-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Safety Engineering

p-ISSN: 2325-0003 e-ISSN: 2325-0011

2012; 1(4): 57-67

doi: 10.5923/j.safety.20120104.02

Modified Method for Reliability Evaluation of Condensation Thermal Electric Power Plant

Z. N. Milovanovic1, D. Knezevic1, A. Milasinovic1, S. R. Dumonjic-Milovanovic2, D. Ostojic3

1University of Banja Luka, Faculty of Mechanical Engineering, BiH, Banja Luka, 78000, Bosnia and Herzegovina

2Partner Engineering Ltd, Kralja Nikole 25, Banja Luka, 78000, Bosnia and Herzegovina

3Serbian Army, Technical Test Center, Vojvode Stepe 445, 11000, Beograd, Serbia

Correspondence to: Z. N. Milovanovic, University of Banja Luka, Faculty of Mechanical Engineering, BiH, Banja Luka, 78000, Bosnia and Herzegovina.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

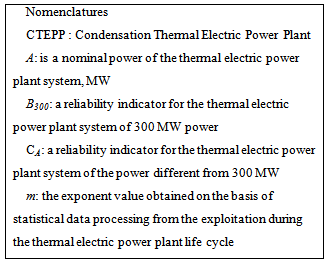

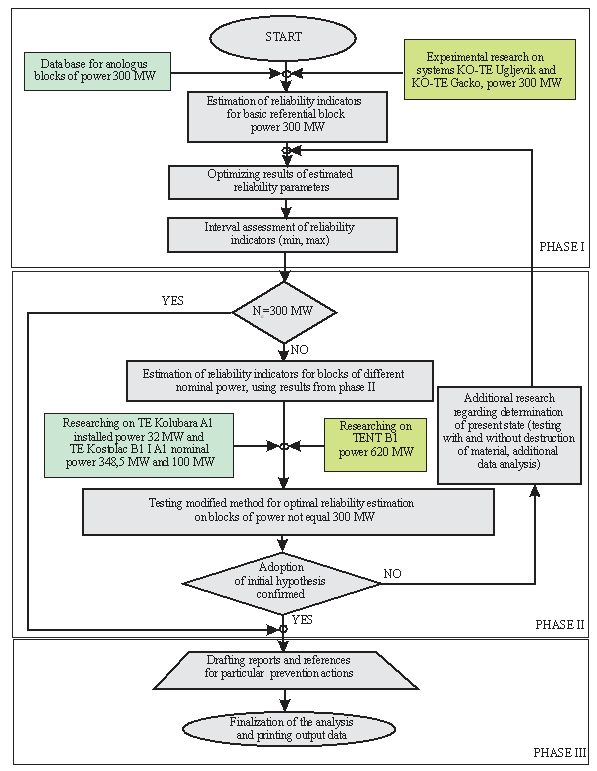

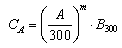

Present methods for forecasting and evaluation of thermal power plants reliability were based on appliance of statistics and probability calculation related to strength and in the same time leaning on modern methods for deterministic project-constructive calculations of elements, subsystems and systems. Applying the advantages of modern directions in system reengineering and structural or RCM (Reliability Centered Maintenance) way of using the best methods in reliability analysis of complex systems, the block diagram of modified method for basis referential 300 MW block has been created. As a starting database, the results of research of basic configurations of thermal power plants for solid fuel Ugljevik and Gacko with nominal referential power of 300 MW were used. For other facilities inside thermal power plants witch nominal power differs from 300 MW, recalculation of reliability indicators has to be carried out. Whereat the simple empirical relation in dependence of previously determined reliability indicator for 300 MW system is used so as the exponent determined on basis of statistical data processing from the exploitation during the lifespan of the power plant. The method is of the iterative nature and is about to be terminated as the starting hypothesis related to matching of results of the forecasting and real exploitation results affirms. The research related for suggested modified method gave several relatively new results which are presented inside the paper. The result represents the algorithm of modified method for evaluation of reliability of referential thermal power plant system and its modification aiming to include thermal power plants of other nominal powers.

Keywords: Thermal Electric Power Plant, Basic 300 MW Power Block, Algorithm, Modified Method, Interval Assessments, Dynamic Corrections

Cite this paper: Z. N. Milovanovic, D. Knezevic, A. Milasinovic, S. R. Dumonjic-Milovanovic, D. Ostojic, "Modified Method for Reliability Evaluation of Condensation Thermal Electric Power Plant", Journal of Safety Engineering, Vol. 1 No. 4, 2012, pp. 57-67. doi: 10.5923/j.safety.20120104.02.

Article Outline

1. Introduction

- The issues of finding the thermal electric power plant optimal reliability have been explored by using the scientific prevention and scientific identification as a modern approach of the TQM, which has been used in high technologies so far. The question of creating the basic method of reliability evaluation for the referential (basic) 300 MW power block is based on the co-ordination of separate specialist analysis within the framework of a complex algorithm, with a certain probability interpretation aiming to obtain a prognostic reliability assessment, and later also its optimization on the basis of a selected criterion. Any change of the project–prognostic conditions also requires additional consideration of other information sources, mostly from the lower hierarchical stages and with higher level of detailing the facilities and processes that take place within them. It is also necessary to complete the basic method of structural calculation of reliability indicators for the conditions of operational and non operational capacities with adequate supplementary correctional factors. Because of the presence of conditions resulting from the random processes effects (mostly of non stationary character) and also due to the difficulties in establishing the correlative connections when there are data limitations, the two-step system of corrections is most frequently used in practice. The first step is the creating of the reliability characteristics change dependency on the basis of the existing data of adequate statistic analysis, the expert evaluations and prognosis, the interval assessments of the mean and limit values and the prognosis of a possible behaviour trend of the dependencies and reciprocal relations, with simplified graphic interpolations according to the mean and final values, with their further supplementing and corrections. Applying the analogous combined approach at the second step the direct relations will be determined, or the differences and dynamic corrections, and with respect to the adopted classification according to the nominal power, with the carrying out of corresponding statistic and graphic extrapolations and mutual linking of the project reliability indicators for the thermal electric power plant system which was considered. Reliability, as a probability that the thermal electric power plant system will meet the required function within particular period of time and under certain conditions, includes four substantial factors: probability, the required function, periods of time and working conditions. Such a manner of presenting reliability enables easier compression and more effective employment. The issues of finding the thermal electric power plant optimal reliability have been explored by using the scientific prevention and scientific identification as a modern TQM approach, which has been used in high technologies so far,[1]. One of the basic goals is also the research on to what extent and in what structural form such an approach can be applied with profitability, also in the classical production systems, such as thermal electric power plants.

2. Methods for Reliability Evaluation

- There are a large number of methods for the assessment of a system and conducting the reliability analysis. Starting from a concept of defining a diagram of activities development for the purpose of the reliability evaluation and optimization of the thermal electric power plant system at all stages of its life time, and like of existing partial solutions it can be concluded as follows: • The analysis of the thermal energetic facility reliability and disposability by a combined procedure for a short term prognosis (ten coefficients method for the assessments of electric power plants engagement, disposability and reliability) represents an attempt of unification and defining of a unique methodology for a short time prognosis of electric power plants operation within the scope of the electro energetic system. The selection of coefficients for the correction of the facilities reliability and disposability indicators obtained by means of using the classical statistical methods was risk bearing in certain respects. Specifically, these coefficients required additional analysis related to the technical diagnostics application level that is the conditions of particular facilities within the system, which might be leading to the possibility of their subjectification by the experts. By applying the coefficient k2 the equipment condition is already “installed” through carrying out the statistical analysis for a five-year period which has been considered, so the blocks correction with above- average good condition was made with the k2>1 value. The next reason of the obtained results deviation is connected with averaging procedure itself and the curve approximation of a five year average (with an error up to 2%). • In the thermal electric system the statistical methods for plant experience analysing have found a place, the Bayes method, while for the reliability and disposability evaluations the following methods were used: failure trees, Markov's and Monte Karlo, Pareto, as well as the extreme values statistics. The analysis results obtained by the use of these methods were generally based on the research of separate unities in a precisely determined system or of its elements and therefore it is very difficult to generalize them to the system in its entirety. Thereby the mutual comparison of solutions and similar problems of the thermal electric plant system with different nominal power has been aggravated. • On the other side, the application of the Total Productive Maintenance – TPM concept aiming to the maximization of the equipment effectiveness and the establishment of preventive maintenance throughout the whole lifetime, as well as the methods required in the TPM application are not recent either. These methods mostly have not been used in the analysis of the thermal electric power plant system reliability and disposability so far, although they can be very efficiently applied to a thermal electric system. Their application opens a possibility of unification of obtained results and their standardization according to particular typified classes defined by their nominal power. • Aiming to increase objectivity of the analysis, it often happens that intensity of malfunction is being given by interval, which may lead to certain problems connected with the development of procedure for critical control point establishing. This method has shown to be very efficient for the analysis of manners, effects and critical stage of failure connected with the most critical elements for the system of a nuclear power plant, submarines, aircrafts etc., so for these reasons there are indications of its applicability in the thermal electric power plant system as well. • As elements of identification theory of the technical state of the system the statistical, metrical and logical methods have been used. Here the concept of control and diagnostics should be pointed out based on the set theory and topology. In that case it is necessary to define each technical system by hierarchical structure, somewhat extended in relation to the reliability theory which, besides the technical system, also includes a part connected with the capacity, surface and linear constituent part of the system, as well as the diagnostics levels. It should be emphasized that these issues are also accompanied by diagnostic software which is based on the macro and micro diagnostics. • The approach to RCM, despite not containing any new method, it introduces the structural manner of applying the best methods. On the basis of such a presentation it is possible to create the diagram concept of activities development of the basic modified method (for the 300 MW power referential block), with its modification and unification for the other blocks, classified according to their nominal power. On the ground of such a method it is possible to take decisions connected with the need of preventive maintenance and of its being founded on time or condition. The RCM process as developed so far, contains three key characteristics: a) The RCM recognizes that internal reliability of any element depends on its project and the way of construction, and that not a single form of maintenance can create reliability which would overcome the reliability installed in the course of projecting. The RCM analysis starts with defining the desired performance for each system and establishing whether reliability is such that maintenance can provide those characteristics. If it appears that it can, then it throws light upon the problems outside the maintenance scope so other activities are required such as projecting, improvement, the operation procedures changes, or the changes of the basic material.b) The RCM recommends that the failure effects are more significant than their technical characteristics. Constructive considerations of the failure effects direct the attention to the failures which, to the maximum extent, affect the safety and the system performances.c) The RCM includes the last research of the causes of the system failure in improved diagram of the course of taking decisions activities, with a selection of preventivemaintenance tasks, or activities which have to be taken in case that no convenient task can be found. This approach identifies all significant forms of maintenance securing the criteria for taking decisions, which is most convenient in any situation. Potential effects of conducting the reliability and disposability analysis through the possible application in the reengineering process, that is after the expiry of the ”basic” operating life, are based on potential improvements on the parts connected with the most critical part of the facility, and thereby indirectly on the system itself in its entirety. Such a reengineering approach should provide the realization of adequate level of required disposability or reliability, with the costs reduction which would cause a stoppage because of waiting for the task execution in the maintenance process of the thermal energetic power plant system. As in most of different industries (nuclear power plants, petro chemistry, thermal electric power plants, industrial power plants) the requirement for establishing the risk probability evaluation has been increased, the number of protection devices and alarm systems has continuously been growing, aiming to encompass the most important elements with the highest degree of risk in the exploitation process. As a result of this is also the increase of components in the reliability analysis chain, which affects the obtained evaluation accuracy.

3. Modified Method for Optimal Reliability Evaluation of CTEPP

- Using the advantages of current re-engineering system and structural or the RCM (Reliability Centered Maintenance) way of using the best methods in the complex systems reliability analysis, a block scheme of modified method for 300 MW power basic referential block has been created, Figure 1. This method also includes the risk level evaluation and indirectly also the evaluation of the way of maintenance of these systems or of their components. The choice of the most adequate maintenance task is realized through using the development of decision making activities diagram which takes in consideration technological possibilities of the proposed tasks and verifications of the realization of that. In the activities development diagram of this method the current knowledge related to the application of the TPM (Total Productive Maintenance) methodology have been incorporated, that is the application of a concept of total productive maintenance, similar to the maintenance according to condition, with the fact that the maintenance requires a special relation of the consumers toward the system and the “total” responsibility for the maintenance quality procedure of all employees within the scope of the thermal electric power plant. The aims of previously stated concept can be reduced to the equipment effectiveness maximization and the establishment of complete preventive maintenance system in the course of the whole lifetime of components and/or of the systems and their auxiliary equipment. The TPM approach is applied through different sectors in a company, covering every employee, and is based on preventive maintenance through the “managing motivation” which includes smaller groups activities. Results of former appliance of this concept highlight the major losses or disturbances such as: losses regarding the duration of malfunction (malfunction of equipment and its impact on unscheduled maintenance, demands regarding the tuning, adjustment and synchronization, activities regarding preventive maintenance of other units during the malfunction duration) losses caused by decreased power in comparison with projected power or working on minimum stable operating level and losses regarding continuity and quality of the electricity distribution. This enables the exploitation of various methods from Table 1 (particularly FTA and FMEA/FMECA) in the lifetime development of the system, with the orientation on the preventive maintenance program. Using the data about the similar facilities operation within the countries of the former JUGEL, then the SSSR, the USA and some European countries (e.g.[2],[4],[6-8]) the obtained results for the lower interval evaluation have been corrected.

| Figure 1. Block diagram of modified method for reliability evaluation of condensation thermal electric power plant |

| (1) |

4. Results

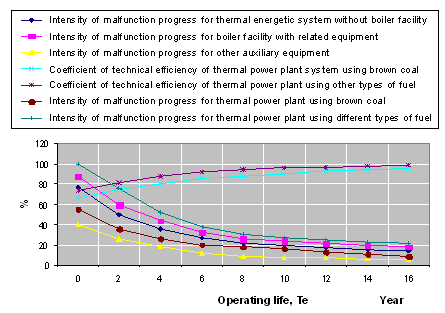

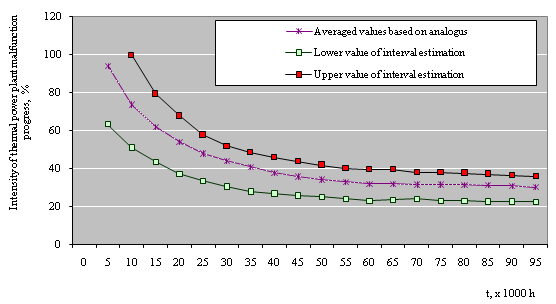

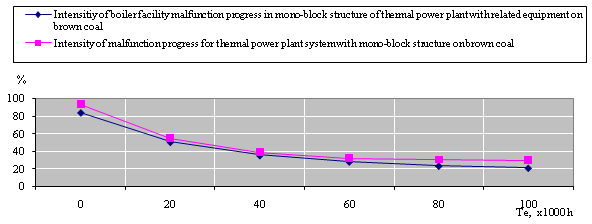

- On the basis of the obtained and processed data concerning the exploitation of the Ugljevik thermal electric power plant system and partially of the Gacko thermal electric power plant, of 300 MW referential power, referential power 300 MW, empirical dependencies of the reliability characteristics have been established for the operation state, which served as the starting initial iteration for further improvement of the output accuracy. The complex or single reliability indicators of the thermal electric power plant system in the most general form can be given in a form of extrapolation prognostic medium values and their potential dispersion, with a change tendency according to time. In Figures 27 a presentation of averaged values for the reliability parameters of the thermal electric power plant system of 300 MW power has been given, while a little more detailed presentations of the intensity course of boiler facility failure for the mono block structure of identical power are given for the case when brown coal is used as a fuel.

5. Discussion

- The research related to the proposed modified method has given some relatively new results. With the aim to meeting the basic requirement in the thermal electric power plant exploitation in terms of continuity in the electric energy generation and the reliability and safety in work, and because of reducing the large consumption of material, the time, the staff and the funds for their investigation and maintenance on a proper level, the criteria have been formulated for the quantity description of the characteristics concerning the disturbances of the capacity for work of the thermal electric power plant condition and established efficiency within the framework of the electro energetic system. The basic and supplementary reliability indicators of the facility as a whole have also been specified, as well as the indicators of their constituent parts on the first hierarchical level of dividing into sections. By using a combination of competitive engineering method and classical statistical methods for determining the malfunction probability the frequency and their duration, used in the analysis of security and reliability of complex mechanical systems, the synthesis of all the investigations so far has been carried out related to an early foreseeing of hidden defects and the thermal electric power plant system reliability level increase. The result of this synthesis is represented by algorithms of the modified method for the reliability evaluation of thermal electric power plant referential system and its modification with the aim of encompassing the thermal electric power of the rest of nominal powers. Because of the exceptional complexity and a large number of constituent components of the thermal electric power plant system a methodology of ranking has been established concerning the most critical facility with respect to the possibility of a failure emerging and its potential effects on the environment and economy of the facility operation. The main technological system (the boiler, turbine and generator facilities) or the boiler plant, as its most sensitive element, has been defined as such. This analysis correctness is also confirmed by another basic element in the system of gathering data on technological systems reliability, through the FMEA/FMECA subsystem. The FMEA/FMECA procedure has been carried out with the boiler facility and terminated by the elements ranking according to the critical stage degree of a particular element failure (e.g. the piping system). In case of lacking the data about the single element failure intensity, the assigning of a scale of values has been suggested for which, through the statistical modelling procedure, the corresponding probabilities of appearance will be established. A special emphasis has been given to the defining of structure and preparing the date base for the case when there exist the data for the “zero” state, as well as for the case of necessity of defining a methodology for the parameters establishment for evaluation of the remaining components operational life for which there are no adequate statistical data and no “zero” state of an object has been precisely established.

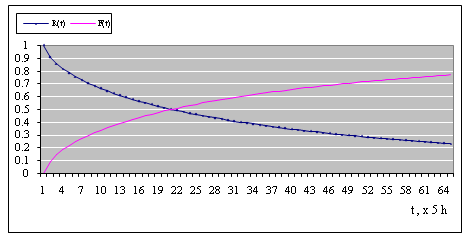

| Figure 2. Graphical representation of reliability and unreliability function of the thermal electric power plant referential block of 300 MW power in its entirety |

| Figure 3. Graphical representation of the function of intensity and density of referential block failure in entirety of power 300 MW, for time-picture of state in labour |

| Figure 4. Graphical representation of starting values for some of the reliability indicators of the referential thermal power plant system and their change in time,[2] |

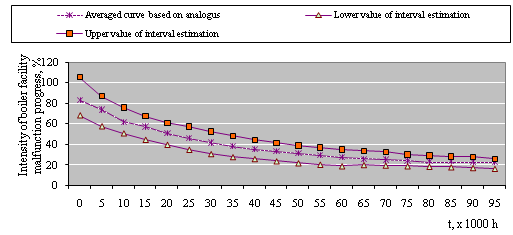

| Figure 5. Prognostic assessments of relative intensity of malfunction progress for boiler facility (mono-block structure) for referential block of 300 MW |

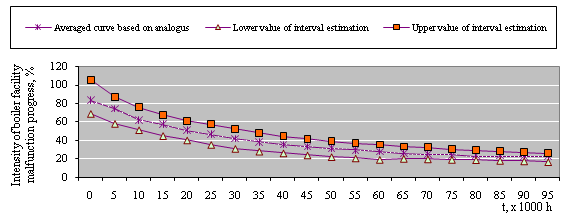

| Figure 6. Prognostic assessments of relative intensity of malfunction progress for referential block of 300 MW, using coal as a fuel (mono-block structure) |

| Figure 7. Graphical representation of intensity of malfunction progress of referential thermal power plant system without boiler facility |

6. Conclusions

- The methods which so far have been applied in the thermal electric power plant systems prognosis and reliability evaluation were based on general methods of elementary reliability assessment developed in the framework of the theory of reliability on the basis of the application of statistical and probability calculations concerning the strength, with their simultaneously leaning on the current methods determinative projecting- constructive calculations of elements, subsystems and systems. The issue of creating a basic reliability evaluation method for the 300 MW power referential block is based on co-ordination of particular specialist analysis in the framework of one complex algorithm with certain probability interpretation with the aim of reaching a prognostic reliability assessment, and later also its optimization on the basis of a selected criterion. The above stated conclusions lead to the possibility of synthesis of the given methods through a specific course of activities diagram for the entire lifetime of a facility and speeding up the process of giving prognostic assessments through generalizing the obtained results of the previously defined most critical facility (or its elements) on the system as a whole. To ensure that such an activity be realized it was necessary, before that, to create an adequate date base for 300 MW power referential block. Thereby, it is also important to point out the necessity of a precise defining of the initial, the so-called “zero” state of elements in the thermal electric power plant system, which coincides with the delivery time of the steam block to the consumer and its transfer to regular exploitation (end of guarantee testing). In case of analysing an older thermal energetic facility for which no “zero” state exists, the evaluation of indispensable reliability indicators is founded on the date base created by means of the specific methodology.

ACKNOWLEDGEMENTS

- The authors would like to thank the referees for their helpful comments which significantly improved the quality of this paper.

References

| [1] | Milovanovic N. Zdravko, "Modified Method for Reliability Evaluation of Condensation Thermal Electric Power Plant", Doctoral thesis, University of Banja Luka, Faculty of Mechanical Engineering Banja Luka, Banja Luka, Republic of Srpska - BiH, 2000. |

| [2] | Каплун Соломон Менделеевич, "Оптимизация надежности энерго установок", Наука, Новосибирск, SSSR, 1982. |

| [3] | N. Pavlovic, "Time energy indicators of reliability of thermal units in the electric power industry system of Yugoslavia and the comparison with the region's UNIPEDE", Tech. Rep. 01-02, Faculty of Mechanical Engineering, Beograd, Serbia, 1986. |

| [4] | Розанов Матвей Никанорович, "Надежность электро-энергетических систем", Справочник, Том 2, Энергоатомиздат, Москва, Россия, 2000. |

| [5] | Papic Ljubisa, Milovanovic N. Zdravko, "Systems Maintainability and Reliability", The DQM monographic library „Quality and Reliability in Practice“, Book 3, the Researching Center for quality and reliability management, Prijevor, Serbia, 2007. |

| [6] | Milovanovic N. Zdravko, "Optimization of thermo power plants liability", University in Banja Luka, Faculty of Mechanics in Banja Luka, Republic of Srpska- BiH, 2003. |

| [7] | Milicic Dragomir, Milovanovic N. Zdravko, "Library Monographs: Energy- Generating Machines Steam Turbines", University in Banja Luka, Faculty of Mechanics, Banja Luka, Republic of Srpska- BiH, 2010. |

| [8] | Milovanovic N. Zdravko, "Library Monographs: Energy- Generating Machines Thermodynamic and Flow dynamics Basics of Thermal Turbo Machines", University in Banja Luka, Faculty of Mechanics, Banja Luka, Republic of Srpska- BiH, 2010. |

| [9] | Milovanovic N. Zdravko, "Library Monographs: Power and Process Plants, Volume 1: Thermal power plants - Theoretical basis", University in Banja Luka, Faculty of Mechanics, Banja Luka, Republic of Srpska- BiH, 2011. |

| [10] | Milovanovic N. Zdravko, "Library Monographs: Power and Process Plants, Volume 2: Thermal power plants - Technological systems, design and construction, operation and maintenance", University in Banja Luka, Faculty of Mechanics, Banja Luka, Republic of Srpska- BiH, 2011. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML