Abdu Zubairu, Yusuf Madu Mshelia

Department of Chemical Engineering, University of Maiduguri, Borno State, Nigeria

Correspondence to: Abdu Zubairu, Department of Chemical Engineering, University of Maiduguri, Borno State, Nigeria.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Abstract

Colouration of fabric is a major process in the production of textile material. In this work, natural dye was extracted from onion skin and used to dye cotton fabrics using selected synthetic and natural mordants. The synthetic mordants considered in this work are potassium dichromate, iron sulphate, copper sulphate and alum whereas the natural mordants are aloe vera and lemon. Cotton fabrics were dyed using each of the selected mordants under three different conventional mordanting techniques; pre-mordanting, simultaneous-mordanting and post-mordanting, adopting the well-known vat dyeing method. A wide range of soft and light colours were obtained using the various mordants considered, also the mordanting technique was found to influence the results of the dyeing process. Natural mordants gave pale yellow colours, while synthetic mordants such as copper sulphate and alum also gave yellow colours. On the other hand, iron sulphate gave darker shades of colours. The dyed fabric samples were allowed to age for a week and then washed in standard industrial detergent solution. The wash offs from the samples were assessed for dye bleeding using the conventional photo-sphectrometric method. The absorbance and transmittance measurements were conducted using spectrophotometer at 420nm, and the reflectance evaluated. The colour fast of the wash offs was evalutated using the Kubelka-Munk equation. It was concluded that onion skin dye with iron sulphate as mordant under post-mordanting technique gave the best result of colour fast of the onion skin dye.

Keywords:

Onion Skin, Natural Dye, Mordant, Cotton Fibre

Cite this paper: Abdu Zubairu, Yusuf Madu Mshelia, Effects of Selected Mordants on the Application of Natural Dye from Onion Skin (Allium cepa), Science and Technology, Vol. 5 No. 2, 2015, pp. 26-32. doi: 10.5923/j.scit.20150502.02.

1. Introduction

The art of dyeing is an ancient practice. For instance, it was in use during the Bronze Age in Europe, were common dyeing techniques include sticking plants to fabric or rubbing crushed pigments into cloth. These methods were later developed, leading to sophisticated techniques using natural colours from crushed fruits, berries and other plants, often boiled into the fabric to enhance light and water resistance property of the fabric [1]. The art of dyeing therefore, could be said to have stems from the use of natural dyes. Natural dyes are thus regarded as all colours and dye pigments derived from plant, animal or insect matter without any chemical processing [2].Dyeing textile materials; natural or synthetic, is aimed to add value, improve look and enhance product desire of the customers. As pointed earlier, this purpose of colouring textile was initiated using colours of natural source. However, the use of natural dyes subsequently diminish with the invention and commercialization of synthetic dyes. In addition, the ready availability of pure synthetic dyes of different types or classes and their cost advantages, propelled most textile dyers and manufacturers to shift towards the use of synthetic colourants.Almost all the synthetic colourants were being manufactured from petrochemical sources through hazardous chemical processes which poses serious threat towards their eco-friendliness [3].Few natural dyes are colour-fast with fibres, therefore the use of mordants which increases the dye fastness to the fabric is often necessary. Mordants are essentially substances which are used to fix a dye to the fibres, they also improve the take-up quality of the fabric and help improve colour and light-fastness. Mordants are usually metallic salt of aluminium, chromium, iron, copper and tin, as well as other substance such as tanning agents. Mordants found in nature include wood ash, stale urine and acidic fruits extracts such as lime [1]. The use of mordant in dyeing not only increase the dye take up and colour fastness but the use of different mordant on a natural dye can yield different colours and shades. Detailed comparisons of the advantages and disadvantages of natural dyes relative to synthetic dyes were presented in previous literature [3].Recently, dyes and colours of natural origin are gaining worldwide recognition as substitute for synthetic dyes in textile manufacture, for colouring of food products, cosmetics and pharmaceutical products [4]. This renewed interest in the use of natural dyes is primarily due to increase health concern of many of the synthetic dyes because of their toxic nature and adverse environmental impacts.

2. Theory

Natural dyes are dyes or colorants derived from plants, animals, or sources. The majority of natural dyes are vegetable dyes from plant sources e.g. roots, berries, skin, barks, leaves, wood and other organic sources such as fungi and lichens [5].

2.1. Onions

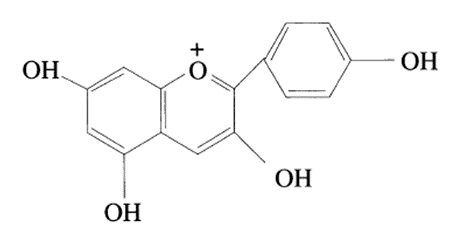

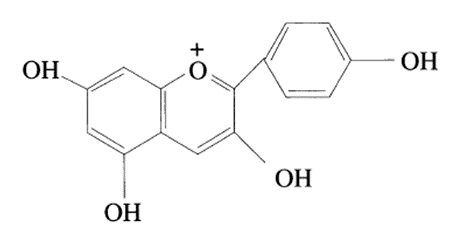

Onions (Allium cepa) also known as bulb onions are vegetable used in preparing food and widely cultivated around the world. Most onions cultivated are about 89% water, 4% sugar, 1% protein, 2% fiber. Onions also contains vitamins which include Vitamin B1, Vitamin B2, Vitamin B3, and Vitamin C, it also contains compounds such as phenolics and flavonoids as well as elements like iron, calcium, magnesium, manganese, and zinc [6]. The skin of onions is inedible however it contains a dyestuff called “Pelargonidin” (3, 5, 7, 4 tetrahydroxy antocyanidol) which has a structural formula represented in Figure 1.  | Figure 1. Structure of “Pelargonidin” (3, 5, 7, 4 tetrahydroxyl antocyanidol - a dye stuff in onion skin [5] |

3. Materials and Method

3.1. Materials

3.1.1. Natural Dye Source

Waste onion skin was collected from Maiduguri Monday Market Borno State, Nigeria. The onion skin were cleaned and dried and used to extract the natural dyestuff.

3.1.2. Natural Mordants

Lemon juice and Aloe vera were used as natural mordants. Fresh lemon was purchased from Maiduguri Monday market and fresh aloe vera was collected from the University of Maiduguri garden which were used as natural mordants. Fresh lemon was squeezed and the juice was collected and filtered.Fresh leaves of Aloe Vera was collected and washed thoroughly, the outer green surface was peeled off and the linear white mass was collected and crushed to semi solid consistency 200ml of the aloe vera semi liquid was mixed with 600ml of water and then filtered.

3.1.3. Synthetic Mordants

Ferrous sulphate, Copper sulphate, Potassium dichromate and Alum.

3.1.4. Substrates

White cotton fibre were desized to 11cm by 9cm. The cut fibres were bleached and scoured cotton fabrics were used for dyeing.

3.2. Methodology

3.2.1. Extraction of the Natural Dye

A 115g of the processed onions skin was subjected to aqueous extraction with 1 liter of distilled water and heated for 1 hour at 100°C, and the extract was filtered and allowed to cool.

3.2.2. Scouring of the Cotton Fibre

As preparatory processes for dyeing of the cotton fabrics, the desized cotton fabrics samples were washed in a solution containing 0.5g/l of sodium carbonate and 2g/l of detergent at 50°C for 25minutes. The scoured material was thoroughly rinsed with water and dried at room temperature.

3.2.3. Dyeing

The dyeing of the scoured cotton fabrics was conducted adopting the well-known vat dyeing procedure [1]. Three batches were dyed in turn, each batch consisting of six (6) scoured cotton fabrics samples. The six (6) fabric samples were mordanted with Cupric Sulphate, Ferrous Sulphate, Potassium Dichromate, Alum, Lemon Juice and Aloe Vera respectively. Three different mordanting techniques [3] i.e. pre-mordanting, simultaneous mordanting and post- mordanting were carried out, in which one batch of the cotton was used batch for each technique. A separate fabric was also dyed with no mordant. The detailed procedure for each mordanting techniques is presented.Pre mordanting: For each of the selected synthetic mordants, 2g of the mordant was dissolved in 500ml of distilled water. The scoured cotton sample was heated for 30 minutes at a temperature of 100°C in the mordant solution. The fabrics were dried without washing. On the other hand the cotton fabric was pre-mordanted with the natural mordant via the following procedure; 60ml of lemon juice was mixed with 600ml of distilled water, the resulting mordant solution was used to heat the scoured cotton samples for 30 minutes at a temperature of 100°C. Similarly, 600ml of aloe vera solution was also use to heat the scoured cotton samples for 1hr at a temperature of 100°C. The fabrics were dried without washing.The dried pre-mordanted fabrics were then placed in a 750ml of onion skin dyebath, gradually raising the temperature to 100°C and allowed to simmer for 50 minutes. The dyed fabrics were removed and cool washed in a 2g/l detergent solution according to the ISO prescription.Simultaneous mordanting: For each of the selected synthetic mordants 2g of the mordant was dissolved in 750ml of onion skin dyebath solution. The dry scoured cotton fabric sample was placed in the dyed/mordant mix solution and allowed to simmer at a 100°C for 50 minutes. The dyed fabrics were removed and cool washed in a 2g/l detergent solution.For the natural mordants: For the lemon, 60ml of lemon juice was mixed with 750ml of onion skin dyebath solution. The dry scoured cotton fabric samples was placed in the resulting mixture solution and allowed to simmer a temperature of 100°C for 50 minutes. The dyed fabrics were removed and cool washed in a 2g/l detergent solution.Similarly for aloe vera, 200ml of the semi liquid aloe vera was mixed with 750ml of onion skin dyebath solution, the resulting mixture was filtered. The dry scoured cotton and allowed to simmer a temperature of 100°C for 50 minutes. The dyed fabrics were removed and cool washed in a 2g/l detergent solution.Post mordanting: The dried scoured cotton fabrics were placed in a 750ml of onion skin dyebath, gradually raising the temperature to 100°C and allowed to simmer for 50 minutes. The dyed fabrics were dried.For each of the selected synthetic mordants 2g of the mordant was dissolved in 500ml of distilled water, the dyed cotton fabric was mordanted in the solution at 100°C for 50 minutes. For the natural mordants: 60ml of lemon solution was mixed with 600ml of distilled water; the resulting solution was used to mordant the dyed cotton fabric for 30 minutes at a temperature of 100°C. Similarly, 600ml of aloe vera solution was used to mordant dyed cotton fabric for 30minutes at a temperature of 100°C.

3.2.4. Evaluation of Colour Strength (K/S) of Wash-offs

After dyeing, the cotton samples were allowed to age for a week (seven days) before they were washed. Each dyed sample was washed in three (3) separate detergent solution containing 250 ml of water and 2g of normal detergent powder. The wash-offs of each sample was analysed with the UV-visible spectrophotometer to assess the dye fastness and ultimately to determine the degree of dye bleeding from the fabric [7]. The percentage of light reflected (R) by the wash-offs sample was evaluated as a function of the percent absorbed (A) and percent transmitted (T) by recourse to the standard procedure as presented in Equation 1. | (1) |

The values of the three components of the incident light on the wash-offs could be used to evaluate the concentration of the dye in the wash-offs, i.e. the degree of dye bleeding from the fabric sample by adopting the conventional procedure of measuring liquid solution using the well-known Kubelka – Munk theory [8]. The theory illustrated in Equation 2 defines the relationship between spectral reflectance (R) of the wash-off of the sample, its light absorption (K) and its scattering characteristic (S). | (2) |

The ratio K/S is the colour strength of the wash-off, in other words, the higher the value of this ratio the higher the degree of dye bleeding, or the less colour fast the dye is to the fabric.

4. Results and Discussion

4.1. Results

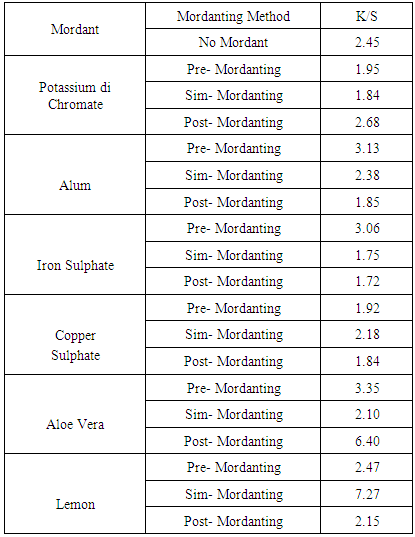

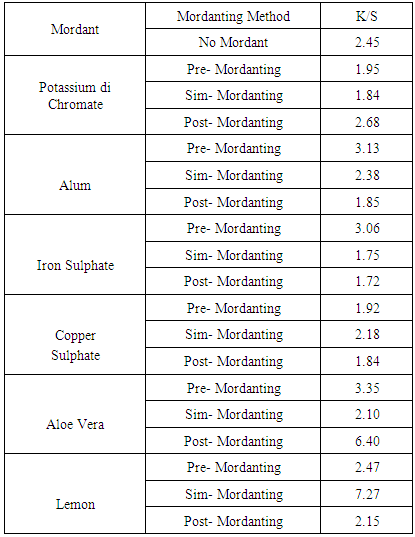

The detailed results for the onion skin dye when applied to cotton fabric samples (photographs of dyed fabrics) using various mordants and mordanting techniques are presented in the appendix. The results indicates that there were many shade of colours obtained after dyeing the cotton fabric samples with onion skin using different mordants and mordanting techniques. Generally, natural mordants gave pale yellow colours, synthetic mordants like copper sulphate and alum also gave yellow colours while iron sulphate gave darker shades of colours. Table 1. Colour Strength of Values of the Wash-offs

|

| |

|

4.2. Discussions

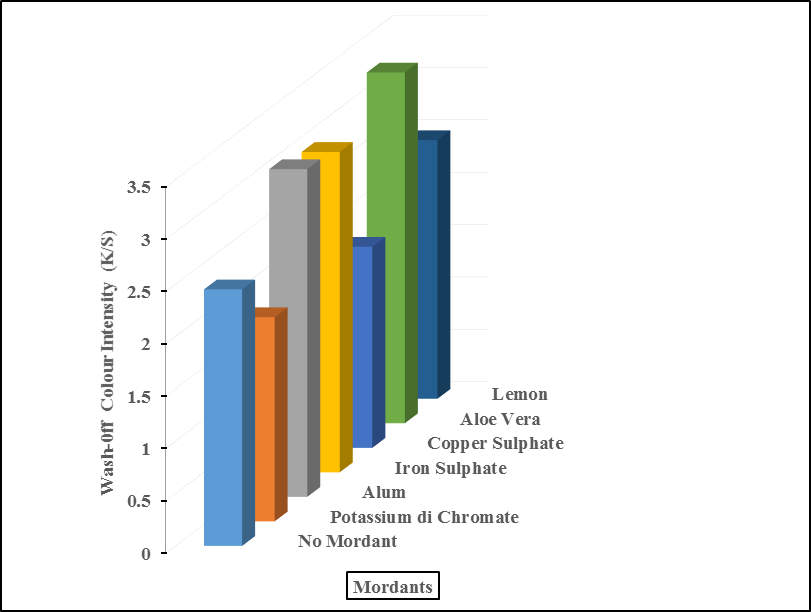

4.2.1. Pre-Mordanting

It could be observed from Table 1 and Figure 1 that application of onion skin dye with pre-mordanting indicates that copper sulphate yield the best colour fastness, while pre-mordanting with aloe vera has the worst colour fastness to washing. Also it may be seen that pre-mordanting with the synthetic mordants, copper sulphate and potassium dichromate perform better than other synthetic mordants considered. It may be seen that copper sulphate is 2% better in colour fastness than potassium dichromate. On the other hand, the natural mordant both show significant colour fastness on the cotton fabric, but aloe vera performed worse than lemon juice and worse than all other synthetic mordants investigated. However lemon juice performed better than iron sulphate and alum.  | Figure 1. Pre-mordanting technique - colour strength of wash-offs |

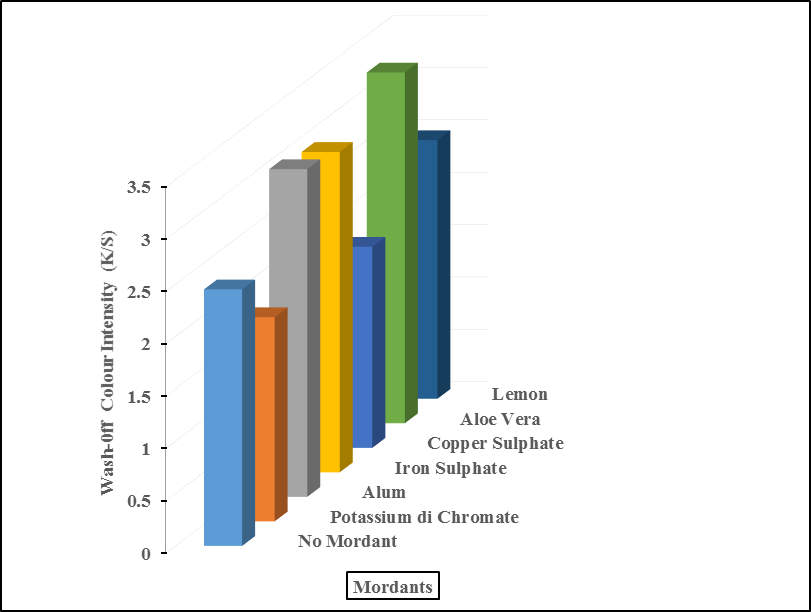

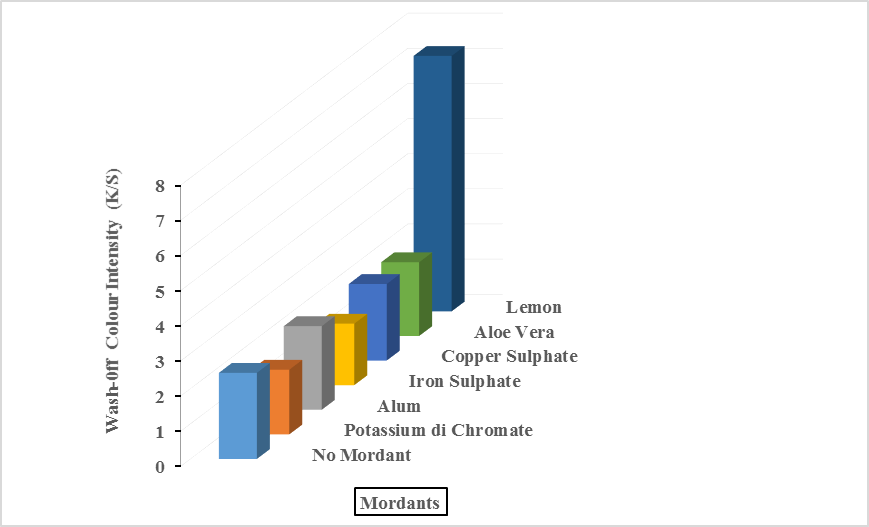

4.2.2. Simultaneous Mordanting

All mordants exhibit satisfactory colour fastness with simultaneous-mordanting except lemon juice that indicates worst colour fastness among all the mordants as can be seen from Table 1 and Figure 2. Iron sulphate has the best colour fastness to washing if used under this mordanting technique. It is also worth noting that among the natural mordants, aloe vera performed better than lemon juice as against the trend observed when the fabrics were dyed with pre-mordanting technique. | Figure 2. Simulteneous-mordanting technique - colour strength of wash-offs |

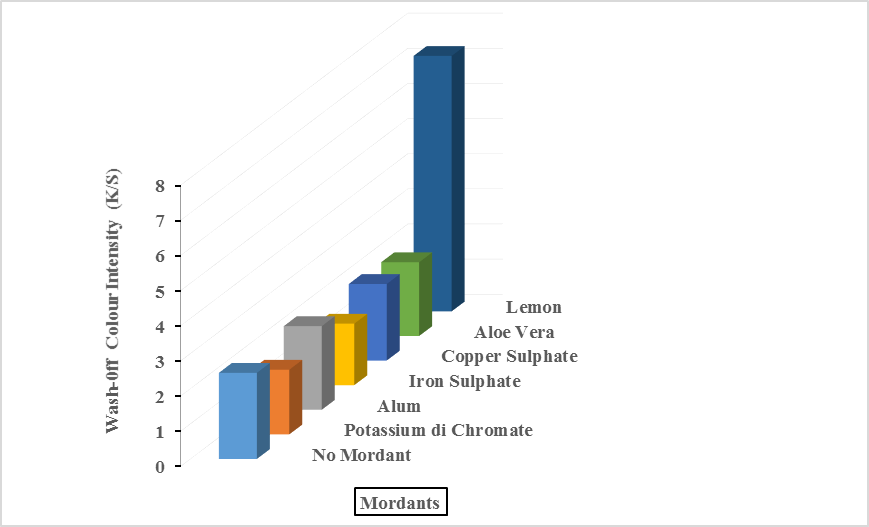

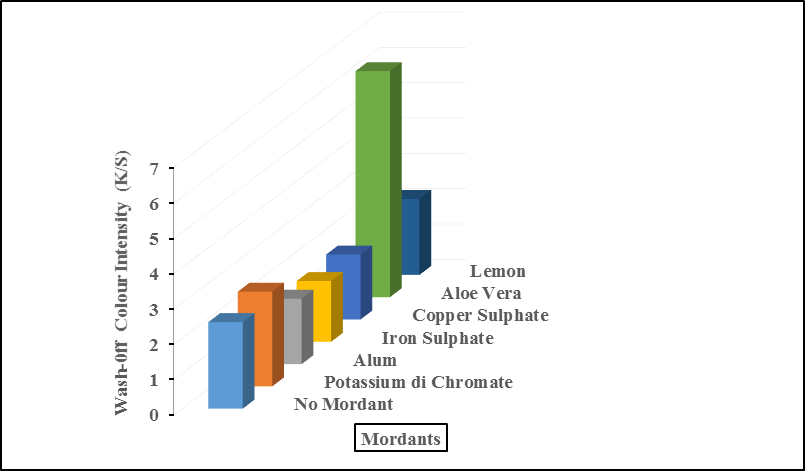

4.2.3. Post Mordanting

From Table 1 and Figure 3 it could be seen that post-mordanting with iron sulphate gave least colour strength of wash-offs with colour strength value of about 1.72 while on the other hand, aloe vera has the highest wash-off colour strength value of 6.4. This indicates that applying onion skin dye with post-mordanting, aloe vera has very poor colour fastness while iron sulphate has the best. | Figure 3. Post-mordanting technique - colour strength of wash-offs |

In general, comparing the colour strength of wash-offs of samples dyed with different mordanting techniques, post-mordanting gave the best result compared to other mordanting techniques with four (alum, iron sulphate, copper sulphate and lemon juice) out of the six mordants considered showing good results of dyeing with post mordanting technique.

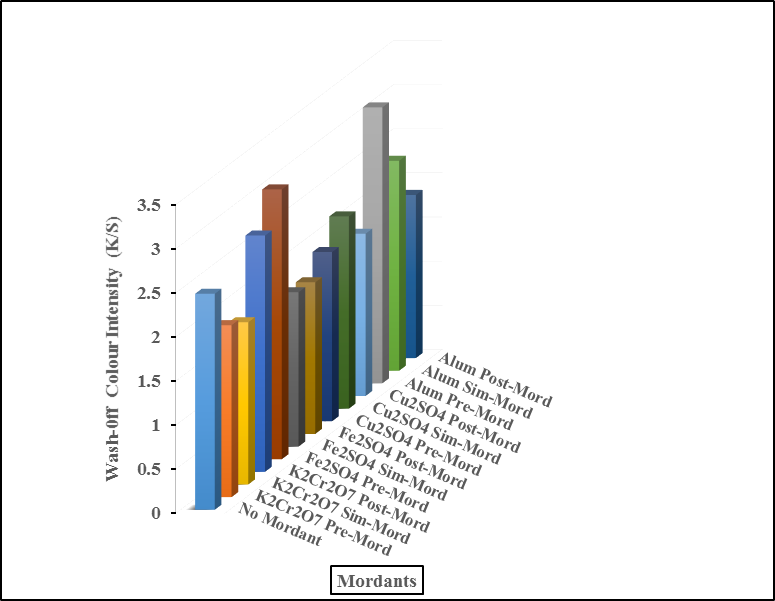

4.2.4. Comparison of K/S Values for Different Mordants

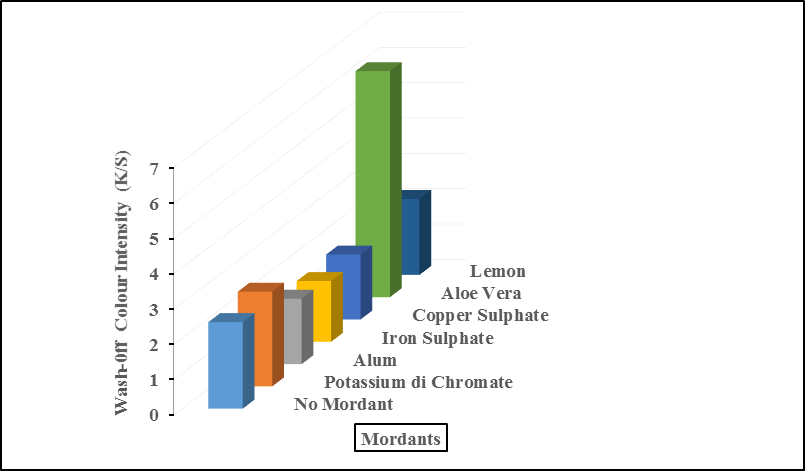

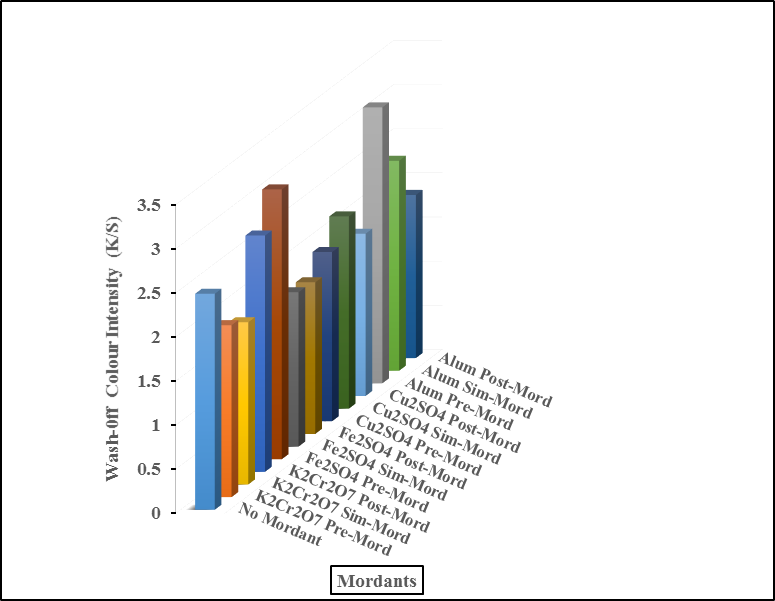

The mordants were also assessed on the basis of types to compare their performance with respects to the various mordanting techniques considered. Figure 4 indicates the performance of the different synthetic mordants considered, it can be observed that iron sulphate applied via the post-mordanting technique have the least wash off colour strength value which consequently makes it the best out of the all synthetic mordants. Generally, alum applied under the pre-mordanting technique gave the worst result among the synthetic mordants with the highest colour wash-off strength (see Table 1), in other words has the least colour fastness of the onion dye. On average iron sulphate with post-mordanting, iron sulphate with simultaneous- mordanting, alum with post-mordanting, potassium dichromate with simultaneous mordanting and potassium dichromate with pre-mordanting exhibit satisfactory colour fasness of the dye, with a colour wash-off strength in the range of 1.72 to 1.95.  | Figure 4. Colour strength of wash-offs for synthetic mordants under different mordanting techniques |

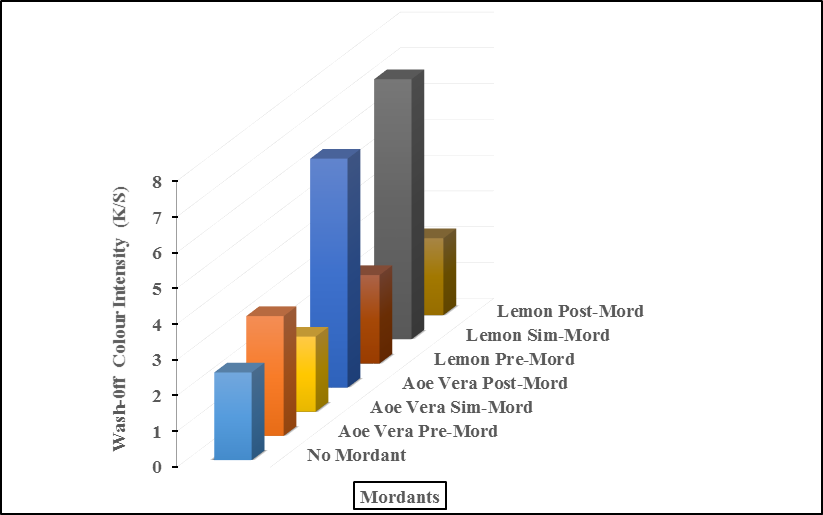

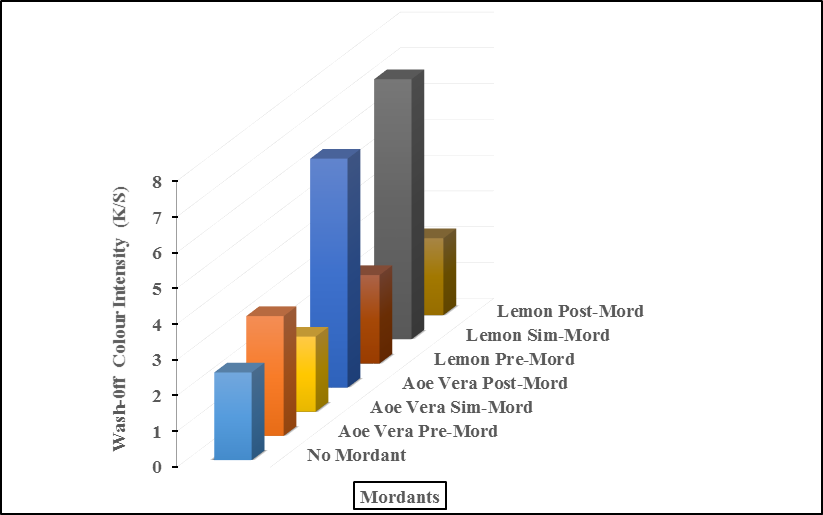

The performance of natural mordants was also observed to be fairly satisfactory. Figure 5 indicates aloe vera with pre-mordanting, aloe vera with post-mordanting, lemon with pre-mordanting and lemon with simultaneous- mordanting have wash off colour strength values greater than the dyed sample without mordant. However, lemon with pre-mordanting has only about 1% different in wash off colour strength compared to the dyed sample without mordant. Aloe vera simultaneous-mordanting and lemon post-mordanting showed a good wash off colour strength values and thus they present a high potential of being used as mordants if applied with under the respective mordanting technique.  | Figure 5. Colour strength of wash-offs for natural mordants under different mordanting techniques |

Overall, it may also be seen that synthetic mordants performed fairly more effectively than the natural mordants. Interestingly however, alum and iron sulphate under pre-mordanting both have poor colour strength since the sample dyed without mordant have a lower wash off colour strength value compared with the samples dyed with these mordants.

5. Conclusions

From the work conducted it was demonstrated that onions skin can be used to successfully dye cotton fabric; it is shown that a wide range of soft and light colours could be derived by using different mordants and mordanting techniques. Synthetic mordants tends to perform better with onion skin as a source of dyestuff than natural mordants. Nonetheless, it was found that as natural mordants aloe vera if used under simultaneous-mordanting technique; lemon under post-mordanting technique and lemon under pre-mordanting technique did produce good results, yielding satisfactory colour fastness to the fabric compared to applying the onion skin dye without mordant. They also compared favourably to some of the synthetic mordants considered in this work. In general, iron sulphate under post-mordanting technique gave the best result interms of colour fastness of the onion skin dye to the fabric. Also overall, all the mordants considered appear to do better if applied under simultaneous-mordanting technique in relation to pre-mordanting and post-mordanting techniques. It is therefore obvious that further research should be carried out on natural mordants and their application with natural dyes. A possible trend to investigate is to consider the efficacy of blending the mordants (either natural mordant with natural mordant or natural mordant with synthetic mordant) as some of the mordants from this research work have shown some impressive results under different conditions. So by blending them with other mordants may improve their mordanting properties.

Appendix

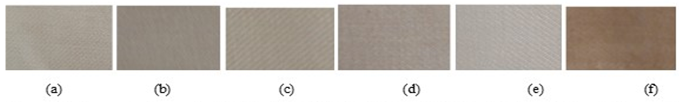

| Figure A1. Onion skin dye (a) undyed cotton fabric (b) dyed fabric no mordant (c) washed dyed fabric no mordant |

| Figure A2. Pre-mordanting unwashed fabric: (a) FeSO4 (b) K2CrO7 (c) CuSO4 (d) Aloe Vera (e) Alum (f) Lemon Juice |

| Figure A3. Pre-mordanting washed fabric: (a) FeSO4 (b) K2CrO7 (c) CuSO4 (d) Aloe Vera (e) Alum (f) Lemon Juice |

| Figure A4. Simulteneous-mordanting unwashed fabric: (a) FeSO4 (b) K2CrO7 (c) CuSO4 (d) Aloe Vera (e) Alum (f) Lemon Juice |

| Figure A5. Simulteneous-mordanting washed fabric: (a) FeSO4 (b) K2CrO7 (c) CuSO4 (d) Aloe Vera (e) Alum (f) Lemon Juice |

| Figure A6. Post-mordanting unwashed fabric: (a) FeSO4 (b) K2CrO7 (c) CuSO4 (d) Aloe Vera (e) Alum (f) Lemon Juice |

| Figure A7. Post-mordanting washed fabric: (a) FeSO4 (b) K2CrO7 (c) CuSO4 (d) Aloe Vera (e) Alum (f) Lemon Juice |

References

| [1] | Practical Action, Dyeing of Textiles, a technical brief, The Schumacher Centre for Technology & Developmnt, Bourton Hall, Warwickshire United Kingdom. https://practicalaction.org/docs/technical_information_service. Retrieved 8/12/2012. |

| [2] | Rangari, D. V., 2004, Natural colourants and dye, Pharmacognosy and Phytochemistry, 1st Edit. Part II, Career publications, p. 98 – 117. |

| [3] | Ashis, K. S. and Adwaita, K., 2011, Natural dyes, InTech open science publishing Europe, p. 29 – 56. |

| [4] | Nilani, P., Duraisamy, B., Dhamodaran, P., Khasthuribai, N., Alok, S. and Suraish, B., 2008, A study on the effect of marigold flower dye with natural mordant on selected fibers, Journal of Pharmacy Research, (1) 2 p. 175 – 181. |

| [5] | Mishra, P. and Patni, V., 2011, Extraction and application of dye extracted from eriophyid leaf galls of Quercus leucotrichophora - A Himalayan blue jack oak, African Journal of Biochemistry Research (5) 3, p. 90-94. |

| [6] | Onal, A., 1996, Extraction of dyestuff from onion (Allium cepa L.) and its application in the dying of wool, feathered-leather and cotton, Tr. J. of Chemistry, (20) p. 194 – 203. |

| [7] | Perkin Elmer, Inc., 2012, Absorbance, Reflectance and Transmittance. www.perkinelmer.com. Retrieved 26/06/2013. |

| [8] | Hunter Lab, 2012, Kubelka-Monk theory and K/S. www.hunterlab.com. Retrieved 16/06/2012. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML