-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Science and Technology

p-ISSN: 2163-2669 e-ISSN: 2163-2677

2016; 6(3): 68-75

doi:10.5923/j.scit.20160603.02

Effects of Implementing TQM Principles in the Apparel Manufacturing Industry: Case Study on a Bangladeshi Clothing Factory

Md. Syduzzaman1, Md. Monirul Islam2, Md. Ahashan Habib3, Dilruba Yeasmin4

1Department of Textile Engineering Management, Bangladesh University of Textiles, Tejgaon, Dhaka, Bangladesh

2Faculty of Textile Management & Business Studies, Bangladesh University of Textiles, Tejgaon, Dhaka, Bangladesh

3Department of Textile Engineering Management, Bangladesh University of Textiles, Bangladesh

4Production Merchandiser, NEXT Sourcing (BD.) Ltd, Bangladesh

Correspondence to: Md. Syduzzaman, Department of Textile Engineering Management, Bangladesh University of Textiles, Tejgaon, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2016 Scientific & Academic Publishing. All Rights Reserved.

This work is licensed under the Creative Commons Attribution International License (CC BY).

http://creativecommons.org/licenses/by/4.0/

Textiles or clothing is one of the fundamental needs of human being. Today human being does not only meet this basic need, but also inclined to more fashion garments. They are introducing new and more fashion items on a regular basis to cope with the present era. That’s why the RMG (Ready Made Garment) sector is running to its full swing with a huge variety of fashions. Bangladesh is one of the most promising garments manufacturing country in the present world now. It is now 2nd largest textile and garments exporter in the world market. Textile and RMG sector is the core portion of this country’s national economy as it earns nearly 81% foreign currencies from RMG sector [1]. It’s now a crying need and todays demand to prepare a best RMG sector so that it can meet the growing demand more effectively. Besides, today’s market is much more competitive and the only driving factor to sustain in this market is nothing but quality. So ensuring quality in RMG sector is the burning question now. To ensure this crucial factor (quality) there are so many tools and techniques have been emerged and implemented now-a-days. Among them the smartest and latest technique is Total Quality Management (TQM) Principles. By implementing TQM effectively, a production environment can be ensured which delivers quality products. In this research it will be pulled out, why TQM principles are vital and what the effects of implementing TQM in the apparel industry.

Keywords: Apparel Industry, TQM, TQM Tools, Framework, Productivity

Cite this paper: Md. Syduzzaman, Md. Monirul Islam, Md. Ahashan Habib, Dilruba Yeasmin, Effects of Implementing TQM Principles in the Apparel Manufacturing Industry: Case Study on a Bangladeshi Clothing Factory, Science and Technology, Vol. 6 No. 3, 2016, pp. 68-75. doi: 10.5923/j.scit.20160603.02.

Article Outline

1. Introduction

- TQM refers to a management process and set of disciplines that are coordinated to ensure that the organization consistently meets and exceeds customer requirements. TQM engages all divisions, departments and levels of the organization. TQM companies are focused on the systematic management of data in all processes and practices to eliminate waste and pursue continuous improvement. The goal is to deliver the highest value for the customer at the lowest cost while achieving sustained profit and economic stability for the company [2]. All types of manufacturing industries have reduced costs, increased process efficiency and improved the quality of their products and services by working to meet the needs of the people they serve through the application of total quality management (TQM) principles. With growing global competition, quality management is becoming increasingly important to the leadership and management of manufacturing industries. Quality management principles provide understanding of and guidance on the application of quality management. By applying following quality management principles, organizations will produce benefits for customers, owners, employees, suppliers and society as a whole. Companies actually compete on three major issues; Quality, Price and Delivery. If the choice is to compete in the marketplace on the basis of product or service price, then the level of competition is clearly defined; the low-cost provider wins. However, companies choosing the low cost approach may find themselves losing premium business to competitors while retaining the low-margin business in the long term [3]. Many companies understand that TQM is necessary for them to remain competitive, retaining their market share and to be able to respond to changing 2 competitive demands in todays business world. Based on some studies, not all companies are able to implement TQM successfully. This is because it requires a different implementation approach to cater for the varying needs of the industries in order for effective implementation. Small and medium sized enterprises (SMEs), for example, have been slow in adopting TQM when compared to large companies. Their involvement has focused primarily on ISO 9000 certification, and very few had advanced beyond that [4]. Therefore, the identification of Critical aspects of successful implementation as well as the problems faced by apparel manufacturing industries in implementing TQM is an important area to be understood. The value of this research is one of the primary steps towards reaching the needs of the Bangladeshi RMG sector that are trying to implement TQM in their business. With a better understanding of these issues, it can be a nice groundwork for the development of an appropriate TQM framework for practical implementation of the RMG sector.

2. Methodology

- The research starts with a detailed literature review of TQM that requires a general understanding of TQM. Next, the objective and scope of research are defined to give a clearer picture of the research. All related quality issues in Bangladesh faced, especially by RMG sectors were being gathered to learn about the current trend of Bangladeshi Apparel manufacturing industries’ quality activities. Further to that, all the TQM concepts will be compiled to suit the objective and scope of research as well as providing a guideline for future review. Then the research expects to provide a good guideline for a TQM model that can be applied to suit the needs of the Apparel manufacturing industries in Bangladesh. This can be done by identifying the common causes of failure in implementing TQM in Bangladeshi Apparel manufacturing industries. And finally found the feasibility and effectiveness of TQM application in the apparel industry.

3. Resources & Tools for the Research

- Various research resources and tools were employed in this research to collect the required data. The resources are:v Factory documents and statistics related to the research objectives.v Literatures and researches related to the research questionsv Interviews with employees of clothing industry in Bangladeshv Questionnaire to collect data and information necessary for the research, statistical analysis, and get results.v Internet search

4. Literature Review

4.1. Definitions of Quality

- The simple definition of quality is meeting the customer requirements. Moreover, and aiming at increasing customers’ satisfaction, many organizations have focused on quality and reduced their costs to gain maximum customer satisfaction, examples of this being Toyota in Japan, Samsung in South Korea. Besides, the term quality has been defined by so many quality experts. Quality refers to the different workmanship of various activities. Consequently, each business or activity has a different definition of quality, for example in sales the term quality is more focused on the services which are provided to the customer, while in manufacture, the term quality is more focused on the production process, and in Apparel Manufacturing, quality refers to both of services provided and output products [5].Quality is "The totality of features and characteristics of a product or service that bears on its ability to satisfy stated or implied needs" [6]. So, most of the quality concepts which mentioned above focuses on providing a product that satisfies and meet the customers’ needs. Quality is therefore extremely necessary for the organizations to ensure that they have delivered their products or services according to the customer expectations and requirements.

4.2. Definitions of Total Quality Management

- Numerous definitions have been given on Total Quality Management (TQM) by quality gurus, practitioners and academician. Besterfield defined TQM as both a philosophy and a set of guiding principles that represents the foundation of a continuously improving organization. It integrates fundamental management techniques, existing improvement efforts and technical tools under a disciplined approach [7]. Using a three-word definition, Wilkinson and Wither defines TQM as below-Total: every person is involved (its customers and suppliers)Quality: customer requirements are met exactlyManagement: senior executives are fully committed [8].Berry defined TQM process as a total corporate focus on meeting and exceeding customer’s expectations and significantly reducing costs resulting from poor quality by adopting a new management system and corporate culture [9]. In this context, TQM has emerged as a holistic management model because the concept of TQM is much broader than the traditional quality concepts. It encompasses not only product, service and process improvement, but those relating to costs and productivity and to people involvement and development [10]. TQM has been arguably the most significant approach to the management of organizations and their operations and its improvement and has provided many tools and techniques [11-14].Much research has been conducted about TQM. However, it is evident from the literature that different researchers have adopted different definitions and frameworks based on the context of the application or the theme of the research.

4.3. Tools and Techniques of TQM

- Chan said ' You cannot manage what you cannot measure' [15]. Consequently, there is a need to establish a process for measurement of quality management system performance, aiming at monitoring data on current and end user customer satisfaction for all essential processes. Therefore the organization needs to establish a sufficient and workable process. TQM tools are technical means used to work in the quality programs, and often include diagrams, statistical graphs, also, used to improve processes or develop products in any organization by identifying, analyzing and evaluating data that is relevant to their business. Therefore, by using the tools and techniques, one can investigate problems, identify solutions and implement them in work practices, by measuring and analyzing the outcome.The seven quality control tools described by Ishikawa are usually perceived as too simplistic and not appropriate [16]. In a study conducted by Scheuermann L. et al., the tools classified as Qualitative tools include flow charts, cause-and-effect diagrams, multi-voting, affinity diagram, process action teams, brainstorming, election grids, and task list), whereas Quantitative tools include Shewaryt cycle (PDCA), Pareto charts, control chart, histogram, run chart, and sampling [17]. TQM tools are practical methods, skills, means or mechanisms that can be applied to particular tasks. A technique has a wider application, often resulting in the need for more thought, skill and training to be used effectively, such as SPC, benchmarking, quality function deployment [18]. The most popular sets of TQM tools are as below-Ÿ Pareto Principle: Identifying the key problemsŸ Control Charts: Variation Control Ÿ Cause and Effects, Fishbone, Ishikawa DiagramŸ Histogram or Bar GraphŸ Traffic Light SystemŸ 5SŸ Quality Function DeploymentŸ Failure Mode & Effect Analysis

4.4. Requirements for Implementing TQM in the Apparel Manufacturing Industry

- Implementing TQM in Apparel Manufacturing industry means a comprehensive change to each and every aspect of the Apparel Manufacturing process. Some studies have established that the process of change is difficult because the Apparel Manufacturing industry has been historically reluctant to implement change. This fact was also emphasized in interviews with Apparel Manufacturing factories in Bangladesh, where it was observed that some of the employees disliked any kind of improvement/change and since they thought that the improvement means changes in their activities or positions.Several studies have discussed TQM’s critical success factors and some of these factors were common in most of these studies. Therefore, the discussion in this section mainly focuses on some of the critical success factors which have an impact on the Apparel Manufacturing industry in Bangladesh, such as management commitment, customer satisfaction, cultural change, education and training, and employee relations [19].

4.5. Barriers to TQM Implementation

- According to Quazi and Padibjo, unlike large organizations, SME’s have limited management capabilities, and incentive resources, in addition, owner / managers, lack business experience and knowledge [20]. The main problem faced by industry in trying to implement TQM is a shortage of finance, limited human resources, and the time required for implementation. The underlying barriers to TQM implementation is inadequate human resource development and management, lack of planning for quality, lack of leadership for quality, inadequate resources and a lack of customer focus [21]. Besides, lack of education is also one of the reasons why TQM would fail, adding, corruption, negligence and irresponsibility as critical issues to TQM success [22].However, resource limitations and resistance to change can affect the introduction of TQM within industry, which is attributed to workers who believe that change will threaten their current positions. Tannock listed four main barriers specific to SME in terms of TQM [23]:** Cultural barriers: The culture of SME may not be conducive to TQM.** Management awareness barriers: There is wide acceptance that without full management commitment, successful TQM implementation is unlikely.** Financial barriers: Managers of SME’s cite the cost of training and lost production time as a major reason for not implementing TQM.** Training barriers: People who do not hold any formal business qualifications operate large portion of SME’s. Such owners and managers will not value formalized learning such as training so much as more highly educated people.

5. Case Study

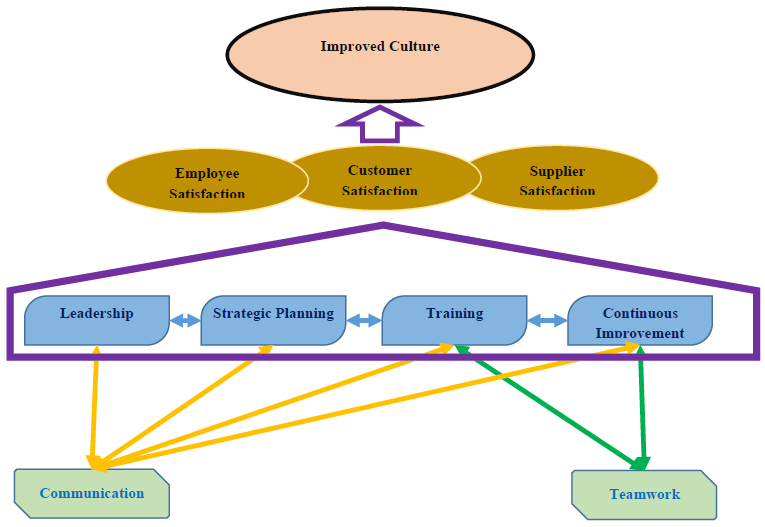

- As a major part of the research methodology, a case study has been conducted at a very well-known textile factory named Knit Asia Ltd, Bangladesh. The researcher has implemented a proposed framework in this factory. The major aim of the case study was to provide a practical example of how to use the TQM implementation model in practice and to show the effectiveness of TQM application. The framework which has been implemented is as below-

| Figure 1. Proposed framework for implementing TQM in clothing industry |

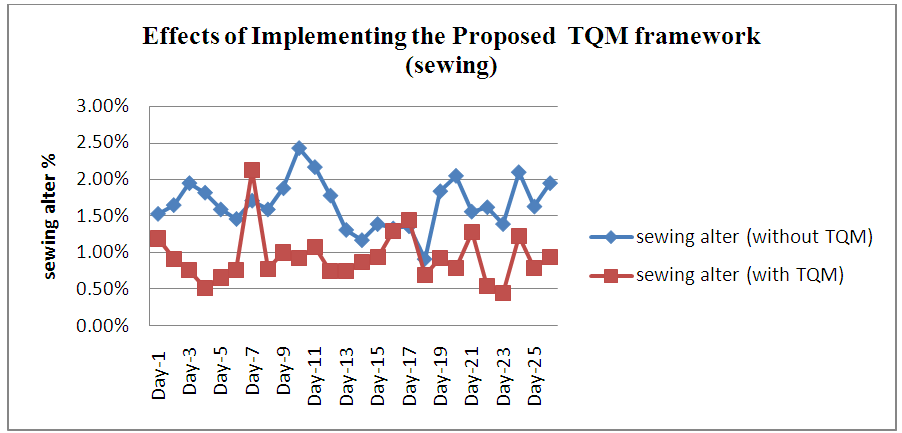

| Figure 2. Comparison of sewing Alter & reject% with & without implementing TQM |

6. Result and Discussion

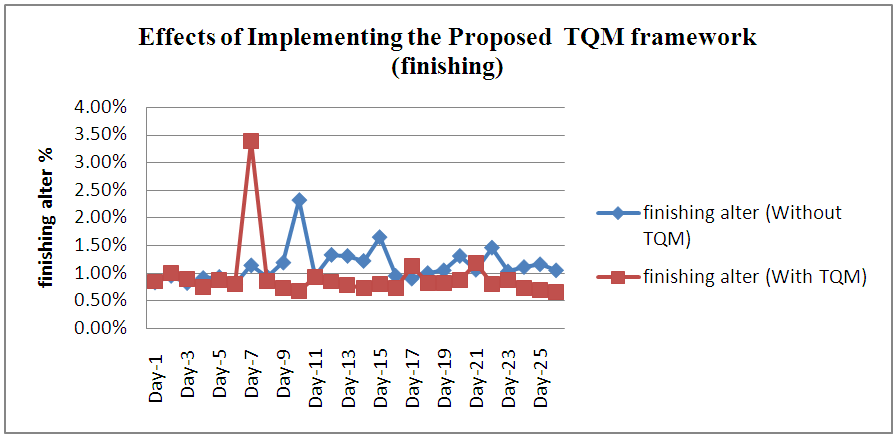

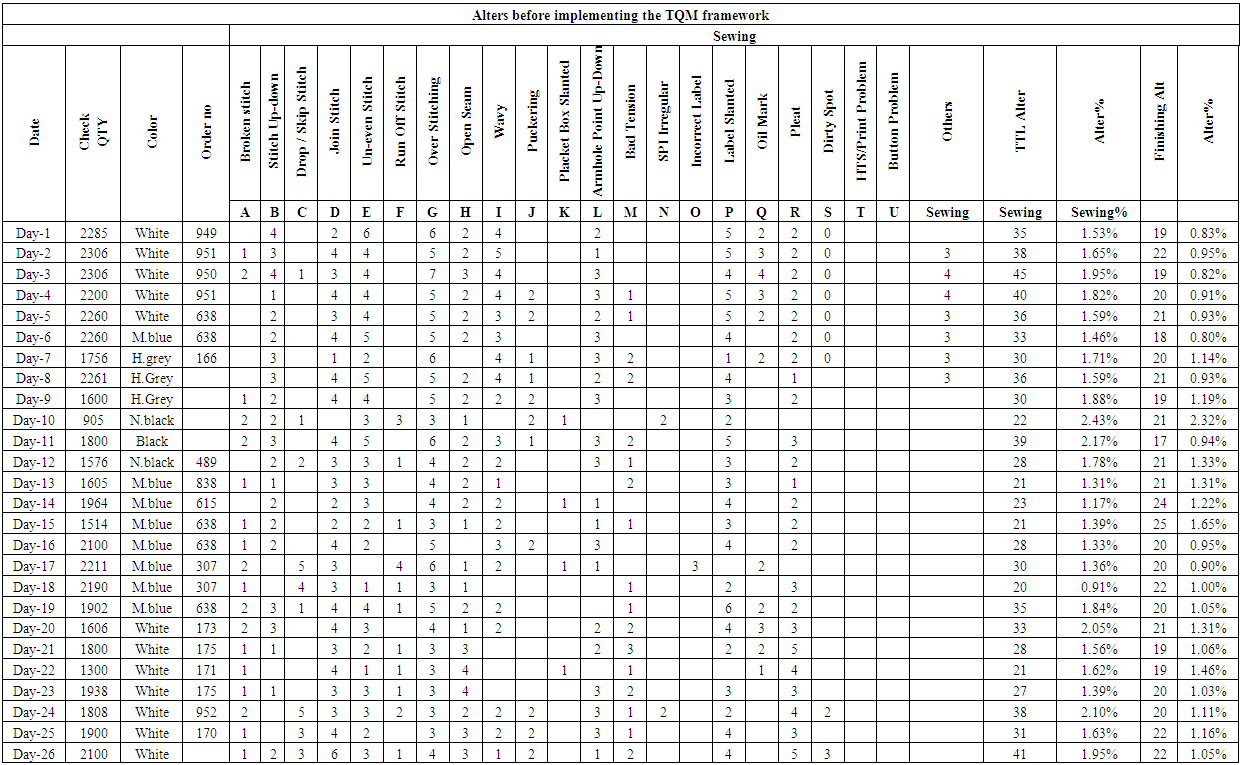

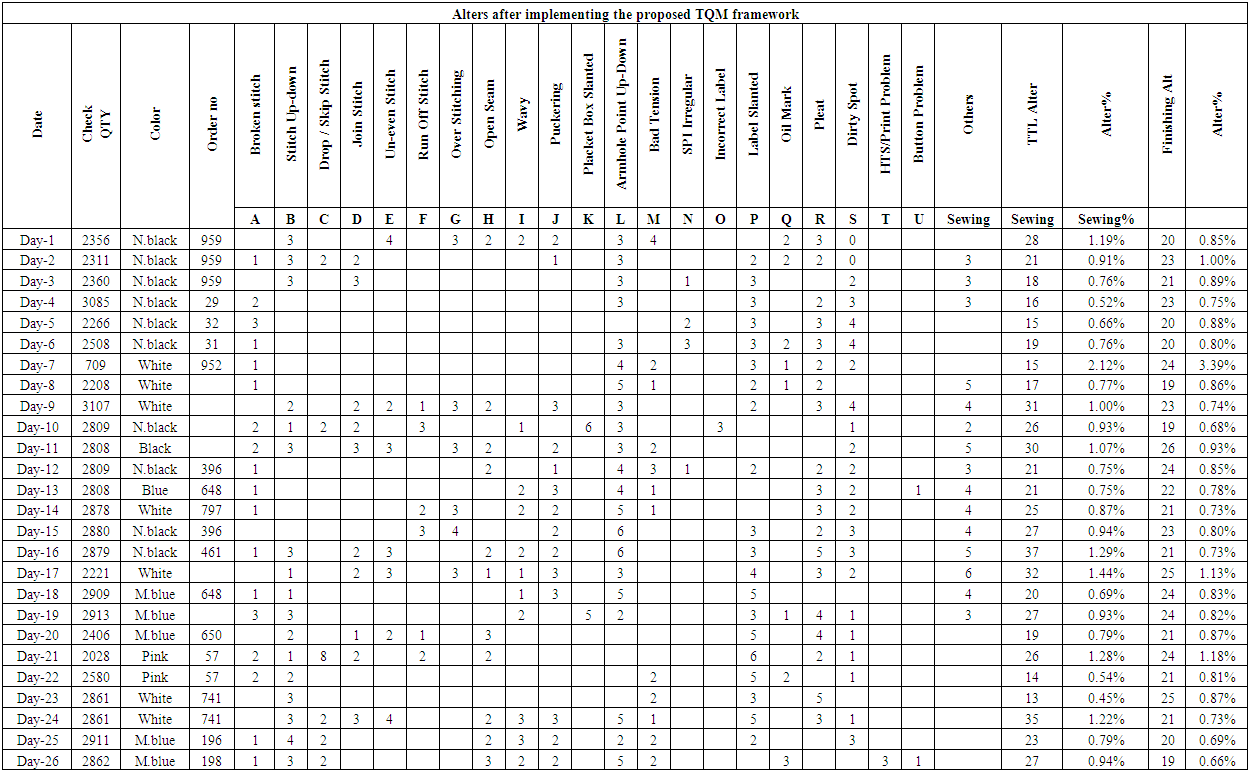

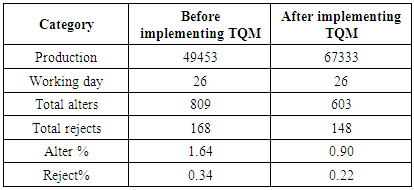

- In apparel manufacturing processes, especially in sewing there are so many faults or alters may occur. Some are repairable alters and some are not (non-repairable) which are unavoidable, but may be reduced in quantity but cannot be removed. To find out the benefits or advantages of implementing the proposed TQM framework, the two experiments have been carried out simultaneously considering so many limitations. Here two sewing floors have been taken into considerations for the experiments. One has been considered “Before implementing the proposed TQM framework” that is their ongoing floor with particular garment style & order and another followed the TQM principles has been considered as “After implementing the proposed TQM framework”. Then both the floors have been observed regularly for about a month: how is the production, how much faults are occurring and what about the status of alters or reworks, etc. From the data mentioned above, it’s been found that production has been improved as total alters and rejections have been considerably reduced after implementing the proposed TQM framework.

| Figure 3. Comparison of finishing Alter & reject% with & without implementing TQM |

| Table 1. Statistics showing alters or reworks% before TQM implementation |

| Table 2. Statistics showing alter or reworks% after TQM implementation |

| Table 3. Comparative statistics of before and after TQM implementation |

7. Challenges Faced in the TQM Adoption

- While doing the case study, the researcher has faced some unavoidable difficulties and challenges. But the remarkable challenges have been illustrated below-Ÿ Quality definition: Most of the factory workers don’t have the clear idea about what is quality and what should they do to ensure the customers’ expectation.Ÿ Commitment: commitment is one of the most important critical successful factors in the adoption of TQM framework. But the poor commitment of top management has been found as a challenge and a barrier against continuous improvement. At the same time, the researcher believes that such commitment should not be limited to the top management only, but everyone in the organization, all of whom ought to be committed to the implementation of TQM principles. Ÿ Culture: The researcher has found that the ongoing traditional culture of the organization or factory is one of the most remarkable challenges faced while adopting TQM framework. Everyone is set to the existing culture and fears to any kinds of changes. Ÿ Communication: The proper communications between different levels of people are important factors that have an impact on quality. Since most of the workers in the Apparel Manufacturing industry in Bangladesh are local but the top management are foreigners, so language is the main obstacle to improving the communication between workers themselves from one side, and with their bosses on the other.

8. Limitations of the Research

- Of course, this research has some limitations and these limitations of the research are presented as follows:v Since the TQM as a topic is almost new in developing countries, and never been fully implemented in the Apparel Manufacturing industry in Bangladesh, the literature review is based on work done in the developed countries such as Japan, UK and USA.v Newly proposed TQM framework has been applied in only one Apparel Manufacturing industry as its very vast concept and needs to change the whole factory set-up. v The proposed TQM framework has been applied in two separate but almost same type sewing lines having the same style running through it. v It was not possible to do the experiment in the same sewing line with same garment styles as this garment orders has very short lead time for sewing. That’s why two parallel sewing lines have been taken; one with TQM and another without TQM.

9. Conclusions

- In the recent years, people have been working for writing mature and effective procedures for requirement gathering. The variation in the characteristics of the customer plays a vital role in requirement gathering. Experiences have shown that requirement gathering is relatively simple where customer characteristics are similar. The diverse the customer characteristics are, the more difficult it will be to gather the requirements, which will ultimately affect the quality of the product or service and make it even more difficult to come up with a TQM framework that is fit for purpose. Here in this research work, its been tried to find out the barriers for implementing TQM principles and the effectiveness of its application.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML