Arun Kanti Guha, Oaliur Rahman, Sumit Das, Md. Sazzad Hossain

Department of Textile Engineering, Southeast University, Tejgaon, Dhaka, Bangladesh

Correspondence to: Arun Kanti Guha, Department of Textile Engineering, Southeast University, Tejgaon, Dhaka, Bangladesh.

| Email: |  |

Copyright © 2015 Scientific & Academic Publishing. All Rights Reserved.

Abstract

The separated semi solid obtained after effluent treatment is called sludge. 2.81 million metric ton sludge has been produced every year from Textile sector in Bangladesh. There is a burning question, how this sludge will be managed? There are several options for sludge management. One of those option is composting. In this work, we have analyzed heavy metals (Cu, Cr & Fe) in sludge and studied the effects of composting of Textile sludge on different plants, Tagar, Joba, Gandhoraj, Mehogony and Rain Tree. We found Cu: 8.80 mg/kg, Cr: 9.55 mg/kg and Fe: 2.61% in Textile sludge. Adverse effect was observed in Tagar, Joba and Mahogony plants whereas positive impact was found in Gandharaj and Rain Tree. Direct composting is suitable for non-crop plants because plants get nutrients as well as toxic substances from direct composting of sludge. Direct composting of Textile sludge on crop producing plants will be hazardous for human being for migration of toxic substances through food chain.

Keywords:

Textile Sludge, Characterization, Composting Effects

Cite this paper: Arun Kanti Guha, Oaliur Rahman, Sumit Das, Md. Sazzad Hossain, Characterization and Composting of Textile Sludge, Resources and Environment, Vol. 5 No. 2, 2015, pp. 53-58. doi: 10.5923/j.re.20150502.01.

1. Introduction

Textile sector is the backbone of economy of Bangladesh. The export incomes were US $ 17.9 billion in the year 2010-11, US $ 19.0 billion in the year 2011-12 and US $ 21.5 billion in the year 2012-13 [1]. Textile industries use 1500 billion ground water every year in Bangladesh [2]. As a result Textile sector of Bangladesh has been discharging 2 million m3 effluent/day and 2.81 million metric ton sludge is produced every year in Bangladesh from this sector [3]. Sludge is the separated semi solid part obtained after effluent treatment in the Effluent Treatment Plant (ETP). Textile sludge is an inevitable by-product of Textile wastewater treatment process [4]. Textile sludge is consists of a cluster of organic and inorganic complex with high concentrations of heavy metals such as Fe, Cu, Cd, Zn, Cr etc. because a variety of dyes & chemicals are used in different wet processing steps. There are several wastewater treatment methods are used for Textile effluent treatment. These are physicochemical, biological and biochemical [5]. In all methods sludge is generated after effluent treatment. The most versatile biological oxidation method which is also called activated process has been employed for the treatment of wastewater containing dissolved solids and colloids. In this process, the wastewater is aerated and agitated in a reaction tank in which some microbial floc is suspended. The aerobic bacteria flora bring about biological degradation of the waste into carbon dioxide, water and heat while consuming some organic matter for bacteria. The bacteria grows and remains suspended in the form of a floc, which is called “Activated Sludge”. The effluent from the reaction is separated from the sludge by settling and discharged. A part of the sludge is recycled to the oxidation tank to provide an effective microbial population to utilize alive bacteria present in the sludge. The surplus sludge is digested in a sludge digester along with the primary sludge obtained primary sedimentation. After that sludge is dried in filter press and a burning question arises how this sludge will be managed? There are several options available in Textile sludge management. It can be used to prepare brick, the sludge can be mixed with cement, it can be incinerated to produce electricity, sludge can be utilized for sanitary land filling, it can be used for biogas generation [6] and it can be used for composting [7]. The composting of Textile sludge is more effective method than other traditional methods of disposal of residues and it is also a commitment to reducing the production of waste products. Composting is defined as the aerobic biological decomposition and stabilization of organic substrates, under conditions that allow development of thermophilic temperatures as a result of biologically produced heat, to obtain a final product that is stable, free of pathogens and plant seeds and can be beneficially applied to land [8]. The composting of Textile sludge could be converted into a fertilizer product for agricultural use [9]. Moreover composting can decrease or eliminate the toxicity of Textile sludge [10]. Literature survey showed that, Textile sludge was composted on various seeds and plants such as, soy and wheat seeds [11], algae [12] and sunflower [13]. Textile sludge is made of macro (nitrogen, phosphorus, potassium and calcium) and micro (sodium and magnesium) nutrients [7]. So that plants can take nutrients from sludge for their growth. This paper includes the effects of direct composting of Textile sludge on various plants. In this work we have analysed heavy metals (Cu, Cr and Fe) in Textile sludge and studied the effects of composting of Textile sludge on five local plants named Tagar, Joba, Gandharaj, Mehogony and Rain Tree. Reports on Textile sludge composting on these five plants were not found in literature as per our survey. The objective of this work is to study the effects of composting of Textile sludge on non-crop plants which are used for flower gardening and furniture manufacturing. The composting on non-crop plants is emphasized in this paper because the direct composting of Textile sludge on crop producing plants such as paddy is high risky because toxic substance can migrate directly to human body through food chain. But this problem can be avoided if we use Textile sludge for composting on non-crop plants.

2. Materials and Methods

This section includes experimental procedures in details.

2.1. Sludge Collection

Sludge sample was collected form Knit Concern Group, Narayangonj, Bangladesh. | Figure 1. Sludge sample collected from the industry |

2.2. Plants Collection

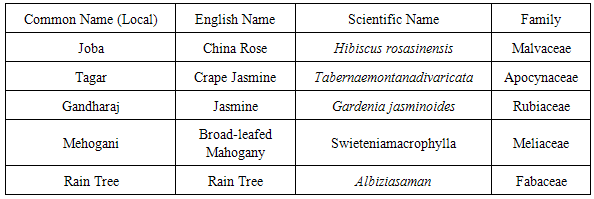

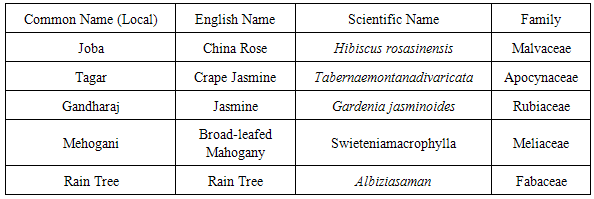

We have collected plants from a nursery of Dhaka, Bangladesh. Specifications have been given in the following table. | Figure 2. Photograph of China Rose |

| Figure 3. Photograph of Crape Jasmine |

| Figure 4. Photograph of Jasmine |

| Figure 5. Photograph of Broad-leafed Mahogany |

| Figure 6. Photograph of Rain Tree |

Table 1. Specifications of plants

|

| |

|

2.3. Sludge Analysis

Quantitative analysis of sludge for three metals, Cu, Cr & Fe were done in BCSIR Laboratories, Dhaka, Bangladesh. Atomic Adsorption Spectrophotometer (AAS), model: AA240FS, VARIAN, Country of Origin, USA, was used for metal analysis. The method of American Public Health Association (APHA) was followed for analysis. At first 0.6701g sludge sample was taken in a 250 mL beaker. Then it was digested with 10 mL nitric acid on the hot plate until it was completely dissolved. After cooling the total volume was made up to 100 mL. Then it was filtered in a plane container. After that it was analyzed by the Atomic Adsorption Spectrophotometer (AAS). It should be noted that the reported value of each metal was average of triplicate measurements and these results were reproducible concluding the accuracy and precision were at standard level.

2.4. Sludge Composting

Collected sludge was directly applied in the tub of each plant for composting. The photographs of three stages, before composting, after one week of composting and after one month of composting were taken and have been included in this paper. The changes of plants after one week and one month of sludge composting were recorded and explained in this paper.

3. Results and Discussion

3.1. Sludge Characterization

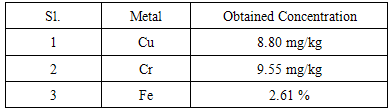

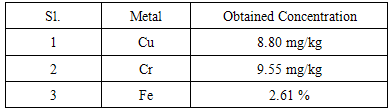

Textile sludge is a combination of heavy metals, inorganic and organic complexes. We found high concentrations of three heavy metals Cu, Cr and Fe. The quantitative analytical results done at BCSIR Laboratories, Dhaka, Bangladesh, have been compiled in Table 2. We got Cu: 8.80 mg/kg, Cr: 9.55 mg/kg and Fe: 2.61% in sludge sample. The total Cr, 1.65 to 32.52 mg/kg is generally observed at flowering stage of crops [14]. However it does not produce any toxic effects to the crops but this concentration range which is similar to this work along with Cu and Fe is harmful for human being because of migration of these metals to human body through food chain. If we apply sludge as fertilizer on non-crop plants such as flower plant it will not be harmful for safe disposal of Textile sludge. These results cannot be compared with standards because of unavailability of metal content standards in Textile sludge in Bangladesh at present.Table 2. Analytical results of heavy metals in Textile sludge

|

| |

|

3.2. Composting of Textile Sludge

Textile sludge collected from industry was mixed with soil in the plant tub and kept for one month. The effect of direct composting of Textile sludge observed in these experiments. Initial condition and changes after one week and one month were recorded. In case of Tagar (Tabernaemontanadivaricate) the condition of plant deteriorated after one week and more deteriorated after one month (Figures 7-9). Besides, similar trend was also observed in case of Joba (Hibiscus rosa-sinensis) (Figures 10-12). But opposite trend was observed in case of plant Gandharaj (Gardenia jasminoides). The condition of Gandharaj plant improved after one week and more improved after one month (Figures 13-15). The qualitative conditions of plants before and after sludge treatment were interpreted by visual estimation of the changes of leaf, root and stem. These observations give an ideathat Gandharaj plant absorbed nutrients from sludge perfectly. The toxic substances did not hamper its growth. The leaves of the plant became more fresh and shiny than its initial condition. Figures 16-18 show the effects of direct composting of Textile sludge on Mahogony (Swieteniamacrophylla). The condition improved after one week. But the condition was deteriorated after one month. The leaves of the plant broken and became fade. On the other hand condition has been improved when sludge was composted on Rain Tree (Albiziasaman). After one week new fresh leaves grew (Figure 20). After one month more leaves grew and stem became more strong and elongated (Figure 21). We found sludge is effective for composting in two cases (Gandharaj and Rain Tree) without any harm. But it was harmful for plants Joba, Tagar and Mehogony. The experiments repeated to check reproducibility of results. Another point should be clarified that the changes occurred due to effect of sludge composting. No other environmental factors were interfering in these cases. Because the weather of Bangladesh is very much friendly for growing plants and trees. The experiments were finished within one month so that the change in weather was not found at that time. There is a risk factor of using Textile sludge for composting on crop plants such as paddy. Because toxic substance of sludge is migrated in human body by food chain. It would be suitable for non-crop pants which are used for flower gardening and furniture manufacturing.  | Figure 7. Initial photograph of Tagar |

| Figure 8. Photograph of Tagar after one week |

| Figure 9. Photograph of Tagar after one month |

| Figure 10. Initial photograph of Joba |

| Figure 11. Photograph of Joba after one week |

| Figure 12. Photograph of Joba after one month |

| Figure 13. Initial photograph of Gandharaj |

| Figure 14. Photograph of Gandharaj after one week |

| Figure 15. Photograph of Gandharaj after one month |

| Figure 16. Initial Photograph of Mehogony |

| Figure 17. Photograph of Mehogony after one week |

| Figure 18. Photograph of Mehogony after one month |

| Figure 19. Initial Photograph of Rain Tree |

| Figure 20. Photograph of Rain Tree after one week |

| Figure 21. Photograph of Rain Tree after one month |

4. Conclusions

Textile sludge contains high concentrations of heavy metals, Cu: 8.80 mg/kg, Cr: 9.55 mg/kg and Fe: 2.61% in sludge sample. Direct composting of Textile sludge on different plants shows different results. Adverse effect was observed in Tagar, Joba and Mahogony plants whereas positive impact was found in Gandharaj and Rain Tree. Direct composting is suitable for non-crop plants because plants get nutrients as well as toxic substances from direct composting of sludge. It can be concluded that composting of Textile sludge is beneficial for some plants but it is harmful for some plants. These conclusions were drawn based on some experimental results and the changes were recorded time to time by taking photographs of the plants. Photographs are strong evidence to support conclusion of the paper. Direct composting of sludge on crop producing plants would be harmful because of migration of hazardous substances to human body by food chain.

References

| [1] | Information available at: www.bgmea.com.bd and Shuchismita Dey and Ashraful Islam, 2015, “A Review on Textile Wastewater Characterization in Bangladesh”, Resources and Environment, 5(1):15-44. |

| [2] | PaCT Annual Event, 2014 in association with International Finance Corporation (IFC). |

| [3] | World Bank CP Workshop, 2011and Hazardous Waste Management in Bangladesh, A Country Inventory, Department of Environment, Dhaka. |

| [4] | W. Yongjie and L. Yangsheng, 2005, “Effects of Sewage Sludge Compost Application on Crops and Cropland in a 3 Year Field Study”, Chemosphere, 59:1257-1265. |

| [5] | A. Islam and A. K. Guha, 2013, “Removal of pH, TDS and Color from Textile Effluent byUsing Coagulants and Aquatic/Nonaquatic Plants as Adsorbents”, Resources and Environment, 3(5):101-114. |

| [6] | M. N. Morshed and A. K. Guha, 2014, “Production of Biogas from Textile Sludge by Anaerobic Digestion, a Sustainable Ecofriendly Sludge Management Method”, Bangladesh Textile Today, June (pp52-56) and July (pp38-44) Issues. |

| [7] | M. A. E. Hammadi, M. Trabelsi and B. Hanchi, 2007, “Comparison of Specific Nutrients of Tunisian Textile Sludge and Produced Composts”, International Journal of Soil Science, 2 (3):230-234. |

| [8] | E. Bertran, X. Sort, M. Solvia and I Trillas, 2004, “Composting Winery Waste: Sludges and Grape Stakes”, Biorseour. Technol., 95:203-208. |

| [9] | P. Koushik and V. K. Grag, 2003, “Vermicomposting of Mixed solid Textile Mill Sludge and Cowdung with Epigeic Earthworm, Eisemiafoetida”, Bioresour. Technol., 90:311- 316. |

| [10] | A. S. F. Araujo, R. T. R. Monterio and E. M. S. Carvalho, 2007, “Effect of Composted Textile Sludge on Growth, Nodulation and Nitrogen Fixation of Soybean and Cowpea”, Bioresour. Technol., 98:1028-1032. |

| [11] | A. S. F. Araujo, F. K. Sahyoun and T.TR.Monterio, 2001, “Evaluation of Toxicity of Textile Sludge Compost on Seed Germination and Root Elongation of Soybean and Wheat”, Rev. Ecossistema, 26:117-119. |

| [12] | E. V. C. Roasa, T. M. Giuradelli, A. X. R. Corrêa, L. R. Rörig, P R. Sshwingeosgalla-Jr. C. and C. M. Radetski, 2007a, “Ecotoxicologigal Evaluation of The Short Term Effects of Fresh and Stabilized Textile Sludge Before Application in Forest Soil Restoration”, Environ. Pollut., 146:463-469. |

| [13] | M. A. Hammadi, M. Trabelsi and B. Hanchi, 2007, “Phytotoxicity of Tunisian Municipal and Textile Sludge Compared to the Product Compost”, Asian J. Agri. Res., 1:86-91. |

| [14] | M. Parameswari, 2014, “Textile and Dye Industry Effluent, Sludge and Amendments on Heavy Metals Chromium, Nickel, Cadmimum and Lead Status of Maize Cultivated Soil”, International Journal of Applied and Natural Sciences, 3(20:2319-4014. |

Abstract

Abstract Reference

Reference Full-Text PDF

Full-Text PDF Full-text HTML

Full-text HTML