-

Paper Information

- Previous Paper

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Journal of Safety Engineering

2012; 1(1): 7-16

doi: 10.5923/j.safety.20120101.02

Strategies for in Automobile: Strategies for Using Automotive Textiles-Manufacturing Techniques and Applications

Kunal Singha

Department of Textile Technology, Panipat Institute of Engineering & Technology, Harayana, India

Correspondence to: Kunal Singha , Department of Textile Technology, Panipat Institute of Engineering & Technology, Harayana, India.

| Email: |  |

Copyright © 2012 Scientific & Academic Publishing. All Rights Reserved.

The safety in automobile is become importance in the modern scenario. The textile product can be use in this purpose in the form of various safety devices like air bag, seat belt, car interior, Power steering filters, Abs brake filter, tire cord production, lining, covering, cushion components, design interior etc. The different grade textile fibers as polyester, nylon, PVC, acrylic, viscose/cotton etc can be the potential option for the new emerging field name called automotive textile.

Keywords: Air Bag, Seat Belt, Car Interior, Tire Cord Production, Lining, Covering, Cushion Component, Design Interior, Polyester, Nylon, PVC, Automotive Textile

Article Outline

1. Introduction

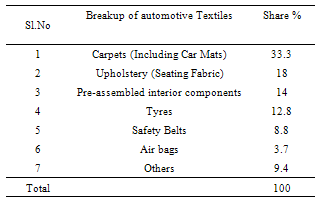

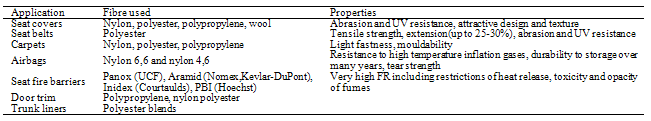

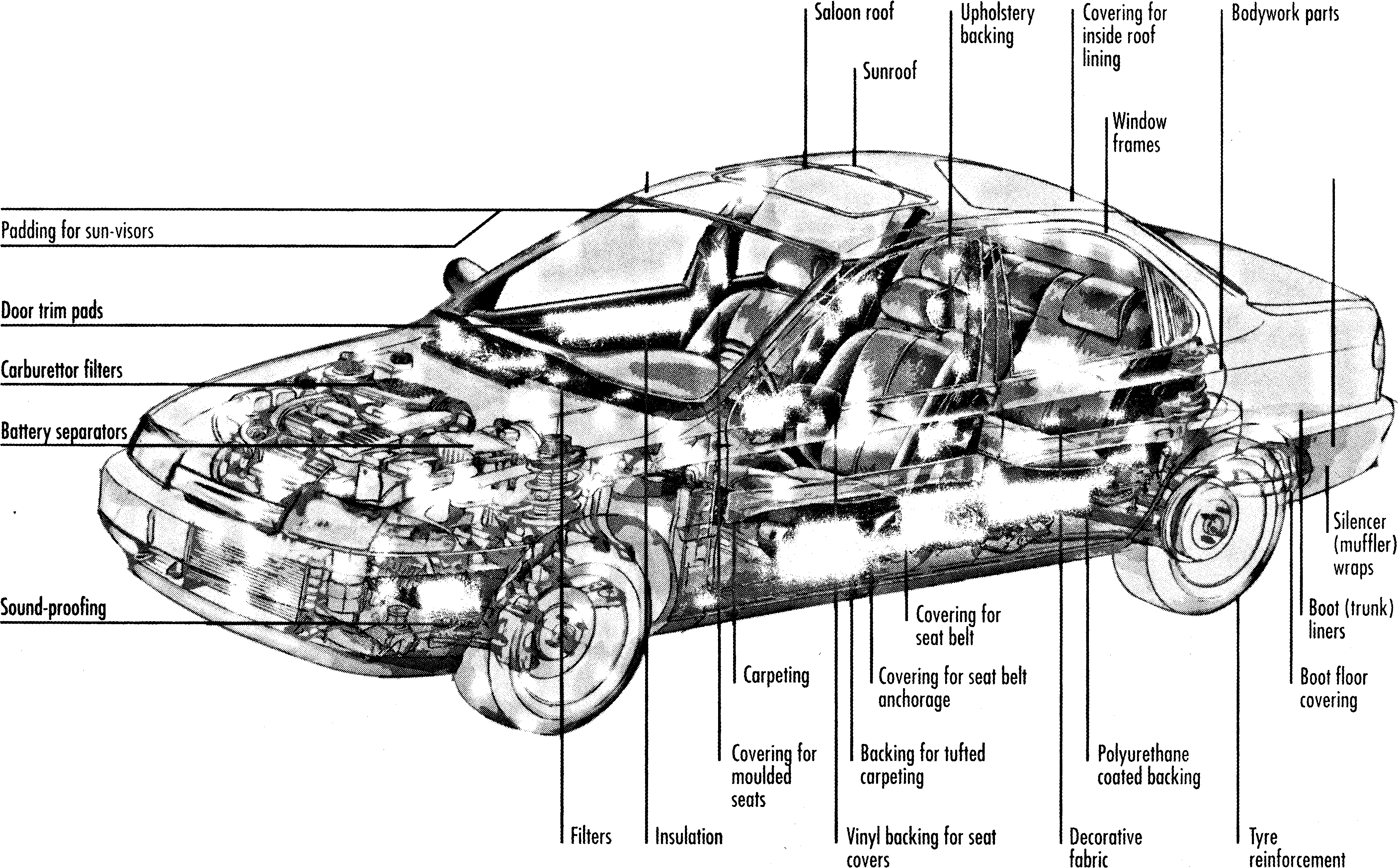

- Textiles are no more limited for use as apparels clothing is just are but not the only purpose of textiles with the rapid changes in the social economic structure of our society. Many efforts are made to some and protect human life. Automotive textiles happens to be the rewarding sector finding extensive use of technical textiles in the product categories viz. interior trims, safety devices like seat belts and airbags, carpets, filters, battery separators, hood liners, hoses & belt reinforcement. Textiles, which constitute approximately 20-25 Kgs in a car, are not only used for enhanced aesthetic of automotives but also for sensual comfort & safety. Additionally, few textile products found their applications as design solutions to engineering problems in the form of composites, tyre reinforcement, sound insulation & vibration control. Apart from woven & knitted constructions, Nonwovens also find applications in transport textiles due to certain advantages served by them. The use of textiles (Table 1) in automotive applications includes floor coverings; upholstery; belts, tubes and tapes; tyre cord; safety belts; airbags; components; and filters[1,2]

1.1. Market for Automotives

- THE Indian automotive industry has experienced an unprecedented boom in the recent years. From 2007-2015 India will contribute 16% to the global automotive textiles. This is due to the sudden increase in the demand of automotives which is triggered primarily by the factors like increase in income and standard of living of the middle class Indian families and Indian government liberalization measures. Further, as travel has become the integral part of everyone’s life, issues such as comfort and safety have taken on a right priority. All these factors clearly indicate brilliant prospect for automotive textile industry which lead to increased demand of the technical textiles components used in automobiles[3, 4]. It is expected that India will be the leading car producer (15%) by 2015. Another reason for large growth in the automotive textiles is that India is a low cost manufacturing base.

|

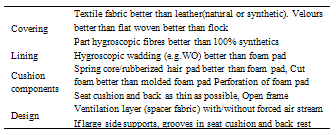

2. Seat Belt: Engineering Principle

- The seat belt is an energy-absorbing device that is designed to keep the load imposed on a victim's body during a crash down to survivable limits. Fundamentally, it is designed to deliver non-recoverable extension to reduce the deceleration forces, which the body encounters in a crash. Basically, it is designed to offer non recoverable extension to decrease the deceleration forces that the body comes across in a crash. Non recoverable extension is significant to prevent the occupants from being restrained into their seats and sustaining whiplash injuries right away after a collision. An efficient seat belt will only permit its wearer to move forward a maximum of about 30 cm to avoid contact with any fixed parts of the car. Seat belt was invented concurrently in United States and Sweden. Earlier seat belts were fixed and adjusted manually by the wearer. With the introduction of automatic belts today wearer has more freedom to move[6].

2.1. Need for Seat Belt

- In an auto smash, seat belts prevent ejection from a moving car and stop people going through the windshield as the vehicle comes to a sudden stop. Seat belts also minimize injuries due to impact with the vehicle's hard interior; they ensure better control of the car. Seat belts also hold people in position for the protective cushioning, if there's an air bag. At speeds under 25 mph, seat belts give adequate protection, but at higher speeds, air bags help to prevent the violent forces exerted on the neck and head in frontal crashes[5, 7].

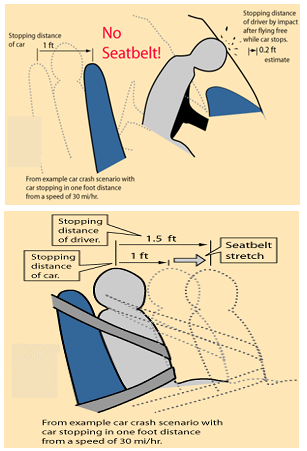

| Figure 1. Forces in Car Crashes |

2.2. Scientific Approaches towards Seat Belt

- It’s a simple Newton’s first law of motion and law of energy conservation. According to Newton’s first law of motion an object at rest tends to stay at rest and an object in motion tends to stay in motion with the same speed and in the same direction unless acted upon by an unbalanced force. Thus, driver continues in motion, sliding forward along the seat. A driver in motion tends to stay in motion with the same speed and in the same direction, unless acted upon by the unbalanced force of a seat belt. Seat belts are used to provide safety for passengers whose motion is governed by Newton's laws (Figure 1). The seat belt provides the unbalanced force, which brings driver from a state of motion to a state of rest[1, 9].Assume, car speed is 13.41 m/s, driver’s weight is 50 kg, then what will be the impact force acting on the car driver? If driver is wearing a non-stretchable seat belt, stopping distance is 0.304 mt.Impact force on driver =[0.5x 50x(13.41)2] / 0.304 = 14788.5 N = 1.5 tonsDeceleration of driver = 14788.5/50 = 295.77 m/s2If driver is without seat belt, suppose stopping distance is 0.0608 mt.Impact force on driver =[0.5x 50x(13.41)2] / 0.0608 = 73942.5 N = 7.5 tonsDeceleration of driver = 73942.5/50 =1478.8 m/s2 ; now if driver is wearing stretchable seat belt, stopping distance is 0.456 mt (Figure 2)

| Figure 2. Safety and signifiance of the seatbelt |

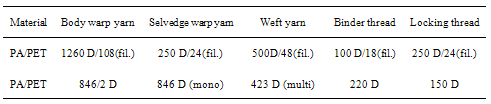

2.3. Raw Material and Manufacturing Method: Constructional Details

- Raw material used for seat belt webbings are Nylon, PET and its derivatives like HTPY. Nylon was utilized in some early seat belts, but due to of its higher UV degradation resistance; polyester is now widely used worldwide and also polyester scores over nylon because of lower extensibility and higher stiffness. Seat belt structures can be single layer or double layer and manufactured on needle looms with plain weave, twill weave, satin weave. Normally 2/2-twill structure is used (Table 2). The needle loom used presently is shuttleless and capable of delivering over 1000 picks per minute[10].A typical seat belt is made of 320 ends of 1,100 dtex polyester each. Most weft yarns made from polyester are 550dtex. Commonly used seat belt webbing is a narrow fabric measuring 46mm wide. Commercial needle looms can accommodate six weaving stations simultaneously side by side. In case of nylon seat belts, the warp yarns are 180 dtex and the weft is either 470 or 940 dtex. Normally, 1000-1500 denier used for main warp yarns, 250-500 denier used for selvedge yarns and same denier or slightly higher denier as selvedge yarns used for weft. Typically, 320 ends of 1100 dtex or 260 ends of 1670 dtex yarn. This structure permit highest yarn packing within a given area for highest strength and sometimes-coarser yarns are used for good abrasion resistance[13].

2.4. Manufacturing Method of Seat Belts Used in Automobile Car

- In the needle loom, the weft is inserted from one side of the warp sheet and here a selvedge is formed. The other side of webbing is held by an auxiliary needle, which manipulates a binder and a lock thread. Once these are combined with the weft yarn, a run-proof selvedge is created. Special care is taken when constructing the selvedge to ensure it is abrasion resistant. It is equally important to ensure that the selvedge is soft and comfortable to wear. In a loom, needle used to move monofilament and multifilament weft yarn across width of the web in single shed. A high tension applied to monofilament compared to multifilament yarn so that it doesn’t protrude beyond selvedge. For selvedge single ply warp yarn is used with reverse twill weave that gives close packing and soft, round edge selvedge. Monofilament weft yarns are rigid yarn that provides good stiffness across web and high resiliency. Monofilament weft yarns are under high tension which controls webbing softness and round shape together with catch cord yarns and finer warp yarns in selvedge than body of the webbing. Low longitudinal stiffness and thinner web gives good winding performance with use of smooth monofilament weft yarns[11].

2.5. Major Machineries Required for the Manufacture of Seat Belt Webbings are

- High speed automatic needle looms, Warp yarn tension control device, Tape collection machine Cone Creel of 600 ends, Continuous Dying machine Steam Boiler, Compressor[12].

2.6. Major Global Manufacturers of Seat Belts and Webbing

- Autoliv, Sweden, Key Safety Systems, USA, TRW, Germany, Delphi Corporation, USA, Ribbons Limited, UK[10,13].

2.7. Seat Belt Quality Details: Requirements

- The seat belt is required to have the properties: Static load bearing capacity upto 1500 kg and extensibility upto 25-30%, Abrasion resistance, Heat and light resistance, Light weight, Flexibility for use[13, 14].

2.8. Performance Tests and Standard for Seat Belt

- Tests are carried out for ascertaining the mechanical performance of the webbing as per BSI and the SAE on the some aspects like; width, thickness , breaking strength and elongation for dry and wet webbing, abrasion resistance at various environmental conditions and in contact with buckles and fittings, influence of extreme environmental conditions and temperatures, rubbing fastness, microbial resistance[11].

2.9. Recent Developments in Seat Belt: Smart Belt

- Autoliv's Smart Belt System uses a switch mechanism to adapt its restraining force – and hence the load on the occupant – to the severity of the crash. In a crash, the Smart Belt System starts – as in most modern seatbelt systems – by tightening the belt, using a pyrotechnic pretensioner. This eliminates slack and makes it possible to release some webbing at a later stage, if the load on the occupant becomes too high. On the Smart Belt System, the Smart Belt can adapt its restraining force – and hence the load on the occupant – to the crash severity. If the vehicle is equipped with an occupant weight sensing systems, it is also possible to adjust the seatbelt load individually to each occupant. This is an important advantage since smaller, lighter weight occupants, such as many women, are more susceptible to high belt loads than the average person, and these individuals do not need the same restraining force as a larger occupant[15].• Trunk Belt: Safety belts which protect fragile goods and prevent luggage from penetrating into the passenger compartment in, for instance, cars with folding rear seats[16].

|

3. Air Bags

- Airbags inflate, or deploy, quickly -- faster than the blink of an eye. Imagine taking one second and splitting it into one thousand parts. In the first 15 to 20 milliseconds, airbag sensors detect the crash and then send an electrical signal to fire the airbags. Typically a squib, which is a small explosive device, ignites a propellant, usually sodium azide. The azide burns with tremendous speed, generating nitrogen, which inflates the airbags. Within 45 to 55 milliseconds the airbag is supposed to be fully inflated. Within 75 to 80 milliseconds, the airbag is deflated and the event is over. When airbags work properly, they dramatically reduce the chance of death or serious injury. However, the speed with which airbags inflate generates tremendous forces. Passengers in the way of an improperly designed airbag can be killed or significantly injured. Unnecessary injuries also occur when airbags inflate in relatively minor crashes when they're not needed[16].

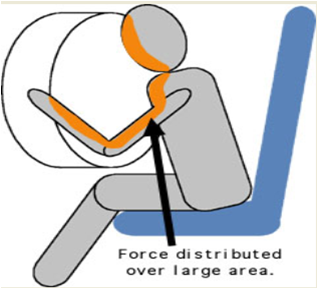

3.1. Engineering Principle: Law of Motion behind Air Bags

- The moving objects have momentum (the product of the mass and the velocity of an object). Unless an outside force acts on an object, the object will continue to move at its present speed and direction. Cars consist of several objects, including the vehicle itself, loose objects in the car and, of course, passengers (Figure 3). If these objects are not restrained, they will continue moving at whatever speed the car is traveling at, even if the car is stopped by a collision.

| Figure 3. Force distribution on body during collision[3] |

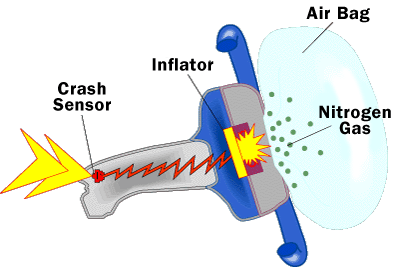

| Figure 4. The airbag and inflation system stored in the steering wheel[19] |

3.2. Airbag Inflation

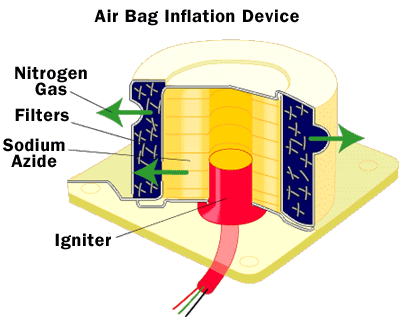

- The goal of an airbag is to slow the passenger's forward motion as evenly as possible in a fraction of a second. There are three parts to an airbag that help to accomplish this feat:• The bag itself is made of a thin, nylon fabric, which is folded into the steering wheel or dashboard or, more recently, the seat or door.• The sensor is the device that tells the bag to inflate. Inflation happens when there is a collision force equal to running into a brick wall at 10 to 15 miles per hour (16 to 24 km per hour). A mechanical switch is flipped when there is a mass shift that closes an electrical contact, telling the sensors that a crash has occurred (Figure 4). The sensors receive information from an accelerometer built into a microchip[19].The airbag's inflation system reacts Sodium azide (NaN3) with potassium nitrate (KNO3) to produce nitrogen gas. Hot blasts of the nitrogen inflate the airbag.[3]Early efforts to adapt the airbag for use in cars bumped up against prohibitive prices and technical hurdles involving the storage and release of compressed gas. Researchers wondered:• If there was enough room in a car for a gas canister• Whether the gas would remain contained at high pressure for the life of the car• How the bag could be made to expand quickly and reliably at a variety of operating temperatures and without emitting an ear-splitting bangThey needed a way to set off a chemical reaction that would produce the nitrogen that would inflate the bag. Small solid-propellant inflators came to the rescue in the 1970s.

| Figure 5. The inflation system uses a solid propellant and an igniter[18] |

3.3. Manufacturing Process: Raw Materials (Fibers) for Air Bags

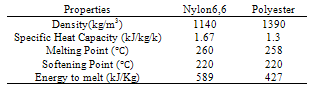

- Air bag fabrics are made of Nylon 6,6 multifilament yarns with counts from 235 to 940 tex. Air bag fabrics are generally dense which a challenging task to weave is. Tensile strength, elongation, tear proportion resistance and weight requirement of air bag fabric are critical. Air permeability of air bag fabric should be uniform across the whole width of the fabric[13, 17]. There are currently two principle material types which are used in the manufacture of airbags. They are uncoated nylon (polyamide 66) and coated nylon. Two types of commonly used coatings are Silicone and Neoprene (Table 3). In general, coated materials are used for driver's side airbags and side impact bags, while passenger side airbags are made from uncoated nylon materials[8].

|

3.4. Manufacturing Techniques of Airbag Fabrics

- An airbag for deployment outside of a vehicle is made from a fabric that is coated on at least one of the surfaces of the fabric. The airbag fabric may be coated to increase the strength of the fabric so that the fabric is reinforced. By increasing the strength of the fabric, breakage of the airbag can be minimized. By employing an airbag that is made from a fabric that is coated on at least one of the surfaces of the fabric, the airbag is less likely to decrease in strength when the airbag comes into contact with a foreign object that presses or scratches against the airbag. The vehicle may be a motorcycle, automobile, train, or other vehicle[9]. • Coated Base Fabric for Air Bags: A coated airbag base fabric made of a textile fabric that has an excellent air barrier property, high heat resistance, improved mountability, and compactness and excellent adhesion to a resin film is characterized in that at least one side of the textile fabric is coated with resin, at least part of the single yarns of the fabric are surrounded by the resin, and at least part of the single yarns of the fabric are not surrounded by the resin. An airbag is characterized by using such a coated airbag base fabric. A method for manufacturing the coated airbag base fabric is characterized by applying a resin solution having a viscosity of 5–20 Pas (5000– 20,000 cP) to the textile fabric using a knife coater with a sharp-edged coating knife at the contact pressure between the coating knife and the fabric of 1–15 N/cm[9, 10].• Laminated Material for Airbag: Disclosed is a polymer film, preferably a polyamide polymer film, which comprises at least one first layer and a second layer and is laminated onto a fabric. The material of the first layer has a glass transition temperature of less than 10oC while the material of the second layer has a glass transition temperature of less than 20oC. Preferably, the polymeric materials contain portions of polyamide blocks[12].

3.5. Method of Manufacturing an Airbag

- • Positioning a first air bag part having at least two connection sections in an opposing relationship to a second air bag part having at least two attachment sections, the attachment and connection sections also opposing each other• Coating at least one opposing surface of the first and second air bag parts with polyurethane, wherein the connection or attachment sections located on the at least one opposing surface are coated as well.• Contacting the opposing connection and attachment sections with each other; and• Heating the first and second air bag parts to thereby weld the first and second airbag parts together at the attachment and connection sections to form an inflatable region between the first and second air bag parts and a first non-inflatable region located within the inflatable region[17].

3.6. Types of Airbags

- • Air bags For Frontal Injury , Side Air bags for cars , Airbags for Motorcycle , Pedestrian Protective Air Bags[8]

3.7. The Future of Airbags

- Until recently, most of the strides made in auto safety were in front and rear impacts, even though 40 percent of all serious injuries from accidents are the result of side impacts, and 30 percent of all accidents are side-impact collisions. Many carmakers have responded to these statistics (and the resulting new standards) by beefing up doors, door frames and floor and roof sections. But cars that currently offer side air bags represent the new wave of occupant protection. Engineers say that designing effective side airbags is much more difficult than designing front airbags. This is because much of the energy from a front-impact collision is absorbed by the bumper, hood and engine, and it takes almost 30 to 40 milliseconds before it reaches the car's occupant. In a side impact, only a relatively thin door and a few inches separate the occupant from another vehicle. This means that door- mounted side airbags must begin deploying in a mere five or six milliseconds! The head airbag, or Inflatable Tubular Structure (ITS), looks a little like a big sausage and, unlike other airbags, is designed to stay inflated for about five seconds to offer protection against second or third impacts. Working with the side airbag, the IT’S is supposed to offer better protection in some side collisions. Another option for head protection in side impacts is the curtain airbag[8,10,17].

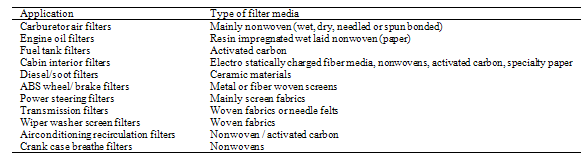

4. Automotive Filters

- Performance of any automotive engine mainly depends on engine technology and filter system used. Automotive filter business is however mainly concerned with air filters, oil filters, fuel filters and cabin filters. The performance of an automobile is bolstered significantly by the presence of high performance filter media in the engine compartment and in various other locations. The purpose of filter is to control contamination through achieving a balance between the sources of contamination and the ability of a system to tolerate contamination. The ultimate goal is to balance filtration performance with the desired cleanliness level. In the modern car machines a varieties of textile fibers are used for auto filter preparations as per as the suitable requirements and end uses (Table 4).• Automotive Oil Filter: Oil Filter Media, Particle size retention (filtration efficiency), Dirt-holding capacity Resistance to oil flow• Automotive Fuel Filter: Diesel Fuel Filters, Air Filter, Automatic Transmission Filter, Coolant Filter[7, 12]

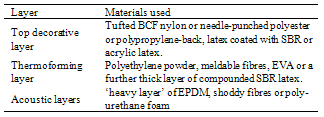

5. Automotive in Car Interior

- The importance of interior design to the potential sales volume of passenger car has always been a major consideration to the automobile stylist. However, despite the fact that textiles had for a long time played a part in automobile manufacture it was not until the early to mid- 1970s that these same companies began to realize the role that well-designed textile fabrics could play in the design of attractive interiors (Figure 6).

|

|

| Figure 6. Textile uses in Car[4] |

5.1. Special Requirements for Auto-interior

- The common expectancy of the car user is that the auto-interior should have: Good appearance and aesthetics, Good comfort, Easy to maintain, Retention of good properties even after prolonged usage, Good durability, Wrinkle resistance, Water and stain proof, Having antistatic and oil release property, No or minimum emission, which may hinder driving by fogging or contamination of inside atmosphere, Flame resistant for safety, Low costs. The main criteria involved in the development of textiles and components in automotive are: Tensile strength, Abrasion resistance, Pill resistance, Air permeability, compression resistance, elasticity, light fastness at high temperatures, stiffness, ease of cleaning, separation force, dimensional stability, flame resistance, anti-fogging resistant, resistance to adverse climatic conditions. The others processing requirements are mouldability, susceptibility to compression, sewability, weldability, adhesive properties, vulcanizing properties (Table 5).

5.2. Flock and Flock Yarns

- Flock in the car has several positive advantages like: sorption of moisture, A feeling of comfort, Serviceability, Smoothness, Acoustic insulation, Easy-care properties. In flock production additives are added to a special polymer during spinning to improve various properties, the filaments then drawn to form a tow. This tow must be cut precisely for flock used in the car industry the staple length is 1mm and the linear density is 3.3dtex.

5.3. Synthetic Wood Pulp (SWP)

- • This material is produced by Mitsui Chemicals, Tokyo, Japan.• These are polyethylene and polypropylene fibrides, which are gained directly after polymerization.SWP has morphologic characterstics similar to natural cellulose, synthetic staple fibres and asbestos fibres. In the automotive sector, SWP as binding fibre is more suitable than phenolic resins and PP fine fibres as regards the distribution properties and minor separation tendencies compared with phenolic resins SWP creates less odorous annoyance. The recycling conditions have been improved, which is becoming more and more imperative in the automotive industry[17].

5.4. Fabric Used for Production of Auto-Interior

- Nonwovens have better adhesion property than woven and so binder application is more uniform. They also possess higher thickness for a given weight per unit length and so are more voluminous and comfortable. In addition they have a more uniform, smooth and random surface. As a result nonwovens are preferred for moulded carpets used in modern cars. Nonwovens are used globally for the various applications likes floor panels, carpets, boot linings, wheel compartments, parcel shelves, linings for the side panels, roof linings, car seats, filters, acoustic insulation and the emergence of nonwovens in auto-interiors is helpful in improving cost-effectiveness, redefining carpet value, finding new filters, preventing fogging, working with contours, easily customized, attractive, durable, strength and weight, abrasion resistance, thermal protection, flame resistance, acoustic insulation, air filtration[1].

5.5. Warp Knitted Spacer Fabrics: Properties

- Soft handle, Spring comfort(determined by yarn count, number of stitches, construction and threading-up arrangement, Air permeability, Task-oriented comfort behavior, transport of moisture, thermal insulation, refraction of light, sorption of noise, filtration, requisite dimensional stability, longitudinal and/or transverse elasticity on one or both sides, plastic deformation, fabric can be folded easily, recyclable[15].

5.6. Evaluation Points for Auto-Seat Covers

- •Physical properties like Extensibility, tear, adhesion to backing (foam or nonwoven)•Effect of heat, light, moisture and chemicals on physical properties, fastness properties of dyes used•Performance criteria (abrasion, pilling, flex), propensity to fog, odour, soil, static[3-4].• Fibre or colour migration to other textiles, which come in contact with it and special demands like flame proofness, thermal insulation, water proofness[7], sound dampening.The type of fabric used for seating varies from location to location:•Both woven and knitted fabrics are used in Europe and USA. In USA, woven velour is preferred whereas in Western Europe, the car builders are favouring Knitted fabrics.• In Asia, however the majority of the car seating fabrics is knitted. In Japanese market, the car builders have always been favouring woven velour fabric and this trend looks unlikely to change[14, 17].

5.7. Seat Comfort

- There are some standard guidelines for the comfortness in a car seat considering different parameters (Table 6).

|

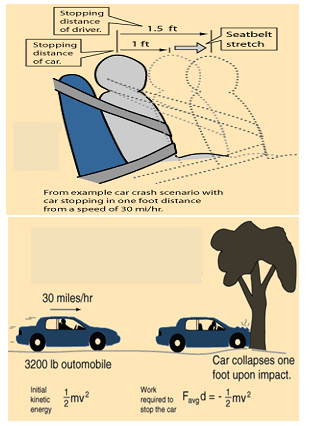

6. Carpets

- There are about 3.5 to 4.5 sq. mt carpet in each car. Apart from ethical and sensual comfort, carpets also play significant role in acoustic and vibration control. Road noise is considered as an environmental pollution in few countries. There are pressures on automobiles to reduce external noise by about 50% (up to 3dB). Carpets are contributing to solve this problem. Carpets by providing thermal and acoustic protection thus directly contribute to safety[9].

6.1. Types of Carpets

- The carpets used in cars are mainly of three types: (a) Tufted cut-pile (b) Tufted loop-pile (c) Needle-felt

6.2. Noise Control

- Sound is propagated through the air and by vibration of the car body and there are three basic methods of reducing it: (a) By absorption (b) By damping (c) By isolation or insulation. In general a thick piece of material will absorb more sound than a thinner piece of the same material (Table 7). Sound absorbency is influenced by: density of the material, air porosity of the material, thickness of the material[10, 13].

|

7. Door and Side Panels

- As in the other areas of the cars, the vehicle models very much dictates the fabric type used on door and side panels. The choice is dictated by cost considerations consistent with desired appearance and aesthetics. The fabrics used for doors etc should have high degree of stretchness. This can be obtained by incorporating elastomeric yarns into structure of fabrics. Now a layer of foam is added to the door panel fabrics to get a more luxurious touch. Still development includes the utilization of high pile polyester fabric without distortion and to eliminate Vinyl backing[17].

7.1. Headliners

- At one time the headliner was simply a covering for the metal roof inside the car and consisted of a piece of fabric, PVC or some other material simply ‘slung’ i.e. held in place only at a few points. Some important requirements of headliners are the lightweight, thin profile but rigid without any tendency to buckle, flex or vibrates directional stability, aesthetically pleasing, soft in touch[14].

7.2. Trunk Liners

- Cars with trunk liners are making rapid gain in the headliner market. Now a days, the automobile manufacturers are making lining attached to the front and rear walls, in many cases attached to sidewalls also. This gives a most luxurious appearance and also serves as protection to both exterior walls and to trunk content such as luggages perfect to date. The liners must be decorative and functional, yet have relative cost. These are usually made from waste fibre that are needled and then naturated with elastomerics materials. However, even spun bonded polypropylene is also used as a substrate for a foamed rubber material that is used as trunk liner[14, 18].

7.3. Landau Tops

- Landau tops give the car an extra leathery look. The top of the car interior is generally covered with a nonwoven fabric[4]. Now a days needle nonwoven is generally used. The process treats the needled polyester nonwoven with finishing materials to prevent wicking and rusting of the metal roof under the top. The extreme care is taken in handling the Landau top material to protect matter that would interfere with the subsequent dielectric sealing process used in assembly plants[9]. Manufacturers are trying their best to make a fabric for top assembly having lightweight, good fastness or rubbing and also good-looking appearances.

7.4. Parcel Shelves

- Parcel shelves, also referred to as package trays or the ‘hat rack’ are now almost invariably covered with needle- punched nonwoven mainly in polypropylene or polyester[10]. Parcel shelves range in size from relatively narrow components in saloon cars, to a much larger and wider article in hatchbacks[17].

7.5. Dashbroad

- The dashboard, probably the hottest area in the car interior, offers some opportunity for textiles, although a very limited number of car models use fabric at present in this very demanding application[9]. The dashboard shape being highly curved and also complex, to accommodate controls and instruments, presents many problems to the textile technologist. It could probably only be obtained by knitting, and 3D knitting would be eminently suitable. Performance criteria fulfilled by textiles are: low gloss (no glare or reflections on the windscreen), soft touch, pleasant aesthetics, non-fogging, non-odorous, UV stability, resistance to heat ageing, resistance to low temperature, high abrasion resistance[12].

7.6. Sunvisors

- In the USA, sunvisors are produced from raised -warp knit fabric, whereas in Europe PVC is still extensively used. Injection moulding produces some sunvisors, others are composed of metal frames and rigid foam or cardboard are also used. The article is close to the windscreen and UV light and heat resistance must be of the highest standard. Passenger safety is also an important consideration[21]. There are opportunities for textiles, especially nonwovens in this area to produce a recyclable product.

8. Future Application of Automotive Fabrics

- • Listings: Listings are strips of fabrics used to attach upholstery to the frame or moulded seat composite. These are interfaces that must be strong, have ample seam strength and low seam slippage, and must be able to hold a metal fastener or staple[18].• Insulator pads: Insulator pads are composites that act as a buffer between the foundation and upholstery.• Map pocket liner: Map pocket liner is a backing that supports the trim fabric.Tie downs: Tie downs are fabrics attached to an extended olefin polymer bead. These are similar to listings in that they are used to attach upholstery to the frame assembly[19-20].

9. Conclusions

- In today’s agile world, many service providers are marketing their products under slogans likes instant connectivity, quick service. Everyone wants quicker services, faster car. As per world health organization, Road accidents are a worldwide problem and now result in over, 1.2 million people die every year from road crashes all around the globe. Occupant restraints, is the best solution such as seat belts and air bags, are highly effective in preventing death and injury from traffic collisions. Seat belts are easy to use, effective and inexpensive means of protection in an accident. Use of airbags in a vehicle provides additional safety but it is not an alternative to seat belts. They co-exist to provide absolute safety to the passenger. This is so because the airbags provide protection against head-on collision while the seat belts provide protection irrespective of the direction of crash. Air bags would reduce motor crash fatalities by an estimated 10-15 per cent over and above the 40 per cent injury- reduction provided by seat belts alone (if worn). Autoliv estimated, seatbelts are expected to reduce the overall risk for serious injuries in crashes by 60-70% and the risk for fatalities by about 45 percent. Automotive filters can serve to the better condition of the vehicles as well as reduce the environment pollution. The noise absorbent automotives helps to reduce in noise pollution.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-Text HTML

Full-Text HTML