-

Paper Information

- Paper Submission

-

Journal Information

- About This Journal

- Editorial Board

- Current Issue

- Archive

- Author Guidelines

- Contact Us

Resources and Environment

p-ISSN: 2163-2618 e-ISSN: 2163-2634

2015; 5(5): 135-145

doi:10.5923/j.re.20150505.01

Assessment of the Feasibility of Using Filter Made of Rice Straw for Treating Aquaculture Effluents in Egypt

Ashraf Ghanem, Mohammed Haggag

Department of Irrigation and Hydraulics, Faculty of Engineering, Cairo University, Giza, Egypt

Correspondence to: Mohammed Haggag, Department of Irrigation and Hydraulics, Faculty of Engineering, Cairo University, Giza, Egypt.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Aquaculture production in Egypt is practiced exclusively on polluted drainage water. This results in low productivity of a low quality product. Current aquaculture practices result in additional waste loads to the existing polluted water. The present paper reports the treatment effectiveness of a filter media for treating wastewater arising from aquaculture farms at the field level. First, wastewater entering the farm from is treated to remove hazardous pollutants. Then, a water recycling and filtration system of the pond water is introduced, to purify fish wastes from the pond and to recover nutrients. A pilot study is conducted at experimental fish ponds in the Northern Delta Region. Fish pond material flow analysis model is developed to simulate the impact of the adoption of the proposed approach on the aquaculture industry. The findings of the pilot study are used to extrapolate its effectiveness in reducing waste loads in water and improving water use efficiency in aquaculture farms at broader scale. Results indicated potential improvement in fish quality and productivity and a considerable reduction in pollution loads to the receiving water bodies. The system provides yield increase of about 15% and reduction in pollution loads by about 95%. However, Nitrogenous compounds in the form of Nitrates remain in the effluent; it is less toxic to the environment than Ammonia. To increase the revenue of this approach, the system is recommended to be combined with renewable energy to operate the circulation pumps.

Keywords: Nile Delta, Water Quality, Rice Straw, Filter, Aquaculture

Cite this paper: Ashraf Ghanem, Mohammed Haggag, Assessment of the Feasibility of Using Filter Made of Rice Straw for Treating Aquaculture Effluents in Egypt, Resources and Environment, Vol. 5 No. 5, 2015, pp. 135-145. doi: 10.5923/j.re.20150505.01.

Article Outline

1. Introduction

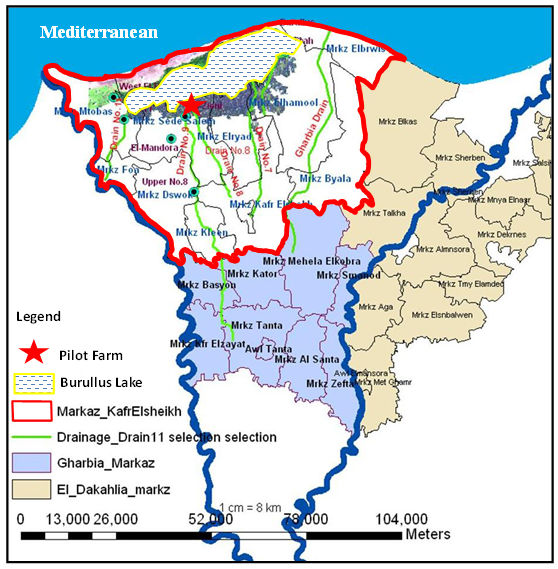

- Aquaculture production is a growing industry in the Nile Basin, in particular in the Northern Nile Delta in Egypt. In the last 30 years, different forms of aquaculture farms were developed in Egypt including earthen pond culture and rice-fish culture. Nile tilapia is cultured as mono or in polyculture combination with catfish to increase the overall fish production and profits [1]. Currently there is an ambitious plans in Egypt to construct new aquaculture farms as part of the development project in the Suez Canal Region as a governmental strategy to reduce the increasing food gap, new aquaculture farms are planned along the eastern bank of the Suez Canal. The project intends to create large-scale basins that extend over 120 km parallel to the Suez Canal.Aquaculture industry in not only concerned with increasing the production quantity, it is also concerned with improving the quality of the fish product. There are several aquaculture practices in Egypt that include, but not limited to, excavated earthen ponds, pens and enclosures, concrete and raceways ponds, circular tanks and floating fish cages. Also there are different production systems and management methods which are classified according to the intensification (extensive, semi-intensive and intensive or according to the fish cultured species (monoculture and polyculture). In Egypt, the most prevailing aquaculture practice is the semi-intensive earthen ponds. In last 15 years the intensive aquaculture farming has grown increasingly, especially in the deserts of northern Sinai based on agricultural drainage waters. A review of fish farming practices in Egypt has been carried out, with focus on the Northern Delta region. Ministry of Water Resources and Irrigation in Egypt (MWRI) [2] reported that all water bodies in Egypt are fished to the maximum which indicates the importance of the aquaculture industry to Egypt food security. Ministry of Agriculture and Land Reclamation (MALR) [3] presented a survey of aquaculture practices in Egypt in which fish production increased from 0.35 Million tons in 1991 to 1.3 Million tons in 2010, valued at 14.5 Billion Egyptian Pounds (EGP). Of these 385 000 tons, 30% are from natural fisheries and 919 000 tons (70%) are from man-made aquaculture. An additional 257 000 tons are imported with tremendous increase of about 90% from the imports in 2009. Major produced species is Nile Tilapia, with production of 130 000 tons from fisheries (about 19%) and 560 000 tons from aquaculture (remaining 81%). Of the total aquaculture production in Egypt, 420 000 tons are produced in Kafr El-sheikh Governorate (about 45% of the total production), which is located in the Northern Part of the Nile Delta (Figure 1).

| Figure 1. Location of the Study area in the Northern Nile Delta in Egypt showing Drainage catchments with official and unofficial reuse |

2. Extent of the Study

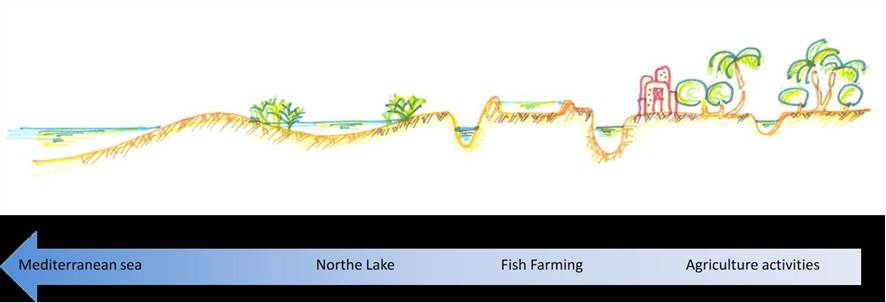

- The pilot experiment is carried out in Kafr El-Sheikh Governorate, which covers the north-western part of the Nile delta bordering the Mediterranean (Figure 1). This region accounts for about 40% of aquaculture production in Egypt [3]. Production is carried out in fish ponds around Lake Burullus using agriculture drainage water. Lake Burullus is a shallow, alkaline, brackish and moderately polluted water body lies in the north of the Nile delta (lon. 31° 22’ – 31° 35’ N, lat. 30° 31’ – 31° 08’E) between the two branches of the Nile along the Mediterranean Coast of Egypt [19]. Lake Burullus is connected to the Mediterranean Sea at the northern side through Boughaz El-Burg which is located in the extreme north-east of the lake with a width up to 1150 m. Lake Burullus has a surface area of 410 km2 and a total length of 56 km and a width varying from 6 to 16 km. The lake had lost about 62.5% of its surface area during two centuries (from 1092.0 km2 in 1801 to 556.5 km2 in 1913 and 410.0 km2 in 1997 [20]. [21] showed that Lake Burullus lost 42.8% of its open water area from 1973 to 2011 due to severe anthropogenic activities such as the reclaiming of its southern margins for agricultural and aquaculture purposes and the backfilling caused by continuous discharge of agricultural wastes. The water depth in Lake Burullus varies between 0.2 m close to the shore of the eastern basin and 2 m in the middle basin and near the sea outlet. The lake includes some 30 islets, those near the lake-sea connection are of sandy nature, while those far from the inlet have clayey bottom. Some of the small islets are covered with water during high water periods [22].Lake Burullus is one of the Ramsar sites and it is declared as a natural protectorate in 1998 [22]. The lake is considered as a unique breeding ground for waterfowl at both Egyptian and international level. It also represents a main tract for the bird migration in the world, especially from Eastern Europe and Northwestern Asia to Central and South Africa. Lake Burullus receives high loads of nutrients of nitrogen and phosphorus. This is due to partial discharge of the domestic and industrial wastewater from Nile Delta urban centers through the networks of agriculture drains, as well as discharges from fish farms waste, and pesticides and toxic chemicals from other sources. Historically Lake Burullus had an inlet opening of 500 meters width, which allowed for circulation and self-purification of the lake. Presently, the width has been reduced to only 50 meters, leading to water quality deterioration leading to sedimentation and increased growth of reeds in the lake. During 2005, a project for reed removal was initiated through cutting of the reeds, which eventually led to subsequent increased reed growth.

3. Material and Methods

3.1. Baseline Survey

- Several field visits have been carried out to the pilot site in Kafr El-Sheikh Governorate, the visits served in the preparation of the baseline survey and determination of common practices, stakeholder assessment, and determination of the exact site for the pilot study. A field survey and data collection has been carried out to identify the common practice of fish aquaculture production in Kafr Elsheikh Governorate. The survey has covered size of fish aquaculture farms, common practice of cultivation (species, feeds, method of water management, yields), and main stakeholders. Structured interviews with farmers as well as decision makers have been conducted. Some ten farmers have been interviewed, which have farms around El-Borrullus Lake. Interviews included also fish feed producers, and other stakeholders. Aquaculture production is concentrated in the vicinity of the Lake Burullus. Drainage water at the end of the agricultural production cycle is used. Expertise of production techniques have been circulated between farmers and no systematic capacity building or training is in place. The main fish species used in aquaculture production are the Nile Tilapia and Mullet, Figure 2. The main problems of the sector are water scarcity, poor water quality, and poor water management. In general, the fish aquaculture industry is in need of better management represented in the selection of optimal stocking density, improved water quality, management of dissolved oxygen, and improved feed ingredients.

| Figure 2. Nile Tilapia and Mullet Fish commonly produced in the Aquaculture farms in Northern lakes – Egypt |

3.2. Description of Farming Practices through Production Cycle

- The baseline survey identified the farming practices through the conventional production cycle in the study area that consists of four production stages. The production cycle starts with land preparation that includes drying of the farm land, removal of sediments, application of lime, and natural drying and disinfection by sun. The second production stage is the application of fertilization of chicken manure (on average one ton per acre), application of nitrate and phosphate fertilizers (about 15 kg per acre each), application of small depth of water for 2-3 days to allow of generation of algae and worms which are used as feed in the early life stages of fry. The third production stage is the introduction of fish fry that include filling the pond with water, introducing the fry (0.1 grams each) with stocking density vary from low intensity of 10,000 - 12,000 tilapia and 1,500 to 3,000 mullet to higher intensity of 25,000 to 35,000 tilapia and 5,000 to 10,000 mullet per single acre of the farm area. The pond is left for about 2 weeks without adding feed during which the fry grow from 0.1 gram to 10 gram. The pond does not require water exchange for a period of about 1 month as the fish are still small and the feeding rate is accordingly low. This period could be increased to 3 months if the start is with clean water. After 1 month, the pond begins to require frequent water exchange depending on stocking density and feed. The farmers face problems due to irrigation water rotations and the location of the farm with respect to the water source. The fourth production stage is the grow out period in which feeding is usually carried out using 25 to 30% protein feed composed of (50 kg fish meal or meat, 300 kg soybean meal, 300 kg rice bran, 100 kg bran, 200 kg heat treated corn, 25 kg other crops meal, and 25 kg salt and lime). The fifth and final production stage is enhancing the water quality conditions in the pond via water exchange, in which farms operates through diesel- driven pumping units.

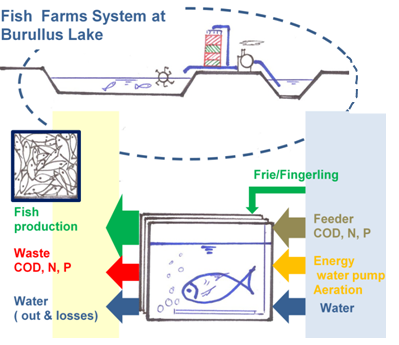

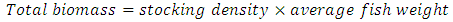

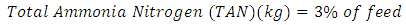

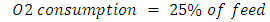

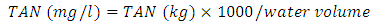

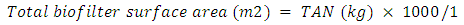

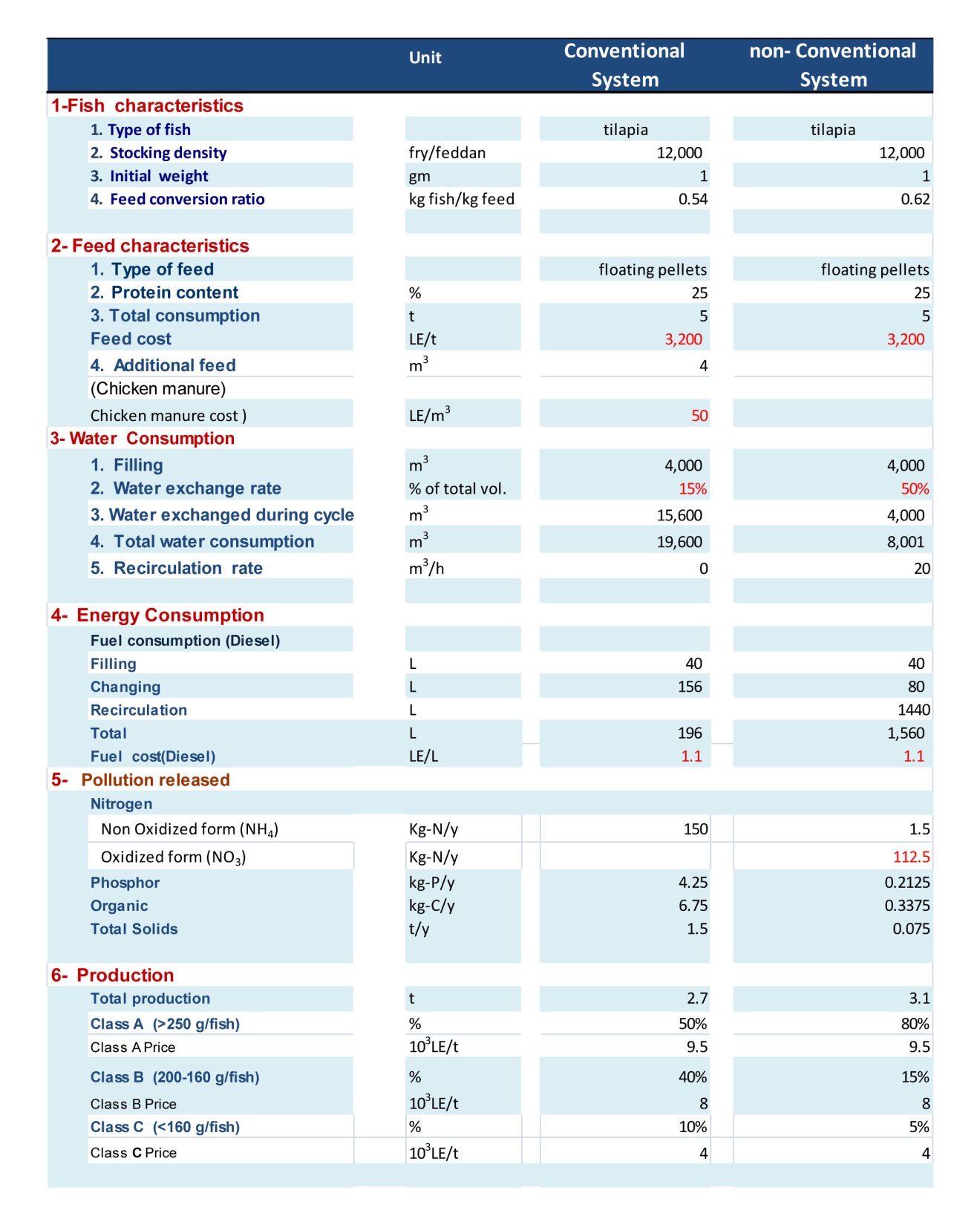

3.3. Fish Pond Material Flow Analysis Model

- Mathematical material flow analysis model is developed to predict the generated pollutants from fish aquaculture production for different practices (run-through or recirculating system). The model is based on a mass balance approach and coded on a simple spreadsheet form. Input parameters can be categorized into the following main categories: a) System components● Tank dimensions (width, length, depth, and side slopes)● Tank specifications (e.g. lining)● Pump specifications (flow rate, pumping head, fuel consumption, etc.)● Pre-retreatment specifications (filter characteristic, operational conditions, etc.) b) Location characteristics ● Climatic conditions (air temperature, wind speed and direction, solar radiations, etc.) ● Soil type and its attributesc) Water quantity and quality parameters ● Intake water characteristics (DO, COD, N, P, pathogen, heavy metals, etc.)● Discharge characteristics and limitation (COD, N, P, pathogen, heavy metals, etc.) ● Water characteristics during operational cycle (DO, COD, N, P, etc.)d) Fish parameters● Type of fish ● Stocking density ● Initial weight ● Feeding pattern● Feed conversion ratio e) Feed parameters ● Type of feed● Fed characteristics (protein, COD, N, P, etc.) f) Financial and economic parameters ● Initial investment cost● Land price (market value, land rent value)● Fingerling cost● Feed cost● Fuel cost● Fish priceThe analysis calculates nutrient loads due to fish digestion and respiration, fish yield and output water discharged to the lakes for the two scenarios (conventional aquaculture scenario and proposed aquaculture scenario). The model simulates the water pollution due to aquaculture production in the Northern Delta Region, and the potential water quality improvements due to the implementation of the proposed treatment system. A conceptual description of the model structure is shown in Figure 3. The main input parameters upon which calculations are based on are the stocking density and the pond dimensions.

| Figure 3. Conceptual Description of Model Structure |

| (1) |

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

| (9) |

| (10) |

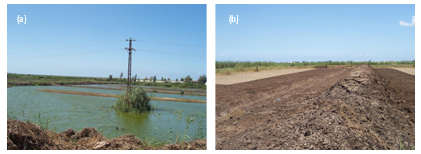

3.4. Pilot Field Selection and Implementation of Water Recycling System

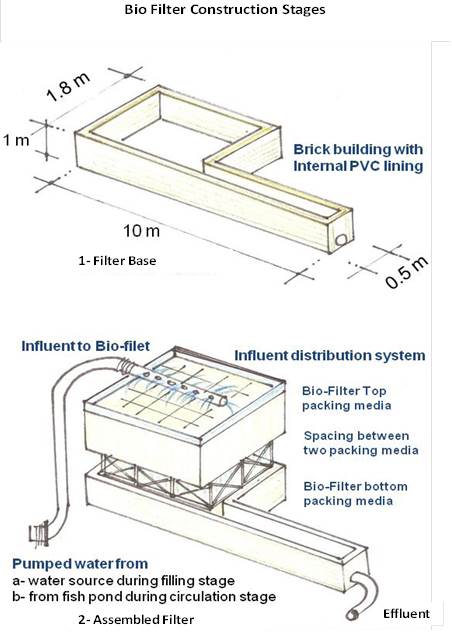

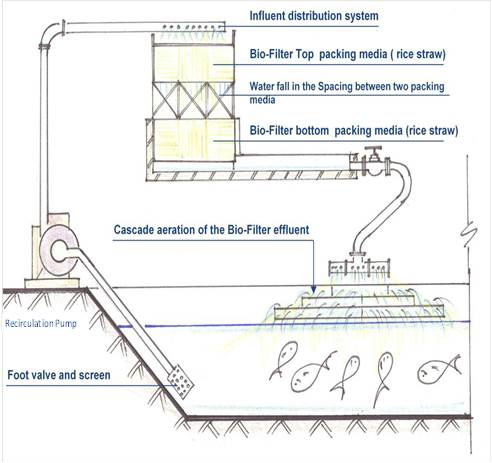

- An experimental farm has been selected to carry out the experiments required to achieve the objectives of this study. The pilot farm location is selected based on the following criteria: (1) availability of small-scale ponds, in the order of 1 to 2 acres each, (2) willingness of the farm’s landlord to allocate the required area to the experiments, (3) preparedness to adhere to the specified operation procedures of the project. As described earlier, the main problem of aquaculture production is the poor management of the water quality. Thus, the pilot has been selected through this study to assess the feasibility of applying a low cost water filtration unit at the entrance of the fish farm. The pilot farm has allocated 3 acres for the pilot experiment, which has been subdivided into two ponds, one for application of the treatment and one for business as usual. Figure 4 shows Photos of the selected pilot farm. Based on the volume of the fish pond and the pumping rate, the water treatment filter has been designed. The filter material is composed of layers of rice straw. It has been tested as an effective filter medium to remove heavy metals from municipal wastewater mixed with industrial wastewater in 6th of October treatment plant, Egypt. To the best of our knowledge, this is the first trial in Egypt for using such a filter in wastewater treatment in aquaculture production industry.

| Figure 4. (a) Typical Fish Farm Layout in the study area and (b) preparation of the pilot fish ponds |

| Figure 5. Bio filter Construction Details |

| Figure 6. Bio filter Operation |

| Figure 7. View of the Complete Filtration System |

3.5. Running a Fish Production Cycle and Evaluation

- A fish production cycle in the run through control pond and in the re-circulating pond has been carried out. Feeding rates, water inflow, water outflow, water utilization were recorded. Samples for water quality analysis at inflow to the farms and inside the ponds and at discharge from the ponds have been collected. Main parameters include nitrogenous compounds, phosphorous, COD, DO, pH and TSS and TDS. Commonly present heavy metals have also been measured in some samples at inflow to the pond. Water quality sampling and analysis in the experimental pilot case study from both ponds has provided input for the model to assess pollution loads entering receiving water bodies in the business as usual case and in the case of wide implementation of the proposed filtration and water management methods. Further, fish samples have been collected and analysed for heavy metals. Water samples for water leaving the pond have served in verifying model results. The developed model has been used to estimate potential for water saving through application of proposed approach in fish farms in the Northern Delta Region. Cost estimates for the application of the proposed scenario in comparison to conventional approach have been prepared. The financial and economic feasibility of recirculating scenario compared to business as usual has been assessed.

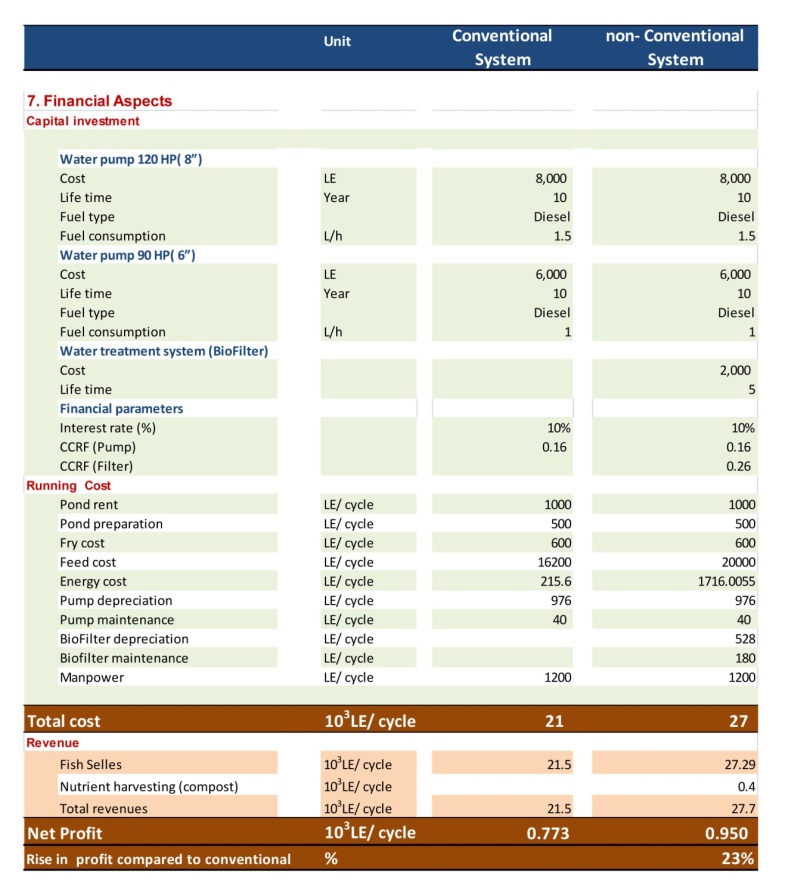

4. Results and Discussion

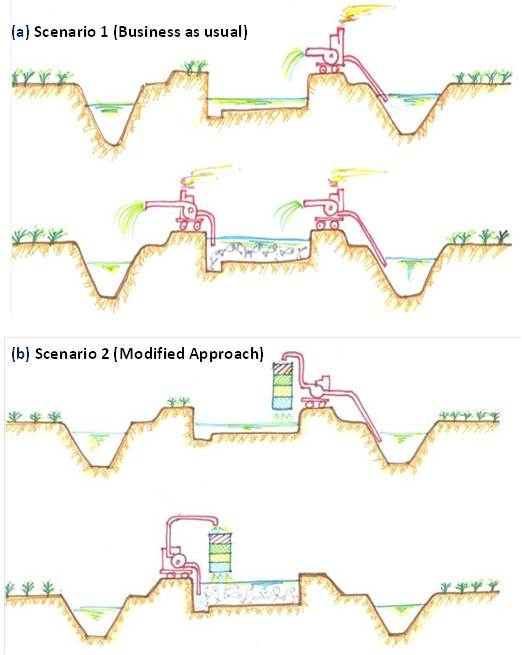

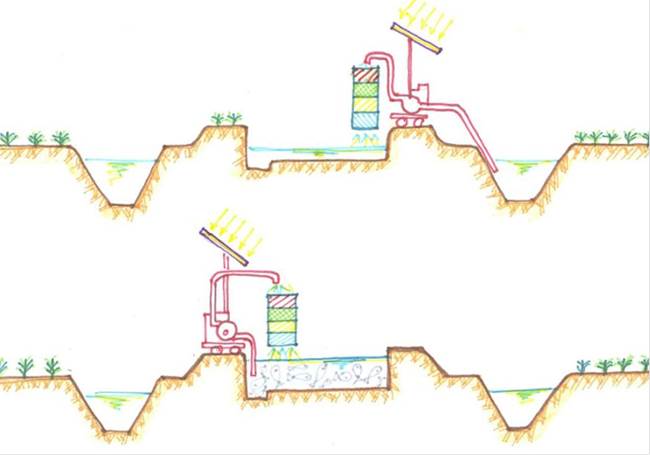

- The mathematical material flow model has been applied to simulate the operation of an aquaculture farm based on two scenarios.Scenario 1: Business as usual, i.e. no water filtration is provided, production starts with polluted water, when pollution in the pond reaches limiting levels, water is flushed to the adjacent drain and fresh (less polluted water) is introduced. Figure 8-a provides a schematic representation.Scenario 2: Modified approach, water is filtered first at entrance to the farm to remove drain pollution such as heavy metals and suspended solids. Another filtration system is provided for recirculating water from the pond to remove and capture nutrients produced by the fish. Figure 8-b shows a schematic representation of Scenario 2.

| Figure 8. Schematic presentation of (a) Scenario 1 “Business as usual” and (b) Scenario 2 “Modified Approach” |

| Table 1. Summary Window of Fish pond Material Flow Analysis Model |

| Table 2. Summary Window of the Financial Aspects of the Fish pond Analysis Model |

| Figure 9. Flow of drainage system in Egypt |

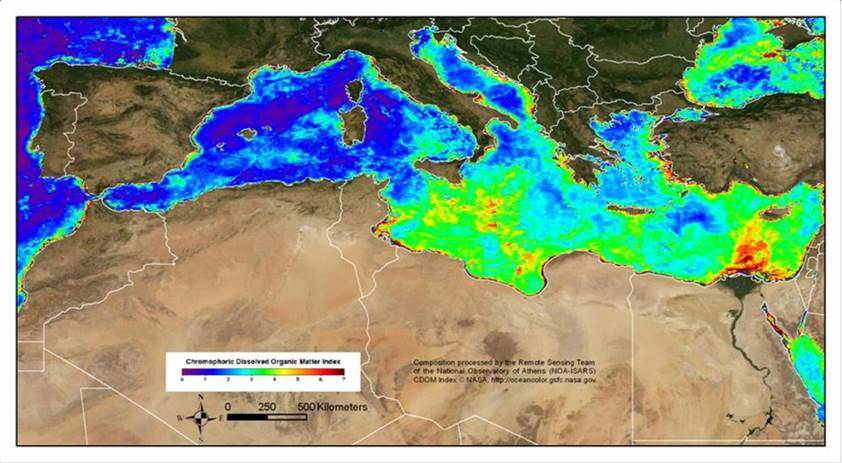

| Figure 10. Chromophoric organic matter index in the Mediterranean (NASA 2012) |

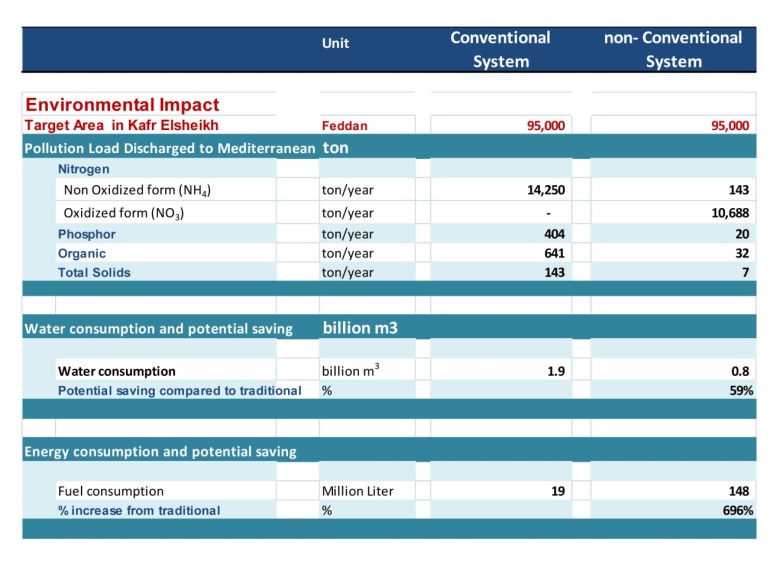

| Table 3. Summary Window of the Environmental Aspects of the Fish pond Analysis Model |

| Figure 11. Proposed System with Solar Energy Driven Pumps |

5. Conclusions

- This paper presented a new filtration system for aquaculture production based on the use of rice straw. In this system influent water is first filtered to remove the pollutants existing in the reused agricultural drainage water such as heavy metals and suspended solids. A recirculation system with rice straw filter is provided to ensure continuous aeration and removal of wastes during the fish production cycle. Under current production conditions (in particular fuel prices) the proposed approach proved technical and economic feasibility in addition to the environmental benefits. Fish produced using the new filtration system are found to be of higher quality and economic value with fish yield increase of about 15% achieved. The system is able to provide reduction in pollution loads from aquaculture production by about 95%. However, Nitrogenous compounds in the form of Nitrates remain in the effluent, which are less toxic to the environment than Ammonia. The system resulted in water saving of about 59% compared to the conventional aquaculture production approach. Considering the expected reduction in water resources in Egypt due to the proposed large scale water resources based development projects in the Nile riparian countries (e.g. Grand Ethiopian Renaissance Dam) and/or the impact of climate change, the proposed aquaculture production system could be considered one of the adaptation measures for this economic sector that achieve several socioeconomic and environmental advantages; i.e. higher quality of fish product, higher economic value, lower water consumption and lower pollutants. The introduction of this system using the available diesel pump for recirculation process would require investment costs in the order of 200x106 EGP for Kafr Elsheikh Governorate. Nationwide application would cost around 500x106 EGP. However, the expected rise in fuel prices may render the proposed intervention unfeasible for fish farmers. The feasibility of the production is marginal at present conditions and may drop under less favorable conditions. A main reason is the low cost of the produced species (Nile Tilapia). The widespread culture of this species may be attributed to its high tolerance to the polluted water. The adoption of the proposed approach could encourage the move to higher value species which are less tolerant to pollution such as Mullet (about double sale price) or Nile Perch (about 3 times sale price of Tilapia). The proposed system may be enhanced to achieve better environmental condition and more attractive economic aspects. Further treatment for Nitrates removal from the effluent may be introduced through introduction of duckweed or algae ponds. This will provide additional resources which could serve as fodder. The feed price is the major limitation in aquaculture production, most feed ingredients are imported, the alternative sources as proposed above may help in increasing the economic feasibility of the system. Finally, the system may be operated with solar energy powered pumping units for water pumping and recycling process. Despite of the high initial investments that may be required, the overall system will be environmental friendly with low carbon emissions.

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML