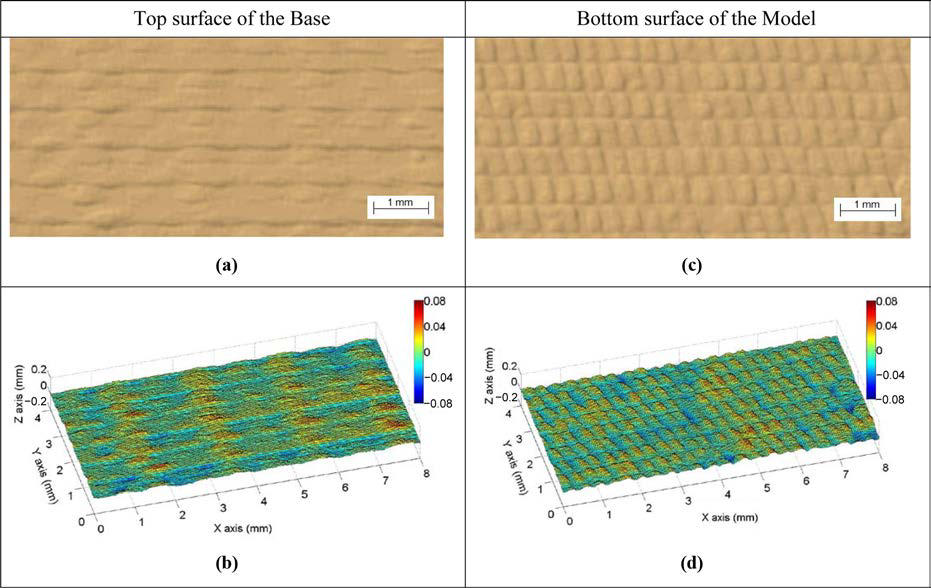

| Figure 21. Scanned images of the top surface of the base (a and b) and bottom surface of the model (c and d) using the modified configuration [53] |

4.4. 3D printing Application in Biomedical

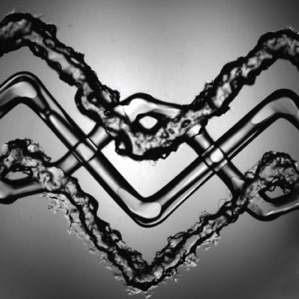

- Most of scientists are working to apply 3D printing technology to the field of medicine, which is most exciting area of research for dramatic changes in technology. However, 3D printing is much easier to print with plastic, metal, or chocolate than to print with living cells. In recent years, researchers have developed successful progress in building tissues and organ like structures in the laboratory. Computer added design and image processing are combined with computer-guided one and two-component air-driven 3D dispensing of hot melts, solutions, pastes, dispersions of polymers as well as monomers and reactive oligomers to produce solid objects with complex shapes and tailor-made internal structures. During the 3D plotting process either individual microdot are positioned in order to construct complex objects, fibers, tubes and scaffolds similar to non-woven. Plotting in liquid media with densities similar to that of the dispensing liquid eliminated the need for construction of temporary support structures [55].Scaffolds are of great importance for tissue engineering because they enable the production of functional living implants out of cells obtained from cell culture. These scaffolds require individual external shape and well defined internal structure with interconnected porosity. Rapid prototyping (RP) method is able to produce such parts. Some RP techniques exist for hard tissue implants and soft tissue scaffolds need a hydrogel material. No bio-functional and cell compatible processing for hydrogels exists in the area of RP [56]. A key feature of this RP technology is the three-dimensional (3D) dispensing of liquids and pastes in liquid media. In contrast to conventional RP systems, mainly focused on melt processing, the 3D dispensing RP process can apply a much larger variety of synthetic as well as natural materials, including aqueous solutions and pastes, to fabricate scaffolds for application in tissue engineering. For the first time, hydrogel scaffolds with a designed external shape and a well-defined internal pore structure can be prepared by this RP process [57]. Three-dimensional fiber deposition (3DF) rapid prototyping technologyis successfully used to produce novel 3D porous Ti6Al4V scaffolds with fully interconnected porous networks and highly controllable porosity and pore size. The main feature of this technology is the 3D computer-controlled fiber depositing of Ti6Al4V slurry at room temperature to produce a scaffold, consisting of layers of directionally aligned Ti6Al4V fibers. The experimental results show how the parameters influence the structure of porous scaffold. The potential of this rapid prototyping 3DF system for fabricating 3D Ti6Al4V scaffolds with regular and reproducible architecture meeting the requirements of tissue engineering and orthopedic implants is demonstrated [58]. One of the main issues in tissue engineering is the fabrication of scaffolds that closely mimic the biomechanical properties of the tissues to be regenerated. Conventional method is not sufficiently suitable to control scaffold structure to modulate mechanical properties. The 3DF process showed great potential for tissue engineering applications because of the precision in making reproducible 3D scaffolds, characterized by 100% interconnected pores with different shapes and sizes [59]. The 3DFprocess allows for the development of metallic scaffolds with accurately controlled pore size, porosity and interconnecting pore size. The titanium alloy scaffolds with different structural properties, such as pore size, porosity and interconnecting pore size are implanted on the decorticated transverse processes of the posterior lumbar spine of 10 goats. The bone formation is monitor after 3, 6 and 9 weeks and the animals are sacrificed at 12 weeks after implantation. In vivo results showed that increase of porosity and pore size, and thus increase of permeability of titanium alloy implants positively influenced their osteoconductive properties [60, 61].Anatomical scaffolds are fabricated from a patient-derived computerized tomography dataset, and compared to cylindrical and toroidal tubular scaffolds. Lewis rat tracheal chondrocytes are seeded on 3DF scaffolds and cultured for 21 days. Interestingly, a lower scaffold's pore volume and porosity resulted in more tissue formation and a better cell differentiation. Scaffolds are compliant and did not show any signs of luminal obstruction in vitro. These results may promote anatomical scaffolds as functional matrices for tissue regeneration not only to help regain the original shape, but also for their improved capacity to support larger tissue formation [62]. Biomaterials is also capable of efficient gene delivery by embedded cells provide a fundamental tool for the treatment of acquired or hereditary diseases. A major obstacle is maintaining adequate nutrient and oxygen diffusion to cells within the biomaterial. Design micro-/macroporous scaffolds to improve cell viability and drug delivery. Murine bone marrow-derived mesenchymal stromal cells (MSCs) genetically engineered to secrete erythropoietin (EPO) are seeded onto poly-l-lactide (PLLA) scaffolds with different micro-porosities. Over a period of 2 weeks in culture, an increase in cell proliferation and metabolic activity is observed with increasing scaffold micro-porosity. The concentration of EPO detected in supernatants also increased with increasing micro-porosity level [63]. In applying the concept of tissue printing for the development of vascularized bone grafts, the primary focus lies on combining endothelial progenitors and bone marrow stromal cells (BMSCs). The 3D printing is very much useful for fiber deposition with a plotting device, Bio-plotter, for the fabrication of spatially organized, cell-laden hydrogel constructs. The results indicate that cells survive the extrusion and that their subsequent viability is not different from that of unprinted cells. The applied extrusion conditions did not affect cell survival, and BMSCs could subsequently differentiate along the osteoblast lineage [64]. Embryonic stem (ES) cells are a potential source for cartilage tissue engineering because they provide an unlimited supply of cells that can be differentiated into chondrocytes. So far, chondrogenic differentiation of both mouse and human ES cells has only been demonstrated in two-dimensional cultures, in pellet cultures, in a hydrogel, or on thin biomaterials. Mouse ES cells readily under went chondrogenic differentiation in vitro in pellets, on bare scaffolds, in Matrigel, and in agarose, both as single cells and in EBs. The ES cells can be used as a cell source for cartilage tissue engineering [65].Despite the periodical and completely interconnected pore network that characterizes rapid prototyped scaffolds, cell seeding efficiency remains still a critical factor for optimal tissue regeneration. The 3D scaffoldis fabricated by combining 3D fiber deposition (3DF) and electrospinning (ESP). The 3DF scaffold provides structural integrity and mechanical properties, while the ESP network works as a “sieving” and cell entrapment system at the extracellular matrix (ECM) scale. 3DFESP scaffolds enhanced cell entrapment as compared to 3DF scaffolds. Furthermore, the ESP surface topology also influenced cell morphology. Thus, the integration of 3DF and ESP techniques provide a new set of “smart” scaffolds for tissue engineering applications [66]. Scaffolds for tissue engineering of bone should mimic bone matrix and promote vascular ingrowth. Porous scaffolds of hydroxyapatite and isogeneic acellular dentin are implanted into the dorsal skinfold chamber of balb/c mice. Additional animals received perforated implants of isogeneic calvarial bone displaying pores similar in size and structure to those of both scaffolds. Angiogenesis and neovascularization as well as inflammatory leukocyte-endothelial cell interaction and microvascular leakage are analyzed over a 14-day time period using intravital fluorescence microscopy. Implantation of both hydroxyapatite and dentin scaffolds showed a slight increase in leukocyte recruitment compared with controls. This is associated with an elevation of microvascular permeability, which was comparable to that observed in response to isogeneic bone [67]. Dynamic cell culture of the scaffolds improved cell viability and decrease the time of in vitro culture when compared to statically cultured constructs. Optimizing culture conditions and scaffold properties could generate optimal tissue/constructs combination for cartilage repair [68]. Hydrogels with low viscosities is difficult to use in constructing tissue engineering (TE) scaffolds to replace or restore damaged tissue, due to the length of time it takes for final gelation to take place resulting in the scaffolds collapsing due to their mechanical instability. This process can allow to plotting the various materials into a media bath containing material of similar rheological properties which can be used to both support the structure as it is dispensed and also to initiate cross-linking of the hydrogel [68].The scaffolds fabricated by rapid prototyping have very smooth surfaces, which tend to discourage initial cell attachment. Initial cell attachment, migration, differentiation and proliferation are strongly dependent on the chemical and physical characteristics of the scaffold surface. The surface is inscribed with nano- and micro-sized pores using three-dimensional (3D) plotting method with a chemical blowing agent to produce a surface-modified 3D scaffold. Cell cultures on the scaffolds demonstrated that chondrocytes interacted better with the surface-modified scaffold than with a normal 3D scaffold [69]. Magnetic scaffolds for bone tissue engineering based on a poly(ε-caprolactone) (PCL) matrix and iron oxide (Fe3O4) magnetic nanoparticles are designed and developed through a three-dimensional (3D) fiber-deposition technique. Furthermore, confocal analysis is undertaken to investigate human mesenchymal stem cell adhesion and spreading on the PCL/Fe3O4 nanocomposite fibers. The results suggest that nanoparticles mechanically reinforced the PCL matrix; the elastic modulus and the maximum stress increased about 10 and 30%, respectively. Confocal analysis highlighted interesting results in terms of cell adhesion and spreading. All of these results show that a magnetic feature could be incorporated into a polymeric matrix that could be processed to manufacture scaffolds for advanced bone tissue engineering and, thus, provide new opportunity in terms of scaffold fixation and functionalize [70]. Soy protein slurry has been successfully printed using the 3D Bioplotter to form scaffolds. This process involved measuring the mass extrusion flow rate of the slurry from the instrument, which is directly affected by the extrusion pressure and the soy protein slurry properties. Scaffold properties, including relative crosslink density, mass loss upon rinsing, and compressive modulus revealed that EDC cross-linked scaffolds are the most robust with moduli of approximately 4 kPa. Scaffold geometry (45° and 90° layer rotations) affected the mechanical properties for DHT and EDC crosslinked scaffolds [71].The bioactivity of sol–gel synthesized poly(ε-caprolactone) (PCL)/TiO2 or poly(ε-caprolactone)/ ZrO2 particles is already known. The potential of 3D fiber-deposition technique to design morphologically controlled scaffolds consisting of PCL reinforced with PCL/TiO2 or PCL/ZrO2 hybrid fillers is improved the properties of scaffold material [72]. Tooth-supporting periodontium forms a complex with multiple tissues, including cementum, periodontal ligament (PDL), and alveolar bone. A single stem/progenitor cell population appears to differentiate into putative dentin/cementum, PDL, and alveolar bone complex by scaffold's biophysical properties and spatially released bioactive cues [73]. Bioplotting is an emerging freeform scaffold fabrication technique useful for creating artificial tissue scaffolds containing living cells. Simultaneous maintenance of scaffold structural integrity and cell viability is a challenging task. General bioplotting method is more sophisticated alginate/hyaluronic acid scaffolds and can be fabricated with the inclusion of living cells into desired structures [74, 75]. Thin artificial tissues like trachea are grown from a patient’s own cells and it is already being used to treat patients. The scientists have shown that specific culture conditions can push stem cells to grow into self-organized structures resembling a developing brain, a bit of a liver, or part of an eye. All regenerative projects have run up against the same wall when trying to build thicker and more complex tissues like a lack of blood vessels. The 3D printed meta-materials with tunable are better mechanical properties which increase the tissue mimicking [76]. 3D printing technology is being used for most possible application in tissue engineering where organs and body parts are built using inkjet techniques. The construction of 3D engineered tissue is usually based on the mimic natural tissues and several key components cells, extracellular matrix (ECM), and vasculature which are useful to be patterned in precise geometries. Deposition of layers of living cells are generated onto a gel medium and gradually built up to form three dimensional structures [77]. Lewis’s group has developed novel 3D printing inks and nozzles that allow to precisely printing multiple materials for the development of tissue with blood vessels, as can be identified from Fig.22.

| Figure 22. 3D printed images of tissue [79] |

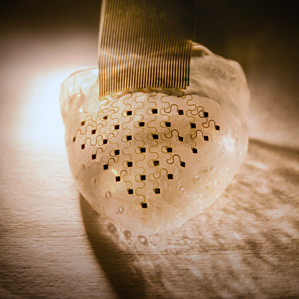

| Figure 23. An array of sensors is embedded in a material designed to fit a beating heart perfectly [82] |

| Figure 24. 3D graphene printing configuration [83] |

| Figure 25. 3D bioprinting allows orthopaedic surgeons create titanium replicas to replace missing or damages bone [86] |

5. Future Opportunities

- The direct inkjet printing offers the ability to rapidly produce pattern of functional materials in complex 3D architectures from a broad array of materials. The 3D printing is drive towards patterning materials at finer length scales and faster printing speeds, which provides to use in many opportunities and challenges in medical sciences. The advances in 3D printing is gaining the importance in the field of medical engineering with new ink designs, better characterization and modeling of ink properties during deposition, and enhanced robotic-control and ink-delivery systems to allow 3D writing with greater precision and local composition specificity. The ability to locally specify both composition and structure is allowing even greater control over the properties and functionality of the resulting patterned materials.3D printing is expected to play an important role in the trend toward personalized medicine, through its use in customizing useful products, organs, and drugs. 3D printing is being used commonly in pharmacy settings. The advanced 3D printing application is anticipated for bio-printing of complex organs. Although, due to challenges in printing vascular networks, the reality of printed organs is still some way off, the progress that has been made is promising. This is also expected that complex heterogeneous tissues, such as liver and kidney tissues will be fabricated successfully. This will be viable for live implants, as well as printed tissue and organ models for use in drug discovery. It may also be possible to print out a patient’s tissue as a strip that can be used in tests to determine the most effective drug. Also, it could even be possible to take stem cells from a child’s baby teeth for lifelong use as a tool kit for growing and developing replacement tissues and organs. False teeth, hip joints, replacement knees, potentially printable skin and organs will drive growth in the burgeoning market for 3D printers over the next decade.

ACKNOWLEDGEMENTS

- The author would like to Department of Mechanical Engineering, Indian Institute of Technology (BHU), Varanasi-221005, India for their supports.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML